brake YAMAHA TTR125 2001 Betriebsanleitungen (in German)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: TTR125, Model: YAMAHA TTR125 2001Pages: 508, PDF-Größe: 16.81 MB

Page 88 of 508

SPEC

2 - 19

MAINTENANCE SPECIFICATIONS

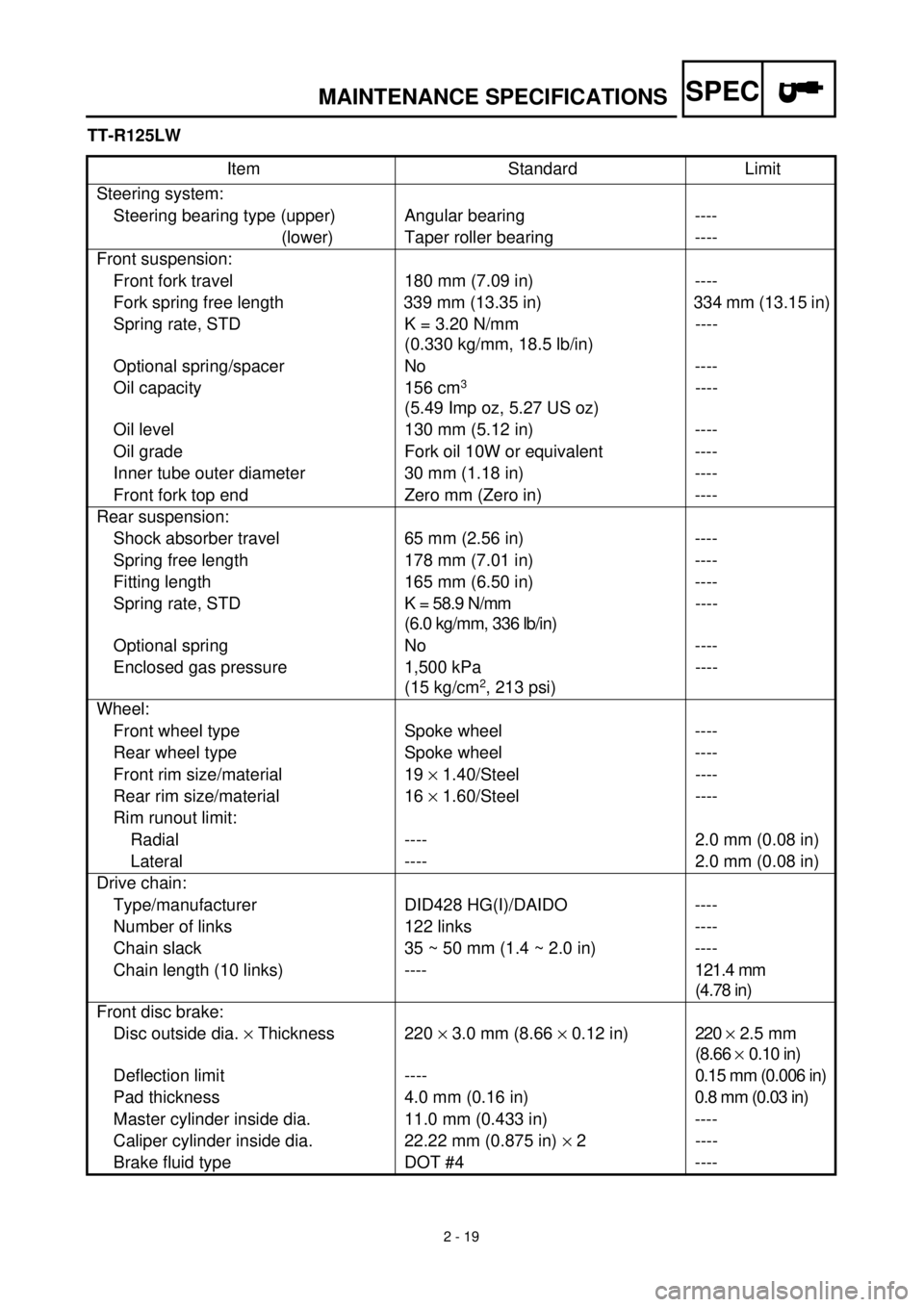

TT-R125LWItem Standard Limit

Steering system: Steering bearing type (upper) Angular bearing ---- (lower) Taper roller bearing ----

Front suspension: Front fork travel 180 mm (7.09 in) ----

Fork spring free length 339 mm (13.35 in) 334 mm (13.15 in)

Spring rate, STD K = 3.20 N/mm (0.330 kg/mm, 18.5 lb/in)----

Optional spring/spacer No ----

Oil capacity 156 cm

3

(5.49 Imp oz, 5.27 US oz) ----

Oil level 130 mm (5.12 in) ----

Oil grade Fork oil 10W or equivalent ----

Inner tube outer diameter 30 mm (1.18 in) ----

Front fork top end Zero mm (Zero in) ----

Rear suspension: Shock absorber travel 65 mm (2.56 in) ----

Spring free length 178 mm (7.01 in) ----

Fitting length 165 mm (6.50 in) ----

Spring rate, STD K = 58.9 N/mm

(6.0 kg/mm, 336 lb/in) ----

Optional spring No ----

Enclosed gas pressure 1,500 kPa (15 kg/cm

2, 213 psi)----

Wheel: Front wheel type Spoke wheel ----

Rear wheel type Spoke wheel ----

Front rim size/material 19 ´ 1.40/Steel ----

Rear rim size/material 16 ´ 1.60/Steel ----

Rim runout limit: Radial ---- 2.0 mm (0.08 in)

Lateral ---- 2.0 mm (0.08 in)

Drive chain: Type/manufacturer DID428 HG(I)/DAIDO ----

Number of links 122 links ----

Chain slack 35 ~ 50 mm (1.4 ~ 2.0 in) ----

Chain length (10 links) ---- 121.4 mm

(4.78 in)

Front disc brake: Disc outside dia. ´ Thickness 220 ´ 3.0 mm (8.66 ´ 0.12 in) 220 ´ 2.5 mm

(8.66 ´ 0.10 in)

Deflection limit ---- 0.15 mm (0.006 in)

Pad thickness 4.0 mm (0.16 in) 0.8 mm (0.03 in)

