fuel cap YAMAHA TT600RE 2004 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2004, Model line: TT600RE, Model: YAMAHA TT600RE 2004Pages: 382, PDF Size: 6.39 MB

Page 95 of 382

INSP

ADJSTEERING INSPECTION/

TYRE INSPECTION

3-41

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Nut (steering axle):

115 Nm (11.5 mkg)

Screws (front fork bracket):

28 Nm (2.8 mkg)

•Tighten the steering axle nut and the front fork

bracket screws.

•Reassemble the fuel tank.

See section “SEAT, FUEL TANK AND REAR

COWLING”.

NOTE:

Check the steering head for looseness or binding

by turning it all the way in both directions. If it

binds, remove the steering axle assembly and

inspect the steering bearings.

Refer to “STEERING HEAD” in Chapter 6.

TYRE INSPECTION

WARNING

•Tyre pressure must be checked when the

tyres are at ambient temperature. Pressure

must be adjusted according to the total

weight of luggage, driver, passenger and

accessories (fairings, bags, if approved for

this model) and speed of the motorcycle.

•A list of tyres approved for this model fol-

lowing severe testing by Yamaha is provid-

ed. There can be no guarantee of safe road-

holding if a combination of tyres different

from those indicated is used.

•Front and rear tyres must have the same

design and be of the same make.

•The use of valves and valve stems other

than those indicated might cause the loss

of tyre pressure at high speeds. Use only

original or compatible spare parts.

•Replace the valve cap securely to prevent

losses of tyre pressure at high speed.

ProCarManuals.com

Page 206 of 382

ENGINE REMOVAL

5-2

ENG

Order Job name/Part name Q.ty Remarks Drain the engine oil (refer to “ENGINE OIL

REPLACEMENT” section in CHAPTER

3). Remove the seat, the fuel tank and

the rear cowling (refer to “SEAT, FUEL

TANK AND REAR COWLING” section in

CHAPTER 3).

1 Battery leads connector 1 Disconnect.

2 Muffler 1

3 Exhaust pipe 1

4 Engine protector 1

5 Shift pedal 1

6 Drive sprocket crankcase cover 1

7 Drive sprocket 1 Displace the drive chain.

8 Clutch cable 1 Disconnect.

9 Plug cap 1 Disconnect.

ProCarManuals.com

Page 209 of 382

ENGENGINE DISASSEMBLY

5-5

ENGINE DISASSEMBLY

CYLINDER HEAD, CYLINDER, CAMSHAFT

AND PISTON

NOTE:

The cylinder head, cylinder, camshaft and piston

can be examined with the engine installed by

removing the following parts.

•Seat

•Fuel tank

•Rear cowling

•Carburetor

•Exhaust pipe

1. Remove:

•Spark plug (1)

•Tappet cover (2) (intake)

•Tappet covers (3) (exhaust)

•Cylinder head cover (4)

•Cap (5)

•Pins (6)

2. Loosen:

•Bolt (1) (chain tensioner)

3. Remove:

•Chain tensioner (2)

