battery YAMAHA TTR50 2006 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR50, Model: YAMAHA TTR50 2006Pages: 390, PDF Size: 9.69 MB

Page 179 of 390

3 - 29

INSPADJ

BATTERY INSPECTION AND CHARGING

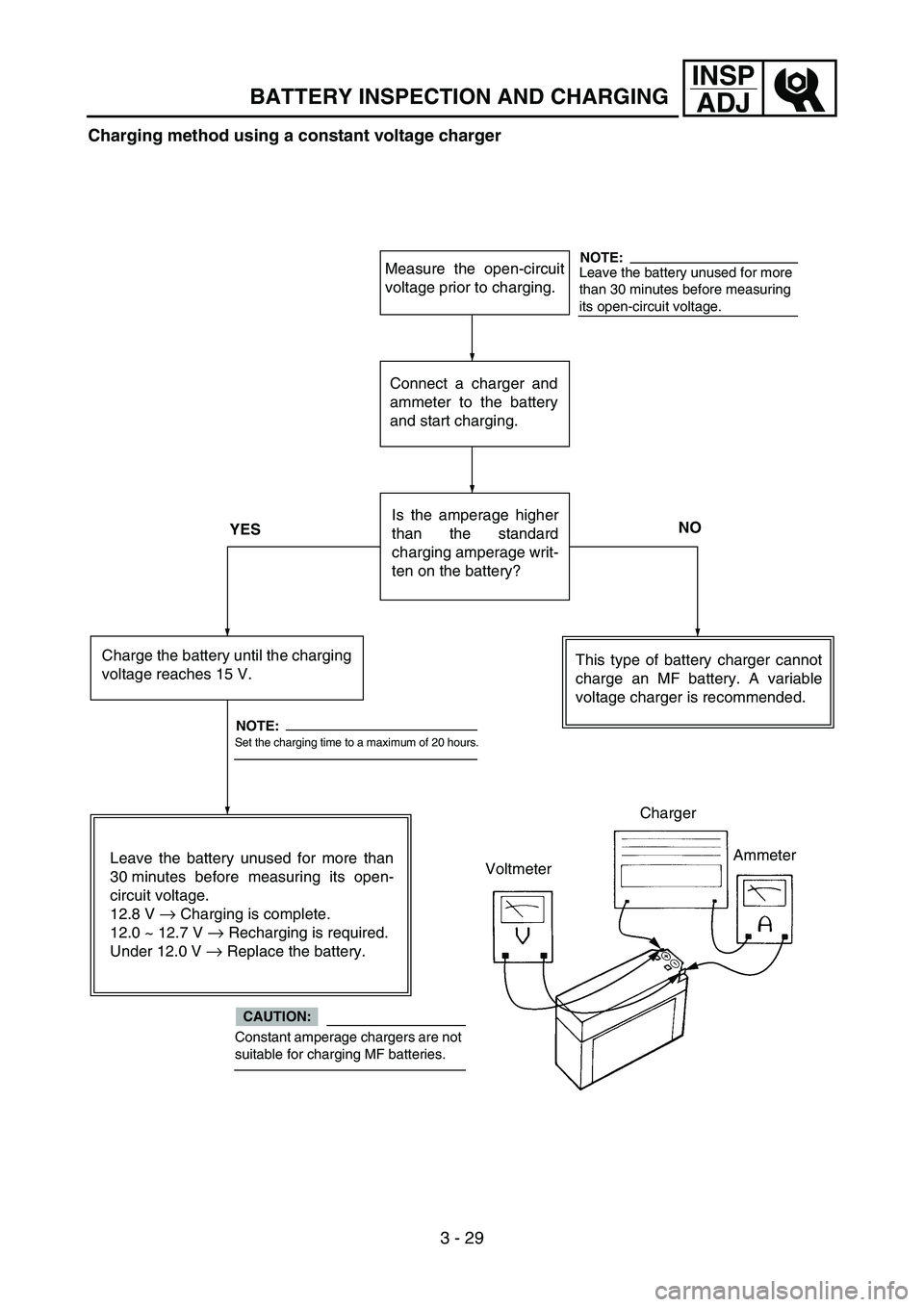

Charging method using a constant voltage charger

Measure the open-circuit

voltage prior to charging.

Connect a charger and

ammeter to the battery

and start charging.

NO

YES Is the amperage higher

than the standard

charging amperage writ-

ten on the battery?

Charge the battery until the charging

voltage reaches 15 V.

Leave the battery unused for more than

30 minutes before measuring its open-

circuit voltage.

12.8 V

→ Charging is complete.

12.0 ~ 12.7 V

→ Recharging is required.

Under 12.0 V

→ Replace the battery. This type of battery charger cannot

charge an MF battery. A variable

voltage charger is recommended.

Leave the battery unused for more

than 30 minutes before measuring

its open-circuit voltage.

Set the charging time to a maximum of 20 hours.

Constant amperage chargers are not

suitable for charging MF batteries.

Charger

Ammeter

Voltmeter

NOTE:

CAUTION:

NOTE:

Page 184 of 390

3 - 30

INSPADJBATTERY INSPECTION AND CHARGING/

FUSE INSPECTION

6. Install:

Battery

Battery band

7. Check: Battery terminals

Dirt → Clean with a wire brush.

