ad blue YAMAHA TTR125 2000 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: TTR125, Model: YAMAHA TTR125 2000Pages: 442, PDF Size: 26.34 MB

Page 220 of 442

4 - 21

ENGCAMSHAFT AND ROCKER ARMS

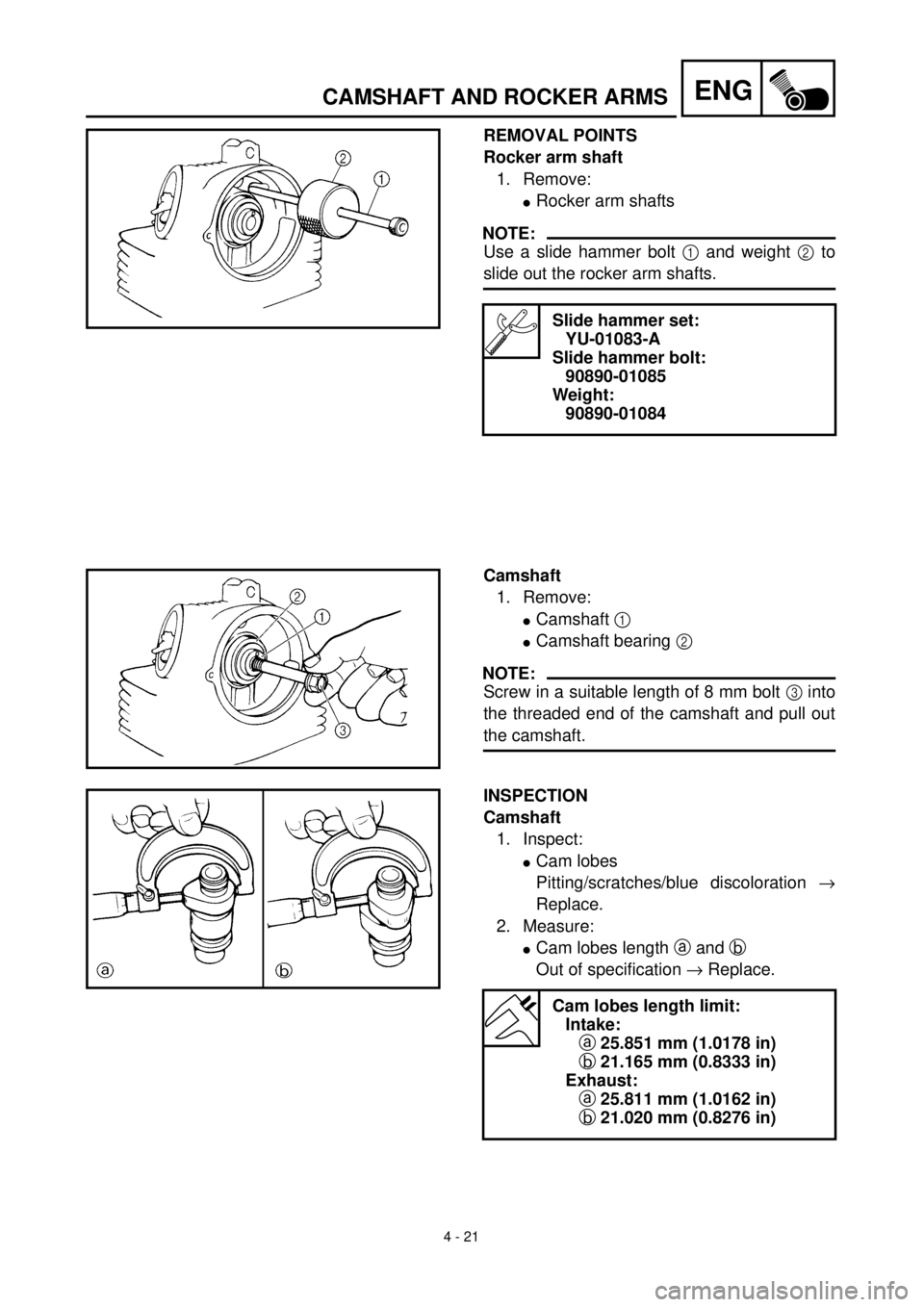

REMOVAL POINTS

Rocker arm shaft

1. Remove:

lRocker arm shafts

NOTE:

Use a slide hammer bolt 1 and weight 2 to

slide out the rocker arm shafts.

