oil YAMAHA TTR50 2006 Betriebsanleitungen (in German)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR50, Model: YAMAHA TTR50 2006Pages: 390, PDF-Größe: 9.69 MB

Page 158 of 390

3 - 18

INSPADJDRIVE CHAIN SLACK ADJUSTMENT/

FRONT FORK INSPECTION/REAR SHOCK ABSORBER INSPECTION

NOTE:

Turn the adjuster so that the chain is in line

with the sprocket, as viewed from the rear.

CAUTION:

Too small chain slack will overload the

engine and other vital parts; keep the

slack within the specified limits.

Tighten the wheel axle nut while pushing

down the drive chain.

T R..

Axle nut:

60 Nm (6.0 m kg, 43 ft lb)

Tighten the locknuts.

T R..

Locknut:

7 Nm (0.7 m kg, 5.1 ft lb)

EC36C000

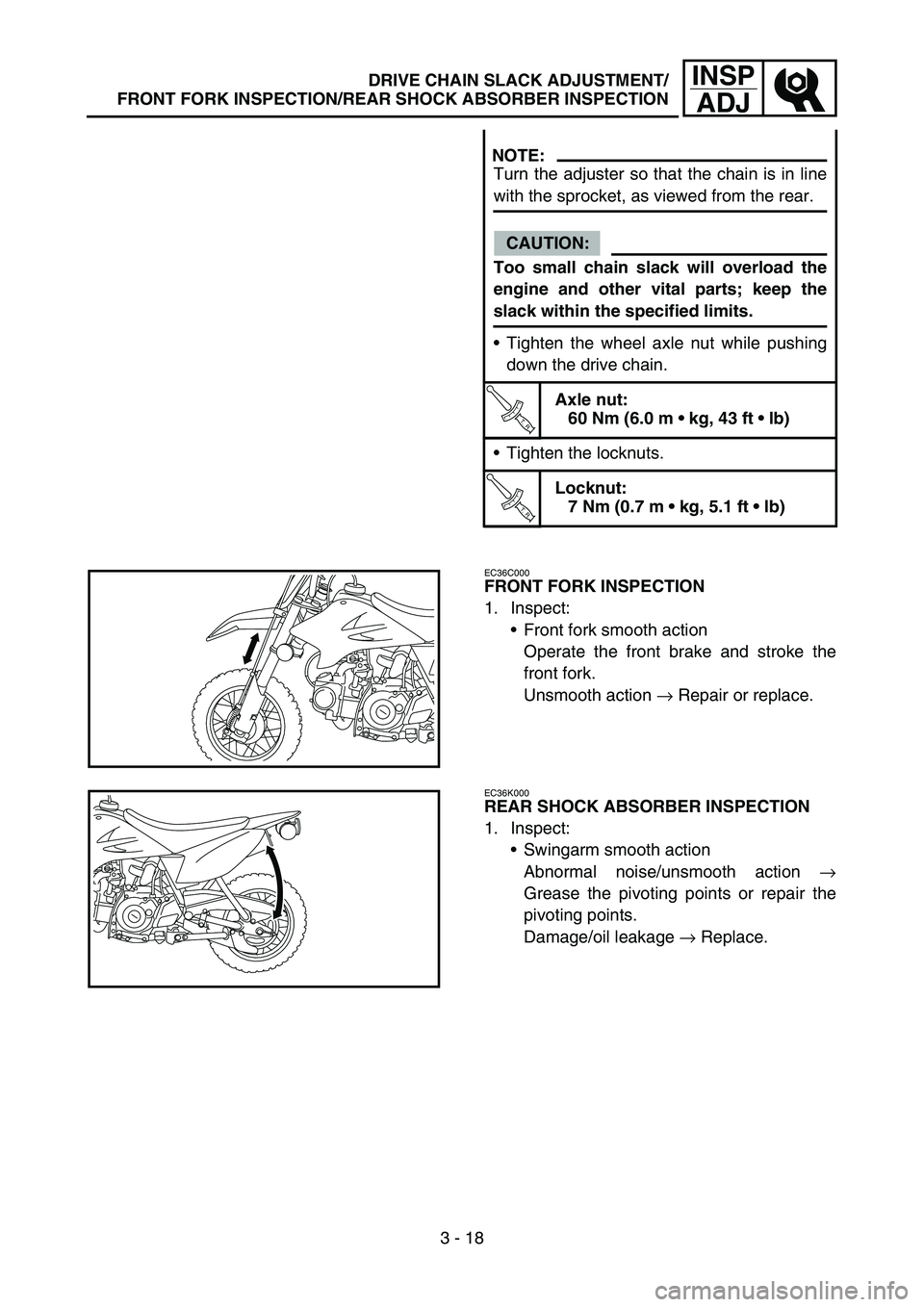

FRONT FORK INSPECTION

1. Inspect:

Front fork smooth action

Operate the front brake and stroke the

front fork.

Unsmooth action → Repair or replace.

EC36K000

REAR SHOCK ABSORBER INSPECTION

1. Inspect:

Swingarm smooth action

Abnormal noise/unsmooth action →

Grease the pivoting points or repair the

pivoting points.

Damage/oil leakage → Replace.

Page 161 of 390

INSPADJ

CONTROLE DE LA PRESSION DES PNEUS/CONTROLE ET SERRAGE

DES RAYONS/CONTROLE DES ROUES

REIFENLUFTDRUCK KONTROLLIEREN/SPEICHEN KONTROLLIEREN UND SPANNEN/RÄDER KONTROLLIEREN

CONTROLE DE LA PRESSION DES PNEUS

1. Mesurer: Pression des pneus

Hors sp écifications → Régler.

N.B.:

Contr ôler les pneus à froid.

Le pneu risque de se d éjanter si le gonflage est

insuffisant.

