warning YAMAHA TTR125 2002 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: TTR125, Model: YAMAHA TTR125 2002Pages: 509, PDF Size: 16.83 MB

Page 394 of 509

5 - 15

CHAS

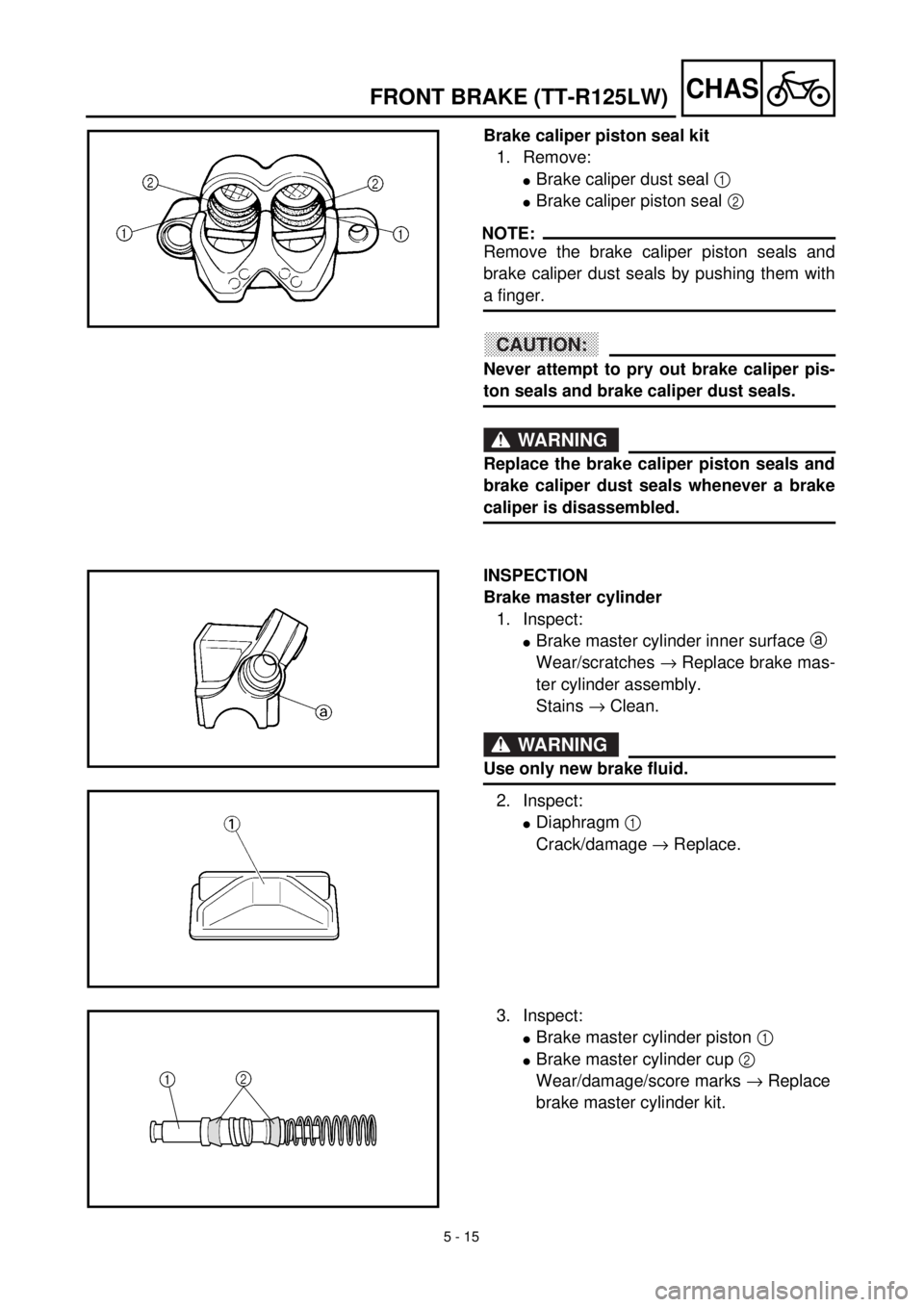

Brake caliper piston seal kit

1. Remove:

lBrake caliper dust seal 1

lBrake caliper piston seal 2

NOTE:

Remove the brake caliper piston seals and

brake caliper dust seals by pushing them with

a finger.

CAUTION:

Never attempt to pry out brake caliper pis-

ton seals and brake caliper dust seals.

WARNING

Replace the brake caliper piston seals and

brake caliper dust seals whenever a brake

caliper is disassembled.