Loose connection → Connect properly.

8. Lubricate: Battery terminal

9. Connect: Battery lead coupler

(to the battery terminals)

10. Install:

Battery cover

Seat assembly

Recommended lubricant:

Lithium soap base grease

FUSE INSPECTION

CAUTION:

To avoid a short circuit, always set the

main switch to “OFF ” when checking or

replacing a fuse.

1. Remove:

Seat assembly

Battery cover

Refer to “FRONT FENDER, SEAT

ASSEMBLY AND FUEL TANK ” section in

the CHAPTER 4.

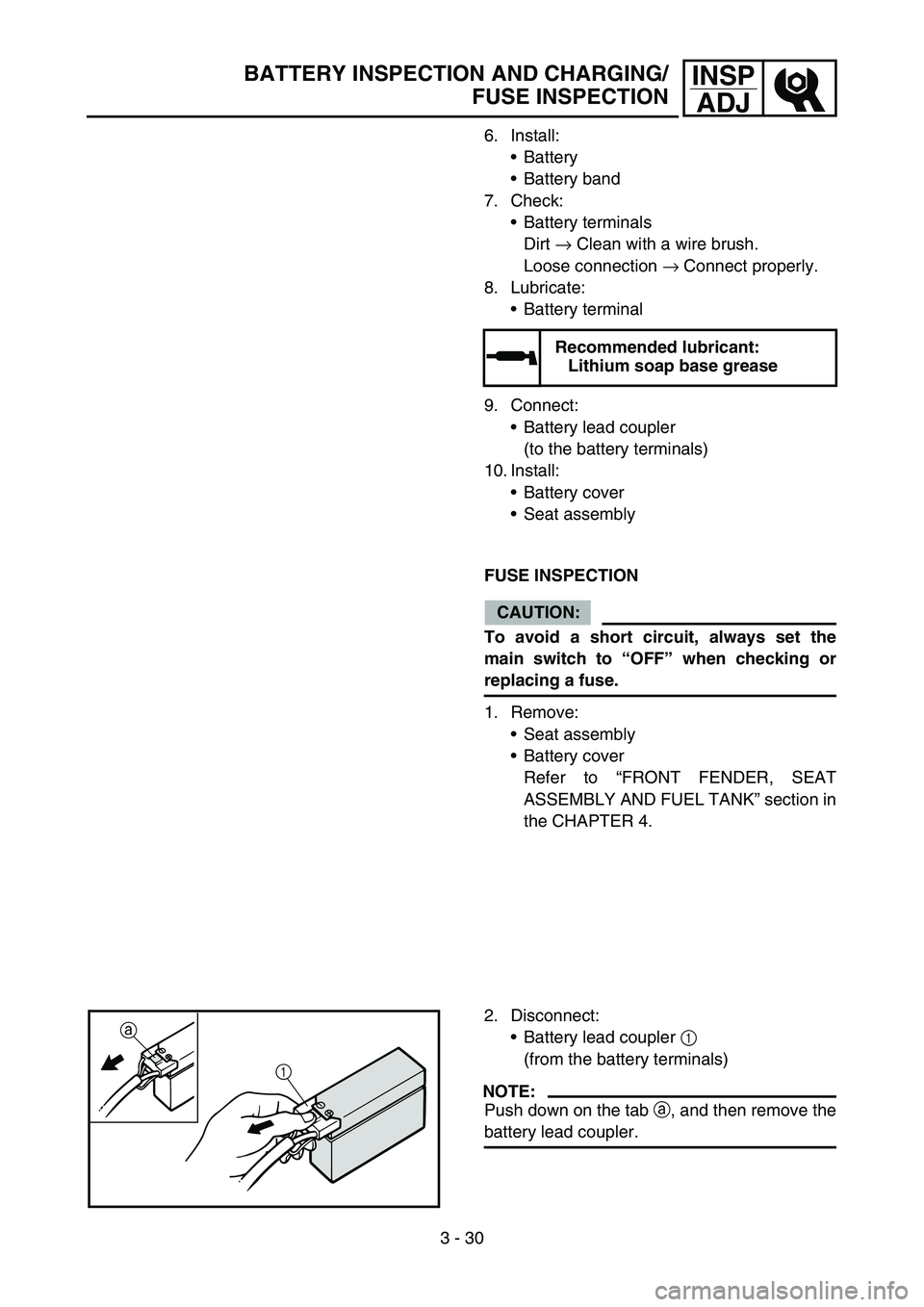

2. Disconnect: Battery lead coupler 1

(from the battery terminals)

NOTE:

Push down on the tab a, and then remove the

battery lead coupler.