Une tige de valve de pneu inclin ée indique que le

pneu est mal assis.

Une tige de valve de pneu inclin ée indique que le

pneu est mal assis. Corriger la position du pneu.

Pression des pneus standard:

100 kPa (1,00 kgf/cm2, 14,2 psi)

CONTROLE ET SERRAGE DES RAYONS

1. Contr ôler:

Rayons 1

D éformation/endommagement → Remplacer.

Rayon mal tendu → Retendre.

2. Serrer: Rayons

N.B.:

Veiller à retendre ces rayons avant et apr ès le

rodage. Apr ès un entra înement ou une course, con-

tr ôler le serrage des rayons.

T R..2 Nm (0,2 m · kg, 1,4 ft · lb)

CONTROLE DES ROUES

1. Contr ôler:

Voile de roue

Sur élever la roue et la faire tourner.

Voile excessif → Remplacer.

3 - 19REIFENLUFTDRUCK KONTROLLIEREN

1. Messen:

Reifenluftdruck

Nicht nach Vorgabe → Korrigieren.

HINWEIS:

Den Reifenluftdruck bei kaltem Reifen kon-

trollieren.

Bei zu niedrigem Reifenluftdruck besteht die

Gefahr, dass der Reifen auf der Felge

rutscht.

Ein schr äg stehender Ventilschaft deutet

darauf hin, dass der Reifen sich verschoben

hat.

Falls der Ventilschaft schr äg steht, sitzt der

Reifen falsch auf. In diesem Fall die Reifen-

lage korrigieren.

Standard-Reifenluftdruck: 100 kPa (1,00 kgf/cm2, 14,2 psi)

SPEICHEN KONTROLLIEREN UND

SPANNEN

1. Kontrollieren:

Speichen 1

Verbogen/besch ädigt → Erneuern.

Speiche locker → Spannen.

2. Festziehen: Speichen

HINWEIS:

Die Speichen m üssen vor und nach dem Ein-

fahren gespannt und nach jeder Fahrt kontrol-

liert werden.

