lock YAMAHA TTR125 2002 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: TTR125, Model: YAMAHA TTR125 2002Pages: 509, PDF Size: 16.83 MB

Page 432 of 509

5 - 34

CHASFRONT FORK

HANDLING NOTE

NOTE:

The front fork requires careful attention. So it is

recommended that the front fork be main-

tained at the dealers.

CAUTION:

To prevent an accidental explosion of air,

the following instructions should be

observed:

The front fork with a built-in piston rod has

a very sophisticated internal construction

and is particularly sensitive to foreign

material.

Use enough care not to allow any foreign

material to come in when the oil is replaced

or when the front fork is disassembled and

reassembled.

EC553000

REMOVAL POINTS

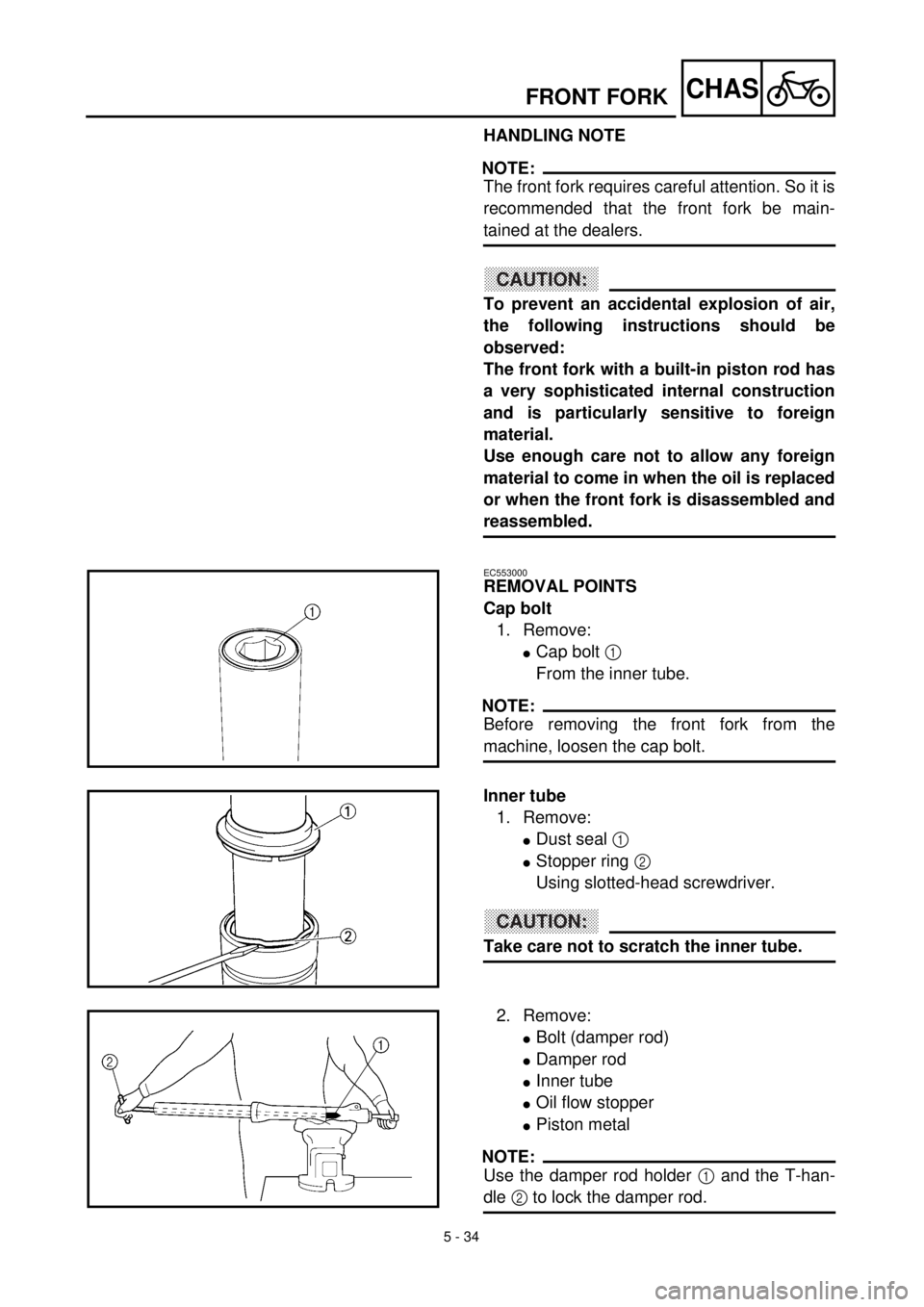

Cap bolt

1. Remove:

lCap bolt 1

From the inner tube.

