warning YAMAHA TTR50 2006 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR50, Model: YAMAHA TTR50 2006Pages: 390, PDF Size: 9.69 MB

Page 164 of 390

3 - 21

INSPADJ

STEERING HEAD INSPECTION AND ADJUSTMENT

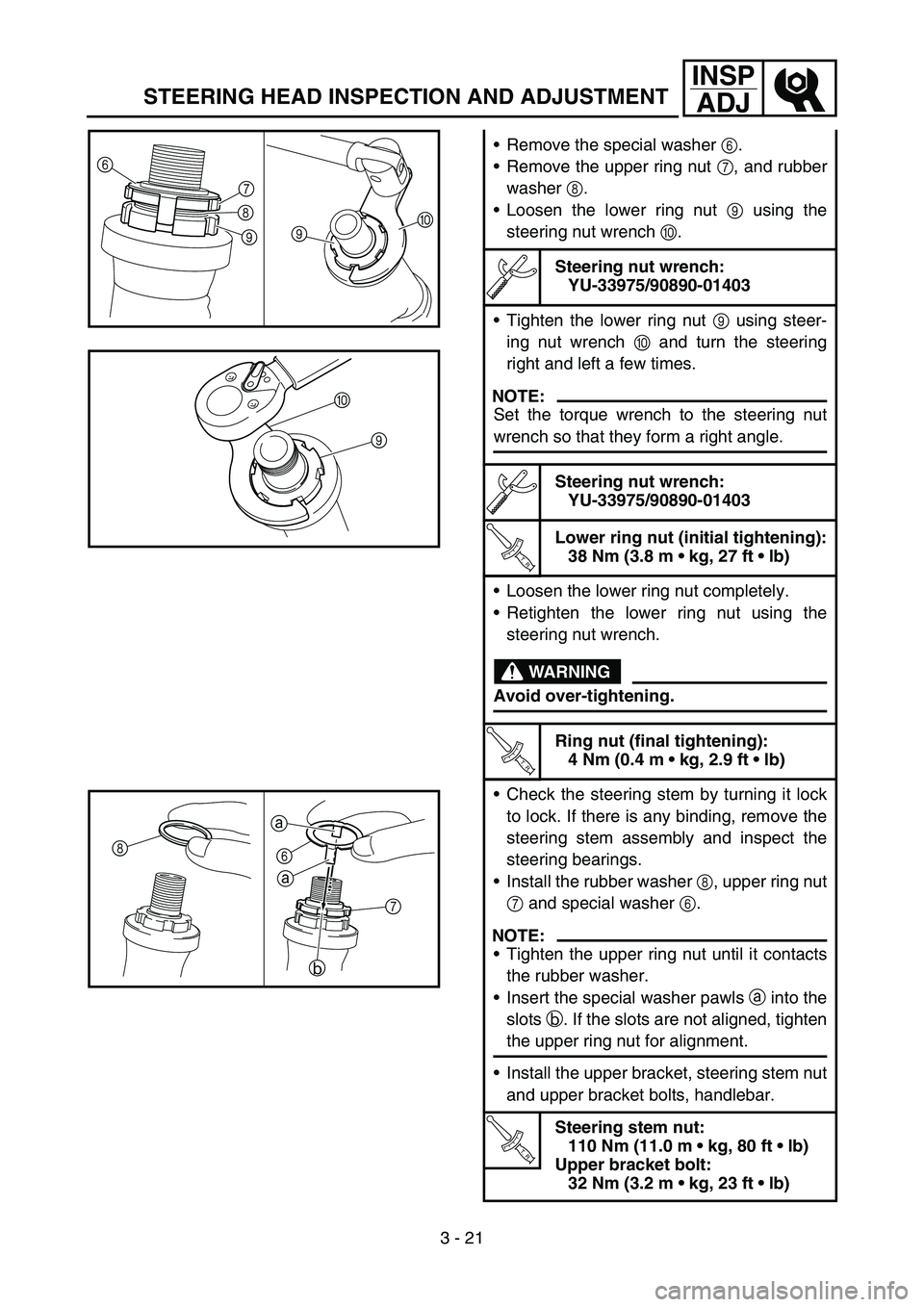

Remove the special washer 6.

Remove the upper ring nut 7, and rubber

washer 8.

Loosen the lower ring nut 9 using the

steering nut wrench 0.

Steering nut wrench:

YU-33975/90890-01403

Tighten the lower ring nut 9 using steer-

ing nut wrench 0 and turn the steering

right and left a few times.

NOTE:

Set the torque wrench to the steering nut

wrench so that they form a right angle.

Steering nut wrench: YU-33975/90890-01403

T R..

Lower ring nut (initial tightening):38 Nm (3.8 m kg, 27 ft lb)

Loosen the lower ring nut completely.

Retighten the lower ring nut using the

steering nut wrench.

WARNING

Avoid over-tightening.

T R..

Ring nut (final tightening):

4 Nm (0.4 m kg, 2.9 ft lb)

Check the steering stem by turning it lock

to lock. If there is any binding, remove the

steering stem assembly and inspect the

steering bearings.

Install the rubber washer 8, upper ring nut

7 and special washer 6.

NOTE:

Tighten the upper ring nut until it contacts

the rubber washer.