Slide hammer set:

YU-01083-A

Slide hammer bolt:

90890-01085

Weight:

90890-01084

Camshaft

1. Remove:

lCamshaft 1

lCamshaft bearing 2

NOTE:

Screw in a suitable length of 8 mm bolt 3 into

the threaded end of the camshaft and pull out

the camshaft.

INSPECTION

Camshaft

1. Inspect:

lCam lobes

Pitting/scratches/blue discoloration ®

Replace.

2. Measure:

lCam lobes length a and b

Out of specification ® Replace.

Cam lobes length limit:

Intake:

a 25.851 mm (1.0178 in)

b 21.165 mm (0.8333 in)

Exhaust:

a 25.811 mm (1.0162 in)

b 21.020 mm (0.8276 in)

Page 222 of 442

4 - 22

ENGCAMSHAFT AND ROCKER ARMS

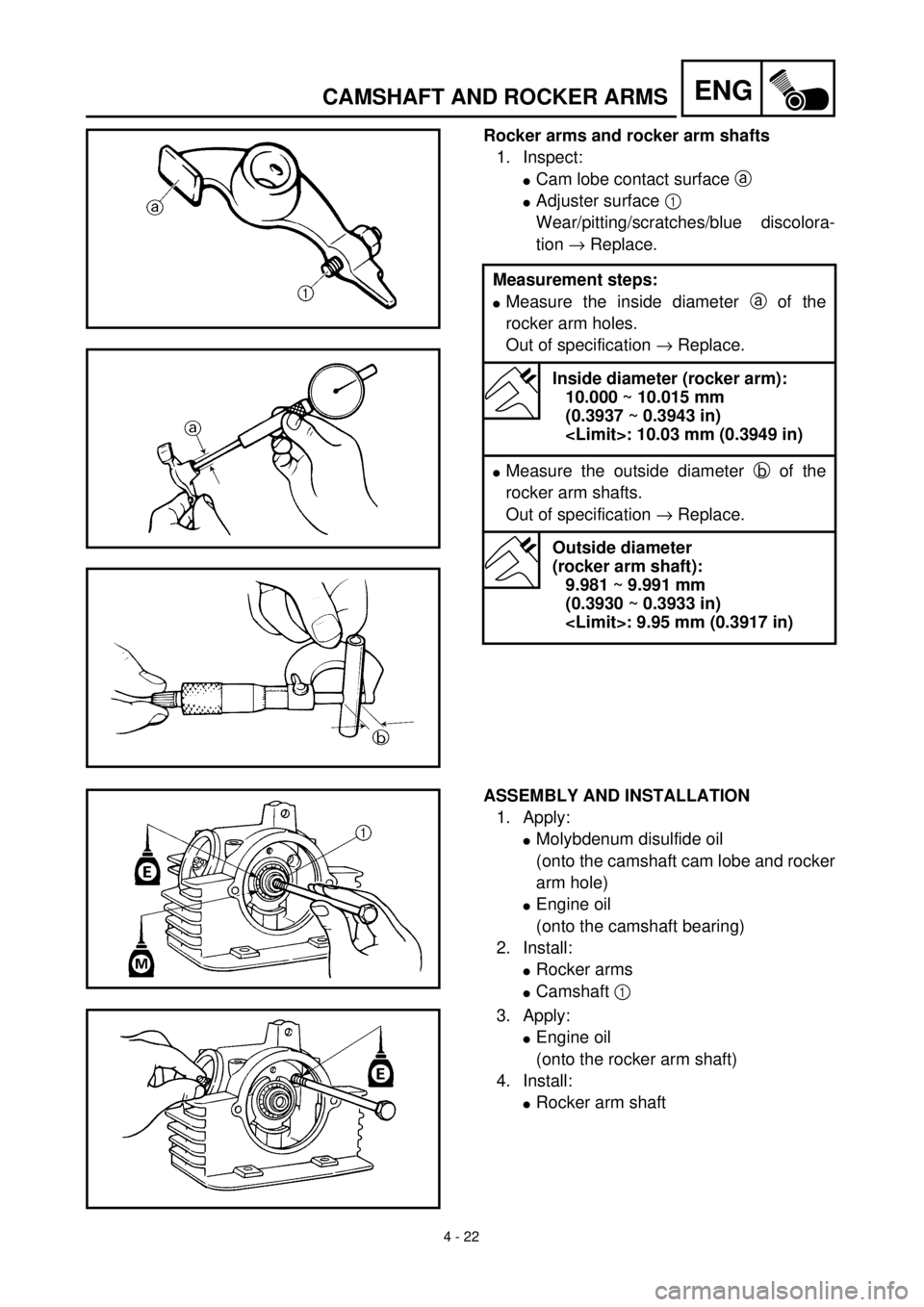

Rocker arms and rocker arm shafts

1. Inspect:

lCam lobe contact surface a

lAdjuster surface 1

Wear/pitting/scratches/blue discolora-

tion ® Replace.