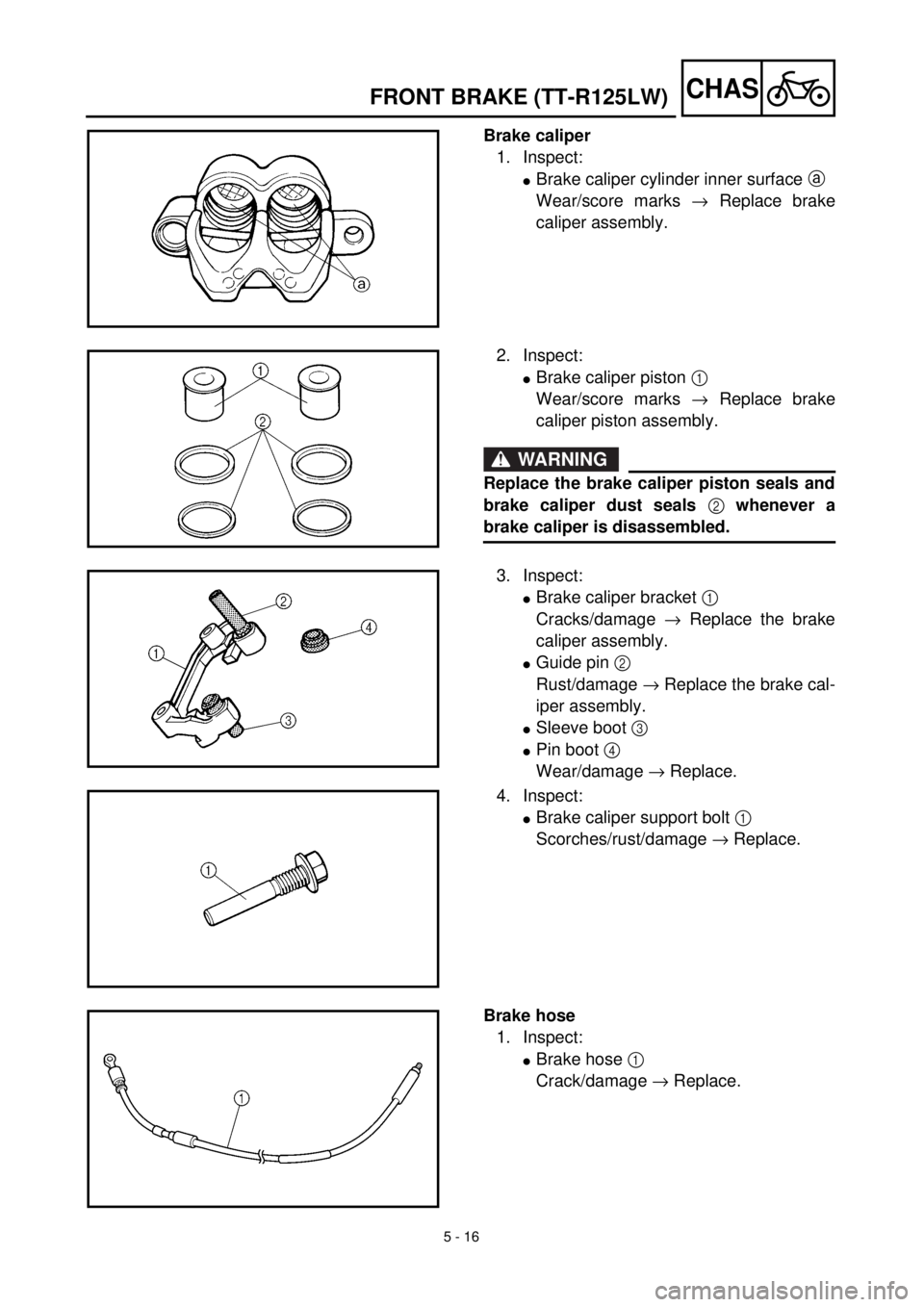

INSPECTION

Brake master cylinder

1. Inspect:

lBrake master cylinder inner surface a

Wear/scratches ® Replace brake mas-

ter cylinder assembly.

Stains ® Clean.

WARNING

Use only new brake fluid.

2. Inspect:

lDiaphragm 1

Crack/damage ® Replace.

3. Inspect:

lBrake master cylinder piston 1

lBrake master cylinder cup 2

Wear/damage/score marks ® Replace

brake master cylinder kit.

FRONT BRAKE (TT-R125LW)

Page 396 of 509

5 - 16

CHAS

Brake caliper

1. Inspect:

lBrake caliper cylinder inner surface a

Wear/score marks ® Replace brake

caliper assembly.

2. Inspect:

lBrake caliper piston 1

Wear/score marks ® Replace brake

caliper piston assembly.

WARNING

Replace the brake caliper piston seals and

brake caliper dust seals 2 whenever a

brake caliper is disassembled.

3. Inspect:

lBrake caliper bracket 1

Cracks/damage ® Replace the brake

caliper assembly.

lGuide pin 2

Rust/damage ® Replace the brake cal-

iper assembly.

lSleeve boot 3

lPin boot 4

Wear/damage ® Replace.

4. Inspect:

lBrake caliper support bolt 1

Scorches/rust/damage ® Replace.

Brake hose

1. Inspect:

lBrake hose 1

Crack/damage ® Replace.

FRONT BRAKE (TT-R125LW)

Page 398 of 509

5 - 17

CHASFRONT BRAKE (TT-R125LW)