T R..2 Nm (0,2 m · kg, 1,4 ft · lb)

R ÄDER KONTROLLIEREN

1. Kontrollieren: Felgenschlag

Das Rad anheben und drehen.

Anormaler Schlag → Erneuern.

Page 166 of 390

3 - 22

INSPADJ

LUBRICATION

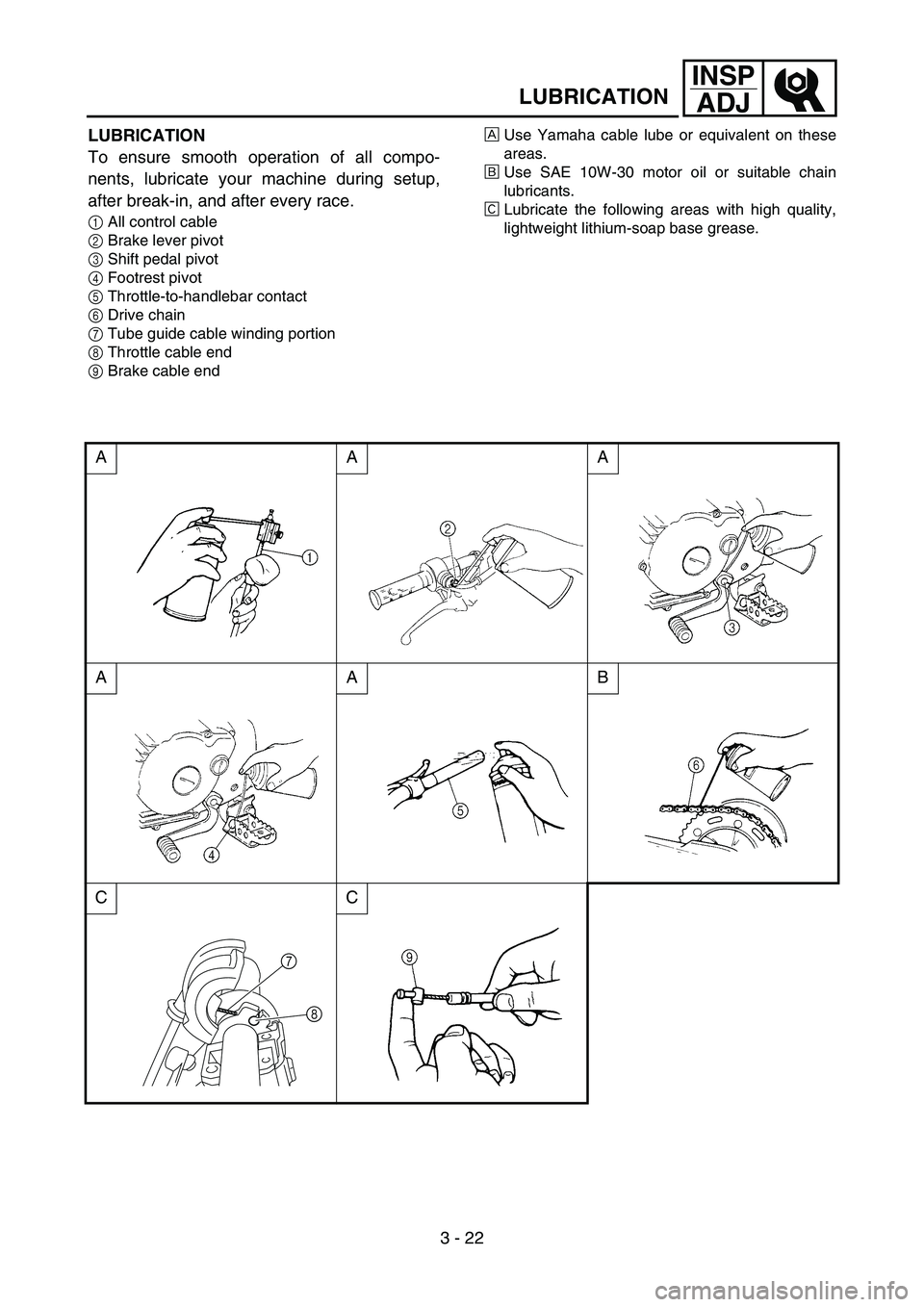

LUBRICATION

To ensure smooth operation of all compo-

nents, lubricate your machine during setup,

after break-in, and after every race.