Insert the special washer pawls a into the

slots b. If the slots are not aligned, tighten

the upper ring nut for alignment.

Install the upper bracket, steering stem nut

and upper bracket bolts, handlebar.

T R..

Steering stem nut:

110 Nm (11.0 m kg, 80 ft lb)

Upper bracket bolt: 32 Nm (3.2 m kg, 23 ft lb)

7

8

\b

6

0

\b

0

\b

86

7

a

a

b

Page 170 of 390

3 - 24

INSPADJ

BATTERY INSPECTION AND CHARGING

WARNING

Batteries generate explosive hydrogen gas

and contain electrolyte which is made of

poisonous and highly caustic sulfuric acid.

Therefore, always follow these preventive

measures:

Wear protective eye gear when handling

or working near batteries.

Charge batteries in a well-ventilated area.

Keep batteries away from fire, sparks or

open flames (e.g., welding equipment,

lighted cigarettes).

DO NOT SMOKE when charging or han-

dling batteries.

KEEP BATTERIES AND ELECTROLYTE

OUT OF REACH OF CHILDREN.

Avoid bodily contact with electrolyte as it

can cause severe burns or permanent eye

injury.

FIRST AID IN CASE OF BODILY CONTACT:

EXTERNAL

Skin — Wash with water.

Eyes — Flush with water for 15 minutes

and get immediate medical attention.

INTERNAL

Drink large quantities of water or milk fol-

lowed with milk of magnesia, beaten egg

or vegetable oil. Get immediate medical

attention.

CAUTION:

Charging time, charging amperage and

charging voltage for an MF battery are dif-

ferent from those of conventional batteries.

The MF battery should be charged as

explained in the charging method illustra-

tions. If the battery is overcharged, the

electrolyte level will drop considerably.

Therefore, take special care when charging

the battery.

BATTERY INSPECTION AND CHARGING

Page 174 of 390

3 - 26

INSPADJ

BATTERY INSPECTION AND CHARGING

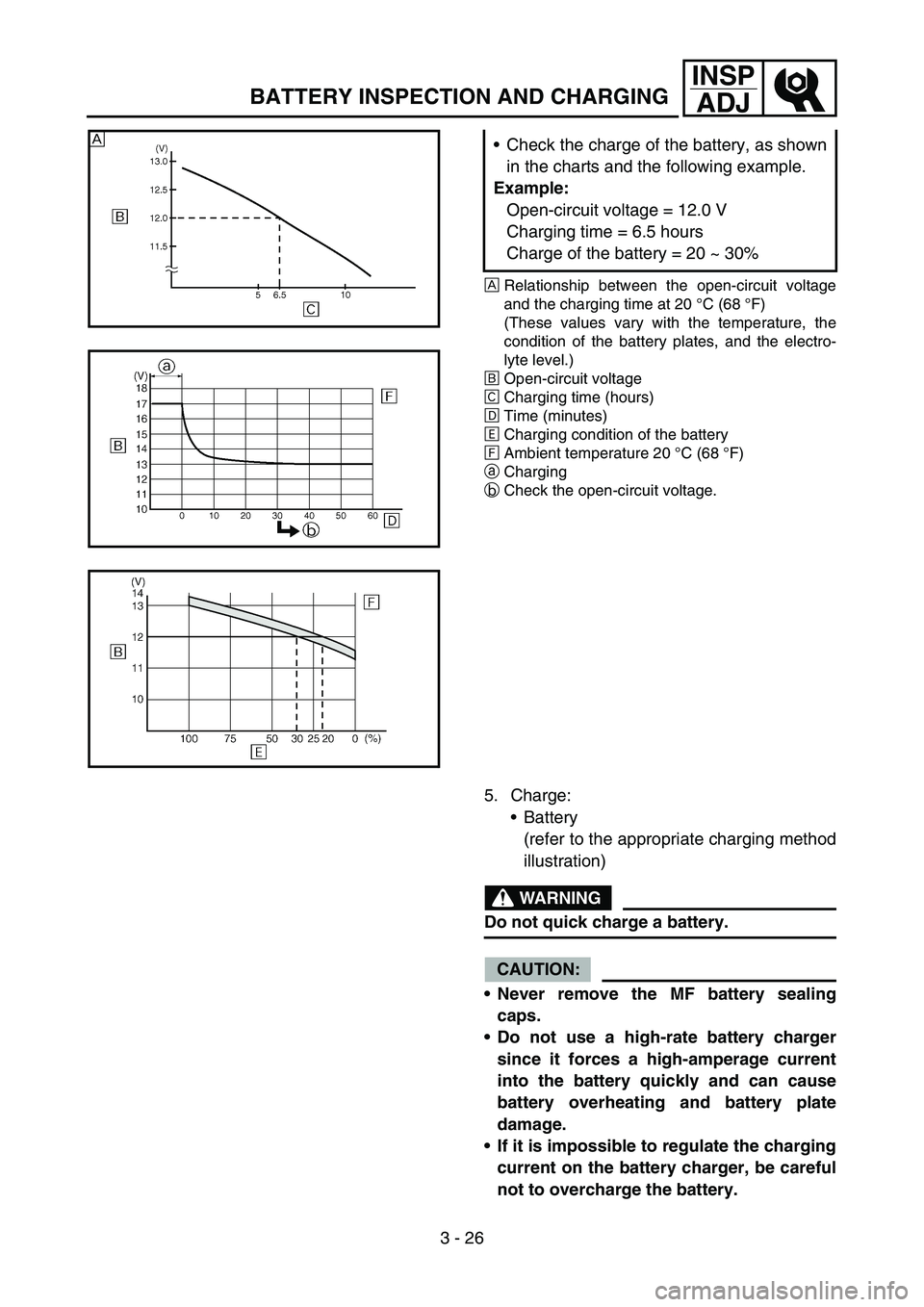

È Relationship between the open-circuit voltage

and the charging time at 20

°C (68 °F)