NOTE:

Before removing the front fork from the

machine, loosen the cap bolt.

Inner tube

1. Remove:

lDust seal 1

lStopper ring 2

Using slotted-head screwdriver.

CAUTION:

Take care not to scratch the inner tube.

2. Remove:

lBolt (damper rod)

lDamper rod

lInner tube

lOil flow stopper

lPiston metal

NOTE:

Use the damper rod holder 1 and the T-han-

dle 2 to lock the damper rod.

Page 436 of 509

5 - 36

CHASFRONT FORK

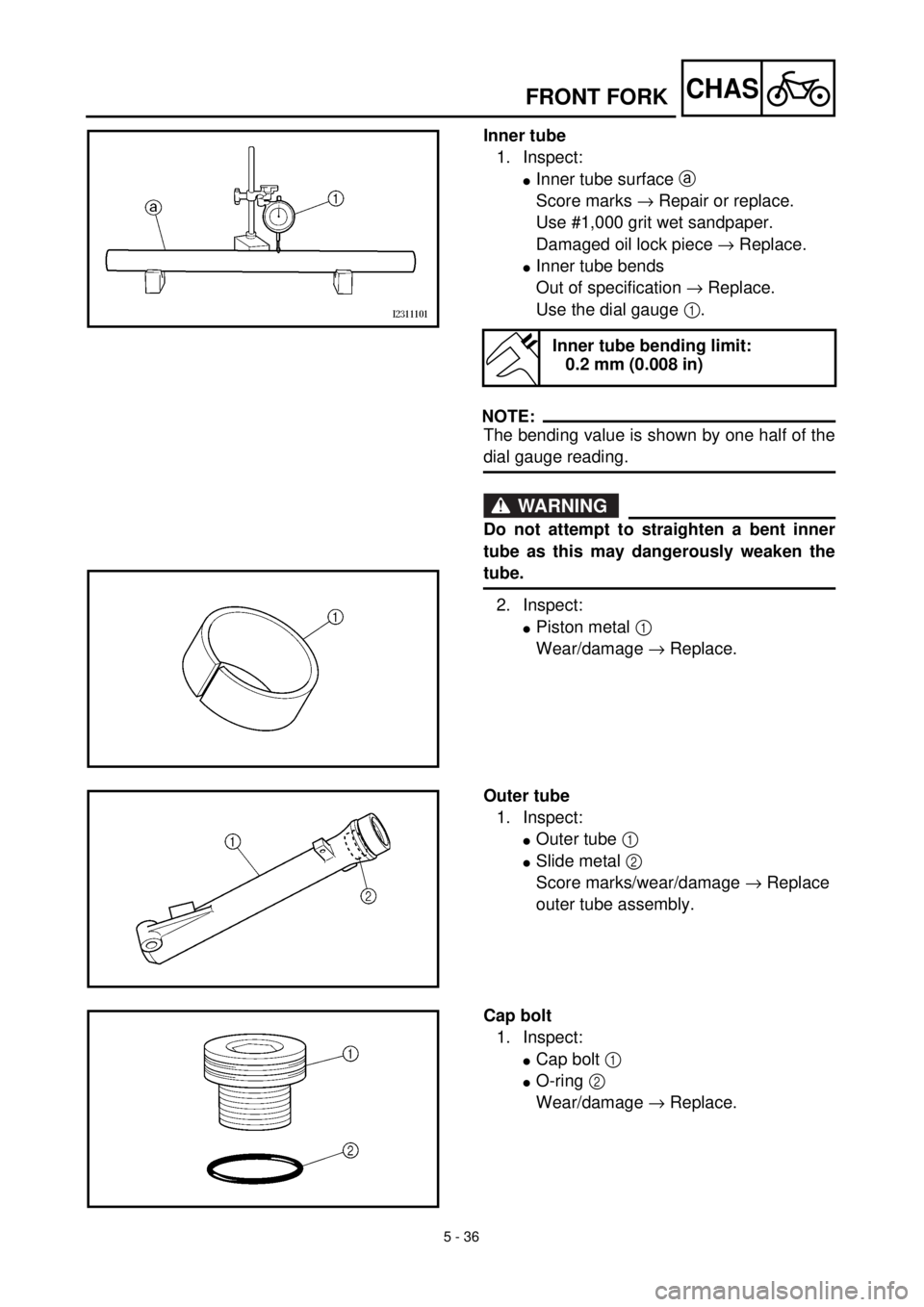

Inner tube

1. Inspect:

lInner tube surface a

Score marks ® Repair or replace.

Use #1,000 grit wet sandpaper.

Damaged oil lock piece ® Replace.

lInner tube bends

Out of specification ® Replace.

Use the dial gauge 1.

NOTE:

The bending value is shown by one half of the

dial gauge reading.

WARNING

Do not attempt to straighten a bent inner

tube as this may dangerously weaken the

tube.

2. Inspect:

lPiston metal 1

Wear/damage ® Replace.

Inner tube bending limit:

0.2 mm (0.008 in)

Outer tube

1. Inspect:

lOuter tube 1

lSlide metal 2

Score marks/wear/damage ® Replace

outer tube assembly.

Cap bolt

1. Inspect:

lCap bolt 1

lO-ring 2

Wear/damage ® Replace.