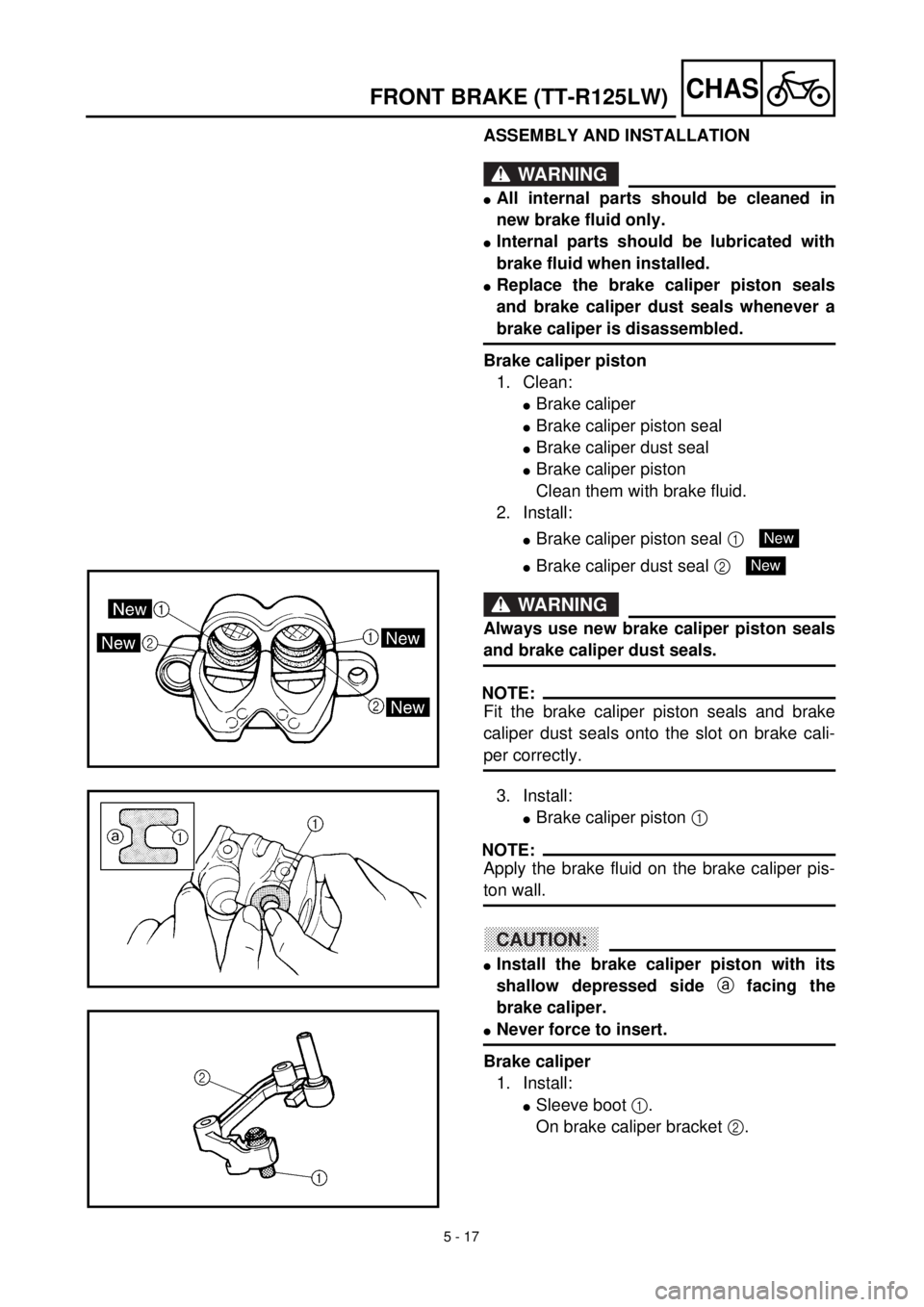

ASSEMBLY AND INSTALLATION

WARNING

lAll internal parts should be cleaned in

new brake fluid only.

lInternal parts should be lubricated with

brake fluid when installed.

lReplace the brake caliper piston seals

and brake caliper dust seals whenever a

brake caliper is disassembled.

Brake caliper piston

1. Clean:

lBrake caliper

lBrake caliper piston seal

lBrake caliper dust seal

lBrake caliper piston

Clean them with brake fluid.

2. Install:

lBrake caliper piston seal 1

lBrake caliper dust seal 2

WARNING

Always use new brake caliper piston seals

and brake caliper dust seals.

NOTE:

Fit the brake caliper piston seals and brake

caliper dust seals onto the slot on brake cali-

per correctly.

New

New

3. Install:

lBrake caliper piston 1

NOTE:

Apply the brake fluid on the brake caliper pis-

ton wall.

CAUTION:

lInstall the brake caliper piston with its

shallow depressed side a facing the

brake caliper.

lNever force to insert.

Brake caliper

1. Install:

lSleeve boot 1.

On brake caliper bracket 2.

Page 402 of 509

5 - 19

CHASFRONT BRAKE (TT-R125LW)

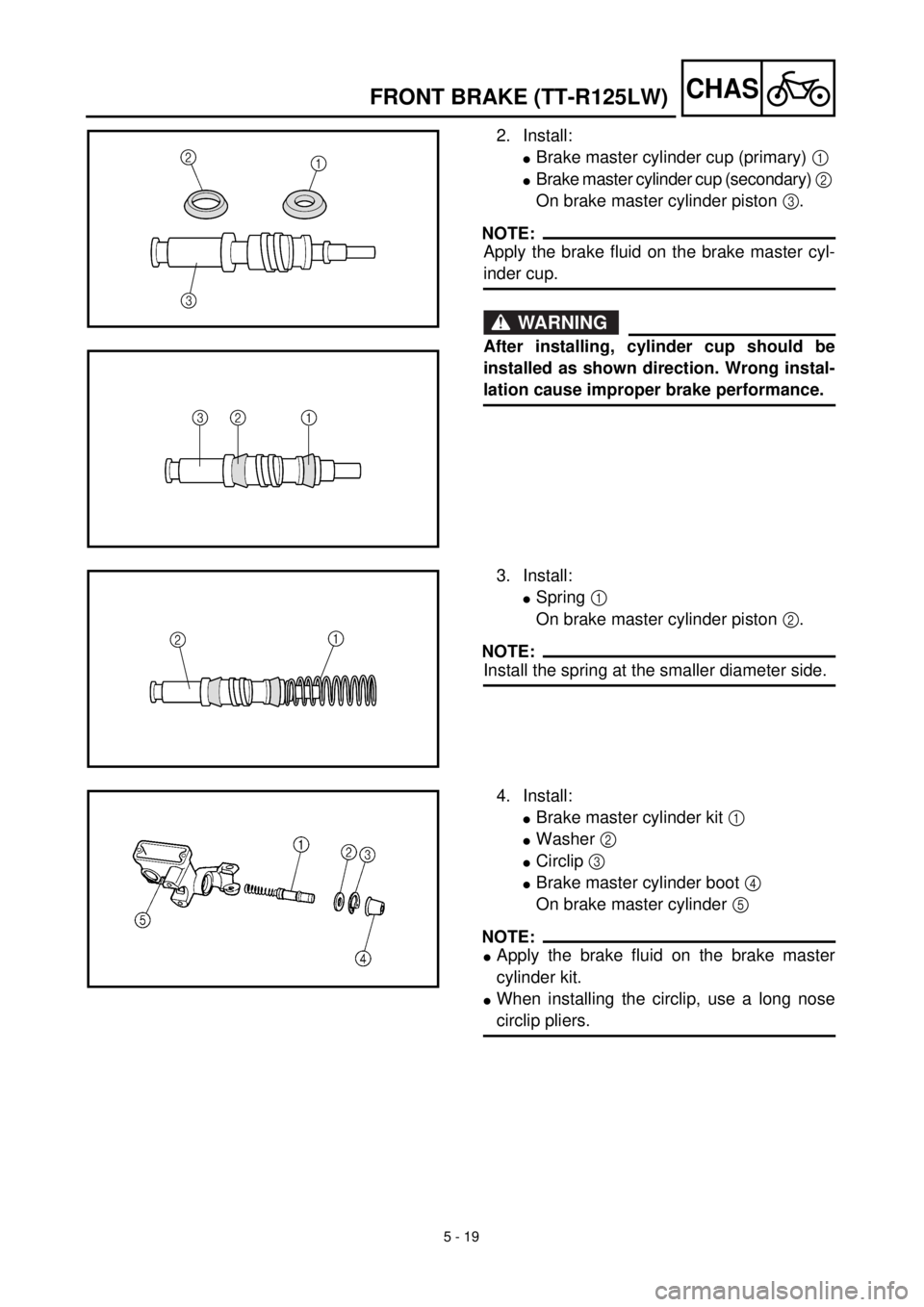

2. Install:

lBrake master cylinder cup (primary) 1

lBrake master cylinder cup (secondary) 2

On brake master cylinder piston 3.

