warning YAMAHA TT600RE 2004 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2004, Model line: TT600RE, Model: YAMAHA TT600RE 2004Pages: 382, PDF Size: 6.39 MB

Page 200 of 382

CHASDRIVE CHAIN, DRIVE SPROCKET AND REAR WHEEL SPROCKET

4-85

3. Tighten:

•Rear wheel sprocket fastening bolts

Rear wheel sprocket fastening bolts: 48 Nm (4.8 mkg)

Nut (drive sprocket): 110 Nm (11.0 mkg)

Nut (swingarm pivot shaft): 90 Nm (9.0 mkg)

Nut (frame-relay arm): 60 Nm (6.0 mkg)

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

DRIVE CHAIN INSTALLATION

Perform “REMOVAL” operations in reverse order.

Pay special attention to the following points.

1. Install:

•Drive chain

•Swingarm

2. Install:

•Rear wheel

Refer to “REAR WHEEL INSTALLATION”

section.

3. Install:

•Drive sprocket

WARNING

Always use a new lock washer.

NOTE:

•Tighten the drive sprocket nut with the rear

brake pulled.

•After tightening the nut, bend the tab on the

lock washer once more over the faces of the

nut.

4. Adjust:

•Drive chain slack

Refer to “DRIVE CHAIN SLACK ADJUST-

MENT” section in CHAPTER 3.

Drive chain slack: 30 ~ 40 mm

ProCarManuals.com

Page 205 of 382

ENGENGINE REMOVAL

5-1

ENGINE

ENGINE REMOVAL

MUFFLER, EXHAUST PIPE, ENGINE PROTECTOR, DRIVE SPROCKET CRANKCASE COVER,

DRIVE SPROCKET AND SHIFT PEDAL

Order Job name/Part name Q.ty Remarks

Muffler, exhaust pipe, engine Remove the parts in order.

protector, drive sprocket crankcase

cover, drive sprocket and shift

pedal removal Park the motorcycle in a stable and level

position.

WARNING

Securely support the motorcycle so there

is no danger of it falling over.

