YAMAHA TT-R110E 2019 Workshop Manual

Manufacturer: YAMAHA, Model Year: 2019, Model line: TT-R110E, Model: YAMAHA TT-R110E 2019Pages: 88, PDF Size: 2.3 MB

Page 51 of 88

Periodic maintenance an d a djustment

7-9

7

4. If the engine oil is not between the

tip of the dipstick and the maxi-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Check the O-ring for damage, and replace it if necessary.

6. Insert the dipstick into the oil filler hole, and then tighten the oil filler

cap.

To chan ge the en gine oil

1. Start the engine, warm it up for several minutes, and then turn it

off.

2. Place an oil pan under the engine to collect the used oil.

3. Remove the engine oil filler cap, the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

4. Install a new gasket and the drain bolt, and then tighten the drain

bolt to the specified torque.

5. Refill with the specified amount of the recommended engine oil.

NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a hi gh-

er quality than specified . In

a dd ition, do not use oils la bele d

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.

6. Check the O-ring for damage, and replace it if necessary.

7. Install and tighten the engine oil filler cap.

8. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

1. Engine oil drain bolt

2. Gasket

Tightening torque:

Engine oil drain bolt: 20 N·m (2.0 kgf·m, 15 lb·ft)

12

Recommended engine oil:

See page 9-1.

Oil change quantity: 0.80 L (0.85 US qt, 0.70 Imp.qt)

1. Engine oil filler cap

2. O-ring

2

1

UB5183E0.book Page 9 Friday, June 9, 2017 8:32 AM

Page 52 of 88

Periodic maintenance an d a djustment

7-10

7 9. Turn the engine off, and then

check the oil level and correct it if

necessary.

EAU41638

Cleanin g the air filter element

The air filter element should be cleaned

or replaced at the intervals specified in

the periodic maintenance and lubrica-

tion chart. Clean or, if necessary, re-

place the air filter element more

frequently if you are riding in unusually

wet or dusty areas.

To clean the air filter element

1. Remove panel A. (See page 7-6.)

2. Remove the air filter case cover by removing the screws.

3. Pull the sponge material and the air filter mesh out.

4. Clean the mesh with solvent, and then wipe the solvent off.

1. Air filter case cover

2. Screw

1. Sponge material

2. Air filter mesh

2

1

1

2

UB5183E0.book Page 10 Friday, June 9, 2017 8:32 AM

Page 53 of 88

Periodic maintenance an d a djustment

7-11

7

5. Clean the sponge material with

solvent, and then squeeze the re-

maining solvent out. WARNING!

Use only a ded icated parts

cleanin g solvent. To avoi d the

risk of fire or explosion, do not

use gasoline or solvents with a

low flash point.

[EWA10432] NOTICE:

To avoi d damag ing the foam

material, han dle it g ently an d

carefully, an d d o not twist or

wrin g it.

[ECA10512]

6. Apply oil of the recommended

type to the entire surface of the

sponge material, and then

squeeze the excess oil out.

TIP

The sponge material should be wet but

not dripping.

7. Insert the mesh and the spongematerial into the air filter case.

NOTICE: Make sure that the

mesh an d the spon ge material

are properly seated in the air fil-

ter case. The en gine shoul d

never be operated without the

mesh an d the spon ge material installe

d, otherwise the pis-

ton(s) an d/or cylin der(s) may b e-

come excessively worn.

[ECA15573]

8. Install the air filter case cover by installing the screws.

TIP

Make sure that the spark plug lead is

inserted into the guide as shown.

9. Install the panel.

To clean the air filter check hose

1. Check the hoses at the bottom of the air filter case for accumulated

dirt or water.

Recommen ded oil:

Yamaha foam air filter oil or other

quality foam air filter oil

1. Spark plug lead

2. Guide

1

12

UB5183E0.book Page 11 Friday, June 9, 2017 8:32 AM

Page 54 of 88

Periodic maintenance an d a djustment

7-12

7 2. If dirt or water is visible, remove

the hoses, clean them, and then

reinstall them.

EAU40422

Cleanin g the spark arrester

The spark arrester should be cleaned

at the intervals specified in the periodic

maintenance and lubrication chart.

WARNING

EWA10981

Always let the exhaust system

cool prior to touchin g exhaust

components.

Do not start the en gine when

cleanin g the exhaust system.

TIP

Make sure to select a well-ventilated

area free of combustible materials to

clean the spark arrester.

