engine oil YAMAHA TTR50 2006 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR50, Model: YAMAHA TTR50 2006Pages: 390, PDF Size: 9.69 MB

Page 218 of 390

4 - 16

ENGCAMSHAFT AND ROCKER ARMS

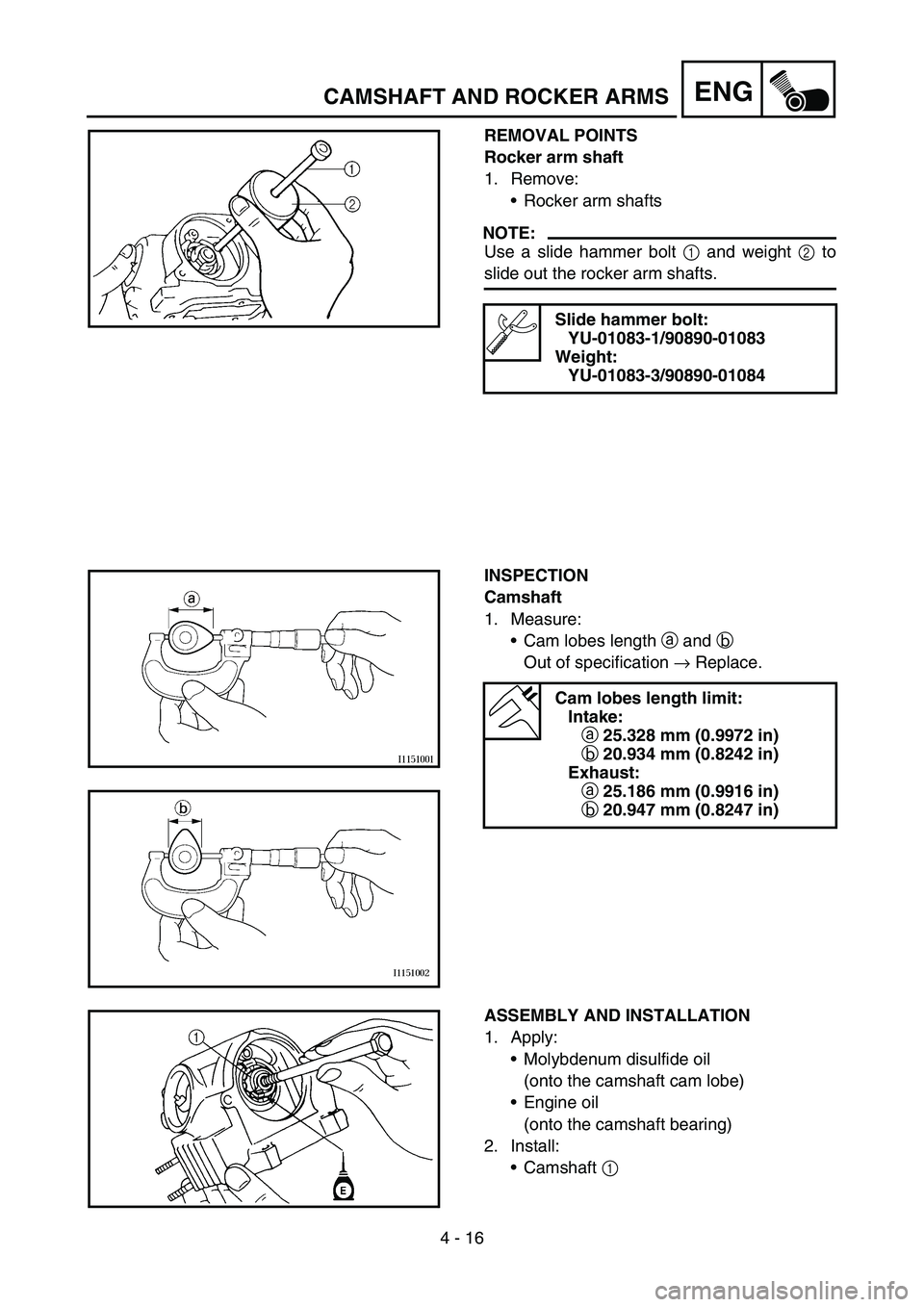

REMOVAL POINTS

Rocker arm shaft

1. Remove:Rocker arm shafts

NOTE:

Use a slide hammer bolt 1 and weight 2 to

slide out the rocker arm shafts.

Slide hammer bolt:

YU-01083-1/90890-01083

Weight: YU-01083-3/90890-01084

INSPECTION

Camshaft

1. Measure:

Cam lobes length a and b

Out of specification → Replace.