ProCarManuals.com

Page 240 of 382

INSPECTION AND REPAIR

5-36

ENG

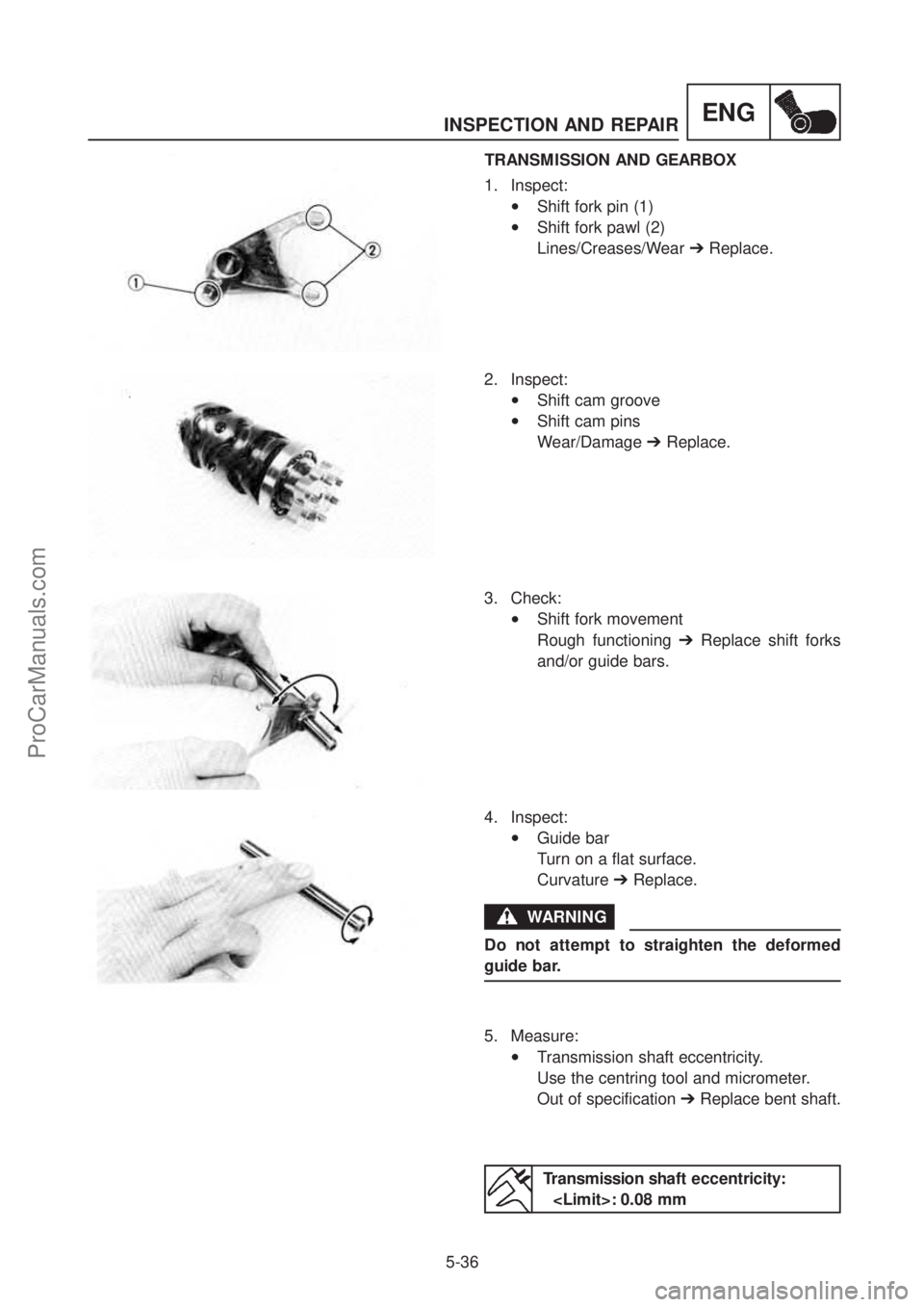

TRANSMISSION AND GEARBOX

1. Inspect:

•Shift fork pin (1)

•Shift fork pawl (2)

Lines/Creases/Wear ➔Replace.

2. Inspect:

•Shift cam groove

•Shift cam pins

Wear/Damage ➔Replace.

3. Check:

•Shift fork movement

Rough functioning ➔Replace shift forks

and/or guide bars.

4. Inspect:

•Guide bar

Turn on a flat surface.

Curvature ➔Replace.

WARNING

Do not attempt to straighten the deformed

guide bar.

5. Measure:

•Transmission shaft eccentricity.

Use the centring tool and micrometer.

Out of specification ➔Replace bent shaft.

Transmission shaft eccentricity:

ProCarManuals.com

Page 255 of 382

ENGENGINE ASSEMBLY AND SETTING

5-51

ENGINE OIL STRAINER

1. Install:

•Oil strainer (1)

•Oil passage cover (2)

Screw (oil strainer): 7 Nm (0.7 mkg)

Screw (oil passage cover): 7 Nm (0.7 mkg)

WARNING

Always use a new gasket.

Yamaha bond N° 1215 ®

:

P/N. 90890-85505

2 Install:

•Dowel pin (2)

3. Assemble the left crankcase to the right. Beat gently with a soft hammer.

NOTE:

Turn the shift cam as shown in the figure so that

it does not interfere with the crankcase during

assembly.

CRANKCASE

1. Apply:

•Yamaha bond N° 1215 ®

(1)

(on the crankcase mating surfaces)

Before installing and tightening the fastening

screws, be sure that the transmission is work-

ing properly by hand, turning the shift cam in

both directions.

CAUTION:

ProCarManuals.com

Page 263 of 382

ENGENGINE ASSEMBLY AND SETTING

5-59

PISTON, CYLINDER, CYLINDER HEAD AND

CAMSHAFT

1. Apply:

•4-stroke engine oil

(on piston pin).

2. Install:

•Piston (1)

•Pin (2)

•Circlip (3)

NOTE:

•Arrow (4) on the piston must point towards the

front of the engine.

•Before installing the piston pin circlips, cover

the crankcase with a clean cloth to prevent

foreign bodies falling into it.

WARNING

Always use new circlips for the piston pin.

3. Install:

•Dowel pins (1)

•O-Ring (2)

4. Install:

•Gasket (1) (cylinder)

NOTE:

Install the cylinder gasket as shown in the illustra-

tion.

ProCarManuals.com

Page 267 of 382

ENGENGINE ASSEMBLY AND SETTING

5-63

13. Install:

•Chain tensioner

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Assembly steps:

•Remove the chain tensioner screw (1), the

washer (2) and the spring (3).

•Release the chain tensioner unidirectional

cam (4) and push the thrust rod (5).

•Install the chain tensioner in the cylinder with

a new gasket.