(These values vary with the temperature, the

condition of the battery plates, and the electro-

lyte level.)

É Open-circuit voltage

Ê Charging time (hours)

Ë Time (minutes)

Ì Charging condition of the battery

Í Ambient temperature 20

°C (68 °F)

a Charging

b Check the open-circuit voltage.

Check the charge of the battery, as shown

in the charts and the following example.

Example:

Open-circuit voltage = 12.0 V

Charging time = 6.5 hours

Charge of the battery = 20 ~ 30% È

5. Charge: Battery

(refer to the appropriate charging method

illustration)

WARNING

Do not quick charge a battery.

CAUTION:

Never remove the MF battery sealing

caps.

Do not use a high-rate battery charger

since it forces a high-amperage current

into the battery quickly and can cause

battery overheating and battery plate

damage.

If it is impossible to regulate the charging

current on the battery charger, be careful

not to overcharge the battery.

Page 186 of 390

3 - 31

INSPADJ

FUSE INSPECTION

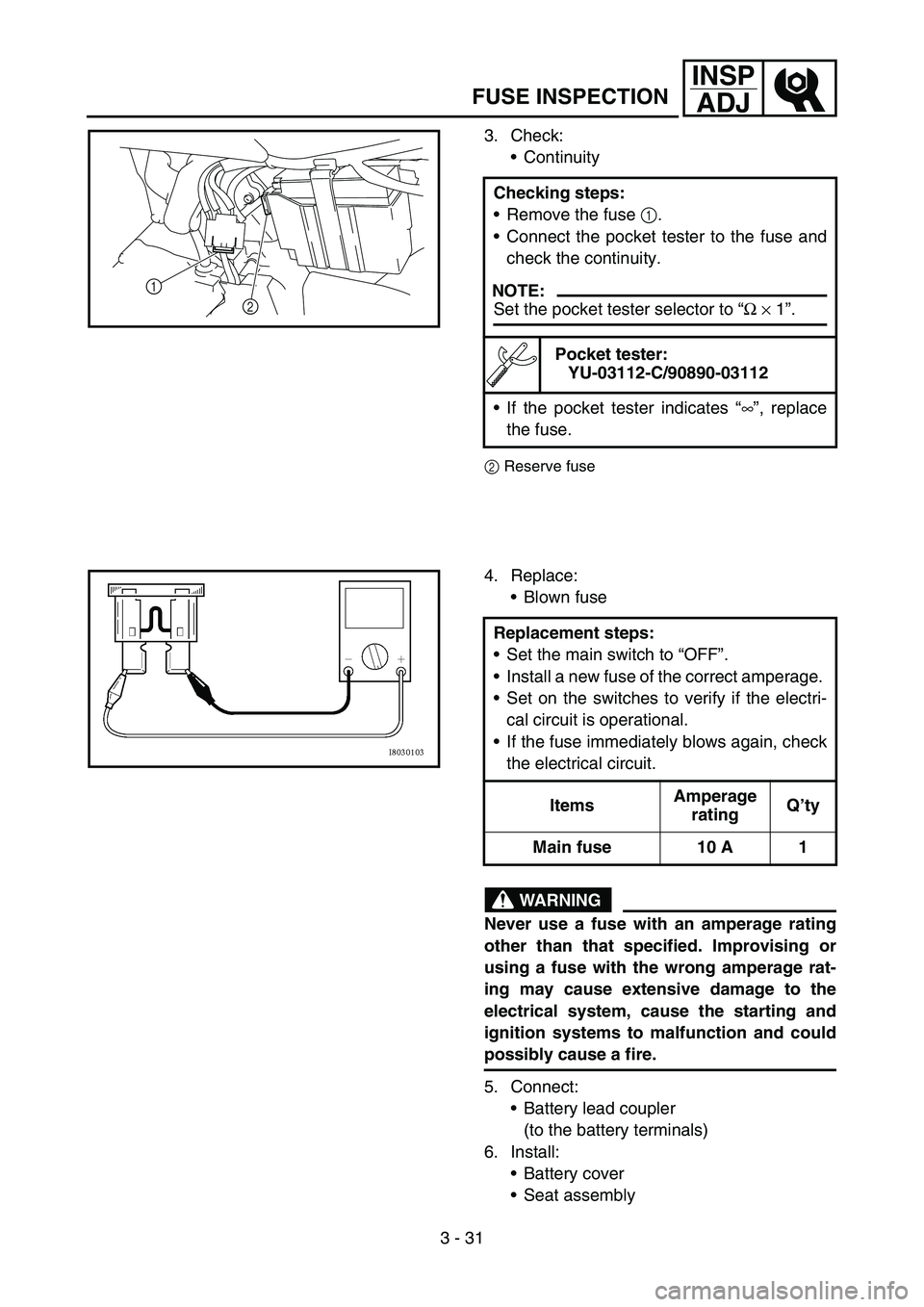

3. Check:

Continuity

2 Reserve fuse

Checking steps:

Remove the fuse 1

.