Cam lobes length limit:

Intake:

a 25.328 mm (0.9972 in)

b 20.934 mm (0.8242 in)

Exhaust:

a 25.186 mm (0.9916 in)

b 20.947 mm (0.8247 in)

ASSEMBLY AND INSTALLATION

1. Apply:

Molybdenum disulfide oil

(onto the camshaft cam lobe)

Engine oil

(onto the camshaft bearing)

2. Install: Camshaft 1

Page 240 of 390

4 - 27

ENGCYLINDER AND PISTON

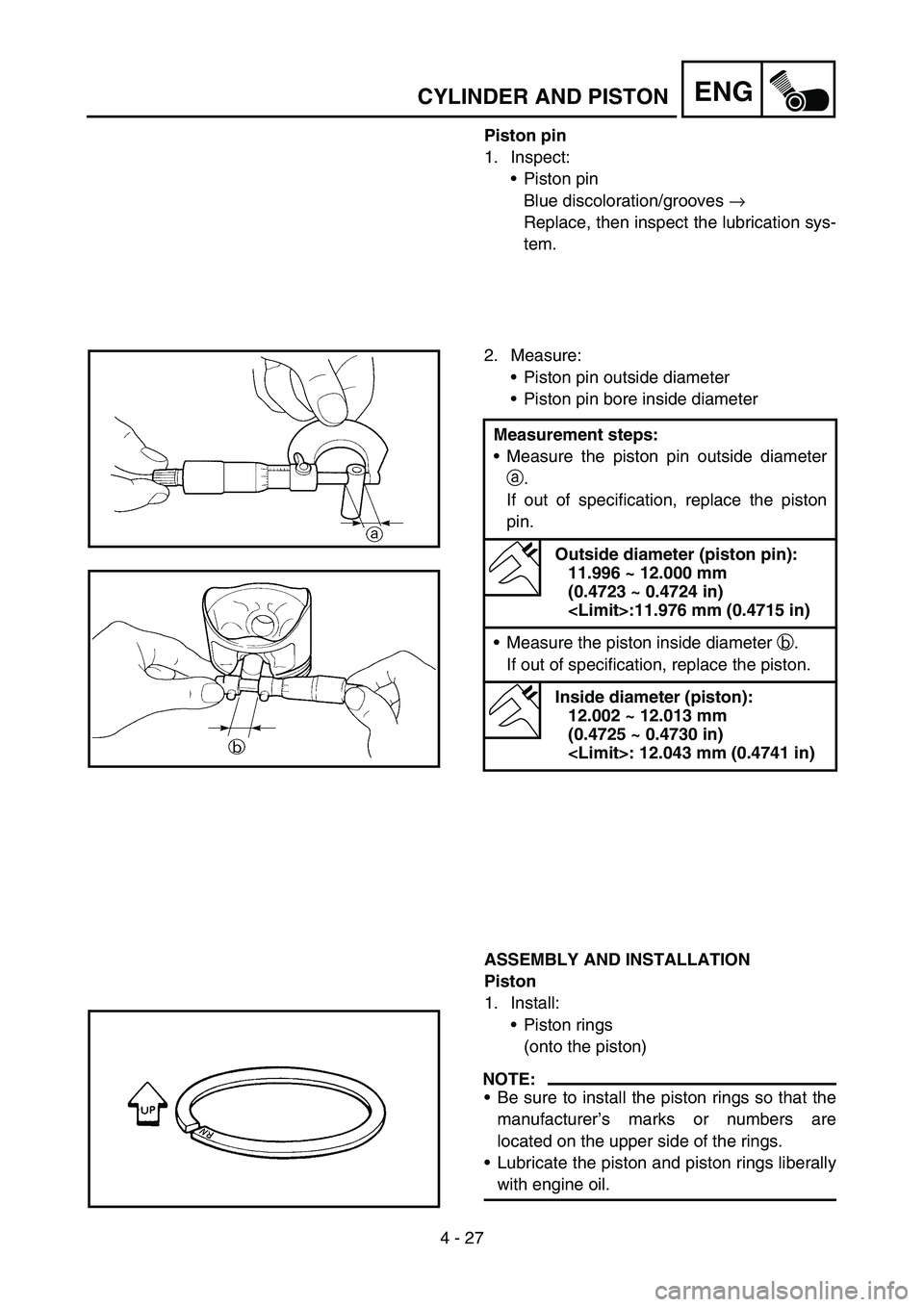

Piston pin

1. Inspect:Piston pin

Blue discoloration/grooves →

Replace, then inspect the lubrication sys-

tem.