Measurement steps:

lMeasure the inside diameter a of the

rocker arm holes.

Out of specification ® Replace.

Inside diameter (rocker arm):

10.000 ~ 10.015 mm

(0.3937 ~ 0.3943 in)

lMeasure the outside diameter b of the

rocker arm shafts.

Out of specification ® Replace.

Outside diameter

(rocker arm shaft):

9.981 ~ 9.991 mm

(0.3930 ~ 0.3933 in)

ASSEMBLY AND INSTALLATION

1. Apply:

lMolybdenum disulfide oil

(onto the camshaft cam lobe and rocker

arm hole)

lEngine oil

(onto the camshaft bearing)

2. Install:

lRocker arms

lCamshaft 1

3. Apply:

lEngine oil

(onto the rocker arm shaft)

4. Install:

lRocker arm shaft

Page 234 of 442

4 - 28

ENGVALVES AND VALVE SPRINGS

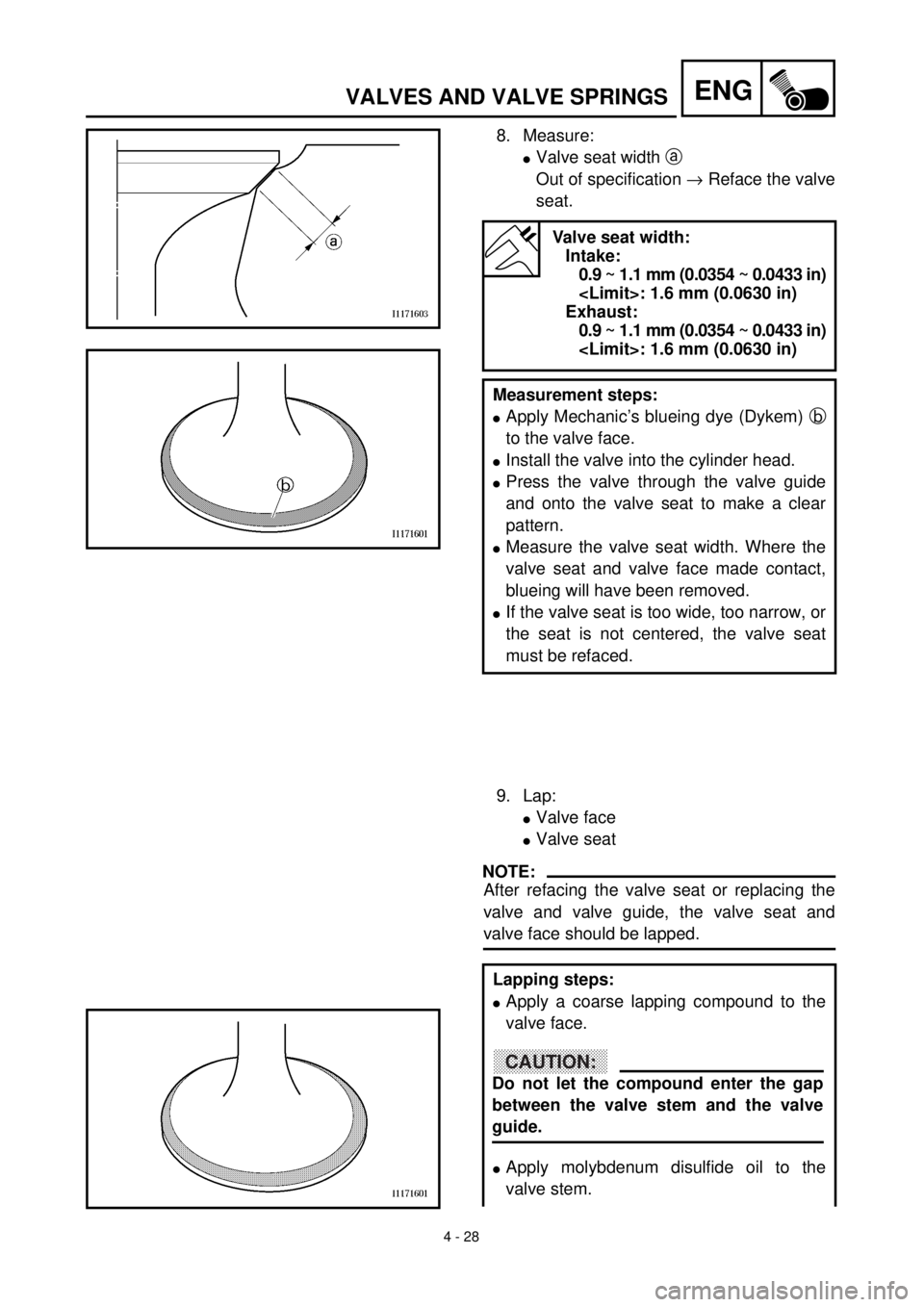

8. Measure:

lValve seat width a

Out of specification ® Reface the valve

seat.

Valve seat width:

Intake:

0.9 ~ 1.1 mm (0.0354 ~ 0.0433 in)

Exhaust:

0.9 ~ 1.1 mm (0.0354 ~ 0.0433 in)

Measurement steps:

lApply Mechanic’s blueing dye (Dykem) b

to the valve face.

lInstall the valve into the cylinder head.

lPress the valve through the valve guide

and onto the valve seat to make a clear

pattern.

lMeasure the valve seat width. Where the

valve seat and valve face made contact,

blueing will have been removed.

lIf the valve seat is too wide, too narrow, or

the seat is not centered, the valve seat

must be refaced.

9. Lap:

lValve face

lValve seat

NOTE:

After refacing the valve seat or replacing the

valve and valve guide, the valve seat and

valve face should be lapped.

Lapping steps:

lApply a coarse lapping compound to the

valve face.

lApply molybdenum disulfide oil to the

valve stem.

CAUTION:

Do not let the compound enter the gap

between the valve stem and the valve

guide.

