lock YAMAHA TT600RE 2004 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2004, Model line: TT600RE, Model: YAMAHA TT600RE 2004Pages: 382, PDF Size: 6.39 MB

Page 226 of 382

INSPECTION AND REPAIR

5-22

ENG

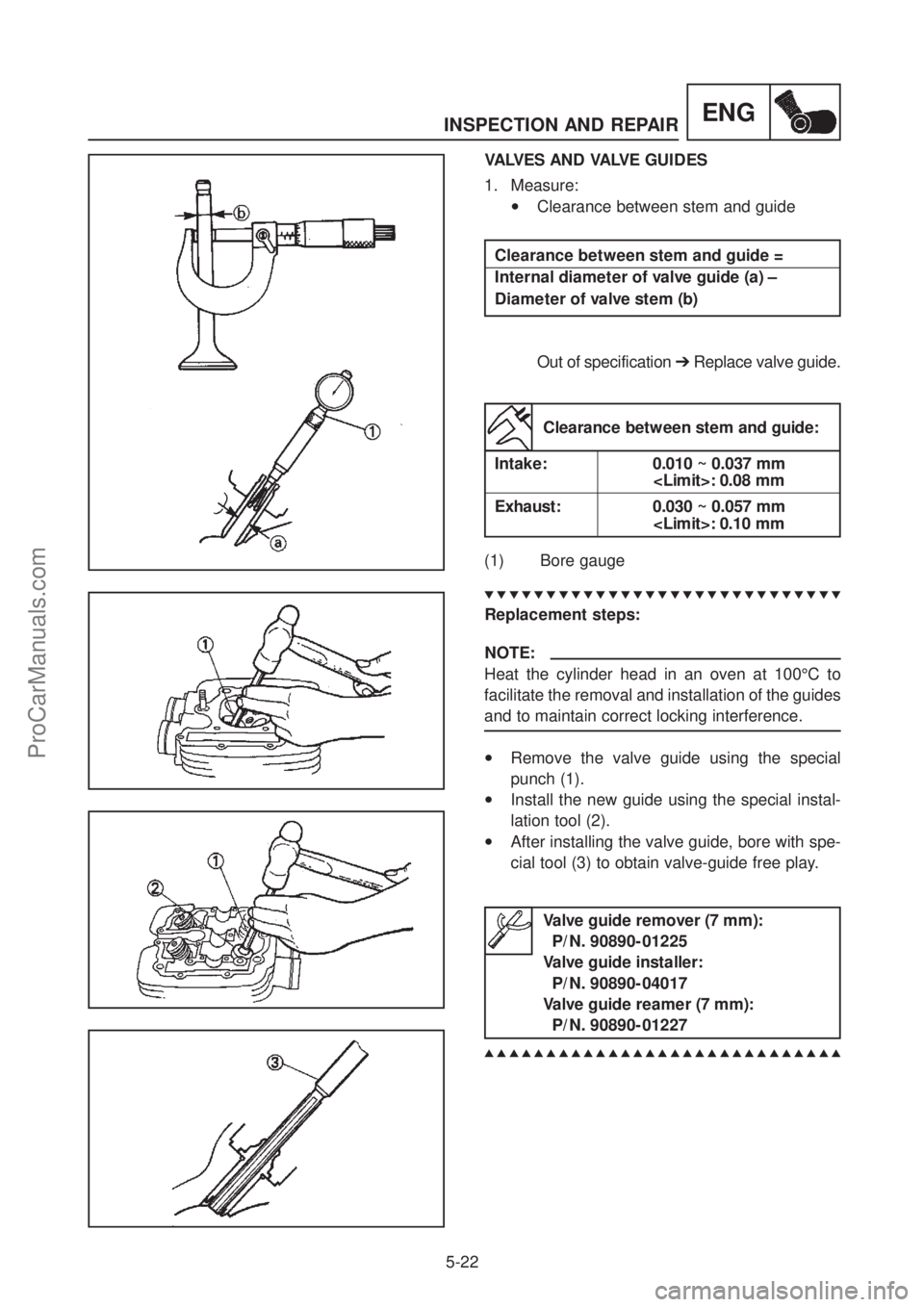

VALVES AND VALVE GUIDES

1. Measure:

•Clearance between stem and guide

Clearance between stem and guide =

Internal diameter of valve guide (a) –

Diameter of valve stem (b)

Out of specification ➔Replace valve guide.