Master cylinder inside dia. 11.0 mm (0.433 in) ----

Caliper cylinder inside dia. 22.22 mm (0.875 in) ´ 2 ----

Brake fluid type DOT #4 ----

Page 89 of 508

SPEC

2 - 20

MAINTENANCE SPECIFICATIONS

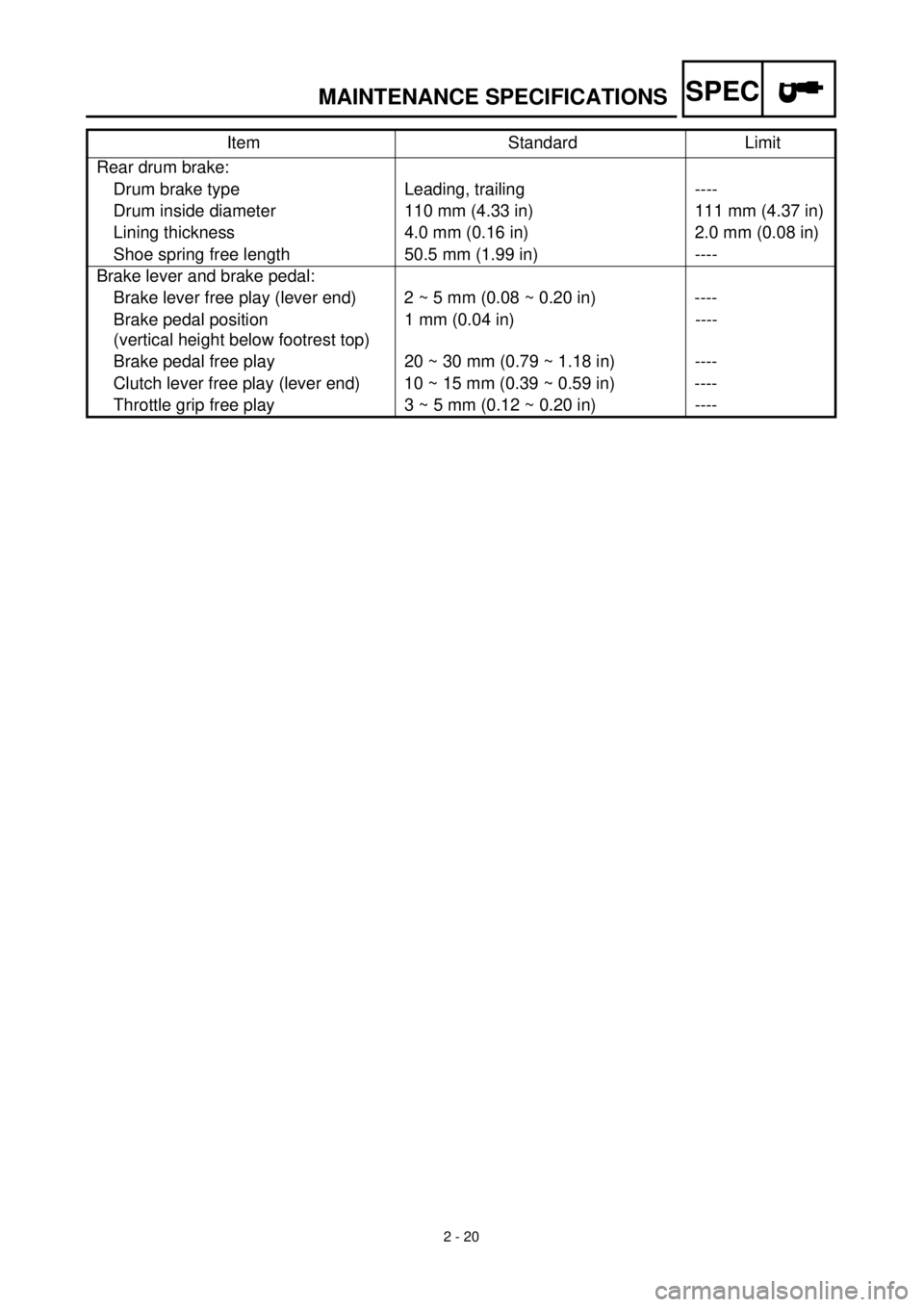

Rear drum brake:

Drum brake type Leading, trailing ----

Drum inside diameter 110 mm (4.33 in) 111 mm (4.37 in)

Lining thickness 4.0 mm (0.16 in) 2.0 mm (0.08 in)

Shoe spring free length 50.5 mm (1.99 in) ----

Brake lever and brake pedal:

Brake lever free play (lever end) 2 ~ 5 mm (0.08 ~ 0.20 in) ----

Brake pedal position

(vertical height below footrest top)1 mm (0.04 in) ----

Brake pedal free play 20 ~ 30 mm (0.79 ~ 1.18 in) ----

Clutch lever free play (lever end) 10 ~ 15 mm (0.39 ~ 0.59 in) ----

Throttle grip free play 3 ~ 5 mm (0.12 ~ 0.20 in) ----Item Standard Limit

Page 90 of 508

SPEC

2 - 21

MAINTENANCE SPECIFICATIONS

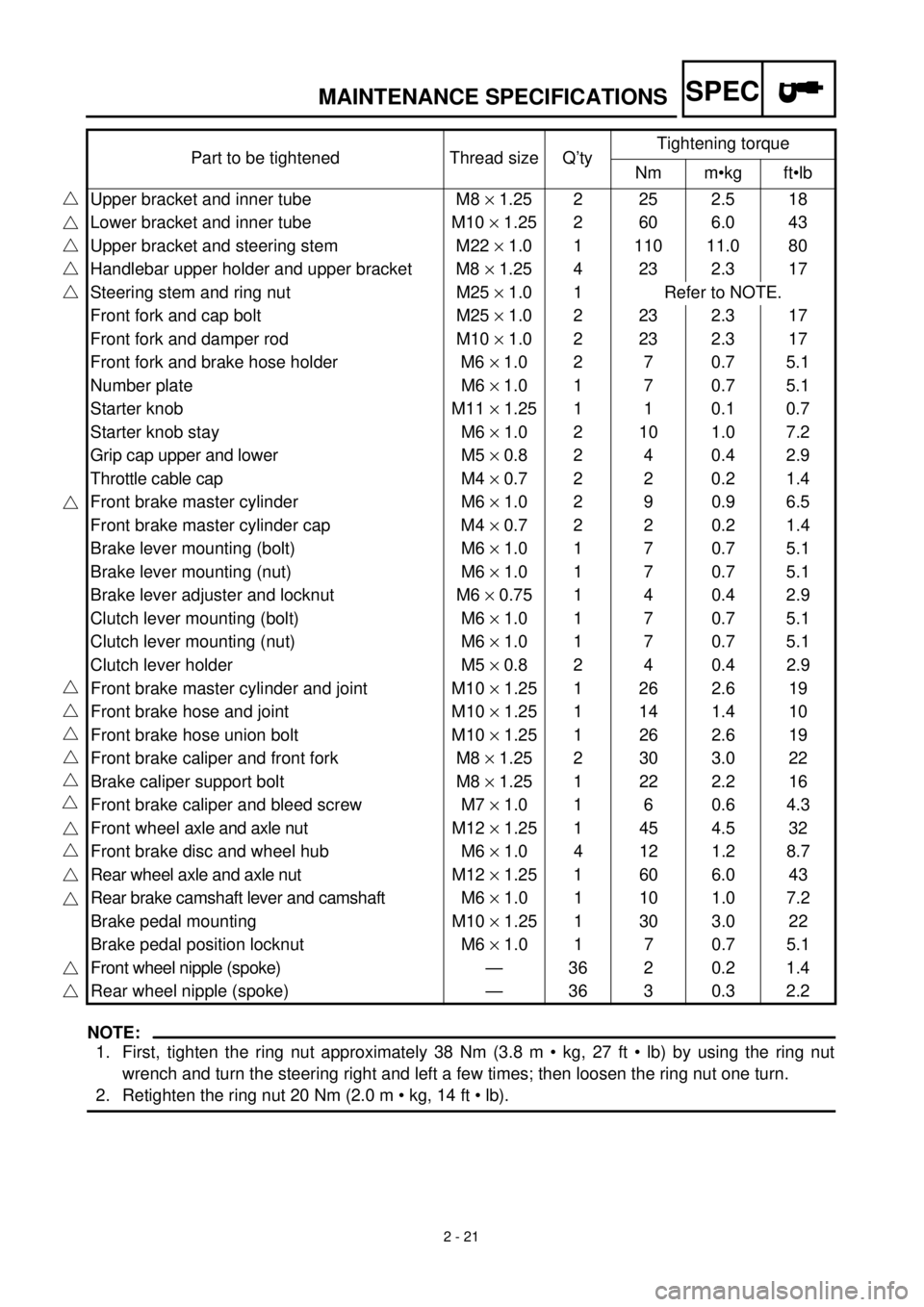

NOTE:

1. First, tighten the ring nut approximately 38 Nm (3.8 m • kg, 27 ft • lb) by using the ring nut

wrench and turn the steering right and left a few times; then loosen the ring nut one turn.

2. Retighten the ring nut 20 Nm (2.0 m • kg, 14 ft • lb).Part to be tightened Thread size Q’tyTightening torque

Nm m•kg ft•lb

Upper bracket and inner tube M8 ´ 1.25 2 25 2.5 18

Lower bracket and inner tube M10 ´ 1.25 2 60 6.0 43

Upper bracket and steering stem M22 ´ 1.0 1 110 11.0 80

Handlebar upper holder and upper bracket M8 ´ 1.25 4 23 2.3 17

Steering stem and ring nut M25 ´ 1.0 1 Refer to NOTE.