Connect the pocket tester to the fuse and

check the continuity.

NOTE:

Set the pocket tester selector to “Ω × 1 ”.

Pocket tester:

YU-03112-C/90890-03112

If the pocket tester indicates “∞ ”, replace

the fuse.

1 2

4. Replace:

Blown fuse

WARNING

Never use a fuse with an amperage rating

other than that specified. Improvising or

using a fuse with the wrong amperage rat-

ing may cause extensive damage to the

electrical system, cause the starting and

ignition systems to malfunction and could

possibly cause a fire.

5. Connect:

Battery lead coupler

(to the battery terminals)

6. Install: Battery cover

Seat assembly

Replacement steps:

Set the main switch to “OFF ”.

Install a new fuse of the correct amperage.

Set on the switches to verify if the electri-

cal circuit is operational.

If the fuse immediately blows again, check

the electrical circuit.

Items Amperage

rating Q

’ty

Main fuse 10 A 1

Page 204 of 390

4 - 9

ENGCARBURETOR

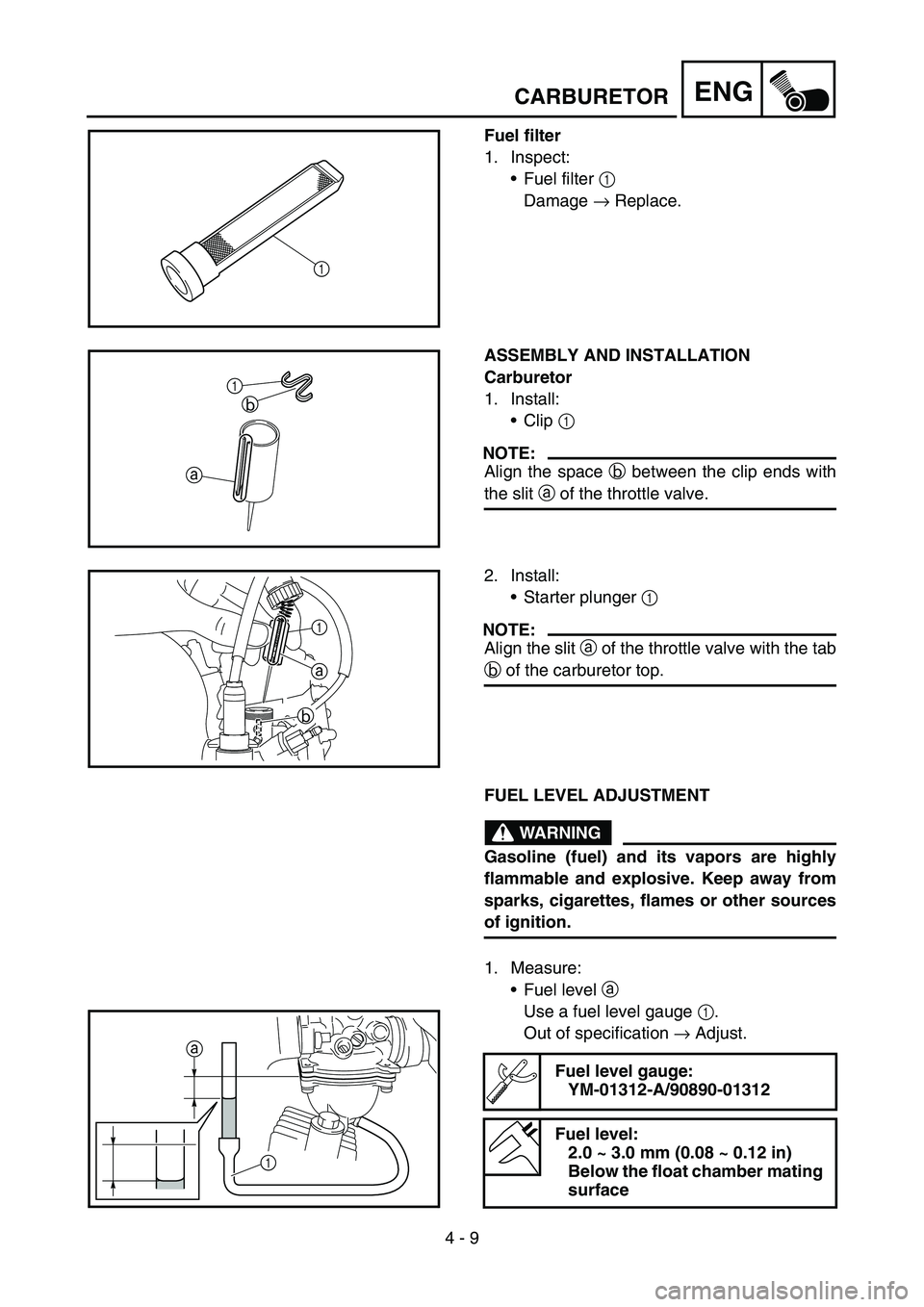

Fuel filter

1. Inspect:Fuel filter 1

Damage → Replace.