2. Measure: Piston pin outside diameter

Piston pin bore inside diameter

ASSEMBLY AND INSTALLATION

Piston

1. Install: Piston rings

(onto the piston)

NOTE:

Be sure to install the piston rings so that the

manufacturer ’s marks or numbers are

located on the upper side of the rings.

Lubricate the piston and piston rings liberally

with engine oil.

Measurement steps:

Measure the piston pin outside diameter

a .

If out of specification, replace the piston

pin.

Outside diameter (piston pin): 11.996 ~ 12.000 mm

(0.4723 ~ 0.4724 in)

Measure the piston inside diameter b.

If out of specification, replace the piston.

Inside diameter (piston): 12.002 ~ 12.013 mm

(0.4725 ~ 0.4730 in)

Page 242 of 390

4 - 28

ENGCYLINDER AND PISTON

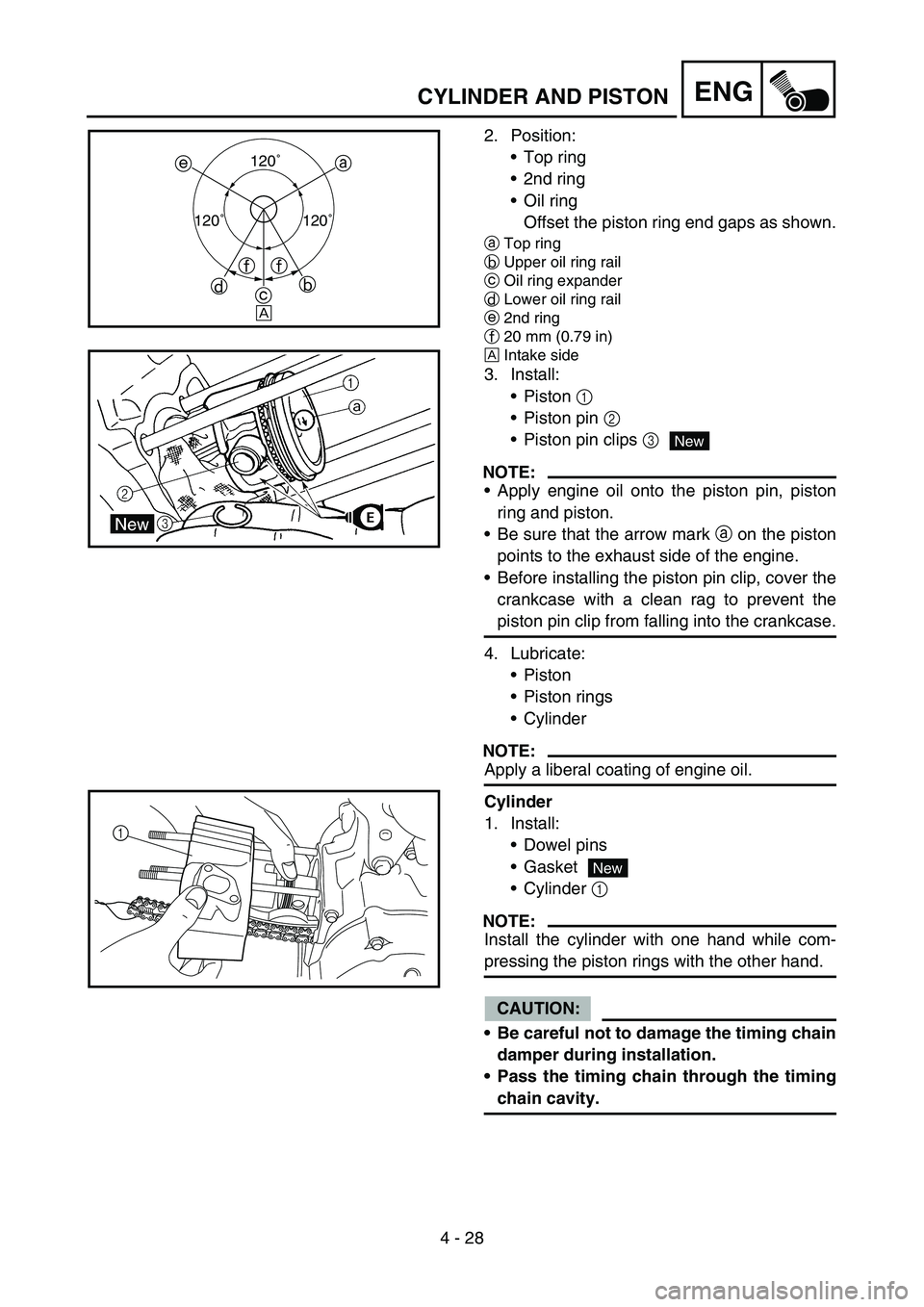

2. Position:Top ring

2nd ring

Oil ring

Offset the piston ring end gaps as shown.

a Top ring

b Upper oil ring rail

c Oil ring expander

d Lower oil ring rail

e 2nd ring

f 20 mm (0.79 in)

È Intake side

3. Install:

Piston 1

Piston pin 2

Piston pin clips 3

NOTE:

Apply engine oil onto the piston pin, piston

ring and piston.