1 All control cable

2 Brake lever pivot

3 Shift pedal pivot

4 Footrest pivot

5 Throttle-to-handlebar contact

6 Drive chain

7 Tube guide cable winding portion

8 Throttle cable end

9 Brake cable end È

Use Yamaha cable lube or equivalent on these

areas.

É Use SAE 10W-30 motor oil or suitable chain

lubricants.

Ê Lubricate the following areas with high quality,

lightweight lithium-soap base grease.

AAA

AAB

CC

7 8

Page 170 of 390

3 - 24

INSPADJ

BATTERY INSPECTION AND CHARGING

WARNING

Batteries generate explosive hydrogen gas

and contain electrolyte which is made of

poisonous and highly caustic sulfuric acid.

Therefore, always follow these preventive

measures:

Wear protective eye gear when handling

or working near batteries.

Charge batteries in a well-ventilated area.

Keep batteries away from fire, sparks or

open flames (e.g., welding equipment,

lighted cigarettes).

DO NOT SMOKE when charging or han-

dling batteries.

KEEP BATTERIES AND ELECTROLYTE

OUT OF REACH OF CHILDREN.

Avoid bodily contact with electrolyte as it

can cause severe burns or permanent eye

injury.

FIRST AID IN CASE OF BODILY CONTACT:

EXTERNAL

Skin — Wash with water.

Eyes — Flush with water for 15 minutes

and get immediate medical attention.

INTERNAL

Drink large quantities of water or milk fol-

lowed with milk of magnesia, beaten egg

or vegetable oil. Get immediate medical

attention.

CAUTION:

Charging time, charging amperage and

charging voltage for an MF battery are dif-

ferent from those of conventional batteries.

The MF battery should be charged as

explained in the charging method illustra-

tions. If the battery is overcharged, the

electrolyte level will drop considerably.

Therefore, take special care when charging

the battery.

BATTERY INSPECTION AND CHARGING

Page 212 of 390

4 - 13

ENGCYLINDER HEAD

4. Remove:Cylinder head

NOTE:

Loosen the bolts and nuts in their proper

loosening sequence.

Start by loosening each bolt and nut 1/2 turn

until all are loose.1

2

5

64

3

ASSEMBLY AND INSTALLATION

1. Install:

Cylinder head

2. Tighten: Nuts

Bolts

NOTE:

Apply the engine oil on the contact surfaces

of the nuts and copper washers.

Apply the engine oil on the thread and con-

tact surface of the bolts.

Follow the numerical order shown in the illus-

tration. Tighten the bolts and nuts in two

stages.

6

5

2

13

4

T R..22 Nm (2.2 m · kg, 16 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

3. Install:

Camshaft sprocket 1

Installation steps:

Turn the crankshaft counterclockwise until

the “I” mark a on the rotor is aligned with

the stationary pointer b on the crankcase

cover.

Align the “I” mark c on the camshaft

sprocket with the stationary pointer d on

the cylinder head.

Fit the timing chain 2 onto camshaft

sprocket and install the camshaft sprocket

on the camshaft.