NOTE:

Apply the brake fluid on the brake master cyl-

inder cup.

WARNING

After installing, cylinder cup should be

installed as shown direction. Wrong instal-

lation cause improper brake performance.

3. Install:

lSpring 1

On brake master cylinder piston 2.

NOTE:

Install the spring at the smaller diameter side.

4. Install:

lBrake master cylinder kit 1

lWasher 2

lCirclip 3

lBrake master cylinder boot 4

On brake master cylinder 5

NOTE:

lApply the brake fluid on the brake master

cylinder kit.

lWhen installing the circlip, use a long nose

circlip pliers.

Page 404 of 509

5 - 20

CHAS

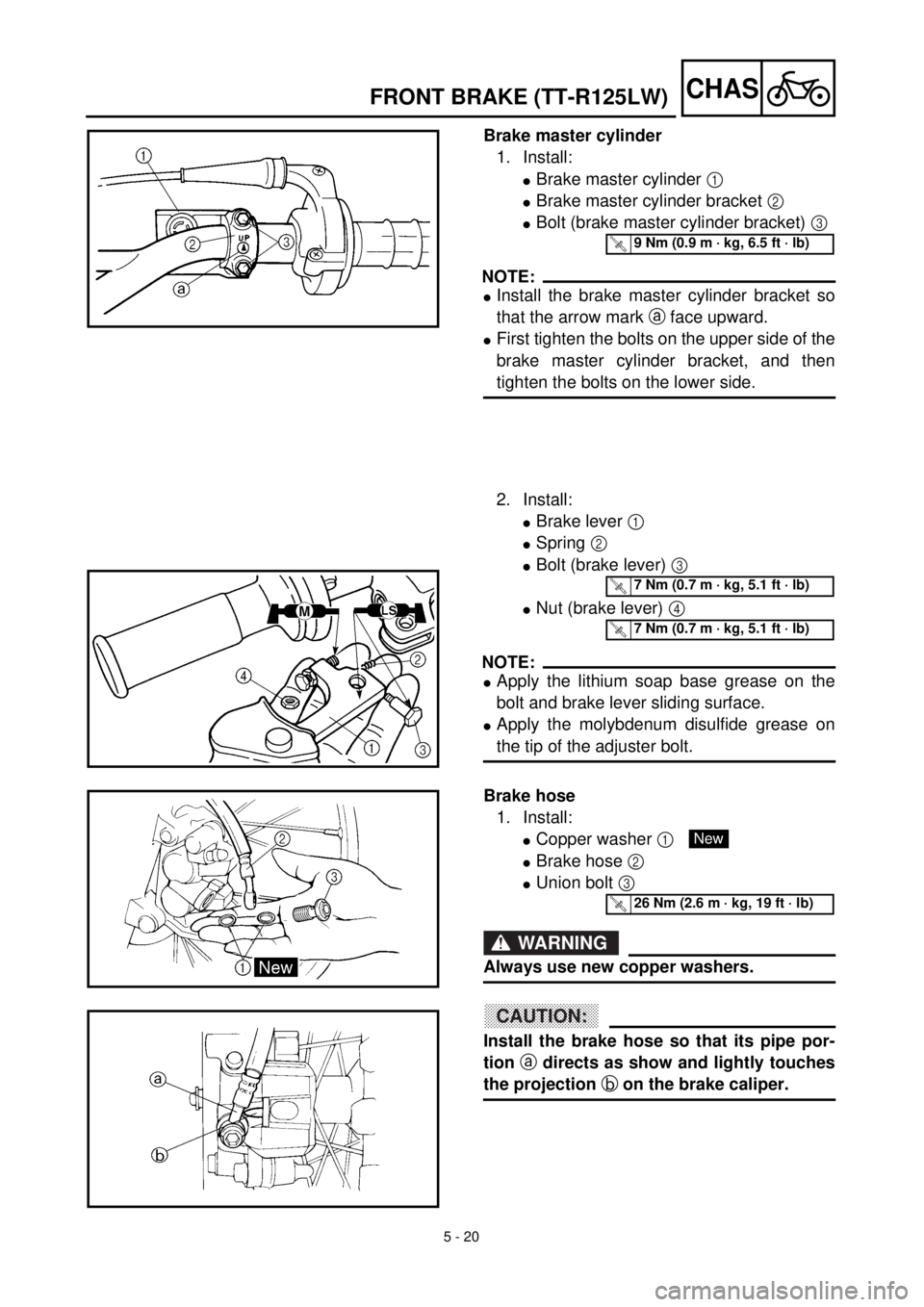

Brake master cylinder

1. Install:

lBrake master cylinder 1

lBrake master cylinder bracket 2

lBolt (brake master cylinder bracket) 3

NOTE:

lInstall the brake master cylinder bracket so

that the arrow mark a face upward.

lFirst tighten the bolts on the upper side of the

brake master cylinder bracket, and then

tighten the bolts on the lower side.

2. Install:

lBrake lever 1

lSpring 2

lBolt (brake lever) 3

lNut (brake lever) 4

NOTE:

lApply the lithium soap base grease on the

bolt and brake lever sliding surface.

lApply the molybdenum disulfide grease on

the tip of the adjuster bolt.