Front fork and cap bolt M25 ´ 1.0 2 23 2.3 17

Front fork and damper rod M10 ´ 1.0 2 23 2.3 17

Front fork and brake hose holder M6 ´ 1.0 2 7 0.7 5.1

Number plate M6 ´ 1.0 1 7 0.7 5.1

Starter knob M11 ´ 1.25 1 1 0.1 0.7

Starter knob stay M6 ´ 1.0 2 10 1.0 7.2

Grip cap upper and lower M5 ´ 0.8 2 4 0.4 2.9

Throttle cable cap M4 ´ 0.7 2 2 0.2 1.4

Front brake master cylinder M6 ´ 1.0 2 9 0.9 6.5

Front brake master cylinder cap M4 ´ 0.7 2 2 0.2 1.4

Brake lever mounting (bolt) M6 ´ 1.0 1 7 0.7 5.1

Brake lever mounting (nut) M6 ´ 1.0 1 7 0.7 5.1

Brake lever adjuster and locknut M6 ´ 0.75 1 4 0.4 2.9

Clutch lever mounting (bolt) M6 ´ 1.0 1 7 0.7 5.1

Clutch lever mounting (nut) M6 ´ 1.0 1 7 0.7 5.1

Clutch lever holder M5 ´ 0.8 2 4 0.4 2.9

Front brake master cylinder and joint M10 ´ 1.25 1 26 2.6 19

Front brake hose and joint M10 ´ 1.25 1 14 1.4 10

Front brake hose union bolt M10 ´ 1.25 1 26 2.6 19

Front brake caliper and front fork M8 ´ 1.25 2 30 3.0 22

Brake caliper support bolt M8 ´ 1.25 1 22 2.2 16

Front brake caliper and bleed screw M7 ´ 1.0 1 6 0.6 4.3

Front wheel axle and axle nutM12 ´ 1.25 1 45 4.5 32

Front brake disc and wheel hub M6 ´ 1.0 4 12 1.2 8.7

Rear wheel axle and axle nutM12 ´ 1.25 1 60 6.0 43

Rear brake camshaft lever and camshaft M6 ´ 1.0 1 10 1.0 7.2

Brake pedal mounting M10 ´ 1.25 1 30 3.0 22

Brake pedal position locknut M6 ´ 1.0 1 7 0.7 5.1

Front wheel nipple (spoke) — 36 2 0.2 1.4

Rear wheel nipple (spoke) — 36 3 0.3 2.2

Page 142 of 508

2 - 25

SPEC

CABLE ROUTING DIAGRAM

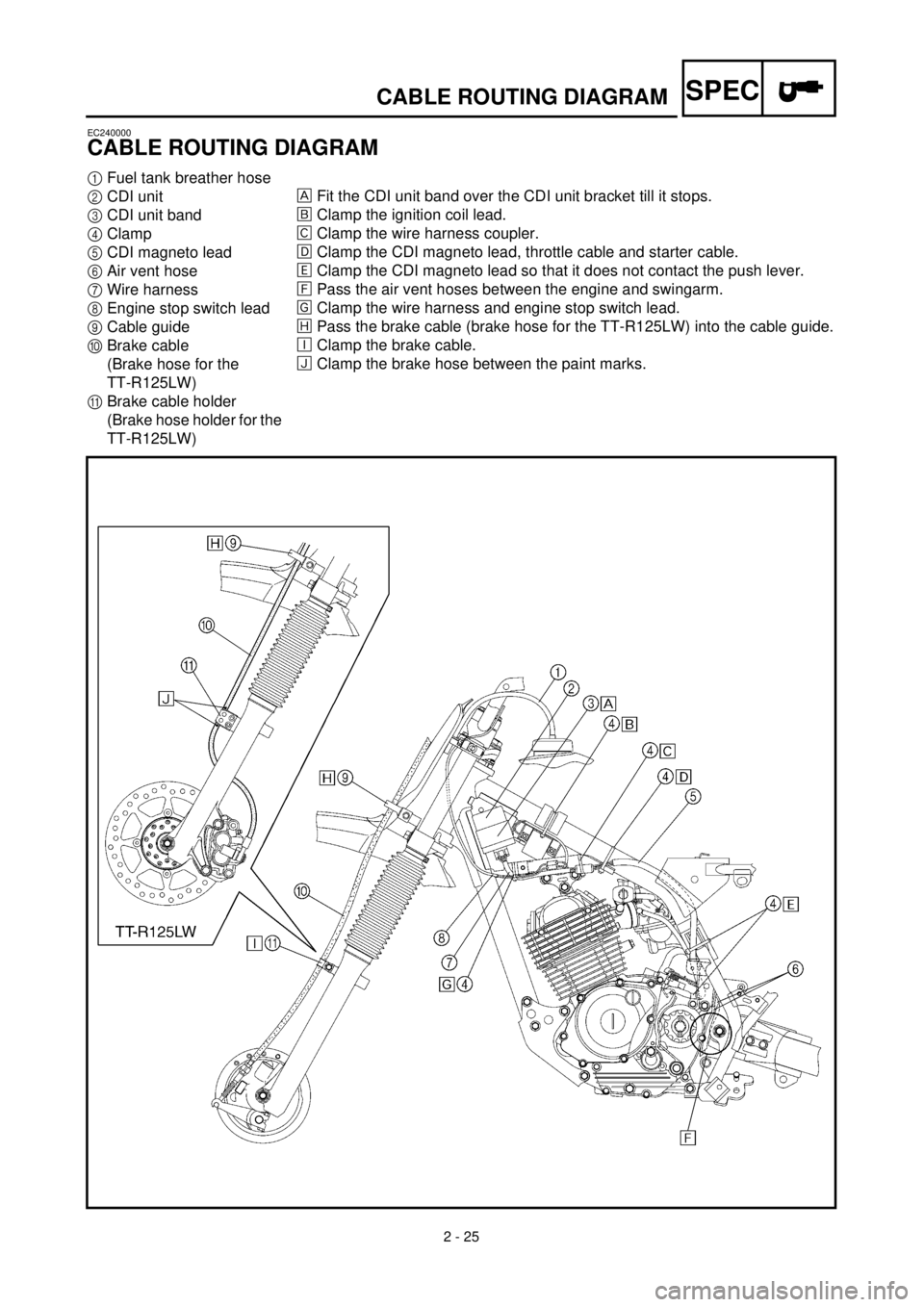

EC240000

CABLE ROUTING DIAGRAM

1

Fuel tank breather hose

2

CDI unit

3

CDI unit band

4

Clamp

5

CDI magneto lead

6

Air vent hose

7

Wire harness

8

Engine stop switch lead

9

Cable guide

0

Brake cable

(Brake hose for the

TT-R125LW)

A

Brake cable holder

(Brake hose holder for the

TT-R125LW)

Fit the CDI unit band over the CDI unit bracket till it stops.

õ

Clamp the ignition coil lead.

‚

Clamp the wire harness coupler.

ë

Clamp the CDI magneto lead, throttle cable and starter cable.

ä

Clamp the CDI magneto lead so that it does not contact the push lever.

ì

Pass the air vent hoses between the engine and swingarm.

í

Clamp the wire harness and engine stop switch lead.

î

Pass the brake cable (brake hose for the TT-R125LW) into the cable guide.

é

Clamp the brake cable.

ï

Clamp the brake hose between the paint marks.

Page 146 of 508

2 - 27

SPEC

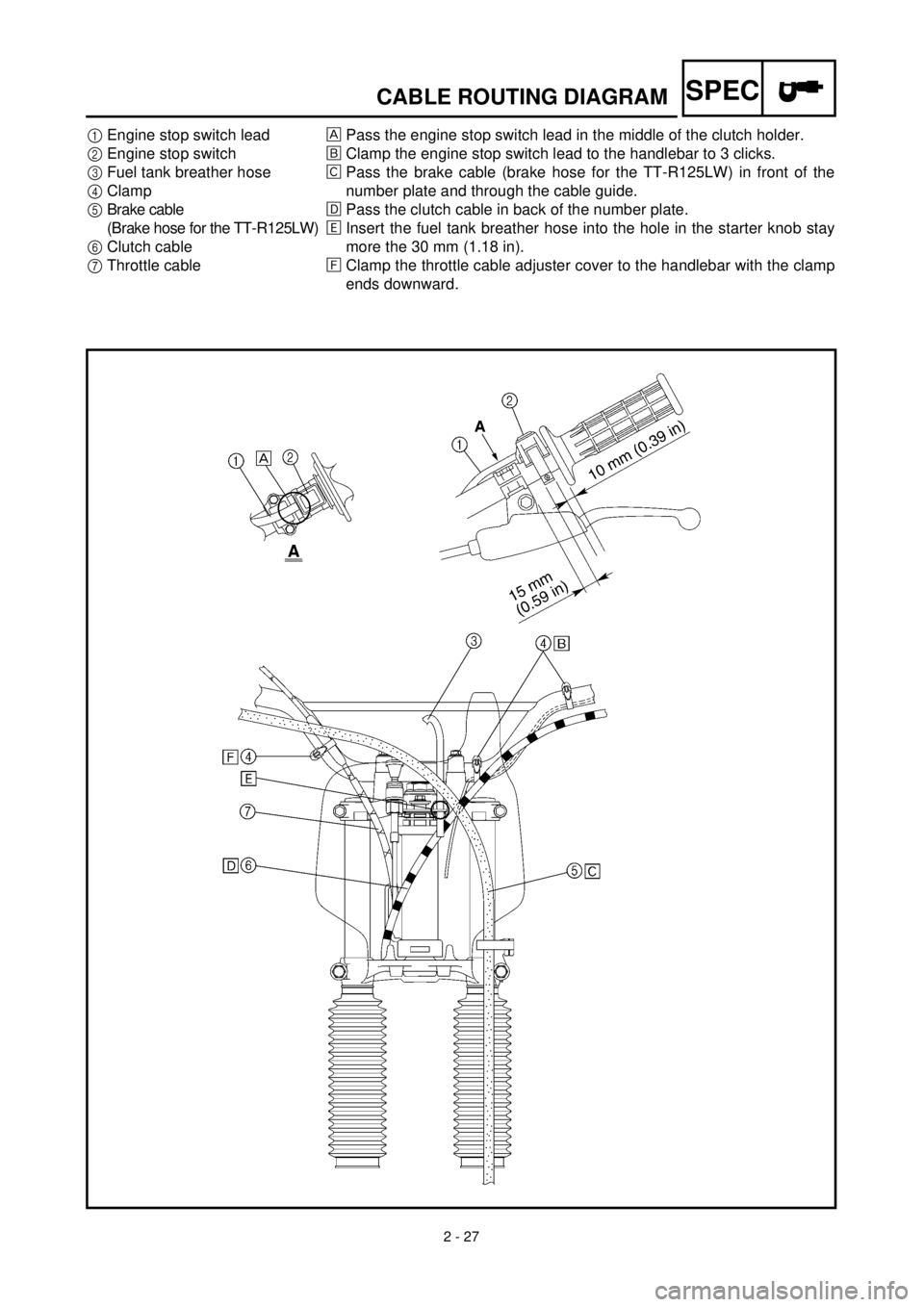

CABLE ROUTING DIAGRAM

1

Engine stop switch lead

2

Engine stop switch

3

Fuel tank breather hose

4

Clamp

5

Brake cable

(Brake hose for the TT-R125LW)

6

Clutch cable

7Throttle cablePass the engine stop switch lead in the middle of the clutch holder.