NOTE:

When installing the camshaft sprocket, keep

the timing chain as tense as possible on the

exhaust side.

b

a

1

2

c

d

Page 218 of 390

4 - 16

ENGCAMSHAFT AND ROCKER ARMS

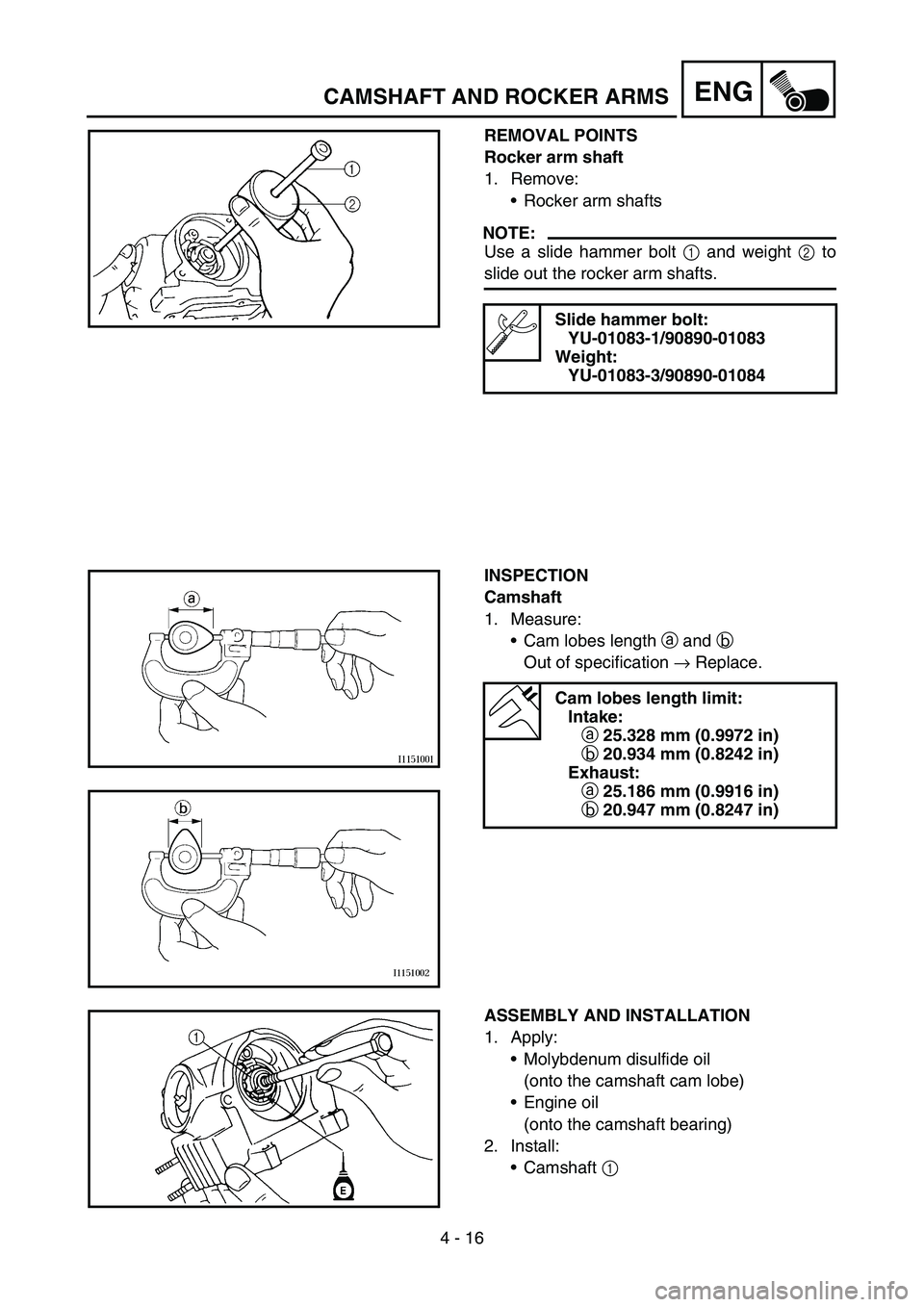

REMOVAL POINTS

Rocker arm shaft

1. Remove:Rocker arm shafts

NOTE:

Use a slide hammer bolt 1 and weight 2 to

slide out the rocker arm shafts.