T R..9 Nm (0.9 m · kg, 6.5 ft · lb)

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

Brake hose

1. Install:

lCopper washer 1

lBrake hose 2

lUnion bolt 3

WARNING

Always use new copper washers.

CAUTION:

Install the brake hose so that its pipe por-

tion a directs as show and lightly touches

the projection b on the brake caliper.

New

T R..26 Nm (2.6 m · kg, 19 ft · lb)

FRONT BRAKE (TT-R125LW)

Page 406 of 509

5 - 21

CHAS

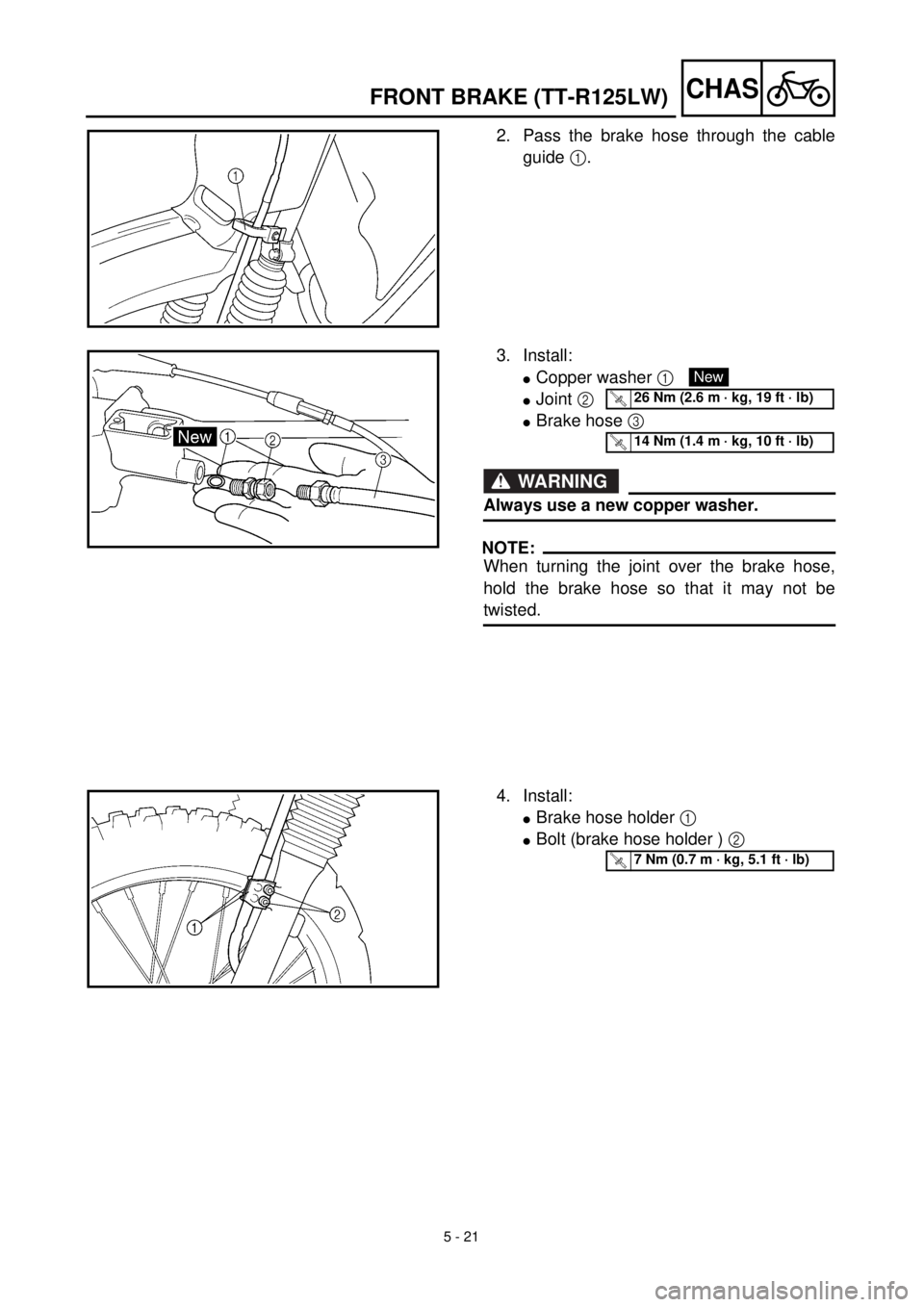

2. Pass the brake hose through the cable

guide 1.

3. Install:

lCopper washer 1

lJoint 2

lBrake hose 3

WARNING

Always use a new copper washer.

NOTE:

When turning the joint over the brake hose,

hold the brake hose so that it may not be

twisted.

New

T R..26 Nm (2.6 m · kg, 19 ft · lb)

T R..14 Nm (1.4 m · kg, 10 ft · lb)

4. Install:

lBrake hose holder 1

lBolt (brake hose holder ) 2

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

FRONT BRAKE (TT-R125LW)