Page 236 of 442

4 - 29

ENGVALVES AND VALVE SPRINGS

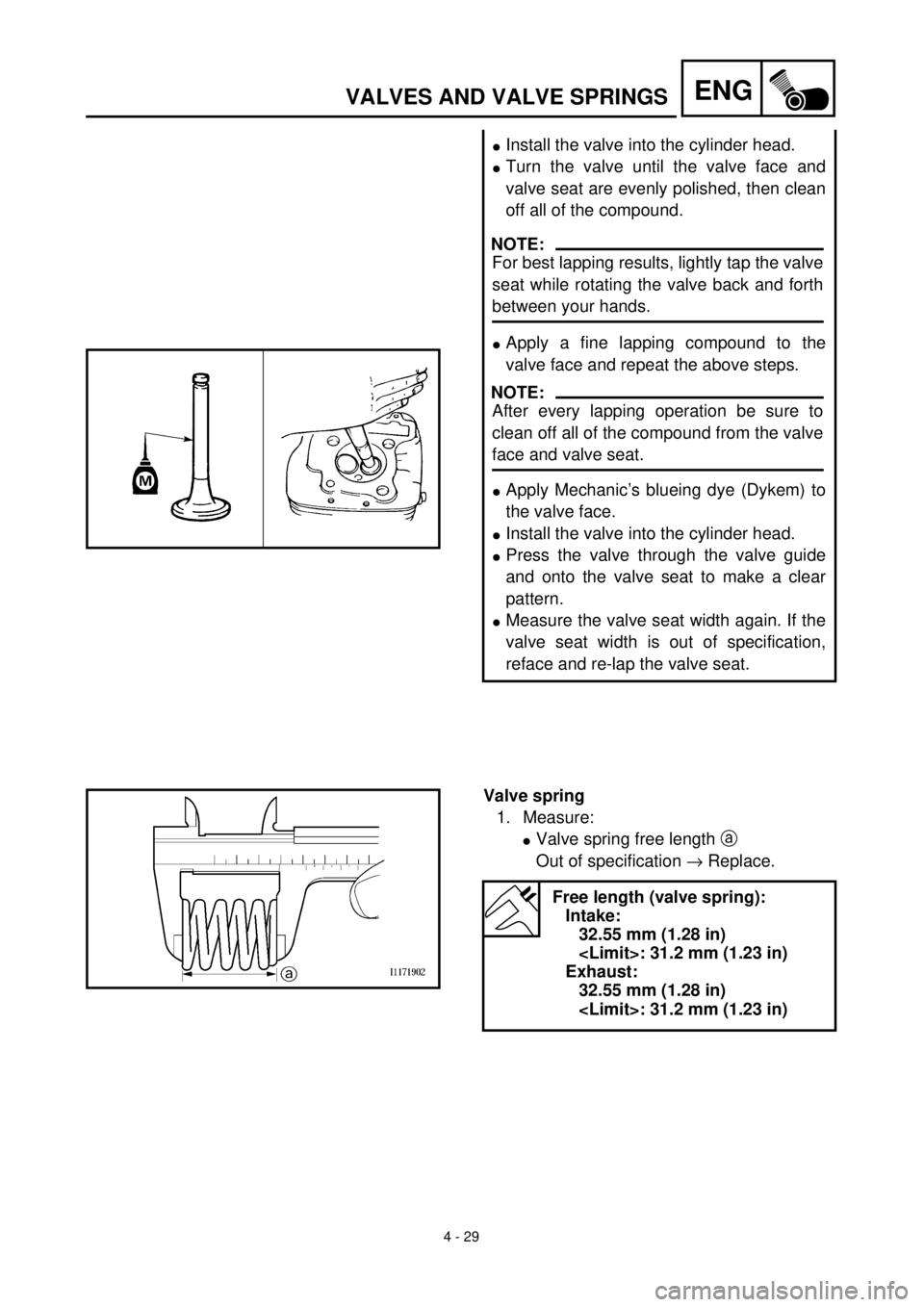

lInstall the valve into the cylinder head.

lTurn the valve until the valve face and

valve seat are evenly polished, then clean

off all of the compound.

lApply a fine lapping compound to the

valve face and repeat the above steps.

lApply Mechanic’s blueing dye (Dykem) to

the valve face.

lInstall the valve into the cylinder head.

lPress the valve through the valve guide

and onto the valve seat to make a clear

pattern.

lMeasure the valve seat width again. If the

valve seat width is out of specification,

reface and re-lap the valve seat.

NOTE:

For best lapping results, lightly tap the valve

seat while rotating the valve back and forth

between your hands.

NOTE:

After every lapping operation be sure to

clean off all of the compound from the valve

face and valve seat.

Valve spring

1. Measure:

lValve spring free length a

Out of specification ® Replace.

Free length (valve spring):

Intake:

32.55 mm (1.28 in)

Exhaust:

32.55 mm (1.28 in)

Page 248 of 442

4 - 35

ENGCYLINDER AND PISTON

lIf out of specification, replace the cylinder,

and replace the piston and piston rings as

a set.

Piston pin

1. Inspect:

lPiston pin

Blue discoloration/grooves ® Replace,

then inspect the lubrication system.

2. Measure:

lPiston pin-to-piston clearance

Measurement steps:

lMeasure the piston pin outside diameter

a.

If out of specification, replace the piston

pin

Outside diameter (piston pin):

14.991 ~ 15.000 mm

(0.5902 ~ 0.5906 in)

lMeasure the piston inside diameter b.

If out of specification, replace the piston.

Inside diameter (piston):

15.002 ~ 15.013 mm

(0.5906 ~ 0.5911 in)

Page 252 of 442

4 - 37

ENGCYLINDER AND PISTON

Combination of piston and cylinder

1. Check:

lCylinder mark a

2. Check:

lPiston mark a

3. Combination:

lCombine the piston and cylinder by the

following chart.

NOTE:

When you purchase a cylinder, you cannot

designate its size. Choose the piston that

matches the above chart.Cylinder mark aCylinder size

A54.000 ~ 54.003 mm

(2.1260 ~ 2.1261 in)

B54.004 ~ 54.007 mm

(2.1261 ~ 2.1263 in)

C54.008 ~ 54.011 mm

(2.1263 ~ 2.1264 in)

D54.012 ~ 54.015 mm

(2.1265 ~ 2.1266 in)

E54.016 ~ 54.019 mm

(2.1266 ~ 2.1267 in)

Cylinder mark a

(color)Piston size

A (red)53.977 ~ 53.980 mm

(2.1251 ~ 2.1252 in)

B (orange)53.981 ~ 53.984 mm

(2.1252 ~ 2.1254 in)

C (green)53.985 ~ 53.988 mm

(2.1254 ~ 2.1255 in)

D (purple)53.989 ~ 53.992 mm

(2.1255 ~ 2.1257 in)

E (blue)53.993 ~ 53.996 mm

(2.1257 ~ 2.1258 in)

Cylinder mark Piston mark (color)

A A (red)

B B (orange)

C C (green)

D D (purple)

E E (blue)