õClamp the engine stop switch lead to the handlebar to 3 clicks.

‚Pass the brake cable (brake hose for the TT-R125LW) in front of the

number plate and through the cable guide.

ëPass the clutch cable in back of the number plate.

äInsert the fuel tank breather hose into the hole in the starter knob stay

more the 30 mm (1.18 in).

ìClamp the throttle cable adjuster cover to the handlebar with the clamp

ends downward.

Page 148 of 508

3 - 1

INSP

ADJ

MAINTENANCE INTERVALS

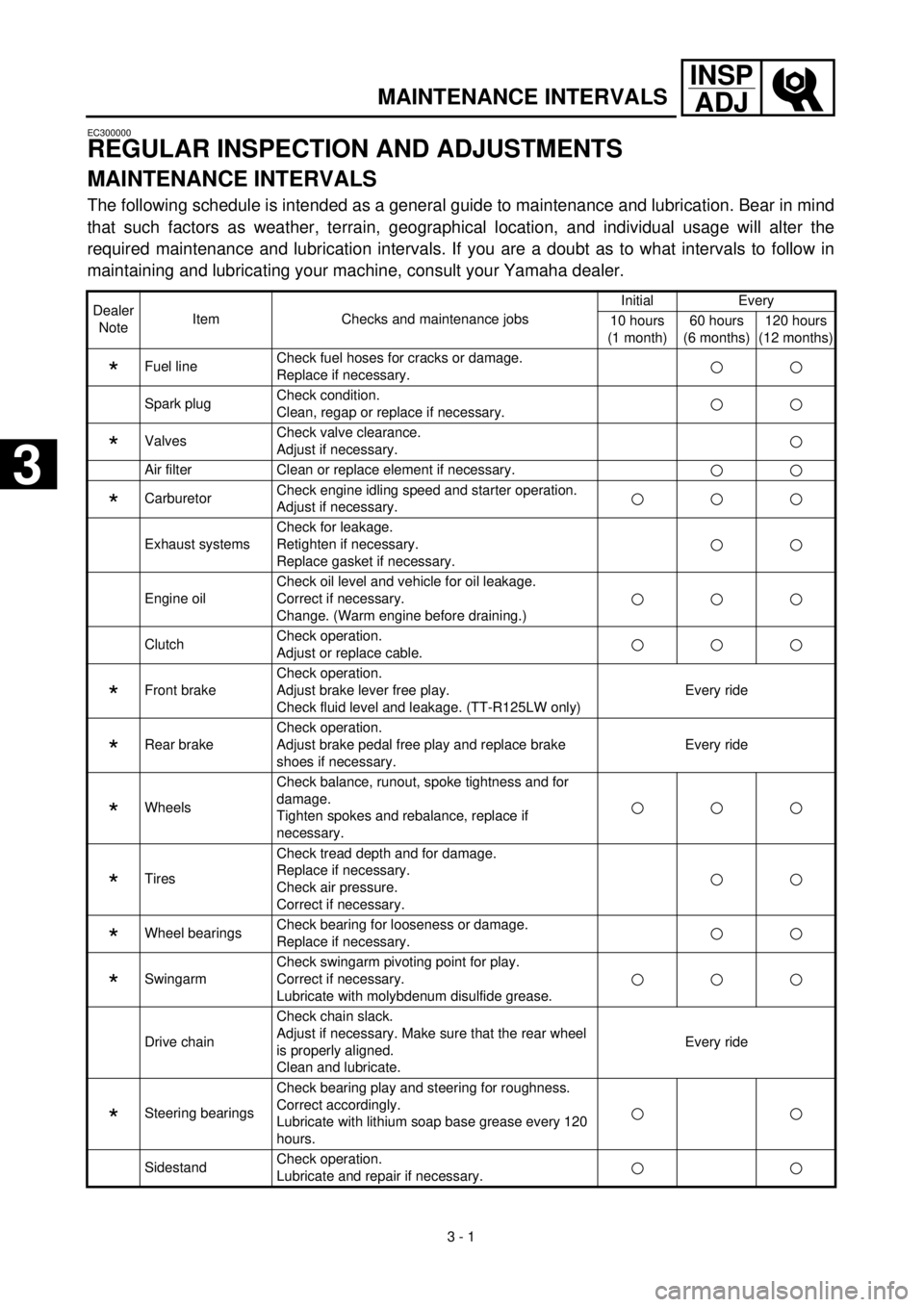

EC300000

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the

required maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your Yamaha dealer.

Dealer

NoteItem Checks and maintenance jobsInitial Every

10 hours

(1 month)60 hours

(6 months)120 hours

(12 months)

*

Fuel lineCheck fuel hoses for cracks or damage.

Replace if necessary.

Spark plugCheck condition.

Clean, regap or replace if necessary.

*

ValvesCheck valve clearance.

Adjust if necessary.

Air filter Clean or replace element if necessary.

*

CarburetorCheck engine idling speed and starter operation.

Adjust if necessary.

Exhaust systemsCheck for leakage.

Retighten if necessary.

Replace gasket if necessary.

Engine oilCheck oil level and vehicle for oil leakage.

Correct if necessary.

Change. (Warm engine before draining.)

ClutchCheck operation.

Adjust or replace cable.

*

Front brakeCheck operation.

Adjust brake lever free play.

Check fluid level and leakage. (TT-R125LW only)Every ride

*

Rear brakeCheck operation.

Adjust brake pedal free play and replace brake

shoes if necessary.Every ride

*

WheelsCheck balance, runout, spoke tightness and for

damage.

Tighten spokes and rebalance, replace if

necessary.

*

TiresCheck tread depth and for damage.

Replace if necessary.

Check air pressure.

Correct if necessary.

*

Wheel bearingsCheck bearing for looseness or damage.

Replace if necessary.

*

SwingarmCheck swingarm pivoting point for play.

Correct if necessary.

Lubricate with molybdenum disulfide grease.

Drive chainCheck chain slack.

Adjust if necessary. Make sure that the rear wheel

is properly aligned.

Clean and lubricate.Every ride

*

Steering bearingsCheck bearing play and steering for roughness.

Correct accordingly.

Lubricate with lithium soap base grease every 120

hours.