Page 408 of 509

5 - 22

CHAS

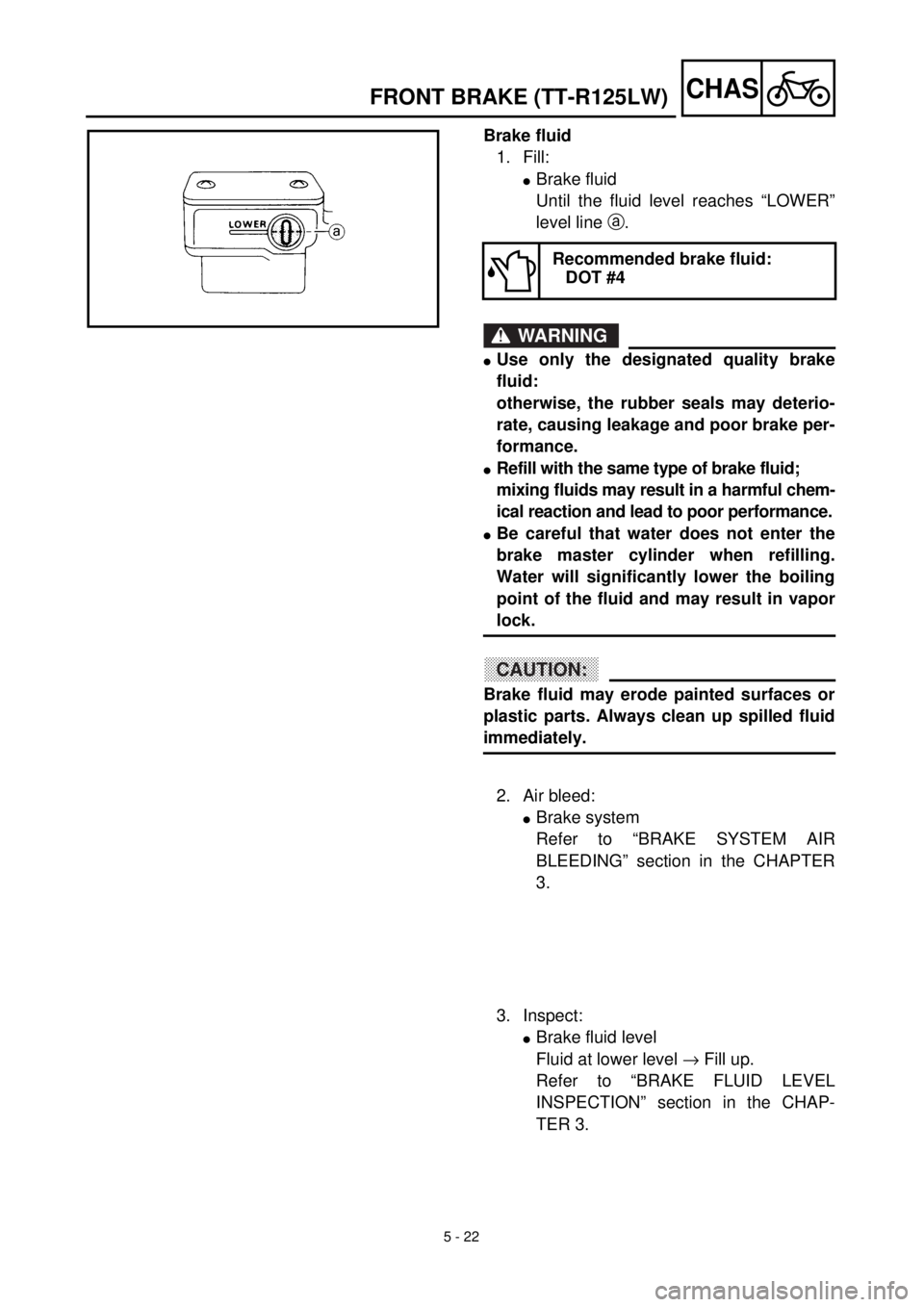

Brake fluid

1. Fill:

lBrake fluid

Until the fluid level reaches “LOWER”

level line a.

WARNING

lUse only the designated quality brake

fluid:

otherwise, the rubber seals may deterio-

rate, causing leakage and poor brake per-

formance.

lRefill with the same type of brake fluid;

mixing fluids may result in a harmful chem-

ical reaction and lead to poor performance.

lBe careful that water does not enter the

brake master cylinder when refilling.

Water will significantly lower the boiling

point of the fluid and may result in vapor

lock.

CAUTION:

Brake fluid may erode painted surfaces or

plastic parts. Always clean up spilled fluid

immediately.

Recommended brake fluid:

DOT #4

2. Air bleed:

lBrake system

Refer to “BRAKE SYSTEM AIR

BLEEDING” section in the CHAPTER

3.

3. Inspect:

lBrake fluid level

Fluid at lower level ® Fill up.

Refer to “BRAKE FLUID LEVEL

INSPECTION” section in the CHAP-

TER 3.

FRONT BRAKE (TT-R125LW)