Be sure that the arrow mark

a on the piston

points to the exhaust side of the engine.

Before installing the piston pin clip, cover the

crankcase with a clean rag to prevent the

piston pin clip from falling into the crankcase.

4. Lubricate: Piston

Piston rings

Cylinder

NOTE:

Apply a liberal coating of engine oil.

Cylinder

1. Install:

Dowel pins

Gasket

Cylinder 1

NOTE:

Install the cylinder with one hand while com-

pressing the piston rings with the other hand.

CAUTION:

Be careful not to damage the timing chain

damper during installation.

Pass the timing chain through the timing

chain cavity.

e a

ff

d cb120

˚

120 ˚ 120˚

È

New

1

New

Page 278 of 390

4 - 46

ENGAC MAGNETO AND STARTER CLUTCH

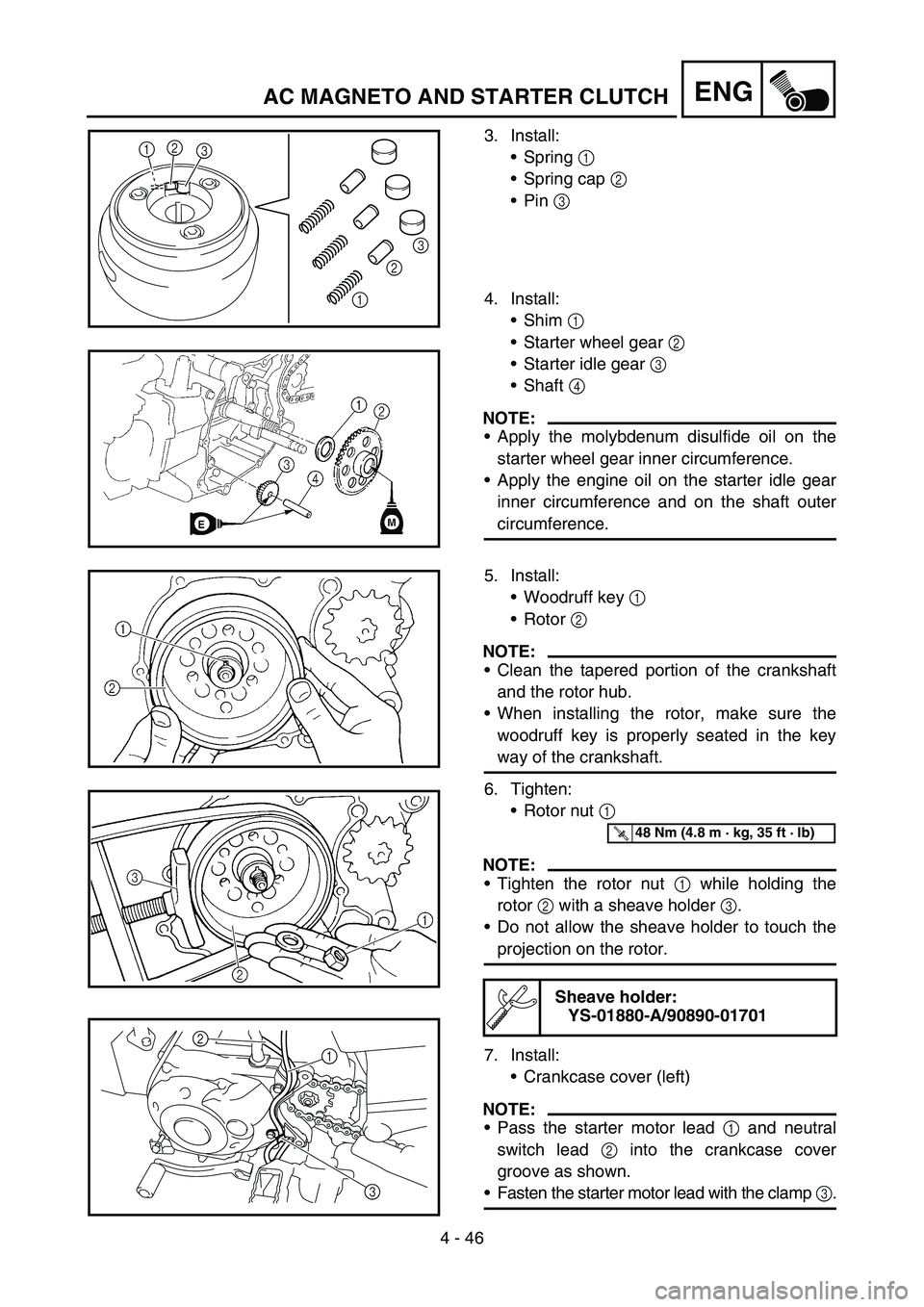

3. Install:Spring 1

Spring cap 2

Pin 3

4. Install: Shim 1

Starter wheel gear 2

Starter idle gear 3

Shaft 4

NOTE:

Apply the molybdenum disulfide oil on the

starter wheel gear inner circumference.

Apply the engine oil on the starter idle gear

inner circumference and on the shaft outer

circumference.

1 2

3

12

3

5. Install:

Woodruff key 1

Rotor 2

NOTE:

Clean the tapered portion of the crankshaft

and the rotor hub.

When installing the rotor, make sure the

woodruff key is properly seated in the key

way of the crankshaft.

6. Tighten: Rotor nut 1

NOTE:

Tighten the rotor nut 1 while holding the

rotor 2 with a sheave holder 3.

Do not allow the sheave holder to touch the

projection on the rotor.

7. Install: Crankcase cover (left)

NOTE:

Pass the starter motor lead 1 and neutral

switch lead 2 into the crankcase cover

groove as shown.

Fasten the starter motor lead with the clamp 3.

Sheave holder:

YS-01880-A/90890-01701

T R..48 Nm (4.8 m · kg, 35 ft · lb)