1

ASSEMBLY AND INSTALLATION

Carburetor

1. Install:

Clip 1

NOTE:

Align the space b between the clip ends with

the slit a of the throttle valve.

1

a

b

2. Install: Starter plunger 1

NOTE:

Align the slit a of the throttle valve with the tab

b of the carburetor top.

1

ba

FUEL LEVEL ADJUSTMENT

WARNING

Gasoline (fuel) and its vapors are highly

flammable and explosive. Keep away from

sparks, cigarettes, flames or other sources

of ignition.

1. Measure:

Fuel level a

Use a fuel level gauge 1.

Out of specification → Adjust.

Fuel level gauge:

YM-01312-A/90890-01312

Fuel level:2.0 ~ 3.0 mm (0.08 ~ 0.12 in)

Below the float chamber mating

surface

a

1

Page 302 of 390

5 - 1

CHAS

EC500000

CHASSIS

FRONT WHEEL AND REAR WHEEL

FRONT WHEEL AND FRONT BRAKE

Extent of removal:1 Front wheel removal

2 Wheel bearing removal

3 Brake shoe plate assembly removal and disassembly

Extent of removal Order Part name Q ’ty Remarks

FRONT WHEEL REMOVAL

WARNING

Support the machine securely so

there is no danger of it falling over.

Preparation for removal Hold the machine by placing the

suitable stand under the engine.