1. Remove the tailpipe by removing

the bolts, and then pulling it out of

the muffler.

2. Tap the tailpipe lightly, and then use a wire brush to remove any

carbon deposits from the spark

arrester portion of the tailpipe and

inside of the tailpipe housing.

1. Air filter check hose

1

1. Tailpipe

2. Tailpipe bolt

21

UB5183E0.book Page 12 Friday, June 9, 2017 8:32 AM

Page 55 of 88

Periodic maintenance an d a djustment

7-13

7

3. Insert the tailpipe into the muffler,

and then install and tighten the

bolts to the specified torque.

TIP

Make sure to align the bolt holes when

inserting the tailpipe.

EAU39931

Adjustin g the car buretor

The carburetor is an important part of

the engine and requires very sophisti-

cated adjustment. Therefore, most

carburetor adjustments should be left

to a Yamaha dealer, who has the nec-

essary professional knowledge and ex-

perience. The adjustment described in

the following section, however, may be

serviced by the owner as part of rou-

tine maintenance.

NOTICE

ECA10551

The car buretor has b een set and ex-

tensively teste d at the Yamaha fac-

tory. Chan gin g these settin gs

without sufficient technical knowl-

e dge may result in poor perfor-

mance of or d amage to the en gine.

1. Spark arrester

Ti ghtening torque:

Tailpipe bolt: 10 N·m (1.0 kgf·m, 7.4 lb·ft)