1

a

Page 186 of 390

3 - 31

INSPADJ

FUSE INSPECTION

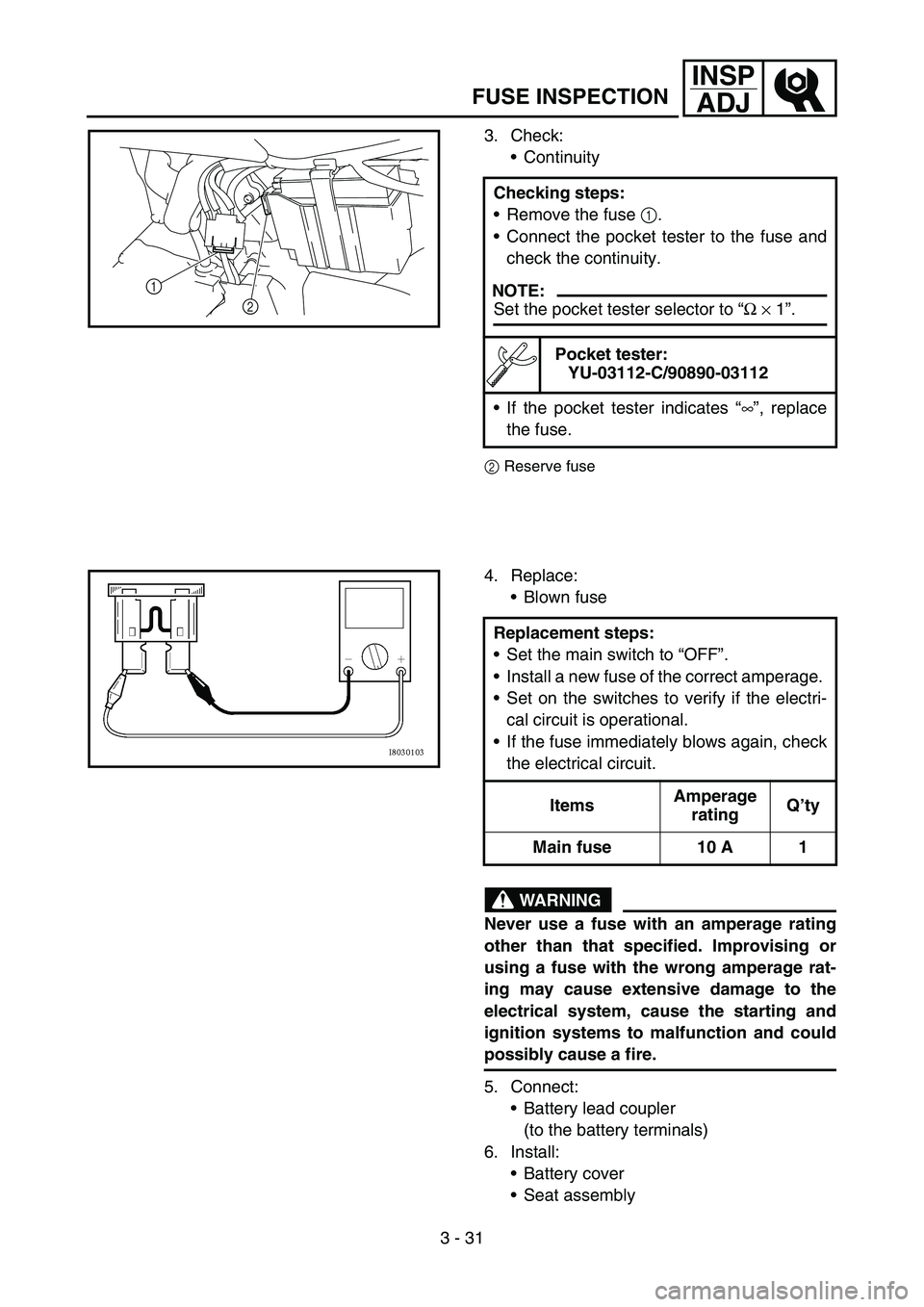

3. Check:

Continuity

2 Reserve fuse

Checking steps:

Remove the fuse 1

.

Connect the pocket tester to the fuse and

check the continuity.

NOTE:

Set the pocket tester selector to “Ω × 1 ”.

Pocket tester:

YU-03112-C/90890-03112

If the pocket tester indicates “∞ ”, replace

the fuse.

1 2

4. Replace:

Blown fuse

WARNING

Never use a fuse with an amperage rating

other than that specified. Improvising or

using a fuse with the wrong amperage rat-

ing may cause extensive damage to the

electrical system, cause the starting and

ignition systems to malfunction and could

possibly cause a fire.

5. Connect:

Battery lead coupler

(to the battery terminals)

6. Install: Battery cover

Seat assembly

Replacement steps:

Set the main switch to “OFF ”.

Install a new fuse of the correct amperage.

Set on the switches to verify if the electri-

cal circuit is operational.

If the fuse immediately blows again, check

the electrical circuit.