1 Front brake adjuster 1

2Pin 1

3Spring 1

4 Locknut 1

5 Brake cable 1 Disconnect at the lever side.

6 Front fork guard (left) 1

7 Front fork guard (right) 1

8 Wheel axle nut 1

9 Front wheel axle 1

21

FRONT WHEEL AND REAR WHEEL

Page 306 of 390

5 - 3

CHASFRONT WHEEL AND REAR WHEEL

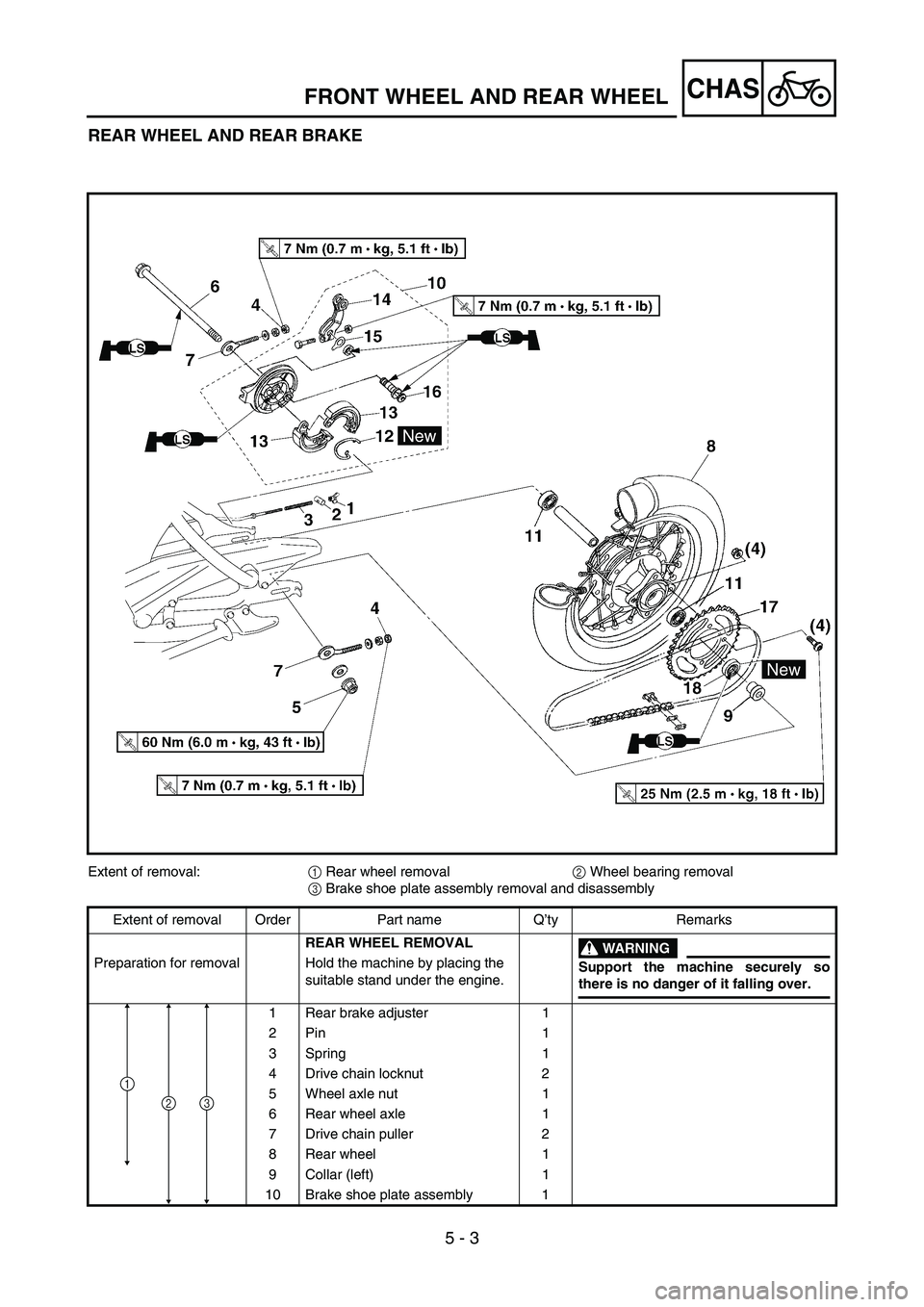

REAR WHEEL AND REAR BRAKE

Extent of removal:1 Rear wheel removal

2 Wheel bearing removal

3 Brake shoe plate assembly removal and disassembly

Extent of removal Order Part name Q ’ty Remarks

REAR WHEEL REMOVAL

WARNING

Support the machine securely so

there is no danger of it falling over.

Preparation for removal Hold the machine by placing the

suitable stand under the engine.

1 Rear brake adjuster 1

2Pin 1

3Spring 1

4 Drive chain locknut 2

5 Wheel axle nut 1

6 Rear wheel axle 1

7 Drive chain puller 2

8 Rear wheel 1

9 Collar (left) 1

10 Brake shoe plate assembly 1

2

1

3

Page 312 of 390

5 - 6

CHAS

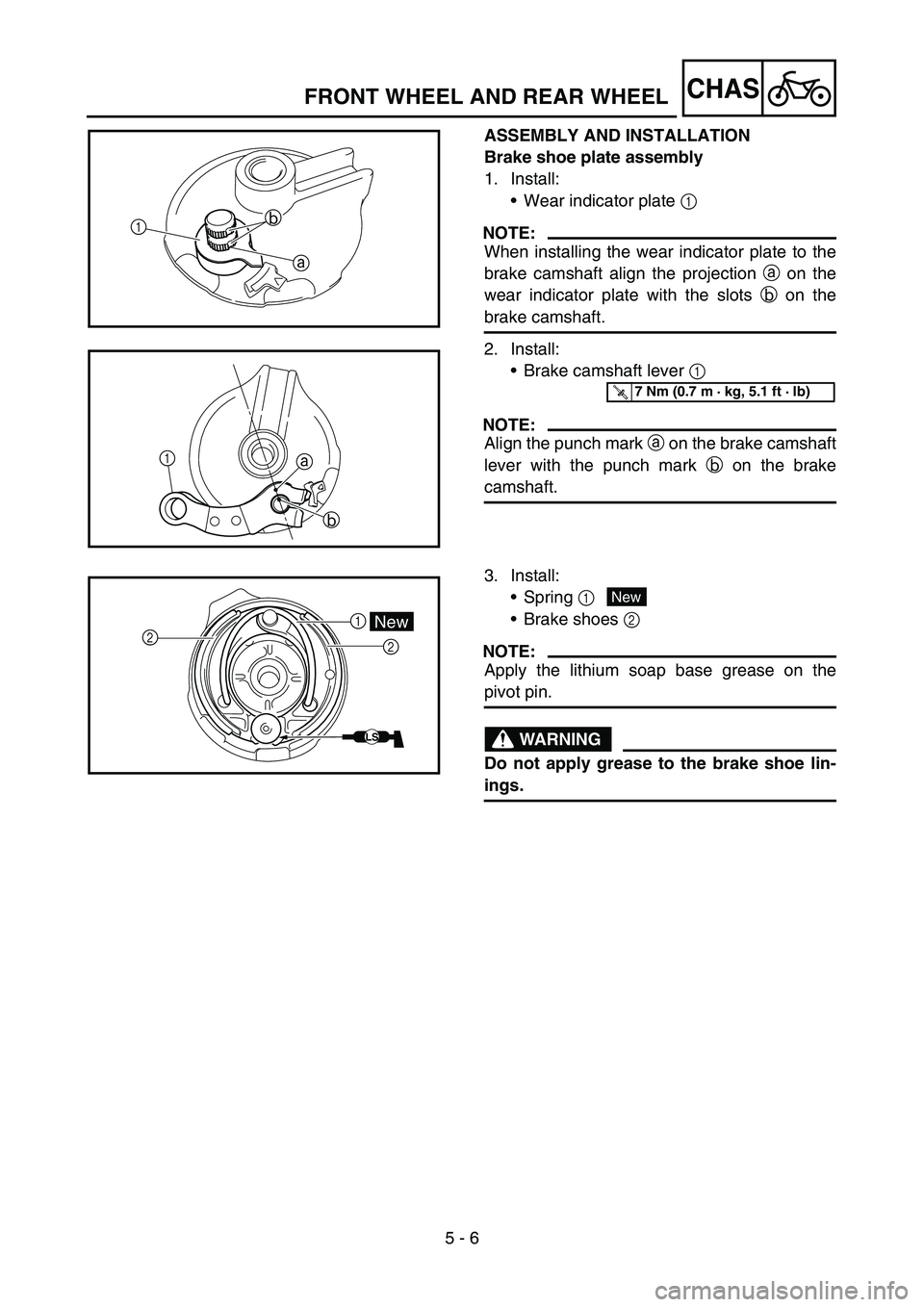

ASSEMBLY AND INSTALLATION

Brake shoe plate assembly

1. Install:Wear indicator plate 1

NOTE:

When installing the wear indicator plate to the

brake camshaft align the projection a on the

wear indicator plate with the slots b on the

brake camshaft.