3

1

2

Page 282 of 390

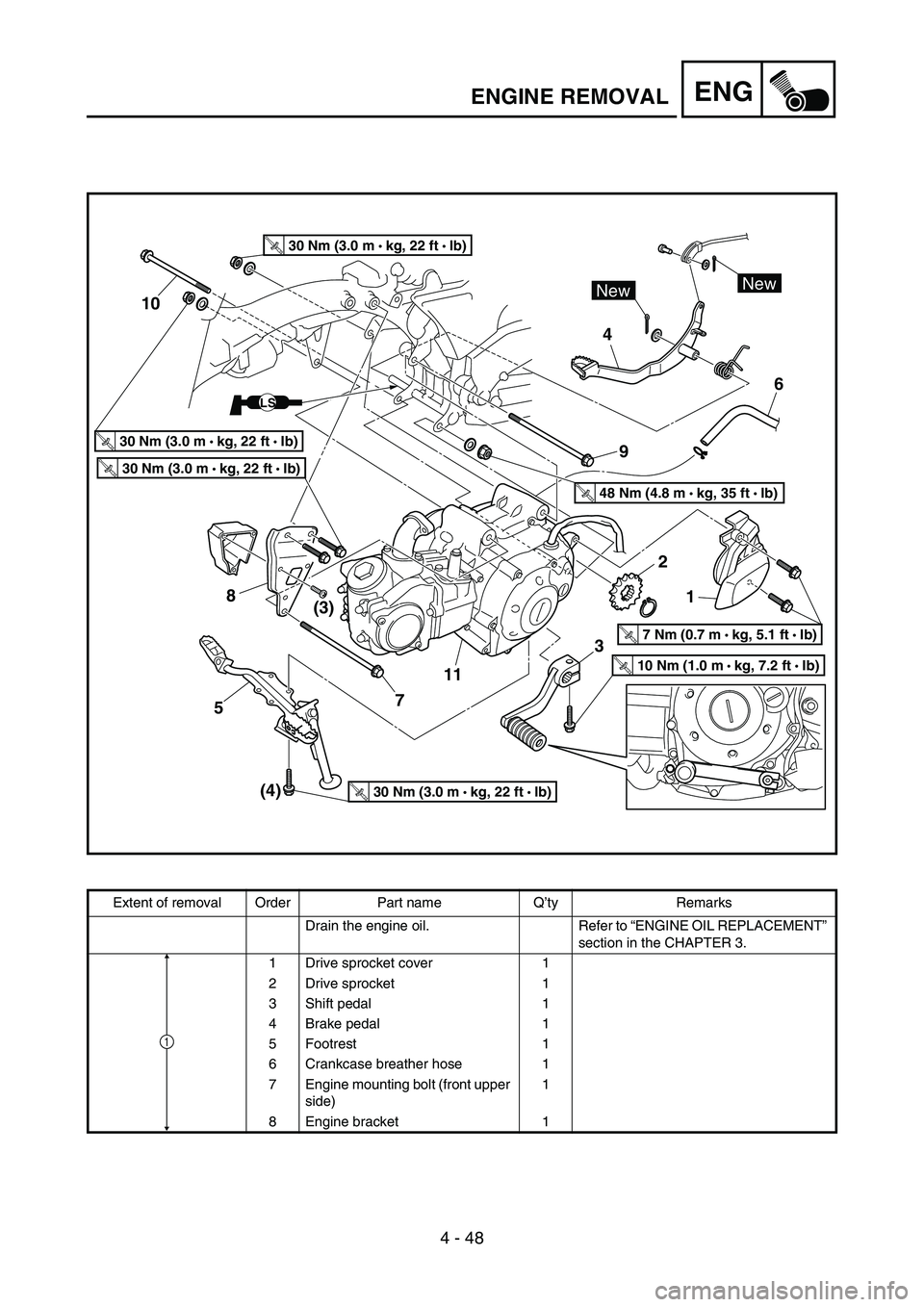

4 - 48

ENGENGINE REMOVAL

(4)

NewNew

LS

T R..30 Nm (3.0 m • kg, 22 ft • Ib)

T R..30 Nm (3.0 m •

kg, 22 ft • Ib)

T R..30 Nm (3.0 m •

kg, 22 ft • Ib)

T R..30 Nm (3.0 m •

kg, 22 ft • Ib)

T R..48 Nm (4.8 m •

kg, 35 ft • Ib)

T R..7 Nm (0.7 m •

kg, 5.1 ft • Ib)

T R..10 Nm (1.0 m • kg, 7.2 ft • Ib)

(3)

10

4

1 6

2

9

3

11

7

5 8

Extent of removal Order Part name Q

’ty Remarks

Drain the engine oil. Refer to “ENGINE OIL REPLACEMENT ”

section in the CHAPTER 3.