ProCarManuals.com

Page 222 of 382

ENGINE DISASSEMBLY

5-18

ENG

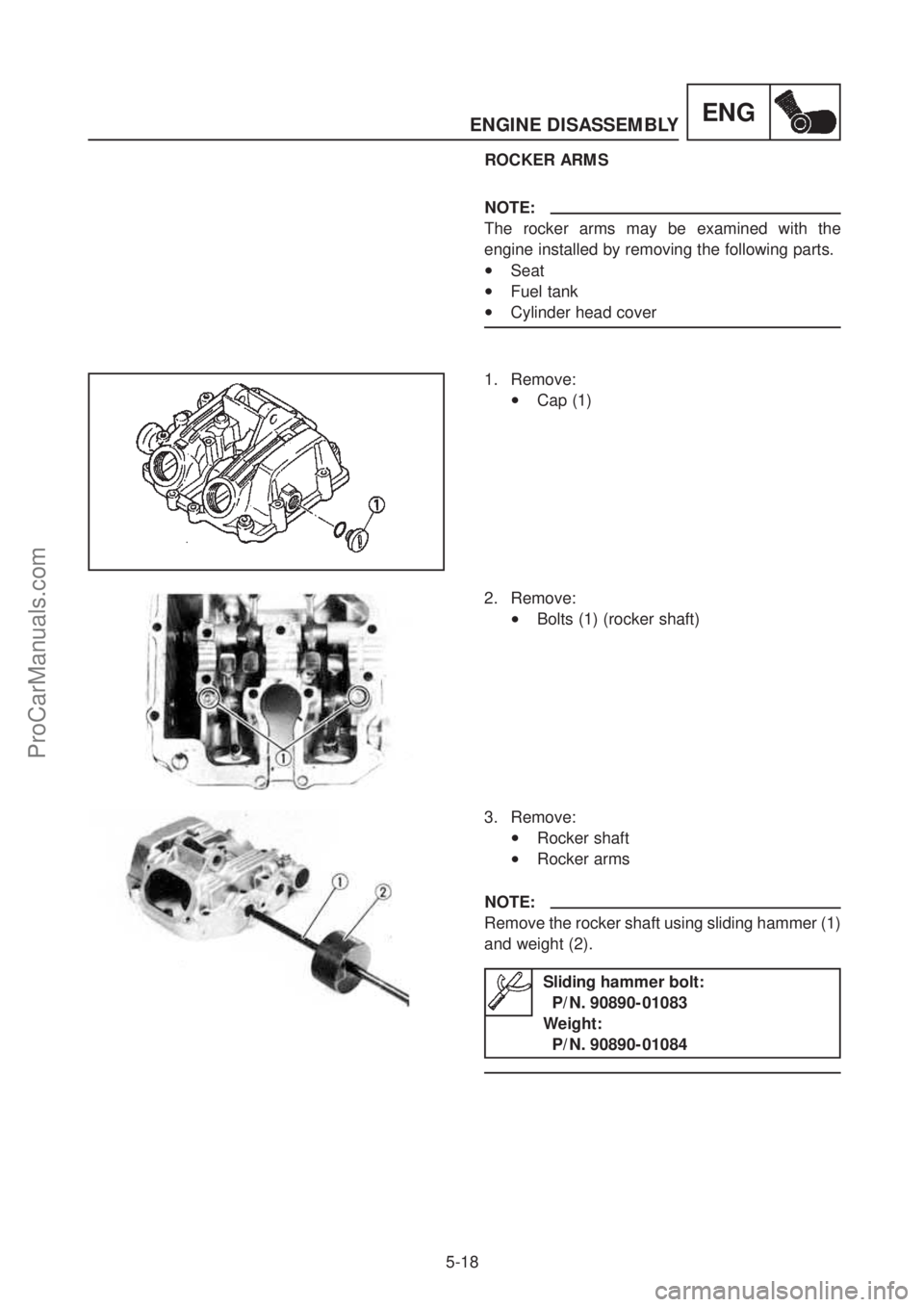

ROCKER ARMS

NOTE:

The rocker arms may be examined with the

engine installed by removing the following parts.

•Seat

•Fuel tank

•Cylinder head cover

1. Remove:

•Cap (1)

2. Remove:

•Bolts (1) (rocker shaft)

3. Remove:

•Rocker shaft

•Rocker arms

NOTE:

Remove the rocker shaft using sliding hammer (1)

and weight (2).

Sliding hammer bolt: P/N. 90890-01083

Weight: P/N. 90890-01084

ProCarManuals.com

Page 286 of 382

CARBCARBURETOR REMOVAL

6-1

CARBURETOR

CARBURETOR REMOVAL

Order Job name/Part name Q.ty Remarks Carburetor removal Remove the parts in order.

Seat Refer to “SEAT, FUEL TANK AND REAR

COWLING" section in CHAPTER 3.

Fuel pipe NOTE:

Fuel tank Be sure the cap is properly tightened and the fuel cock is in the “OFF” position before

removing the fuel tank.