Page 430 of 442

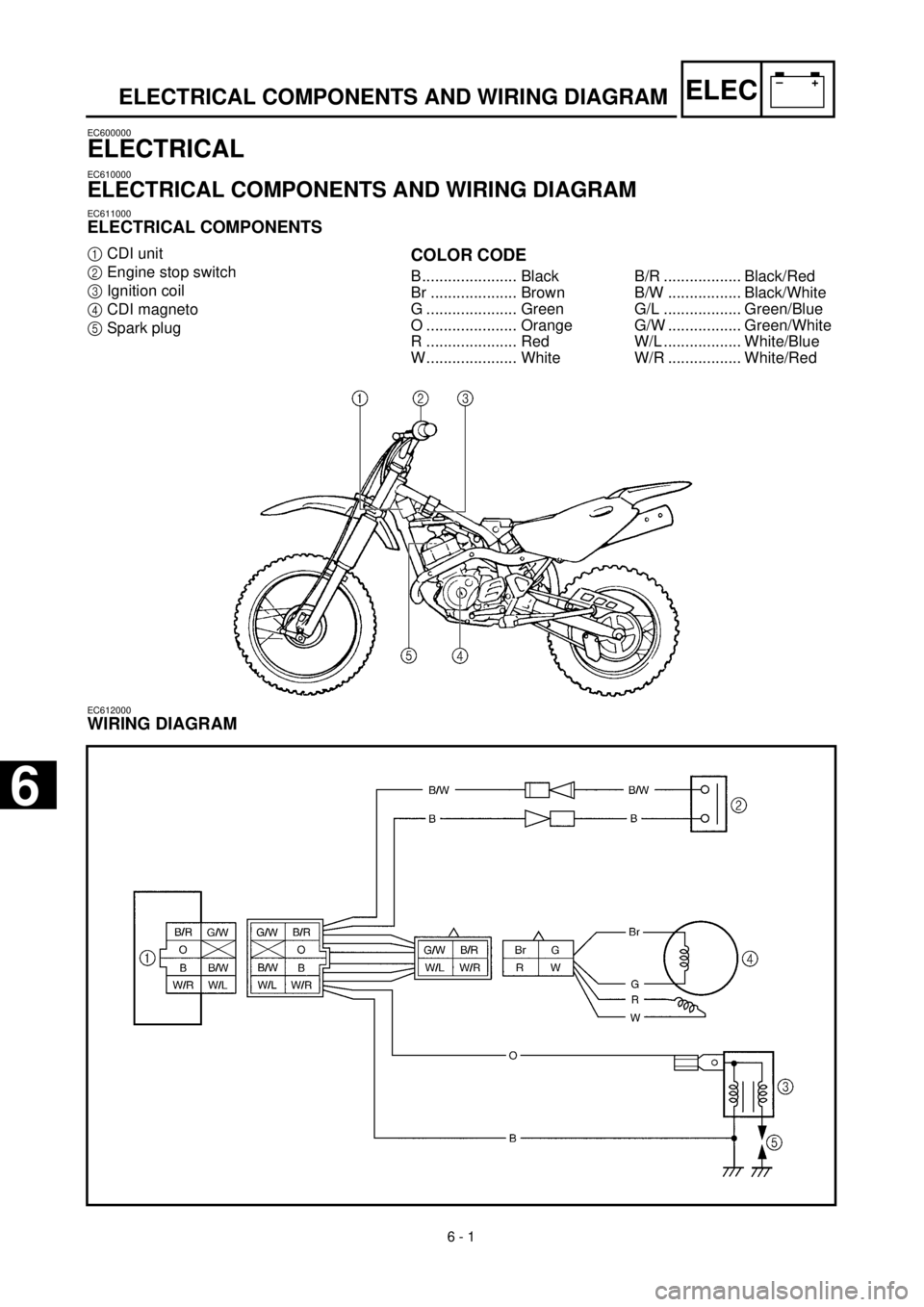

6 - 1

–+ELEC

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC611000

ELECTRICAL COMPONENTS

1

CDI unit

2

Engine stop switch

3

Ignition coil

4

CDI magneto

5

Spark plug

COLOR CODE

B...................... Black

Br .................... Brown

G ..................... Green

O ..................... Orange

R ..................... Red

W..................... WhiteB/R .................. Black/Red

B/W ................. Black/White

G/L .................. Green/Blue

G/W ................. Green/White

W/L .................. White/Blue

W/R ................. White/Red

EC612000

WIRING DIAGRAM

6