Items Amperage

rating Q

’ty

Main fuse 10 A 1

Page 188 of 390

4 - 1

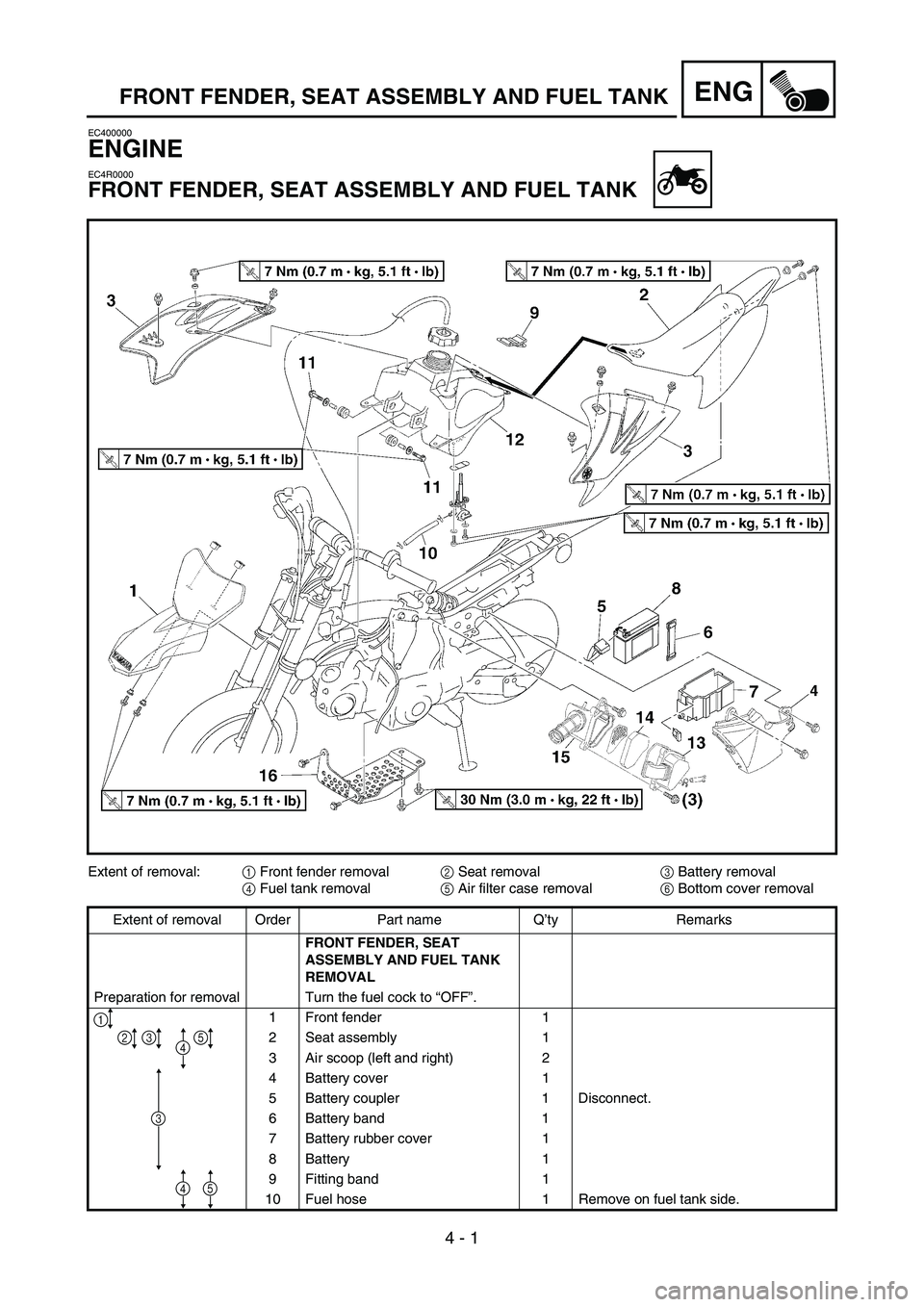

ENGFRONT FENDER, SEAT ASSEMBLY AND FUEL TANK

EC400000

ENGINE

EC4R0000

FRONT FENDER, SEAT ASSEMBLY AND FUEL TANK

Extent of removal:1 Front fender removal

2 Seat removal

3 Battery removal

4 Fuel tank removal

5 Air filter case removal

6 Bottom cover removal

Extent of removal Order Part name Q ’ty Remarks

FRONT FENDER, SEAT

ASSEMBLY AND FUEL TANK

REMOVAL

Preparation for removal Turn the fuel cock to “OFF ”.