1 Lock nut 4 Loosen.

2 Throttle cable adjuster 2 Screw.

3 Throttle cable 2

4 Hose clamp 2 Loosen.

ProCarManuals.com

Page 317 of 382

ELECIGNITION SYSTEM

7-13

DIAGNOSTICS IF THE IGNITION SYSTEM WERE TO STOP WORKING (NO OR INTERMITTENT SPARK)

Procedure

Check:

1. Fuse

2. Battery

3. Spark plug

4. Amplitude of ignition spark

5. Spark plug cap resistance

6. Ignition winding resistance 7. Main switch

8. Engine stop switch

9. Sidestand switch

10. Neutral switch

11. Clutch switch

12. Pick-up coil resistance

13. Wiring connections (whole connection sys- tem)

NOTE:

Before making the inspections mentioned, remove the following parts:

1. Seat

2. Rear cowling 3. Fuel tank

4. Cowling (headlight)

•To check functioning defects use the following special tools.

Dinamic spark tester: P/N. 90890-06754

Pocket tester:P/N. 90890-03112

1. Fuse

•Check the fuse for continuity.

Refer to “CHECKING THE FUSES” in

Chapter 3.

•Is the fuse OK?

YES

2. Battery

•Check the condition of the battery.

Refer to “CHECKING AND CHARGING

THE BATTERY” in Chapter 3.

Min. open-circuit voltage:

2.8 V or more at 20°C (68°F)

•Is the battery OK?

NO

Replace the fuse.

NO

•Clean the battery terminals.

•Recharge or replace the battery.

YES

*

ProCarManuals.com

Page 372 of 382

FAILURE TO START/

DIFFICULTIES IN STARTING

8-1

TRBL

SHTG

?

TROUBLESHOOTING

NOTE:

The troubleshooting tables that follow do not identify every cause of trouble. They may however prove

helpful as a guide to identifying trouble. To inspect, adjust or replace parts, refer to the appropriate sec-

tion in the manual.

FAILURE TO START/DIFFICULTIES IN STARTING

FUEL SYSTEM

Fuel tank

Fuel cock

Carburetor

Air filter PROBABLE CAUSES

•Empty

•Fuel filter obstructed

•Fuel tank air cap passage obstructed

•Petrol contains water or impurities or is adulterated

•Hose obstructed

•Fuel filter obstructed

•Petrol contains water or impurities or is adulterated

•Pilot jet obstructed

•Pilot air passage obstructed

•Infiltrations of air

•Deformation of float

•Needle valve worn or scratched

•Needle valve seat insufficiently sealed

•Fuel level set wrongly

•Pilot jet set wrongly

•Starter jet obstructed

•Malfunctioning of the starter piston

•Air filter element obstructed

ProCarManuals.com

Page 380 of 382

DEFECTIVE FUNCTIONING OF LIGHTS AND INDICATORS/ OVERHEATING OF ENGINE

8-9

TRBL

SHTG

?

PROBABLE CAUSES

•Indicator lamp relay defective

•Insufficient battery capacity

(battery almost flat)

•Incorrect bulb

•Main switch or direction indicator switch defec-

tive

DELAYED TURNING ON OF INDICATORS

PROBABLE CAUSES

•Battery flat

•Main switch or horn switch defective

•Horn wrongly set

•Defective horn

•Harness cut off

THE HORN FAILS TO WORK

OVERHEATING OF ENGINE

PROBABLE CAUSES

•Incorrect bulb

•Indicator lamp relay defective

EXCESSIVE INDICATOR

INTERMITTENCE FREQUENCY

Ignition system

Fuel feed system PROBABLE CAUSES

•Incorrect electrode gap of spark plug

•Spark plug thermal gradation wrong

•Ignition unit defective

•Incorrect carburetor main jet (incorrect setting)

•Incorrect fuel level

•Air filter element obstructed

Engine compression

•Excess of carbon deposits

Engine oil

•Incorrect oil level

•Incorrect oil viscosity

•Incorrect oil gradation

Brake

•Pads fail to return freely (remains blocked)

ProCarManuals.com