2. Install:

Brake camshaft lever 1

NOTE:

Align the punch mark a on the brake camshaft

lever with the punch mark b on the brake

camshaft.

b

1

a

1a

b

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

3. Install:

Spring 1

Brake shoes 2

NOTE:

Apply the lithium soap base grease on the

pivot pin.

WARNING

Do not apply grease to the brake shoe lin-

ings.

1

2

2

LS

New

New

FRONT WHEEL AND REAR WHEEL

Page 322 of 390

5 - 11

CHAS

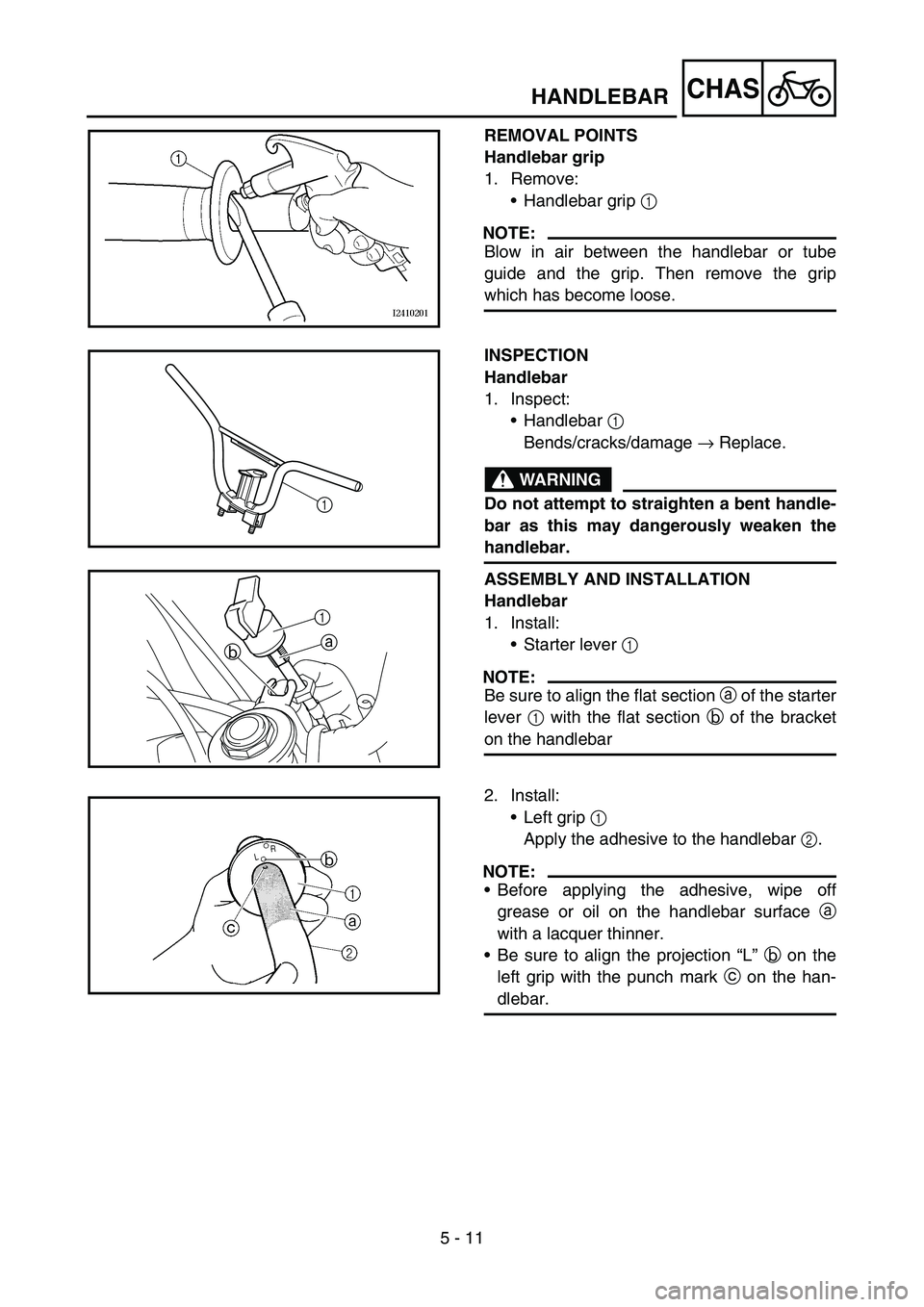

REMOVAL POINTS

Handlebar grip

1. Remove:Handlebar grip 1

NOTE:

Blow in air between the handlebar or tube

guide and the grip. Then remove the grip

which has become loose.

INSPECTION

Handlebar

1. Inspect:

Handlebar 1

Bends/cracks/damage → Replace.

WARNING

Do not attempt to straighten a bent handle-

bar as this may dangerously weaken the

handlebar.