Slide hammer bolt:

YU-01083-1/90890-01083

Weight: YU-01083-3/90890-01084

INSPECTION

Camshaft

1. Measure:

Cam lobes length a and b

Out of specification → Replace.

Cam lobes length limit:

Intake:

a 25.328 mm (0.9972 in)

b 20.934 mm (0.8242 in)

Exhaust:

a 25.186 mm (0.9916 in)

b 20.947 mm (0.8247 in)

ASSEMBLY AND INSTALLATION

1. Apply:

Molybdenum disulfide oil

(onto the camshaft cam lobe)

Engine oil

(onto the camshaft bearing)

2. Install: Camshaft 1

Page 220 of 390

4 - 17

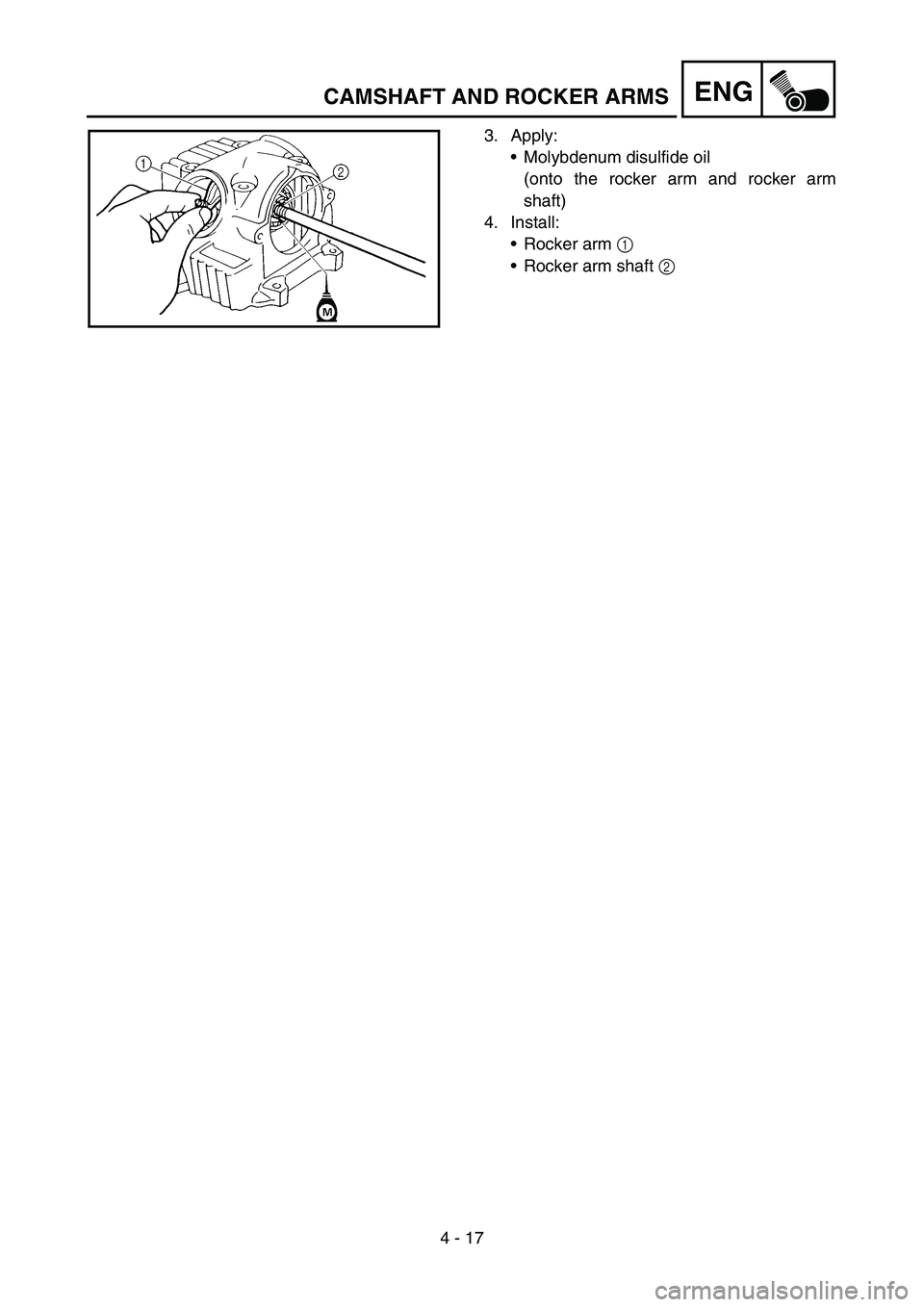

ENGCAMSHAFT AND ROCKER ARMS

3. Apply:Molybdenum disulfide oil

(onto the rocker arm and rocker arm

shaft)

4. Install: Rocker arm 1

Rocker arm shaft 2

Page 228 of 390

4 - 21

ENGVALVES AND VALVE SPRINGS

2. Lap:Valve face

Valve seat

NOTE:

After refacing the valve seat or replacing the

valve and valve guide, the valve seat and

valve face should be lapped.

Lapping steps:

Apply a coarse lapping compound to the

valve face.

CAUTION:

Do not let the compound enter the gap

between the valve stem and the guide.

Apply molybdenum disulfide oil to the

valve stem.

Install the valve into the cylinder head.

Turn the valve until the valve face and

valve seat are evenly polished, then clean

off all of the compound.

NOTE:

For best lapping results, lightly tap the valve

seat while rotating the valve back and forth

between your hands.

Apply a fine lapping compound to the

valve face and repeat the above steps.

NOTE:

After every lapping operation be sure to

clean off all of the compound from the valve

face and valve seat.

Apply Mechanic ’s blueing dye (Dykem) to

the valve face.

Install the valve into the cylinder head.

Press the valve through the valve guide

and onto the valve seat to make a clear

pattern.

Measure the valve seat width again. If the

valve seat width is out of specification,

reface and relap the valve seat.