1 Drive sprocket cover 1

2 Drive sprocket 1

3 Shift pedal 1

4 Brake pedal 1

5 Footrest 1

6 Crankcase breather hose 1

7 Engine mounting bolt (front upper side) 1

8 Engine bracket 1

1

Page 288 of 390

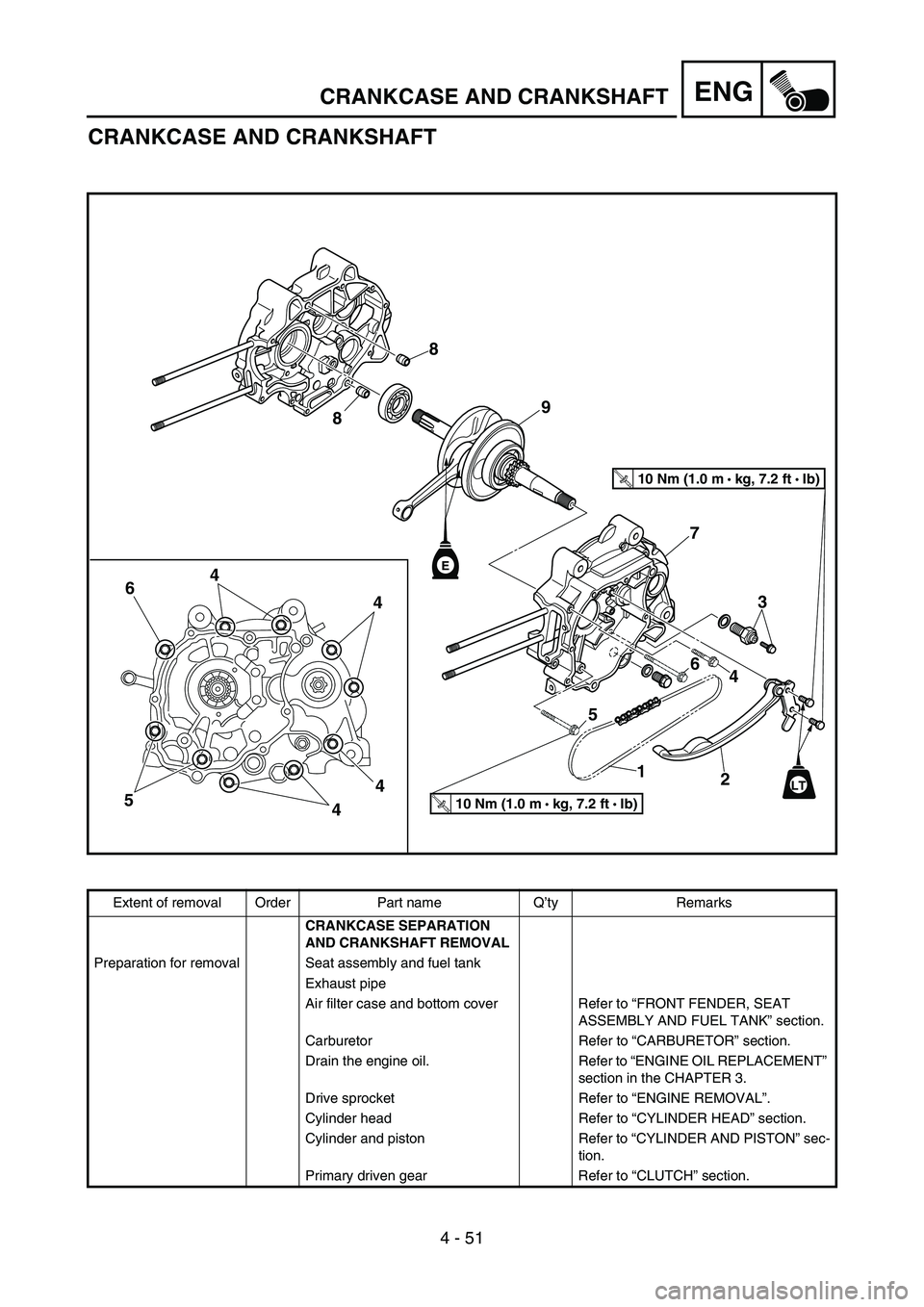

4 - 51

ENGCRANKCASE AND CRANKSHAFT

CRANKCASE AND CRANKSHAFT

E

T R..10 Nm (1.0 m • kg, 7.2 ft • Ib)

T R..10 Nm (1.0 m •

kg, 7.2 ft • Ib)

LT

4

4 3

4

4

5 6

7

9

8

8

12

5 6

4

Extent of removal Order Part name Q ’ty Remarks

CRANKCASE SEPARATION

AND CRANKSHAFT REMOVAL

Preparation for removal Seat assembly and fuel tank

Exhaust pipe

Air filter case and bottom cover Refer to “FRONT FENDER, SEAT

ASSEMBLY AND FUEL TANK ” section.

Carburetor Refer to “CARBURETOR ” section.

Drain the engine oil. Refer to “ENGINE OIL REPLACEMENT ”

section in the CHAPTER 3.

Drive sprocket Refer to “ENGINE REMOVAL ”.

Cylinder head Refer to “CYLINDER HEAD ” section.

Cylinder and piston Refer to “CYLINDER AND PISTON ” sec-

tion.

Primary driven gear Refer to “CLUTCH ” section.