1 Front fender 1

2 Seat assembly 1

3 Air scoop (left and right) 2

4 Battery cover 1

5 Battery coupler 1 Disconnect.

6 Battery band 1

7 Battery rubber cover 1

8 Battery 1

9 Fitting band 1

10 Fuel hose 1 Remove on fuel tank side.

1

2

3

43

4

5

5

Page 340 of 390

6 - 1

–+ELEC

345

6

78

\b0

B\f

2

1

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC611000

ELECTRICAL COMPONENTS

1 Thermo switch

2 Main switch

3 Engine stop switch

4 Ignition coil

5 Ground lead

6 Fuse

7 Battery

8 CDI unit

9 Starter relay 0

Rectifier/regulator

A Neutral switch

B AC magneto

C Carburetor heater

D Start switch

E Spark plug

F Starter motorCOLOR CODE

B ...................... Black

Br .................... Brown

O ..................... Orange

R ..................... Red

Sb .................... Sky blue

W ..................... White

Y ...................... Yellow

EC612000

WIRING DIAGRAM

R

WR

W

BL /WSb B

RW

W

W

OO

B

B

Y /R

R

W

B

R

Y /RY /R

Y

ON

OFF

OFF ON

Y

B

BY

/RRB

SbY /RR B

W

B

B

RBrR

Br

R

/WBr

R /W

L /W

OFF

RUN

Sb

BrBr

Sb

WBY

/RW SbY

B

B

B

RR

RR

R

R

R

/W

L /W

RRRB

R /W

L

/WR

R

RR

B Br

BO

R

WB

\f

2 8

4

E

1

C

D

0

63

\b F

5 7

Br

L/W .................. Blue/White

R/W .................. Red/White

Y/R ................... Yellow/Red

E

F

D

C

Page 352 of 390

–+ELEC

6 - 6

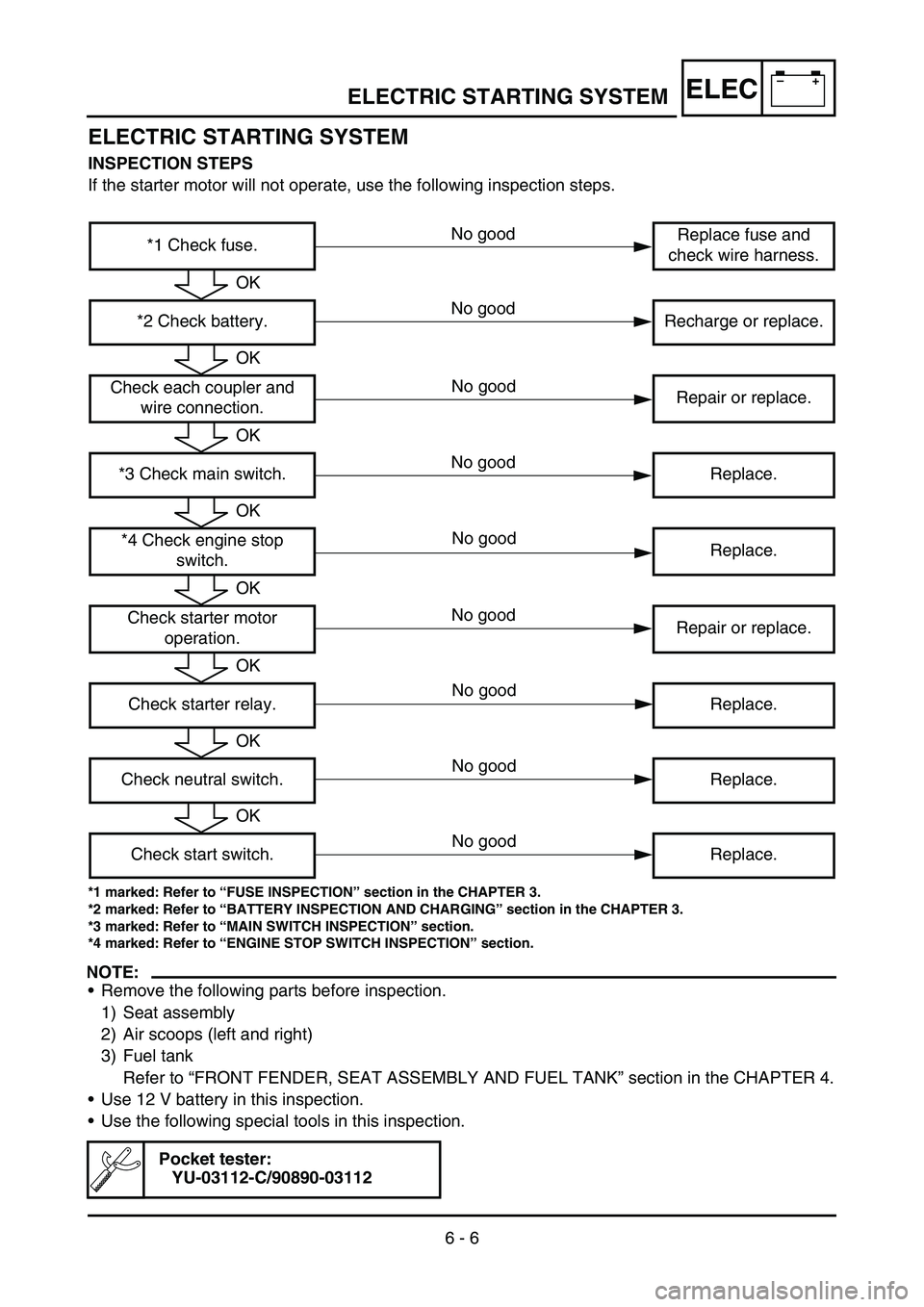

ELECTRIC STARTING SYSTEM

INSPECTION STEPS

If the starter motor will not operate, use the following inspection steps.

*1 marked: Refer to “FUSE INSPECTION ” section in the CHAPTER 3.

*2 marked: Refer to “BATTERY INSPECTION AND CHARGING ” section in the CHAPTER 3.

*3 marked: Refer to “MAIN SWITCH INSPECTION ” section.

*4 marked: Refer to “ENGINE STOP SWITCH INSPECTION ” section.