Clearance between stem and guide:

Intake: 0.010 ~ 0.037 mm

Exhaust: 0.030 ~ 0.057 mm

(1) Bore gauge

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Replacement steps:

NOTE:

Heat the cylinder head in an oven at 100°C to

facilitate the removal and installation of the guides

and to maintain correct locking interference.

•Remove the valve guide using the special

punch (1).

•Install the new guide using the special instal-

lation tool (2).

•After installing the valve guide, bore with spe-

cial tool (3) to obtain valve-guide free play.

Valve guide remover (7 mm): P/N. 90890-01225

Valve guide installer: P/N. 90890-04017

Valve guide reamer (7 mm): P/N. 90890-01227

ProCarManuals.com

Page 238 of 382

INSPECTION AND REPAIR

5-34

ENG

2. Inspect:

•Clutch gear assy bearing

Damaged ➔Replace.

3. Inspect:

•Groove in clutch boss.

Pitting:

Moderate ➔Burr.

Accentuated ➔ Replace clutch boss.

NOTE:

Pitting of the clutch boss grooves causes irregular

functioning.

4. Measure:

•Thickness of friction plates

Out of specification ➔Replace all plates.

Thickness Wear

limit

Type “A” 2.94 ~ 3.06 mm 2.8 mm

(2 parts)

Type “B” 2.72 ~ 2.88 mm 2.6 mm

(6 parts)

5. Measure:

•Deformation of clutch plates

Out of specification ➔Replace all plates.

Clutch plates deformation:

Clutch push rod runout:

6. Measure:

•Runout limit of clutch push rod.

Turn clutch push rod on two V blocks.

ProCarManuals.com

Page 242 of 382

•Install the starter rim on the gear and hold

the gear firm.

•When turning the gear rim in a clockwise

direction (A), the gear and rim must be

meshed. Otherwise, the gear is faulty and

must be replaced.

•When the gear rim is turned in a anti-

clockwise direction (B), it must turn freely.

Otherwise, the gear is faulty and must be

replaced.

INSPECTION AND REPAIR

5-38

ENG

STARTER TRANSMISSION

1. Check:

•Starter clutch functioning (1).

Turn the clutch in the direction indicated

by the arrow.

Irregular functioning/Damage ➔ Replace

the clutch.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

2. Inspect:

•Starter neutral gear teeth (1)

•Starter neutral gear teeth (2)

•Starter rim teeth (3)

Burrs/Shavings/Roughness/Wear ➔

Replace.

3. Inspect:

•Starter rim (contact surfaces)

Pitting/Wear/Damage ➔ Replace.

ProCarManuals.com

Page 254 of 382

ENGINE ASSEMBLY AND SETTING

5-50

ENG

CRANKCASE

(1) Crankcase (R)

(2) Crankcase (L)

(3) Crankcase ventilation hose

(4) Dowel pin

(5) Dowel pin

(6) Dowel pin

(7) Bearing cover plate

(8) Collar

(9) Lock plate

ProCarManuals.com

Page 265 of 382

ENGENGINE ASSEMBLY AND SETTING

5-61

7. Install:

•Dowel pins (1)

•O-Ring (2)

•Gasket (3) (cylinder head)

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Cylinder head:

Screw (l), (2), (3) and (4): 29 Nm (2.9 mkg)

Nut (5) and (6): 22 Nm (2.2 mkg)

Screw (7): 10 Nm (1.0 mkg)

8. Install:

•Cylinder head

NOTE:

Tighten screws beginning with the one with the

lowest number.

9. Install:

•Chain stopper guide

•Camshaft

•Cam chain sprocket

Timing chain installation:

•Install the cam chain on the cylinder head as

illustrated (compression phase timing).

•Run the cam shaft in an anticlockwise direc-

tion until the mark on the crankcase (1) and

the point on the cam chain gearwheel (2) are

aligned.

ProCarManuals.com

Page 270 of 382

ENGINE ASSEMBLY AND SETTING

5-66

ENG

AC GENERATOR

1. Install:

•Woodruff key (1)

•Washer (2)

•Bearing (3)

•Rotor (4)

•Washer (5)

•Nut (6)

NOTE:

When installing the AC generator rotor, check that

the woodruff key fits properly into its seat on the

crankshaft. Apply a thin layer of lithium soap-

based grease on the conical tip of the crankshaft.