Page 412 of 509

5 - 24

CHAS

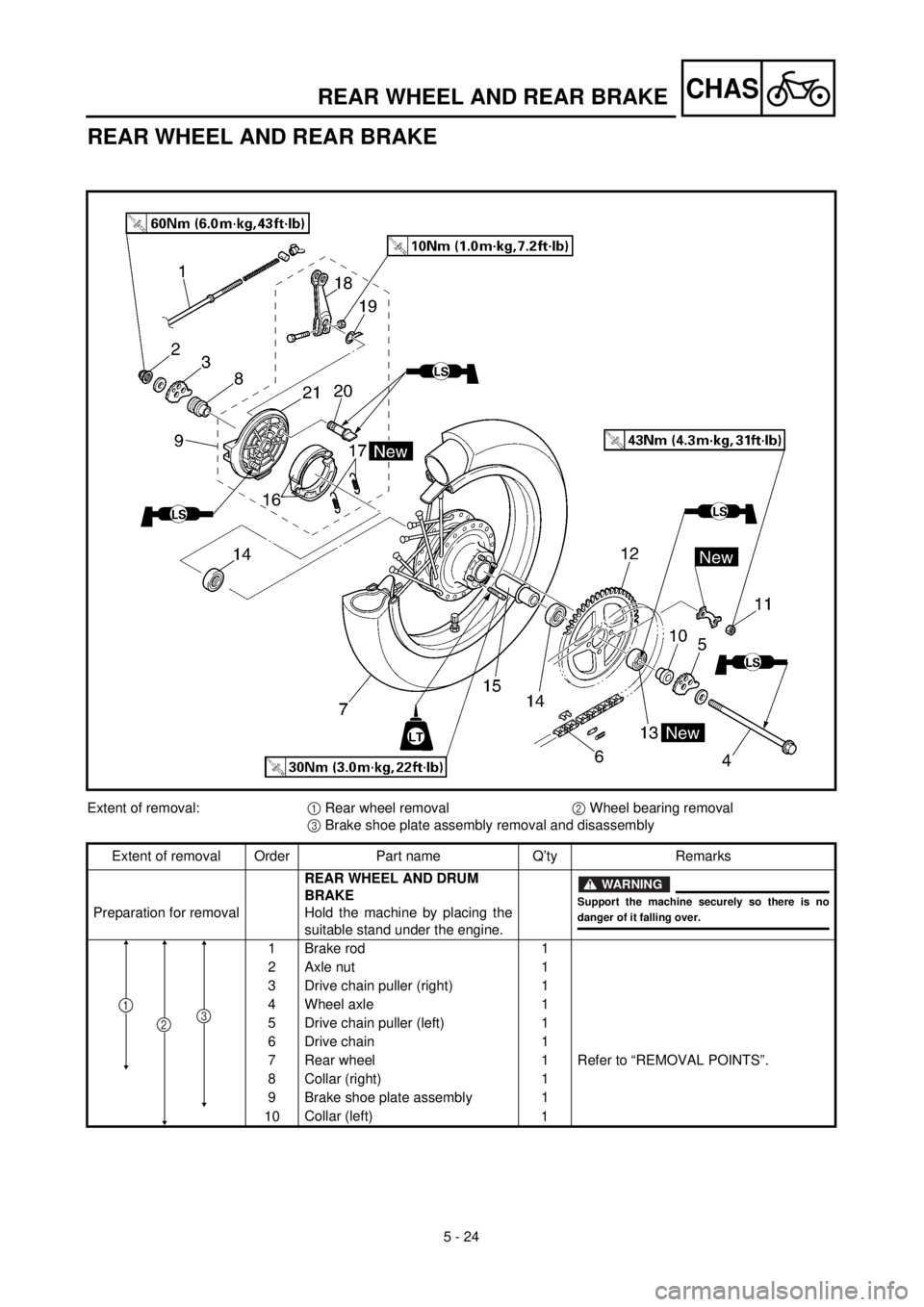

REAR WHEEL AND REAR BRAKE

Extent of removal:1 Rear wheel removal 2 Wheel bearing removal

3 Brake shoe plate assembly removal and disassembly

Extent of removal Order Part name Q’ty Remarks

Preparation for removalREAR WHEEL AND DRUM

BRAKE

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is nodanger of it falling over.

1 Brake rod 1

2 Axle nut 1

3 Drive chain puller (right) 1

4 Wheel axle 1

5 Drive chain puller (left) 1

6 Drive chain 1

7 Rear wheel 1 Refer to “REMOVAL POINTS”.

8 Collar (right) 1

9 Brake shoe plate assembly 1

10Collar (left)

1

231

REAR WHEEL AND REAR BRAKE

Page 418 of 509

5 - 27

CHASREAR WHEEL AND REAR BRAKE

NOTE:

The bending value is shown by one half of the

dial gauge reading.

WARNING

Do not attempt to straighten a bent axle.

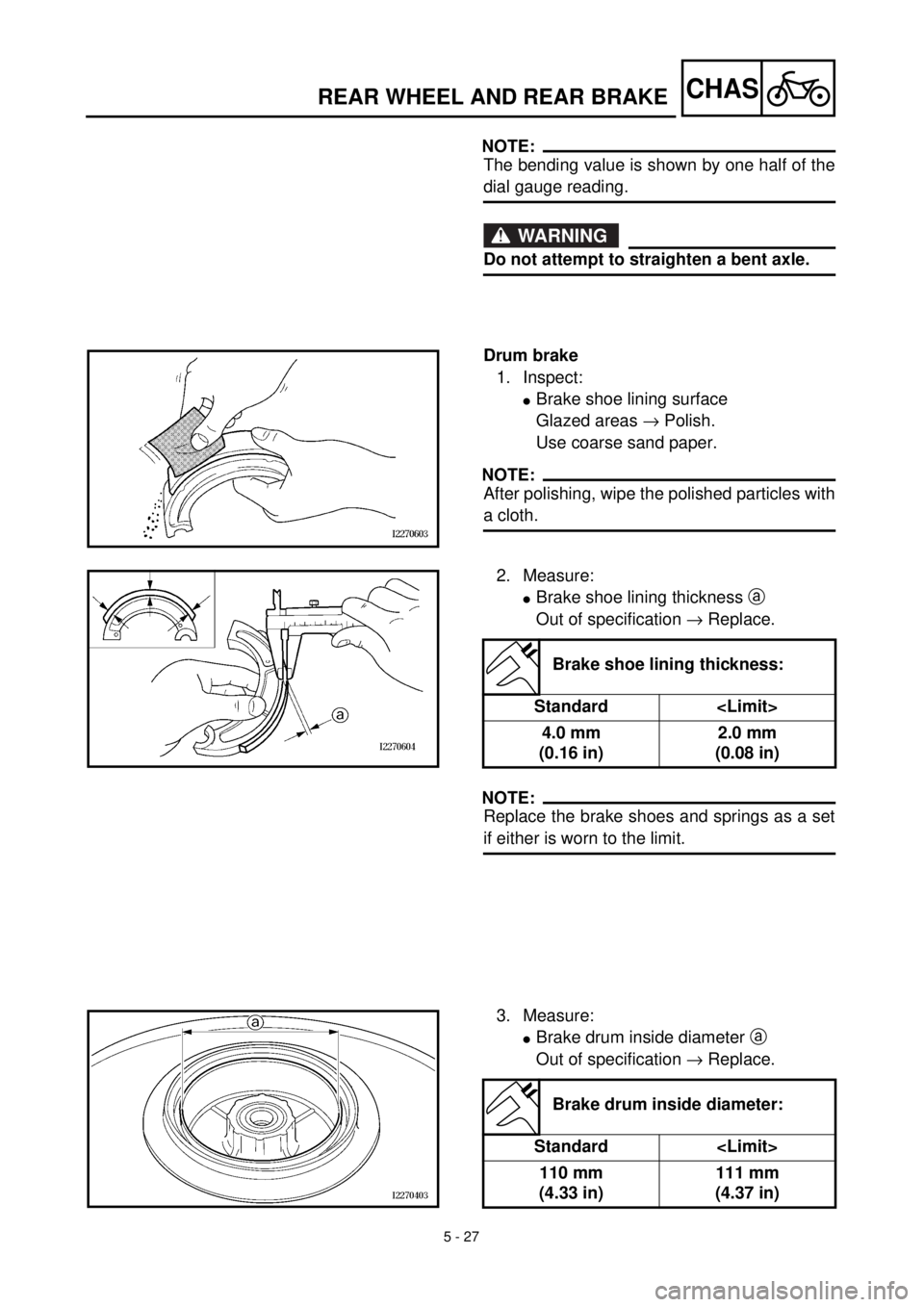

Drum brake

1. Inspect:

lBrake shoe lining surface

Glazed areas ® Polish.