NOTE:

Remove the following parts before inspection.

1) Seat assembly

2) Air scoops (left and right)

3) Fuel tank

Refer to “FRONT FENDER, SEAT ASSEMBLY AND FUEL TANK ” section in the CHAPTER 4.

Use 12 V battery in this inspection.

Use the following special tools in this inspection.

Pocket tester:

YU-03112-C/90890-03112

*1 Check fuse. Replace fuse and

check wire harness.

*2 Check battery. Recharge or replace.

Check each coupler and wire connection. Repair or replace.

*3 Check main switch. Replace. *4 Check engine stop switch. Replace.

Check starter motor operation. Repair or replace.

Check starter relay. Replace.

Check neutral switch. Replace. Check start switch. Replace.

OK

OK

OK

OK

OK

OK

OK

OK

No good

No good

No good

No good

No good

No good

ELECTRIC STARTING SYSTEM

No good

No good

No good

Page 356 of 390

6 - 7

–+ELEC

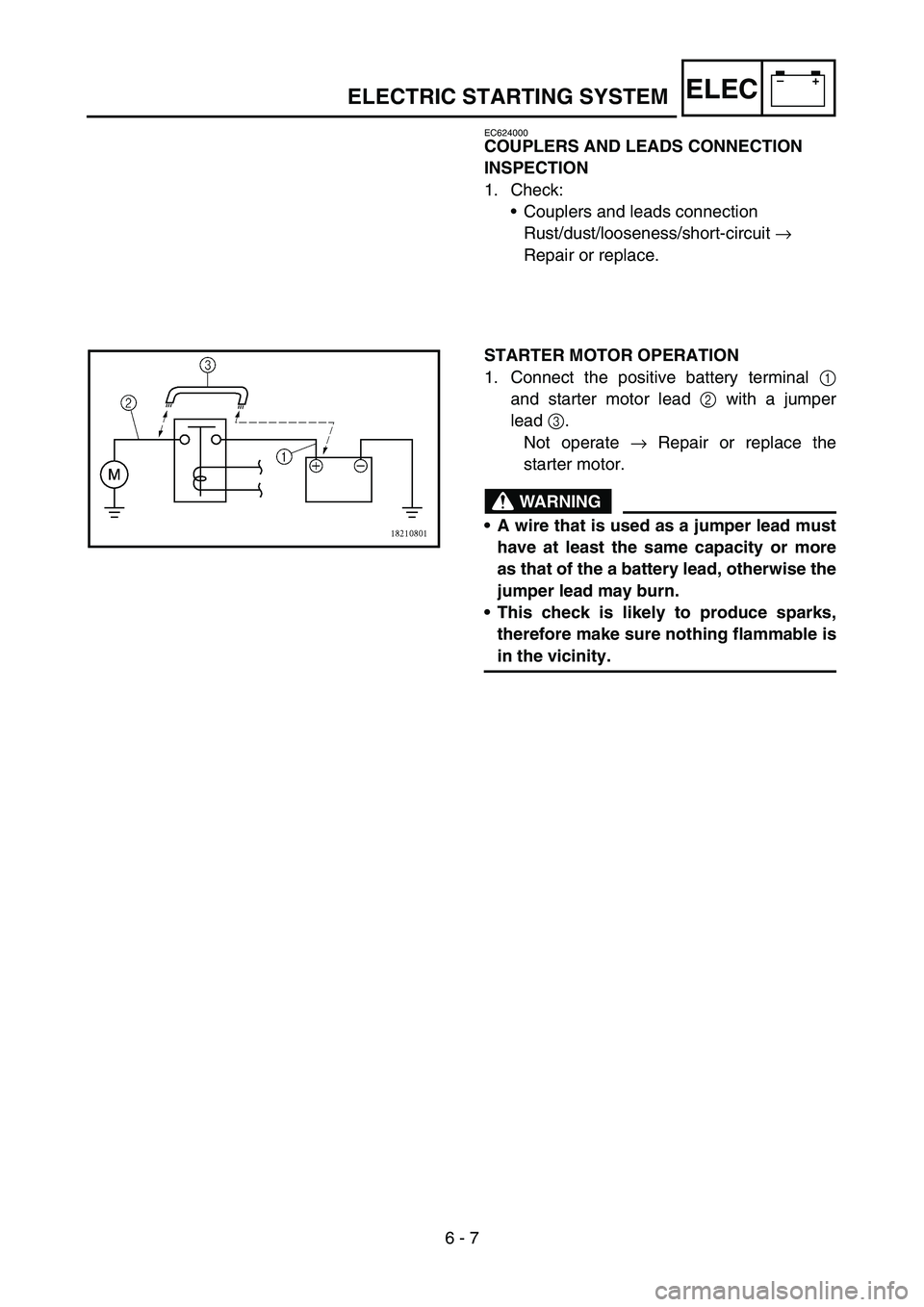

EC624000

COUPLERS AND LEADS CONNECTION

INSPECTION

1. Check:

Couplers and leads connection

Rust/dust/looseness/short-circuit →

Repair or replace.

STARTER MOTOR OPERATION

1. Connect the positive battery terminal 1

and starter motor lead 2 with a jumper

lead 3.