SidestandCheck operation.

Lubricate and repair if necessary.

3

Page 154 of 508

3 - 3

INSP

ADJ

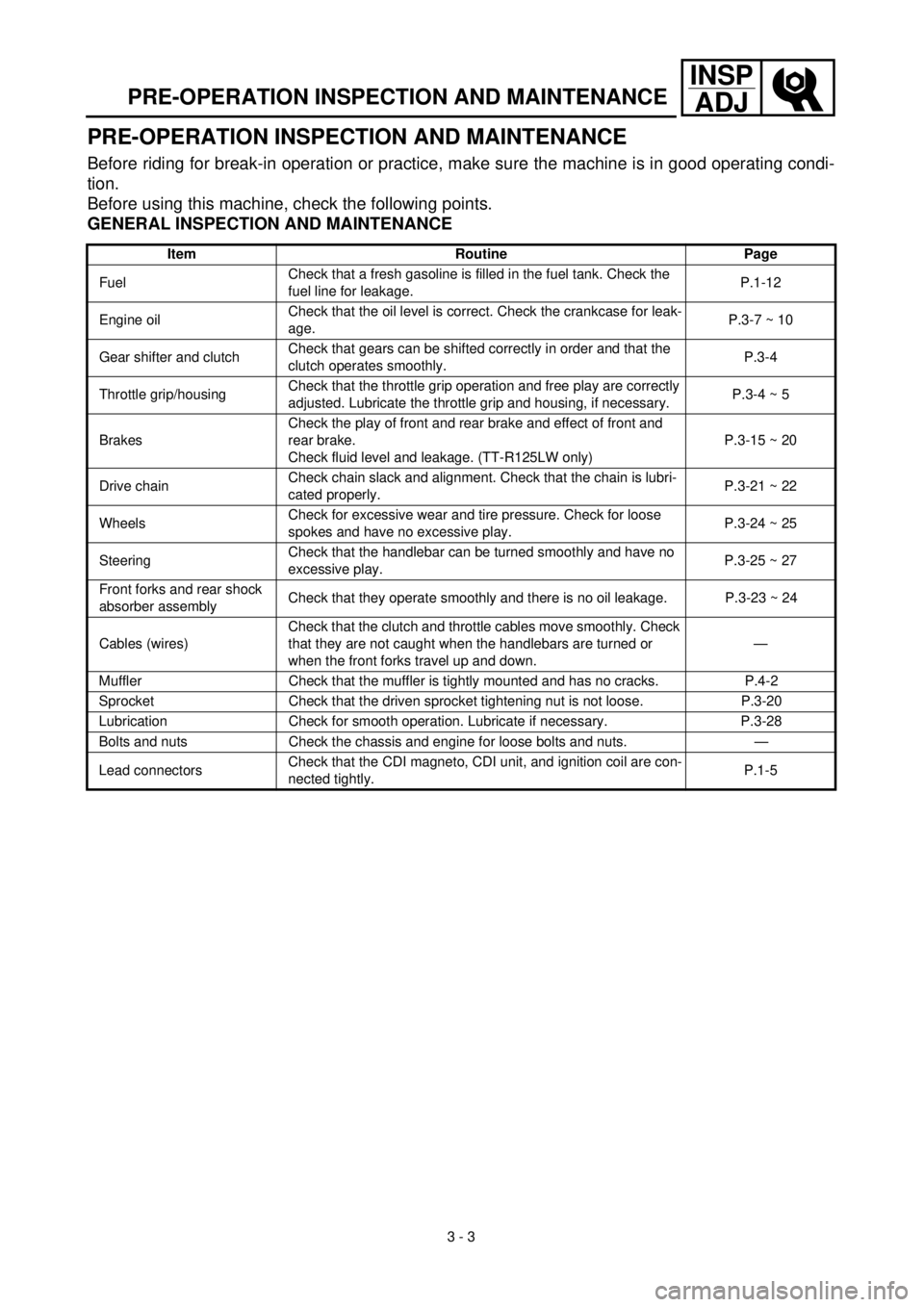

PRE-OPERATION INSPECTION AND MAINTENANCE

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation or practice, make sure the machine is in good operating condi-

tion.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-12

Engine oilCheck that the oil level is correct. Check the crankcase for leak-

age.P.3-7 ~ 10

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-4

Throttle grip/housingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-4 ~ 5

BrakesCheck the play of front and rear brake and effect of front and

rear brake.

Check fluid level and leakage. (TT-R125LW only)P.3-15 ~ 20

Drive chainCheck chain slack and alignment. Check that the chain is lubri-

cated properly.P.3-21 ~ 22

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-24 ~ 25

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-25 ~ 27

Front forks and rear shock

absorber assemblyCheck that they operate smoothly and there is no oil leakage. P.3-23 ~ 24