Page 438 of 509

5 - 37

CHAS

EC555000

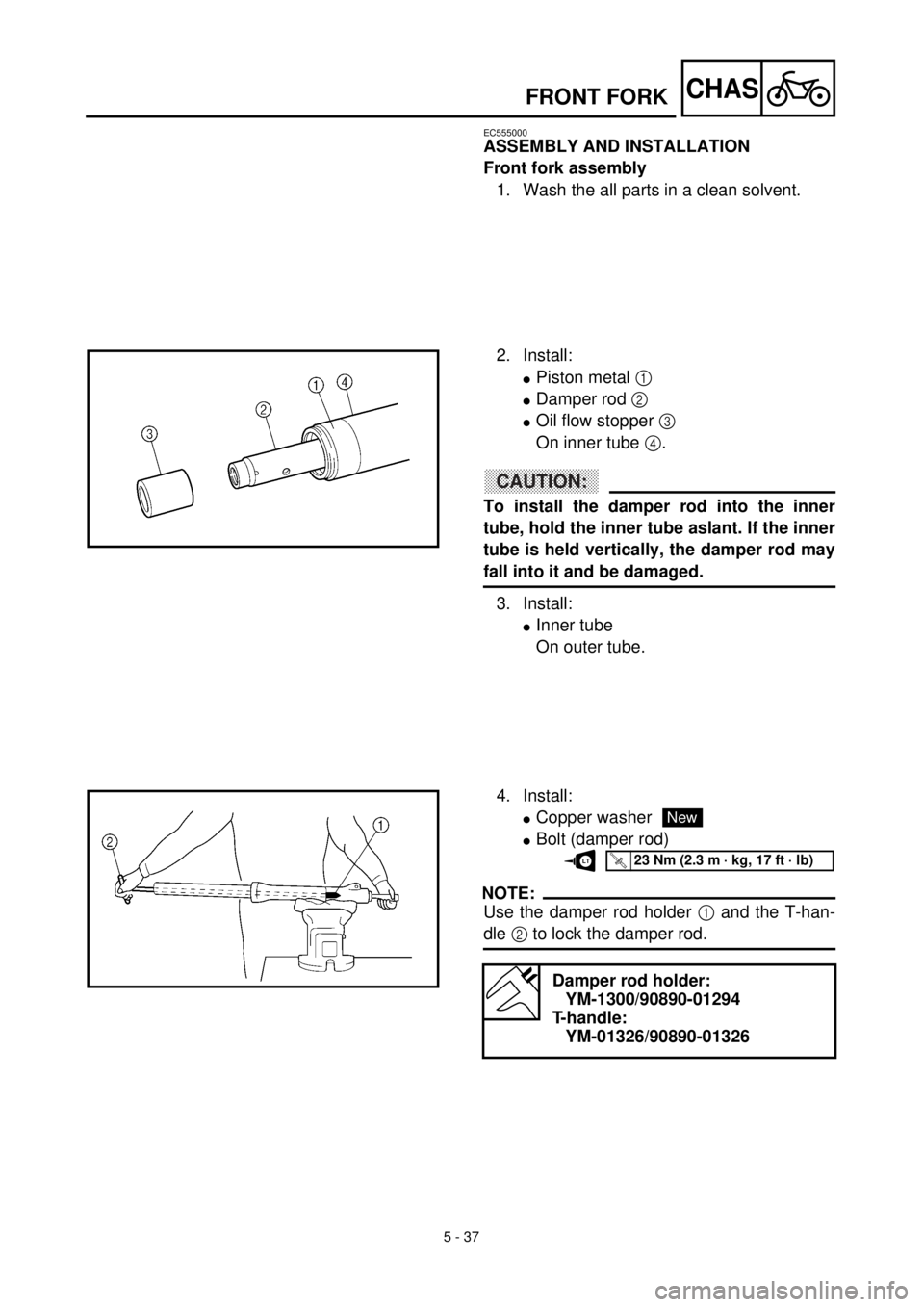

ASSEMBLY AND INSTALLATION

Front fork assembly

1. Wash the all parts in a clean solvent.

2. Install:

lPiston metal 1

lDamper rod 2

lOil flow stopper 3

On inner tube 4.

CAUTION:

To install the damper rod into the inner

tube, hold the inner tube aslant. If the inner

tube is held vertically, the damper rod may

fall into it and be damaged.

3. Install:

lInner tube

On outer tube.

4. Install:

lCopper washer

lBolt (damper rod)

NOTE:

Use the damper rod holder 1 and the T-han-

dle 2 to lock the damper rod.

Damper rod holder:

YM-1300/90890-01294

T-handle:

YM-01326/90890-01326

New

T R..23 Nm (2.3 m · kg, 17 ft · lb)LT

FRONT FORK

Page 470 of 509

5 - 53

CHAS

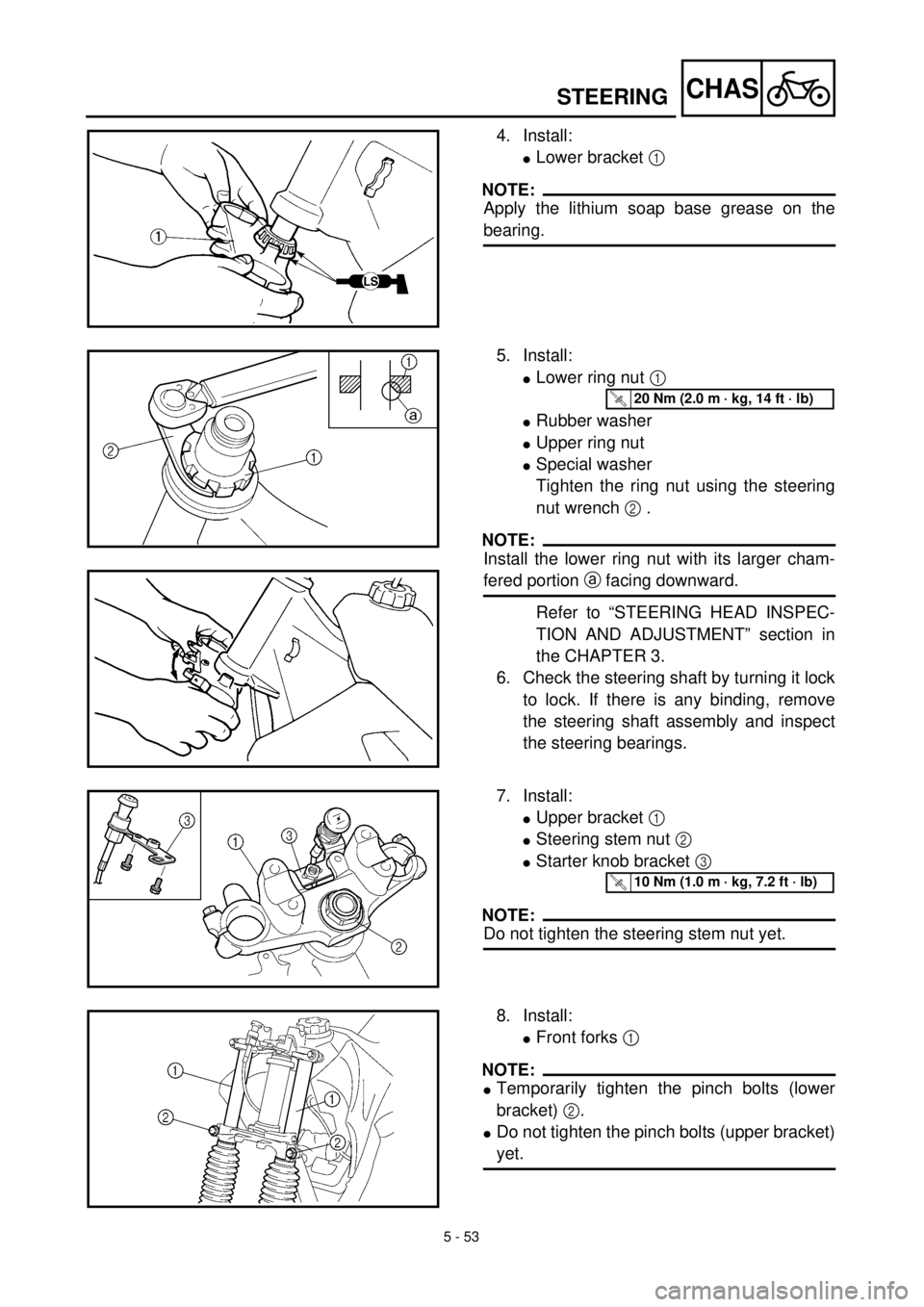

4. Install:

lLower bracket 1

NOTE:

Apply the lithium soap base grease on the

bearing.

5. Install:

lLower ring nut 1

lRubber washer

lUpper ring nut

lSpecial washer

Tighten the ring nut using the steering

nut wrench 2 .

NOTE:

Install the lower ring nut with its larger cham-

fered portion a facing downward.

Refer to “STEERING HEAD INSPEC-

TION AND ADJUSTMENT” section in

the CHAPTER 3.

6. Check the steering shaft by turning it lock

to lock. If there is any binding, remove

the steering shaft assembly and inspect

the steering bearings.

T R..20 Nm (2.0 m · kg, 14 ft · lb)

7. Install:

lUpper bracket 1

lSteering stem nut 2

lStarter knob bracket 3

NOTE:

Do not tighten the steering stem nut yet.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

8. Install:

lFront forks 1

NOTE:

lTemporarily tighten the pinch bolts (lower

bracket) 2.

lDo not tighten the pinch bolts (upper bracket)