2. Tighten:

•Nut (rotor) Nut (rotor): 120 Nm (12.0 mkg)

NOTE:

To tighten the nut, lock the rotor with the special

tool (1).

Sheave holder: P/N. 90890-01701

Be careful not to touch the jutting edges (2) on

the rotor with the sheave holder.

CAUTION:

ProCarManuals.com

Page 272 of 382

ENGINE ASSEMBLY AND SETTING

5-68

ENG

BALANCER SHAFT GEAR AND PRIMARY TRANSMISSION GEAR

(1) Straight key

(2) Balancer shaft gear

(3) Breather plate

(4) Lock washer

(5) Nut

(6) Plate washer

(7) Straight key

(8) Plate (9) Balancer shaft drive gear

(10) Plate

(11) Primary drive gear

(12) Lock washer

(13) Nut

ProCarManuals.com

Page 273 of 382

ENGENGINE ASSEMBLY AND SETTING

5-69

BALANCER SHAFT GEAR AND PRIMARY

TRANSMISSION GEAR

1. Install:

•Key (1)

•Balancer shaft gear (2)

•Plate (3)

•Lock washer (4)

•Nut (5) (balancer shaft gear)

•Washer (6)

•Key (7)

•Plate (8)

•Balancer shaft drive gear (9)

•Plate (10)

•Primary drive gear (11)

•Lock washer (12)

•Nut (13) (primary drive gear)

Nut (balancer shaft gear): 60 Nm (6.0 mkg)

Nut (primary drive gear): 120 Nm (12.0 mkg)

NOTE:

When installing the drive gear, align the mark on

it (14) with that of the balancer shaft gear (15).

WARNING

Always use a new lock washer.

NOTE:

To tighten nuts (5) and (13), keep the AC genera-

tor rotor still with the special tool (16).

Sheave holder: P/N. 90890-01701

Be careful not to touch the jutting part (17) of

the rotor with the sheave holder.

2. Bend the lock washer tab along the face of the nut.

CAUTION:

ProCarManuals.com

Page 275 of 382

ENGENGINE ASSEMBLY AND SETTING

5-71

CLUTCH

1. Install:

•Plain washer

•Spring

•Push lever (1)

Screw (push lever): 12 Nm (1.2 mkg)

2. Install:

•Push rod (1)

•Primary driven gear comp. (2)

•Thrust plate (3)

•Clutch boss (4)

•Lock washer (5)

•Nut (6) (clutch boss)

•Clutch boss spring (7)

•Clutch plate (8)

•Friction plate (9)

•Ball (10)

•Pressure plate (11)

•Compression spring (12)

•Screw (pressure plate) (13)

Nut (clutch boss): 90 Nm (9.0 mkg)

Pressure plate screw: 8 Nm (0.8 mkg)

NOTE:

•To tighten the nut (clutch boss), lock the clutch

drum with the special tool (14).

Clutch holding tool: P/N. 90890-04086

•Bend the lock washer tab along the face of the

nut.

WARNING

Always use a new lock washer.

ProCarManuals.com

Page 280 of 382

ENGINE REASSEMBLY

5-76

ENG

ENGINE REASSEMBLY

To reassemble the engine, repeat the procedures

described in the paragraph “ ENGINE REMOVAL”

in this chapter in reverse order. Pay attention to

the following points.

1. Install:

•Sprocket (1)

•Drive chain Nut (sprocket): 110 Nm (11.0 mkg)

Drive chain slack: 30 ~ 40 mm

Screw (sprocket cover):10 Nm (1.0 mkg)

Use LOCTlTE ®

Screw (shift ptidal): 10 Nm (1.0 mkg)

Screw (footrest): 48 Nm (4.8 mkg)

NOTE:

Bend the lock washer tab along the face of the

nut.

WARNING

Always use a new lock washer.

2. Install:

•Cover (sprocket)

•Shift pedal

•Footrest (L)

3. Adjust:

•Drive chain slack

See section “DRIVE CHAIN SLACK

INSPECTION AND ADJUSTMENT” in

CHAPTER

ProCarManuals.com