1

UB5183E0.book Page 13 Friday, June 9, 2017 8:32 AM

Page 56 of 88

Periodic maintenance an d a djustment

7-14

7

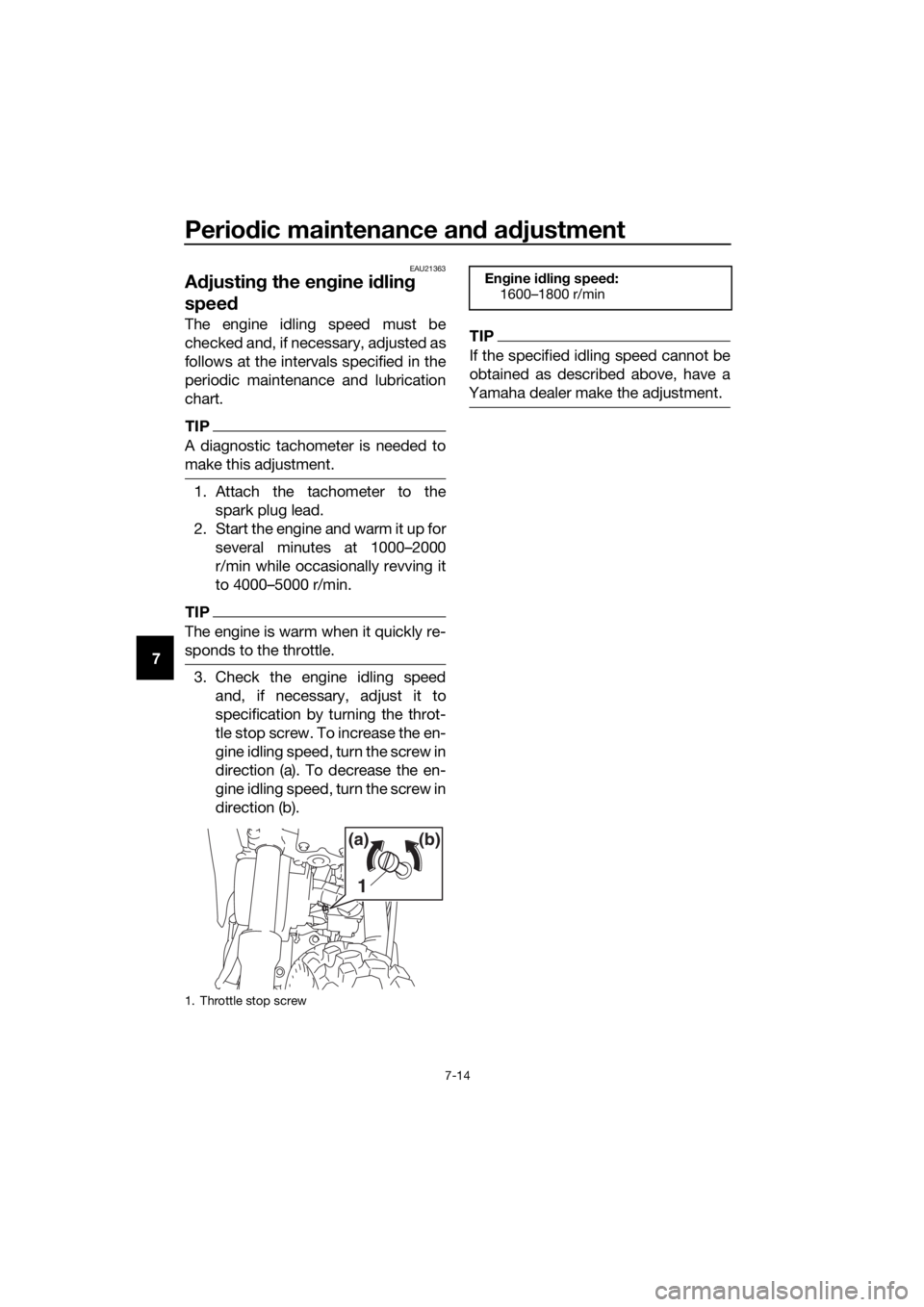

EAU21363

A djustin g the en gine i dlin g

spee d

The engine idling speed must be

checked and, if necessary, adjusted as

follows at the intervals specified in the

periodic maintenance and lubrication

chart.

TIP

A diagnostic tachometer is needed to

make this adjustment.

1. Attach the tachometer to the

spark plug lead.

2. Start the engine and warm it up for several minutes at 1000–2000

r/min while occasionally revving it

to 4000–5000 r/min.

TIP

The engine is warm when it quickly re-

sponds to the throttle.

3. Check the engine idling speedand, if necessary, adjust it to

specification by turning the throt-

tle stop screw. To increase the en-

gine idling speed, turn the screw in

direction (a). To decrease the en-

gine idling speed, turn the screw in

direction (b).

TIP

If the specified idling speed cannot be

obtained as described above, have a

Yamaha dealer make the adjustment.

1. Throttle stop screw

(a) (b)

1

En gine i dlin g spee d:

1600–1800 r/min

UB5183E0.book Page 14 Friday, June 9, 2017 8:32 AM

Page 57 of 88

Periodic maintenance an d a djustment

7-15

7

EAU21386

Checkin g the throttle grip free

play

Measure the throttle grip free play as

shown.

Periodically check the throttle grip free

play and, if necessary, have a Yamaha

dealer adjust it.

EAU21403

Valve clearance

The valves are an important engine

component, and since valve clearance

changes with use, they must be

checked and adjusted at the intervals

specified in the periodic maintenance

chart. Unadjusted valves can result in

improper air-fuel mixture, engine

noise, and eventually engine damage.

To prevent this from occurring, have

your Yamaha dealer check and adjust

the valve clearance at regular intervals.

TIP

This service must be performed when

the engine is cold.1. Throttle grip free play

Throttle g rip free play:

4.0–6.0 mm (0.16–0.24 in)

1

UB5183E0.book Page 15 Friday, June 9, 2017 8:32 AM

Page 58 of 88

Periodic maintenance an d a djustment

7-16

7

EAUW3500

Tires

Tires are the only contact between the

vehicle and the road. Safety in all con-

ditions of riding depends on a relatively

small area of road contact. Therefore, it

is essential to maintain the tires in good

condition at all times and replace them

at the appropriate time with the speci-

fied tires.

Tire air pressure

The tire air pressure should be

checked and, if necessary, adjusted

before each ride.

WARNING

EWA10442

Operation of this vehicle with im-

proper tire pressure may cause se-

vere injury or death from loss of

control. The tire air pressure must be

checked and a djuste d on col d

tires (i.e., when the temperature

of the tires equals the am bient

temperature).

The tire air pressure must be

a d juste d in accor dance with the

ri din g speed and with the total

wei ght of ri der, car go, an d ac-

cessories approved for this

mo del.

WARNING

EWA10512

Never overloa d your vehicle. Opera-

tion of an overloa ded vehicle coul d

cause an acci dent.

Tire inspection

The tires must be checked before each

ride. If the center tread depth reaches

the specified limit (minimum tire tread

depth), if the tire has a nail or glass

fragments in it, or if the sidewall is

cracked, have a Yamaha dealer re-

place the tire immediately.

Tire information

This model is equipped with tube tires.