Page 340 of 390

6 - 1

–+ELEC

345

6

78

\b0

B\f

2

1

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC611000

ELECTRICAL COMPONENTS

1 Thermo switch

2 Main switch

3 Engine stop switch

4 Ignition coil

5 Ground lead

6 Fuse

7 Battery

8 CDI unit

9 Starter relay 0

Rectifier/regulator

A Neutral switch

B AC magneto

C Carburetor heater

D Start switch

E Spark plug

F Starter motorCOLOR CODE

B ...................... Black

Br .................... Brown

O ..................... Orange

R ..................... Red

Sb .................... Sky blue

W ..................... White

Y ...................... Yellow

EC612000

WIRING DIAGRAM

R

WR

W

BL /WSb B

RW

W

W

OO

B

B

Y /R

R

W

B

R

Y /RY /R

Y

ON

OFF

OFF ON

Y

B

BY

/RRB

SbY /RR B

W

B

B

RBrR

Br

R

/WBr

R /W

L /W

OFF

RUN

Sb

BrBr

Sb

WBY

/RW SbY

B

B

B

RR

RR

R

R

R

/W

L /W

RRRB

R /W

L

/WR

R

RR

B Br

BO

R

WB

\f

2 8

4

E

1

C

D

0

63

\b F

5 7

Br

L/W .................. Blue/White

R/W .................. Red/White

Y/R ................... Yellow/Red