Screw (chain tensioner body): 10 Nm (1.0 mkg)

Chain tensioner screw: 20 Nm (2.0 mkg)

WARNING

Always use a new gasket.

•Install the spring, the washer and the chain

tensioner.

14. Adjust:

•Valve clearance Valve clearance: Intake0.05 ~ 0.10 mm

Exhaust 0.12 - 0.17 mm

See section “VALVE CLEARANCE

ADJUSTMENT” in CHAPTER 3.

ProCarManuals.com

Page 273 of 382

ENGENGINE ASSEMBLY AND SETTING

5-69

BALANCER SHAFT GEAR AND PRIMARY

TRANSMISSION GEAR

1. Install:

•Key (1)

•Balancer shaft gear (2)

•Plate (3)

•Lock washer (4)

•Nut (5) (balancer shaft gear)

•Washer (6)

•Key (7)

•Plate (8)

•Balancer shaft drive gear (9)

•Plate (10)

•Primary drive gear (11)

•Lock washer (12)

•Nut (13) (primary drive gear)

Nut (balancer shaft gear): 60 Nm (6.0 mkg)

Nut (primary drive gear): 120 Nm (12.0 mkg)

NOTE:

When installing the drive gear, align the mark on

it (14) with that of the balancer shaft gear (15).

WARNING

Always use a new lock washer.

NOTE:

To tighten nuts (5) and (13), keep the AC genera-

tor rotor still with the special tool (16).

Sheave holder: P/N. 90890-01701

Be careful not to touch the jutting part (17) of

the rotor with the sheave holder.

2. Bend the lock washer tab along the face of the nut.

CAUTION:

ProCarManuals.com

Page 275 of 382

ENGENGINE ASSEMBLY AND SETTING

5-71

CLUTCH

1. Install:

•Plain washer

•Spring

•Push lever (1)

Screw (push lever): 12 Nm (1.2 mkg)

2. Install:

•Push rod (1)

•Primary driven gear comp. (2)

•Thrust plate (3)

•Clutch boss (4)

•Lock washer (5)

•Nut (6) (clutch boss)

•Clutch boss spring (7)

•Clutch plate (8)

•Friction plate (9)

•Ball (10)

•Pressure plate (11)

•Compression spring (12)

•Screw (pressure plate) (13)

Nut (clutch boss): 90 Nm (9.0 mkg)

Pressure plate screw: 8 Nm (0.8 mkg)

NOTE:

•To tighten the nut (clutch boss), lock the clutch

drum with the special tool (14).

Clutch holding tool: P/N. 90890-04086

•Bend the lock washer tab along the face of the

nut.

WARNING

Always use a new lock washer.

ProCarManuals.com

Page 278 of 382

ENGINE ASSEMBLY AND SETTING

5-74

ENG

STARTER NEUTRAL GEAR AND CRANKCASE

COVER (L))

1. Install:

•Stator winding (1)

•Pick-up coil (2)

•Cable clamp (3)

2. Install:

•Bearing (1)

•Intermediate starter gear 2 (2) Screws (stator and coil):

7 Nm (0.7 mkg)

Use LOCTITE ®

Screw (cable clamp): 7 Nm (0.7 mkg)

3. Install:

•Centring pin (1)

•Gasket (2)

•O-Ring (3)

•Crankcase cover (L) (4)

•Plugs

Bolt (crankcase cover): 10 Nm (1.0 mkg)

WARNING

Always use a new gasket.

ProCarManuals.com

Page 280 of 382

ENGINE REASSEMBLY

5-76

ENG

ENGINE REASSEMBLY

To reassemble the engine, repeat the procedures

described in the paragraph “ ENGINE REMOVAL”

in this chapter in reverse order. Pay attention to

the following points.

1. Install:

•Sprocket (1)

•Drive chain Nut (sprocket): 110 Nm (11.0 mkg)

Drive chain slack: 30 ~ 40 mm

Screw (sprocket cover):10 Nm (1.0 mkg)

Use LOCTlTE ®

Screw (shift ptidal): 10 Nm (1.0 mkg)

Screw (footrest): 48 Nm (4.8 mkg)

NOTE:

Bend the lock washer tab along the face of the

nut.

WARNING

Always use a new lock washer.

2. Install:

•Cover (sprocket)

•Shift pedal

•Footrest (L)

3. Adjust:

•Drive chain slack

See section “DRIVE CHAIN SLACK

INSPECTION AND ADJUSTMENT” in

CHAPTER

ProCarManuals.com