Tires age, even if they have not been

used or have only been used occasion-

ally. Cracking of the tread and sidewall

rubber, sometimes accompanied by

carcass deformation, is an evidence of

ageing. Old and aged tires shall be

checked by tire specialists to ascertain

their suitability for further use.

Stan dar d tire pressure:

Front: 100 kPa (1.00 kgf/cm², 15 psi)

Rear:

100 kPa (1.00 kgf/cm², 15 psi)

1. Tire sidewall

2. Tire tread depth

Minimum tire trea d d epth (front an d

rear): 4.0 mm (0.16 in)

1

2

UB5183E0.book Page 16 Friday, June 9, 2017 8:32 AM

Page 59 of 88

Periodic maintenance an d a djustment

7-17

7

WARNING

EWA10462

The front an d rear tires shoul d b e of

the same make an d d esi gn, other-

wise the han dlin g characteristics of

the vehicle may be different, which

coul d lea d to an acci dent.

After extensive tests, only the tires list-

ed below have been approved for this

model by Yamaha.

WARNING

EWA14391

Have a Yamaha dealer replace

excessively worn tires. Operat-

in g the motorcycle with exces-

sively worn tires decreases

ri din g sta bility an d can lead to

loss of control.

The replacement of all wheel-

and b rake-related parts, includ-

in g the tires, shoul d b e left to a

Yamaha dealer, who has the

necessary professional knowl-

e dge an d experience.

It is not recommen ded to patch

a puncture d tu be. If unavoid -

a b le, however, patch the tu be

very carefully an d replace it as

soon as possi ble with a hi gh-

quality prod uct.

EAU21944

Spoke wheels

WARNING

EWA10611

The wheels on this mod el are not

d esi gne d for use with tu beless tires.

Do not attempt to use tu beless tires

on this mo del.

To maximize the performance, durabil-

ity, and safe operation of your motor-

cycle, note the following points

regarding the specified wheels.

The wheel rims should be

checked for cracks, bends, warp-

age or other damage, and the

spokes for looseness or damage

before each ride. If any damage is

found, have a Yamaha dealer re-

place the wheel. Do not attempt

even the smallest repair to the

wheel. A deformed or cracked

wheel must be replaced.

The wheel should be balanced

whenever either the tire or wheel

has been changed or replaced. An

unbalanced wheel can result in

poor performance, adverse han-

dling characteristics, and a short-

ened tire life.

Front tire:

Size:

2.50-14 4PR

Manufacturer/model: CHENG SHIN/C-803

Rear tire: Size:3.00-12 4PR

Manufacturer/model: CHENG SHIN/C-803

UB5183E0.book Page 17 Friday, June 9, 2017 8:32 AM

Page 60 of 88

Periodic maintenance an d a djustment

7-18

7

EAU44664

A djustin g the clutch free play

The clutch free play must be checked

and, if necessary, adjusted as follows

at the intervals specified in the periodic

maintenance and lubrication chart.

1. Loosen the locknut.

2. Slowly turn the clutch adjusting screw in direction (a) until resis-

tance is felt, and then turn it 1/8

turn in direction (b).

3. Tighten the locknut to the speci- fied torque.

TIP

When tightening the locknut, hold the

clutch adjusting screw with a screw-

driver so that it does not turn together

with the locknut.

EAU44886

Adjustin g the brake lever free

play

Measure the brake lever free play as

shown.

Periodically check the brake lever free

play and, if necessary, adjust it as fol-

lows.

1. Slide the rubber cover back.

2. Loosen the locknut at the brake le- ver.

3. To increase the brake lever free play, turn the brake lever free play

adjusting bolt in direction (a). To

decrease the brake lever free play,

turn the adjusting bolt in direction

(b).

TIP

Skip steps 4–7 if the specified brake le-

ver free play could be obtained as de-

scribed above.

4. Fully turn the adjusting bolt at thebrake lever in direction (a) to loos-

en the brake cable.

1. Locknut

2. Clutch adjusting screw

Tightenin g torque:

Locknut:

8 N·m (0.8 kgf·m, 5.9 lb·ft)

1 2

(a)(b)1. Rubber cover

2. Brake lever free play adjusting bolt

3. Locknut

4. Brake lever free play

Brake lever free play:

10.0–20.0 mm (0.39–0.79 in)

3

21

(b)

(a) 4

UB5183E0.book Page 18 Friday, June 9, 2017 8:32 AM