yet.

STEERING

Page 473 of 509

5 - 54

CHAS

9. Festziehen:

lLenkschaftmutter 1

10. Montieren:

lSchutzkappe 2

11. Nach dem Festziehen der Mutter die

Lenkung auf Leichtgängigkeit prüfen. Bei

Schwergängigkeit die Ringmutter schritt-

weise lockern.

T R..110 Nm (11,0 m · kg)

12. Einstellen:

lTeleskopgabel-Oberkante a

Teleskopgabel-Oberkante

(Standard) a

0 mm

13. Festziehen:

lKlemmschrauben (untere Gabelbrücke) 1

lKlemmschrauben (obere Gabelbrücke) 2

T R..60 Nm (6,0 m · kg)

T R..25 Nm (2,5 m · kg)

DIRECTION

LENKUNG

9. Serrer:

lÉcrou de colonne de direction 1

10. Installer:

lCapuchon 2

11. Après avoir serré l’écrou, contrôler le mouve-

ment de la direction. Si nécessaire, desserrer

petit à petit l’écrou crénelé.

T R..110 Nm (11,0 m · kg, 80 ft · lb)

12. Régler:

lSommet du bras de fourche a

Sommet de la fourche avant (stan-

dard) a:

Zéro mm (zéro in)

13. Serrer:

lBoulons de pincement (té inférieur) 1

lBoulons de pincement (té supérieur) 2

T R..60 Nm (6,0 m · kg, 43 ft · lb)

T R..25 Nm (2,5 m · kg, 18 ft · lb)