Not operate → Repair or replace the

starter motor.

WARNING

A wire that is used as a jumper lead must

have at least the same capacity or more

as that of the a battery lead, otherwise the

jumper lead may burn.

This check is likely to produce sparks,

therefore make sure nothing flammable is

in the vicinity.

ELECTRIC STARTING SYSTEM

Page 358 of 390

6 - 8

–+ELEC

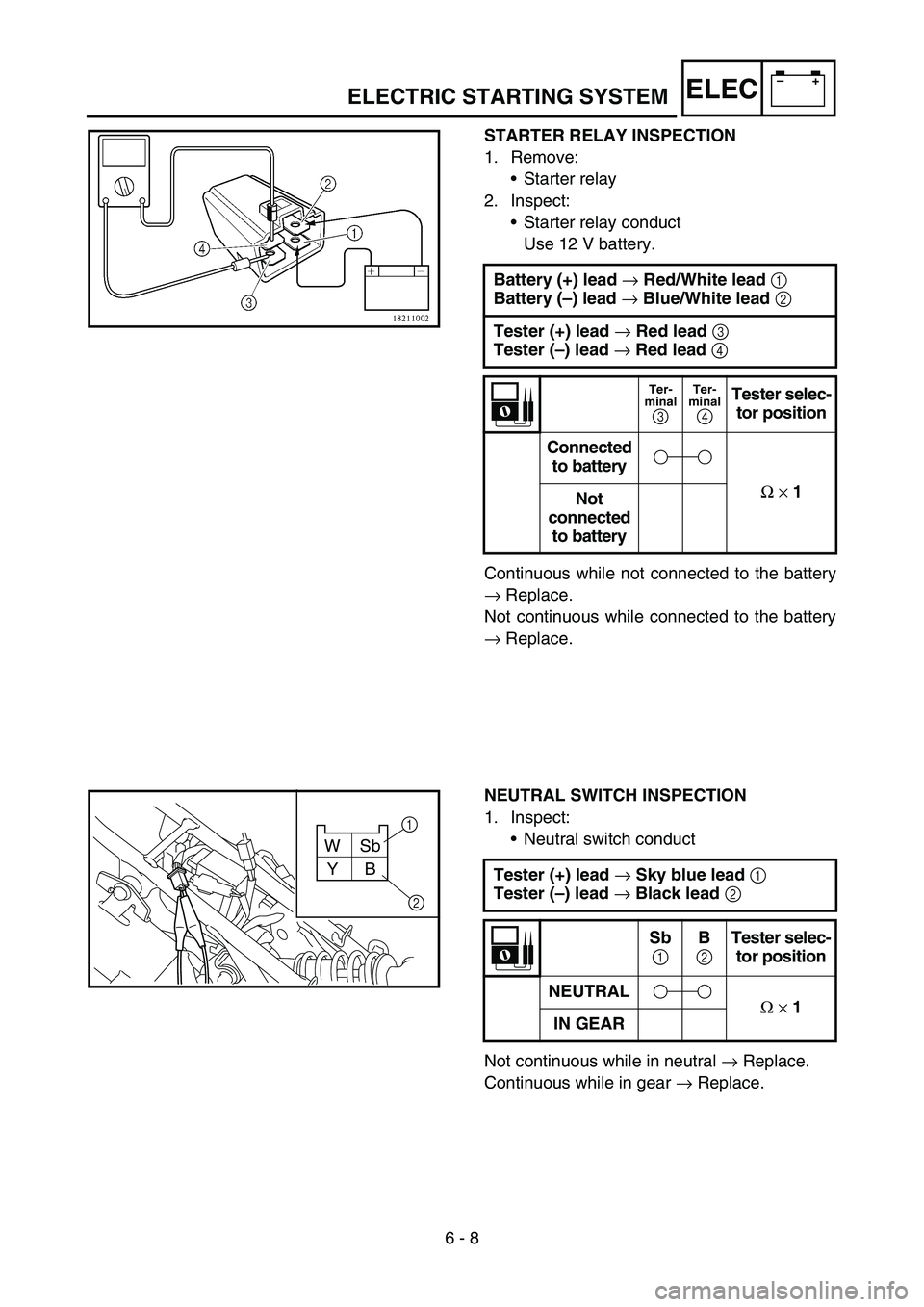

STARTER RELAY INSPECTION

1. Remove:

Starter relay

2. Inspect: Starter relay conduct

Use 12 V battery.

Continuous while not connected to the battery

→ Replace.

Not continuous while connected to the battery

→ Replace.

Battery (+) lead

→ Red/White lead 1

Battery ( –) lead → Blue/White lead 2

Tester (+) lead → Red lead 3

Tester ( –) lead → Red lead 4

Ter-

minal

3

Ter-

minal

4 Tester selec-

tor position

Connected to battery

Ω × 1

Not

connected to battery

NEUTRAL SWITCH INSPECTION

1. Inspect:

Neutral switch conduct

Not continuous while in neutral → Replace.

Continuous while in gear → Replace.