Page 230 of 390

4 - 22

ENGVALVES AND VALVE SPRINGS

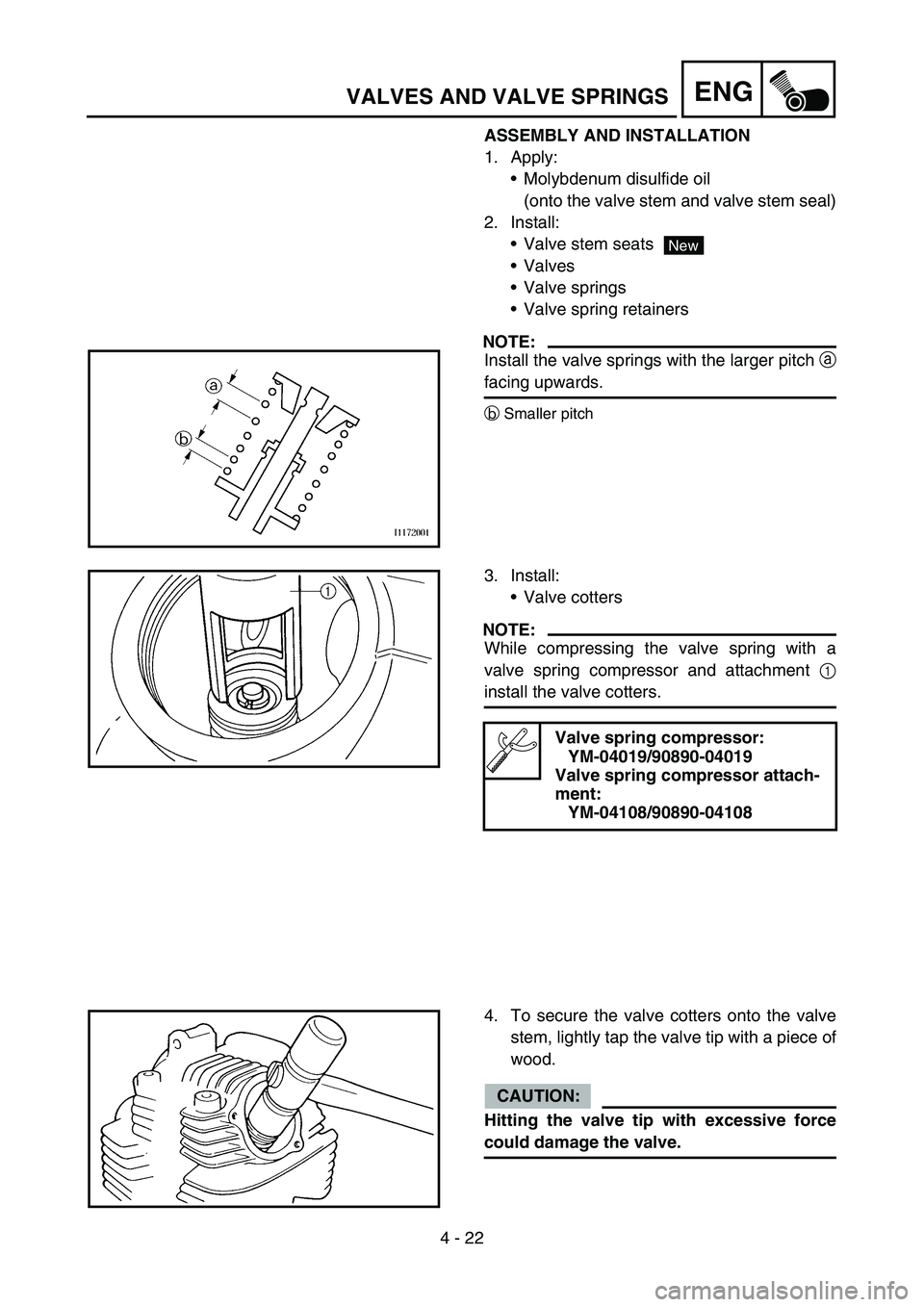

ASSEMBLY AND INSTALLATION

1. Apply:Molybdenum disulfide oil

(onto the valve stem and valve stem seal)

2. Install: Valve stem seats

Valves

Valve springs

Valve spring retainers

NOTE:

Install the valve springs with the larger pitch a

facing upwards.

bSmaller pitch

New

3. Install:

Valve cotters

NOTE:

While compressing the valve spring with a

valve spring compressor and attachment 1

install the valve cotters.

Valve spring compressor:

YM-04019/90890-04019

Valve spring compressor attach-

ment: YM-04108/90890-04108

4. To secure the valve cotters onto the valve

stem, lightly tap the valve tip with a piece of

wood.

CAUTION:

Hitting the valve tip with excessive force

could damage the valve.

Page 232 of 390

4 - 23

ENGCYLINDER AND PISTON

CYLINDER AND PISTON

Extent of removal: 1 Cylinder removal

2 Piston removal

Extent of removal Order Part name Q ’ty Remarks

CYLINDER AND PISTON

REMOVAL

Preparation for removal Cylinder head Refer to “CYLINDER HEAD ” section.

1 Timing chain guide (exhaust) 1

2 Cylinder 1

3 Dowel pin 2

4 Gasket 1

5 Piston pin clip 2 Use special tool.

Refer to “REMOVAL POINTS ”.

6 Piston pin 1

7Piston 1

8 Piston ring (top) 1

Refer to “REMOVAL POINTS ”.

9 Piston ring (2nd) 1

10 Oil ring 1

2

1