ASSEMBLY AND INSTALLATION

Handlebar

1. Install:

Starter lever 1

NOTE:

Be sure to align the flat section a of the starter

lever 1 with the flat section b of the bracket

on the handlebar

1

a

b 1

2. Install:

Left grip 1

Apply the adhesive to the handlebar 2.

NOTE:

Before applying the adhesive, wipe off

grease or oil on the handlebar surface a

with a lacquer thinner.

Be sure to align the projection “L ” b on the

left grip with the punch mark c on the han-

dlebar.

HANDLEBAR

Page 324 of 390

5 - 12

CHAS

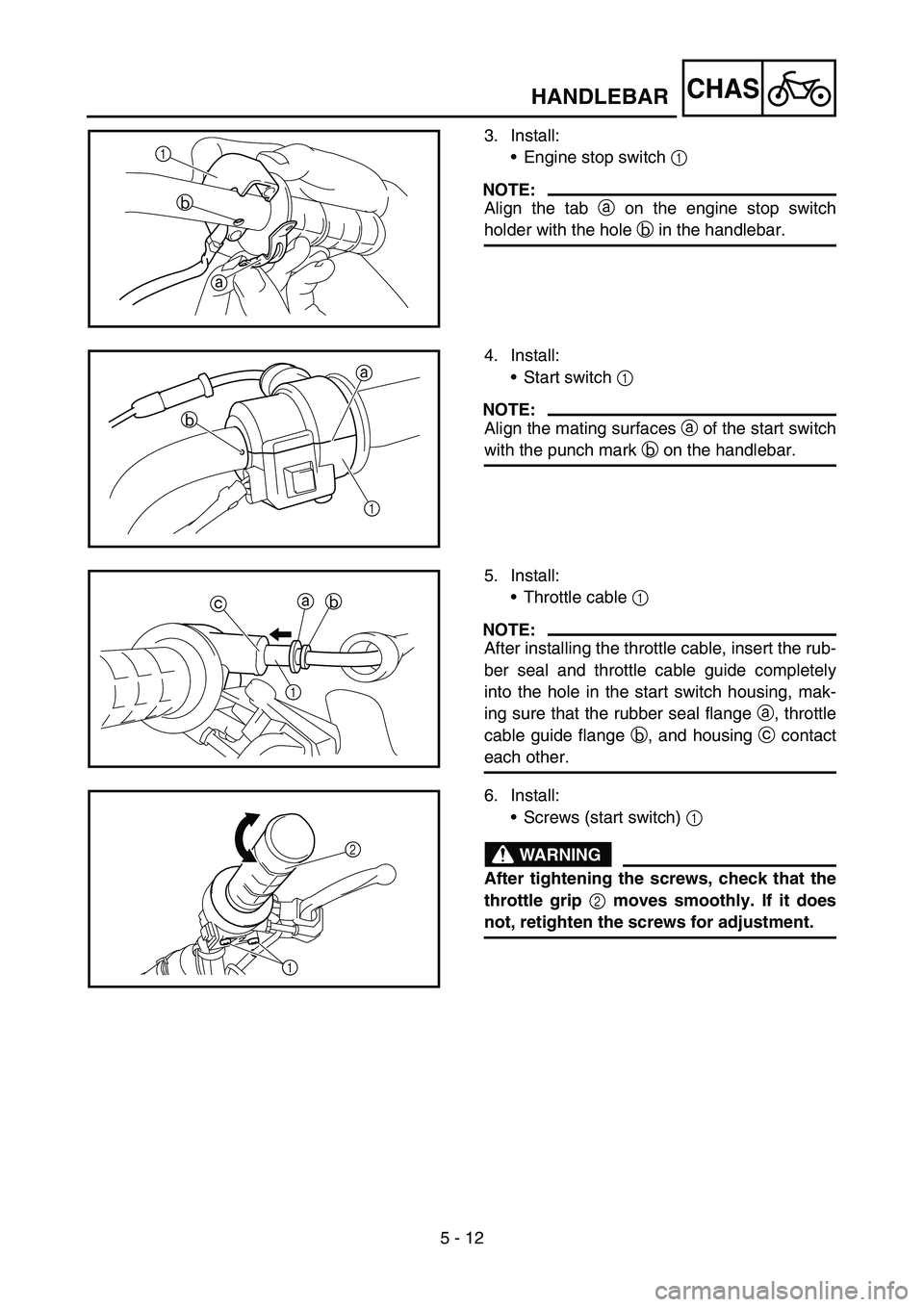

3. Install:Engine stop switch 1

NOTE:

Align the tab a on the engine stop switch

holder with the hole b in the handlebar.

a

b

1

4. Install:

Start switch 1

NOTE:

Align the mating surfaces a of the start switch

with the punch mark b on the handlebar.

1

b a

5. Install:

Throttle cable 1

NOTE:

After installing the throttle cable, insert the rub-

ber seal and throttle cable guide completely

into the hole in the start switch housing, mak-

ing sure that the rubber seal flange a, throttle

cable guide flange b, and housing c contact

each other.

a

c b

1

6. Install:

Screws (start switch) 1

WARNING

After tightening the screws, check that the

throttle grip 2 moves smoothly. If it does

not, retighten the screws for adjustment.

2

1

HANDLEBAR