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or

when the front forks travel up and down.—

Muffler Check that the muffler is tightly mounted and has no cracks. P.4-2

Sprocket Check that the driven sprocket tightening nut is not loose. P.3-20

Lubrication Check for smooth operation. Lubricate if necessary. P.3-28

Bolts and nuts Check the chassis and engine for loose bolts and nuts. —

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-5

Page 180 of 508

3 - 15

INSP

ADJ

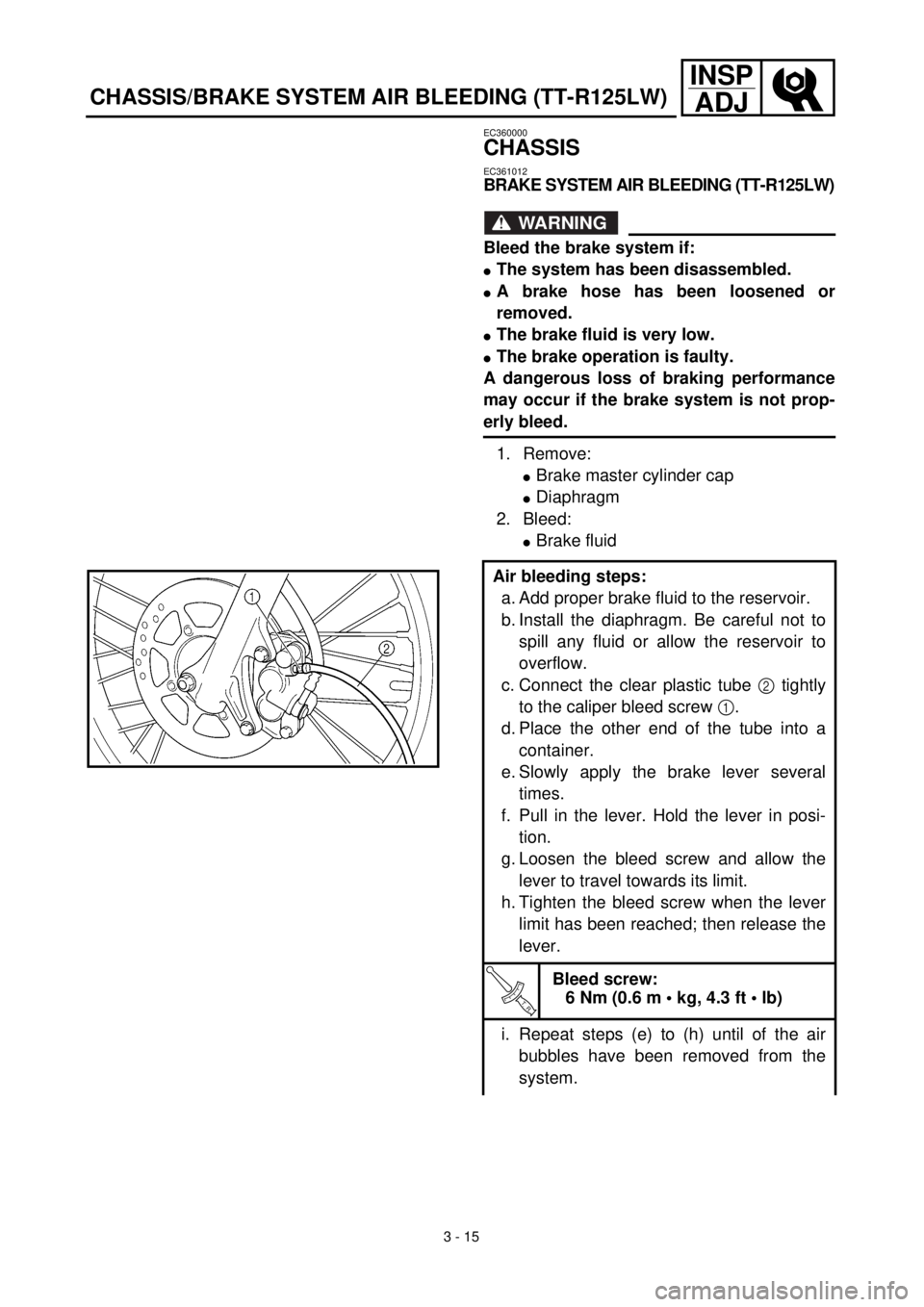

EC360000

CHASSIS

EC361012

BRAKE SYSTEM AIR BLEEDING (TT-R125LW)

WARNING

Bleed the brake system if:

lThe system has been disassembled.

lA brake hose has been loosened or

removed.

lThe brake fluid is very low.

lThe brake operation is faulty.

A dangerous loss of braking performance

may occur if the brake system is not prop-

erly bleed.

1. Remove:

lBrake master cylinder cap

lDiaphragm

2. Bleed:

lBrake fluid

Air bleeding steps:

a. Add proper brake fluid to the reservoir.

b. Install the diaphragm. Be careful not to

spill any fluid or allow the reservoir to

overflow.

c. Connect the clear plastic tube 2 tightly

to the caliper bleed screw 1.

d. Place the other end of the tube into a

container.

e. Slowly apply the brake lever several

times.

f. Pull in the lever. Hold the lever in posi-

tion.

g. Loosen the bleed screw and allow the

lever to travel towards its limit.

h. Tighten the bleed screw when the lever

limit has been reached; then release the

lever.

T R..

Bleed screw:

6 Nm (0.6 m • kg, 4.3 ft • lb)

i. Repeat steps (e) to (h) until of the air

bubbles have been removed from the

system.

CHASSIS/BRAKE SYSTEM AIR BLEEDING (TT-R125LW)

Page 182 of 508

3 - 16

INSP

ADJ

3. Install:

lDiaphragm

lBrake master cylinder cap

NOTE:

If bleeding is difficult, it may be necessary to

let the brake fluid system stabilize for a few

hours. Repeat the bleeding procedure when

the tiny bubbles in the system have disap-

peared.

j. Add brake fluid to the level line on the

reservoir.

WARNING

Check the operation of the brake after

bleeding the brake system.