Use coarse sand paper.

NOTE:

After polishing, wipe the polished particles with

a cloth.

2. Measure:

lBrake shoe lining thickness a

Out of specification ® Replace.

NOTE:

Replace the brake shoes and springs as a set

if either is worn to the limit.

Brake shoe lining thickness:

Standard

4.0 mm

(0.16 in)2.0 mm

(0.08 in)

3. Measure:

lBrake drum inside diameter a

Out of specification ® Replace.

Brake drum inside diameter:

Standard

110 mm

(4.33 in)111 mm

(4.37 in)

Page 422 of 509

5 - 29

CHASREAR WHEEL AND REAR BRAKE

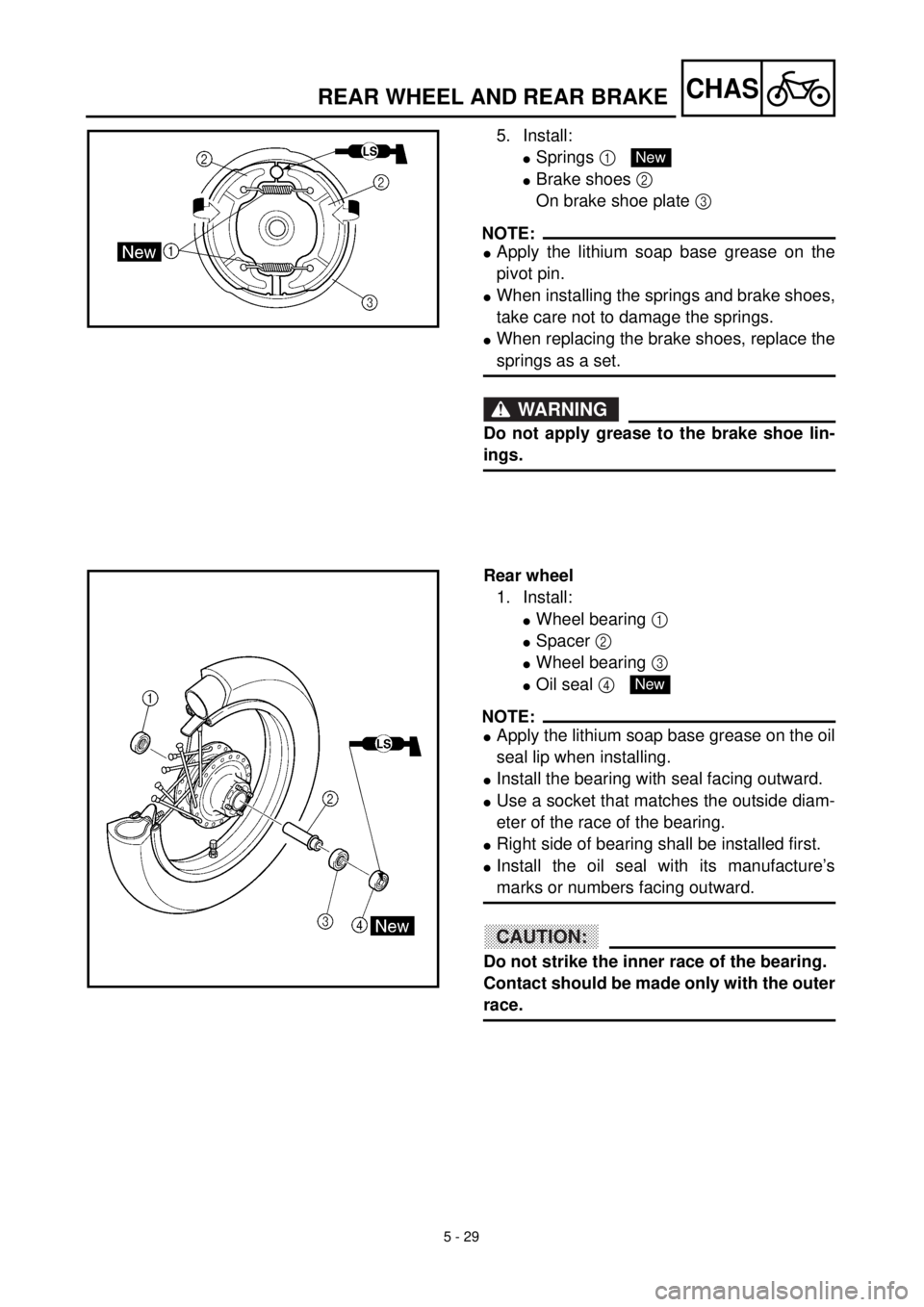

5. Install:

lSprings 1

lBrake shoes 2

On brake shoe plate 3

NOTE:

lApply the lithium soap base grease on the

pivot pin.

lWhen installing the springs and brake shoes,

take care not to damage the springs.

lWhen replacing the brake shoes, replace the

springs as a set.

WARNING

Do not apply grease to the brake shoe lin-

ings.

New

Rear wheel

1. Install:

lWheel bearing 1

lSpacer 2

lWheel bearing 3

lOil seal 4

NOTE:

lApply the lithium soap base grease on the oil

seal lip when installing.

lInstall the bearing with seal facing outward.

lUse a socket that matches the outside diam-

eter of the race of the bearing.

lRight side of bearing shall be installed first.

lInstall the oil seal with its manufacture’s

marks or numbers facing outward.

CAUTION:

Do not strike the inner race of the bearing.

Contact should be made only with the outer

race.

New