Tester (+) lead

→ Sky blue lead 1

Tester ( –) lead → Black lead 2

Sb

1 B

2 Tester selec-

tor position

NEUTRAL Ω × 1

IN GEAR

WSb

B

Y 1

2

ELECTRIC STARTING SYSTEM

Page 370 of 390

–+ELEC

6 - 14

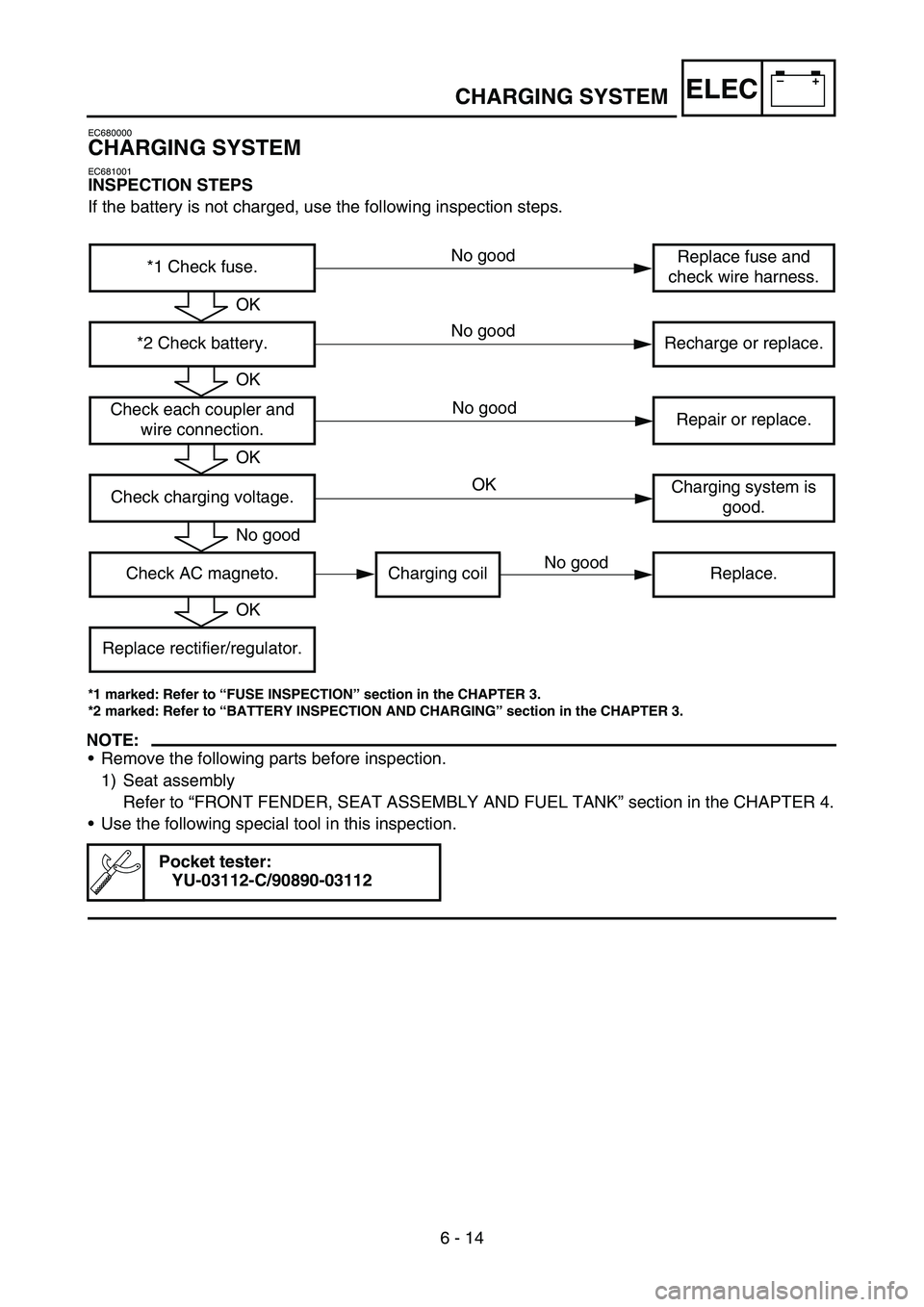

CHARGING SYSTEM

EC680000

CHARGING SYSTEM

EC681001

INSPECTION STEPS

If the battery is not charged, use the following inspection steps.

*1 marked: Refer to “FUSE INSPECTION ” section in the CHAPTER 3.

*2 marked: Refer to “BATTERY INSPECTION AND CHARGING ” section in the CHAPTER 3.

NOTE:

Remove the following parts before inspection.

1) Seat assembly

Refer to “FRONT FENDER, SEAT ASSEMBLY AND FUEL TANK ” section in the CHAPTER 4.

Use the following special tool in this inspection.

Pocket tester:

YU-03112-C/90890-03112

*1 Check fuse. Replace fuse and

check wire harness.

*2 Check battery. Recharge or replace.

Check each coupler and wire connection. Repair or replace.

Check charging voltage. Charging system is

good.

Check AC magneto. Charging coil Replace.

Replace rectifier/regulator.

OK

OK

OK

No good

OK

No good

OK

No good

No good

No good