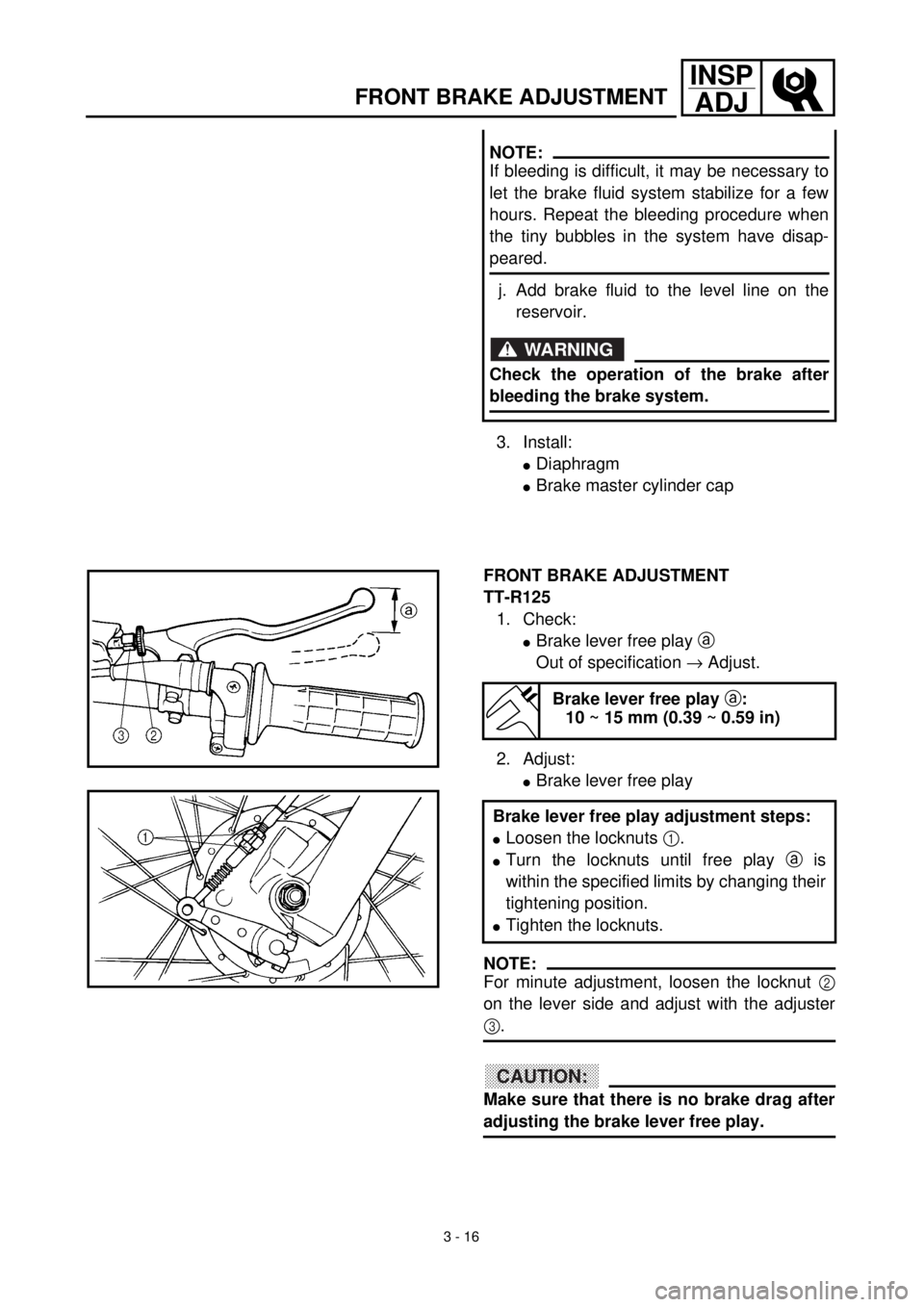

FRONT BRAKE ADJUSTMENT

TT-R125

1. Check:

lBrake lever free play a

Out of specification ® Adjust.

2. Adjust:

lBrake lever free play

NOTE:

For minute adjustment, loosen the locknut 2

on the lever side and adjust with the adjuster

3.

CAUTION:

Make sure that there is no brake drag after

adjusting the brake lever free play.

Brake lever free play a:

10 ~ 15 mm (0.39 ~ 0.59 in)

Brake lever free play adjustment steps:

lLoosen the locknuts 1.

lTurn the locknuts until free play a is

within the specified limits by changing their

tightening position.

lTighten the locknuts.

FRONT BRAKE ADJUSTMENT

Page 184 of 508

3 - 17

INSP

ADJ

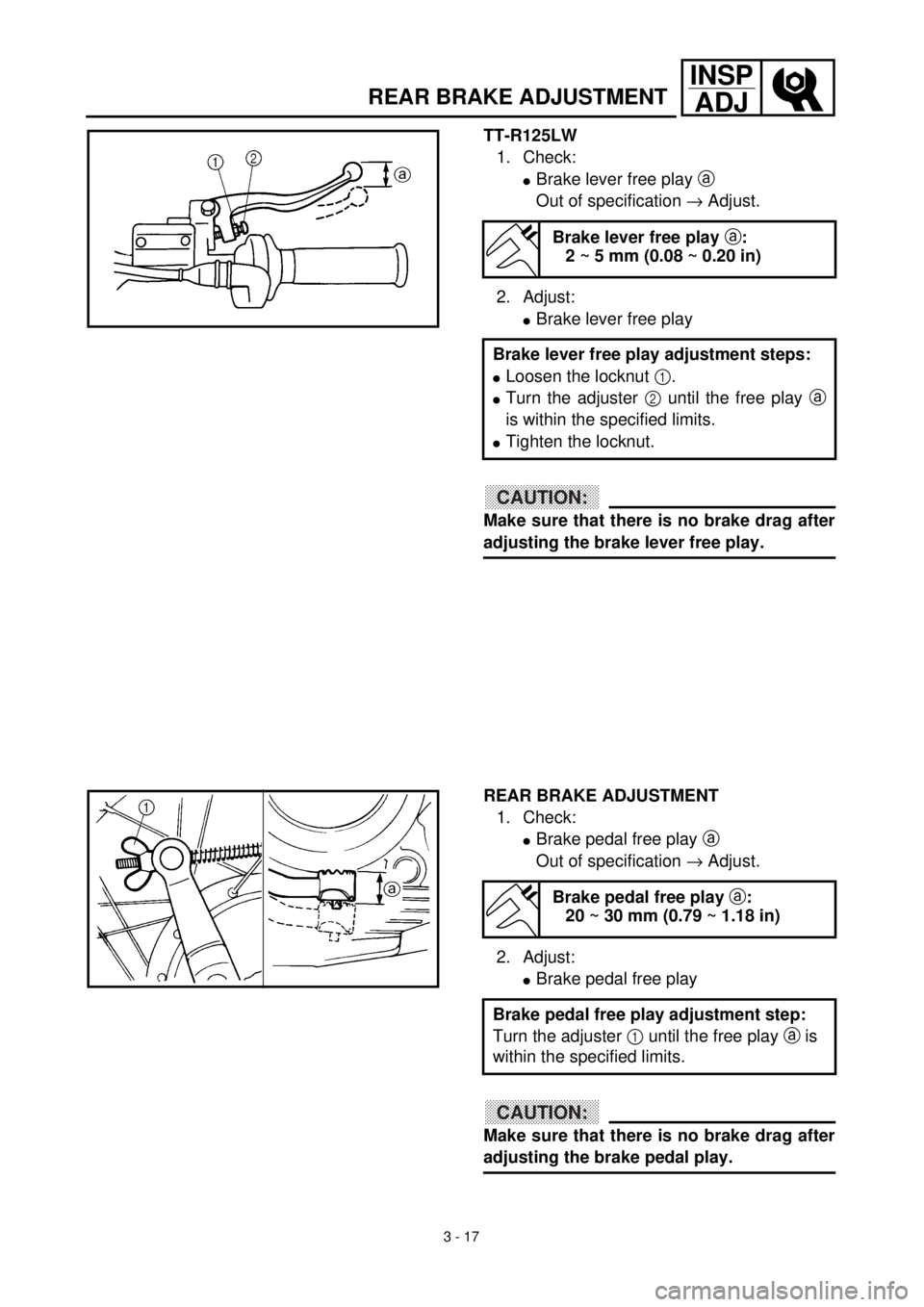

TT-R125LW

1. Check:

lBrake lever free play a

Out of specification ® Adjust.

2. Adjust:

lBrake lever free play

CAUTION:

Make sure that there is no brake drag after

adjusting the brake lever free play.

Brake lever free play a:

2 ~ 5 mm (0.08 ~ 0.20 in)

Brake lever free play adjustment steps:

lLoosen the locknut 1.

lTurn the adjuster 2 until the free play a

is within the specified limits.

lTighten the locknut.

REAR BRAKE ADJUSTMENT

1. Check:

lBrake pedal free play a

Out of specification ® Adjust.

2. Adjust:

lBrake pedal free play

CAUTION:

Make sure that there is no brake drag after

adjusting the brake pedal play.

Brake pedal free play a:

20 ~ 30 mm (0.79 ~ 1.18 in)

Brake pedal free play adjustment step:

Turn the adjuster 1 until the free play a is

within the specified limits.

REAR BRAKE ADJUSTMENT