E

F

D

C

Page 342 of 390

–+ELEC

6 - 2

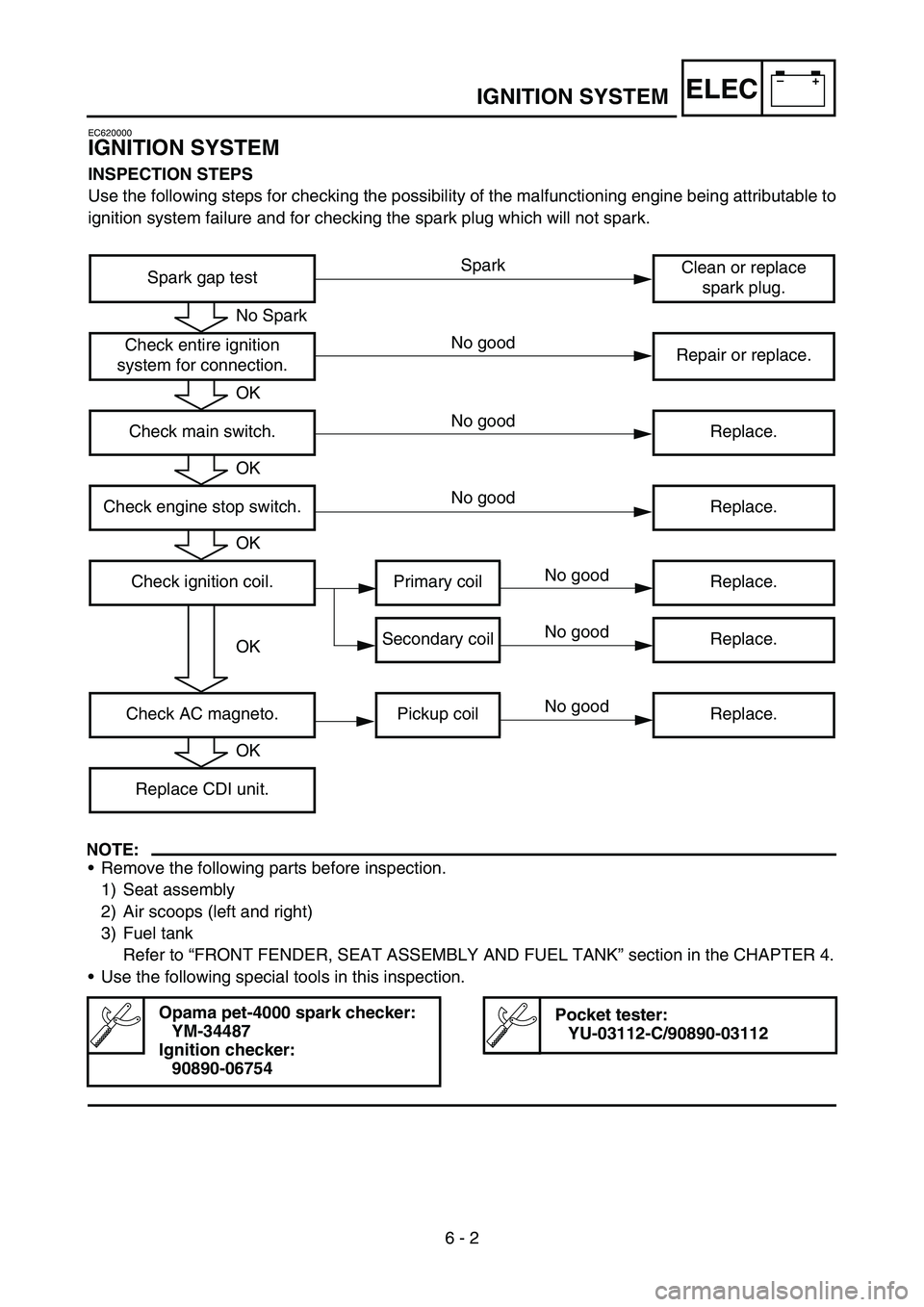

IGNITION SYSTEM

EC620000

IGNITION SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning engine being attributable to

ignition system failure and for checking the spark plug which will not spark.

NOTE:

Remove the following parts before inspection.

1) Seat assembly

2) Air scoops (left and right)

3) Fuel tank

Refer to “FRONT FENDER, SEAT ASSEMBLY AND FUEL TANK ” section in the CHAPTER 4.

Use the following special tools in this inspection.

Opama pet-4000 spark checker:

YM-34487

Ignition checker: 90890-06754Pocket tester:YU-03112-C/90890-03112

Spark gap test Clean or replace

spark plug.

Check entire ignition

system for connection. Repair or replace.

Check main switch. Replace.

Check engine stop switch. Replace.

Check ignition coil. Primary coil Replace. Secondary coil Replace.

Check AC magneto. Pickup coil Replace. Replace CDI unit.

No Spark

OK

OK

OK

OK

OK

Spark

No good

No good

No good

No good

No good

No good

Page 348 of 390

6 - 4

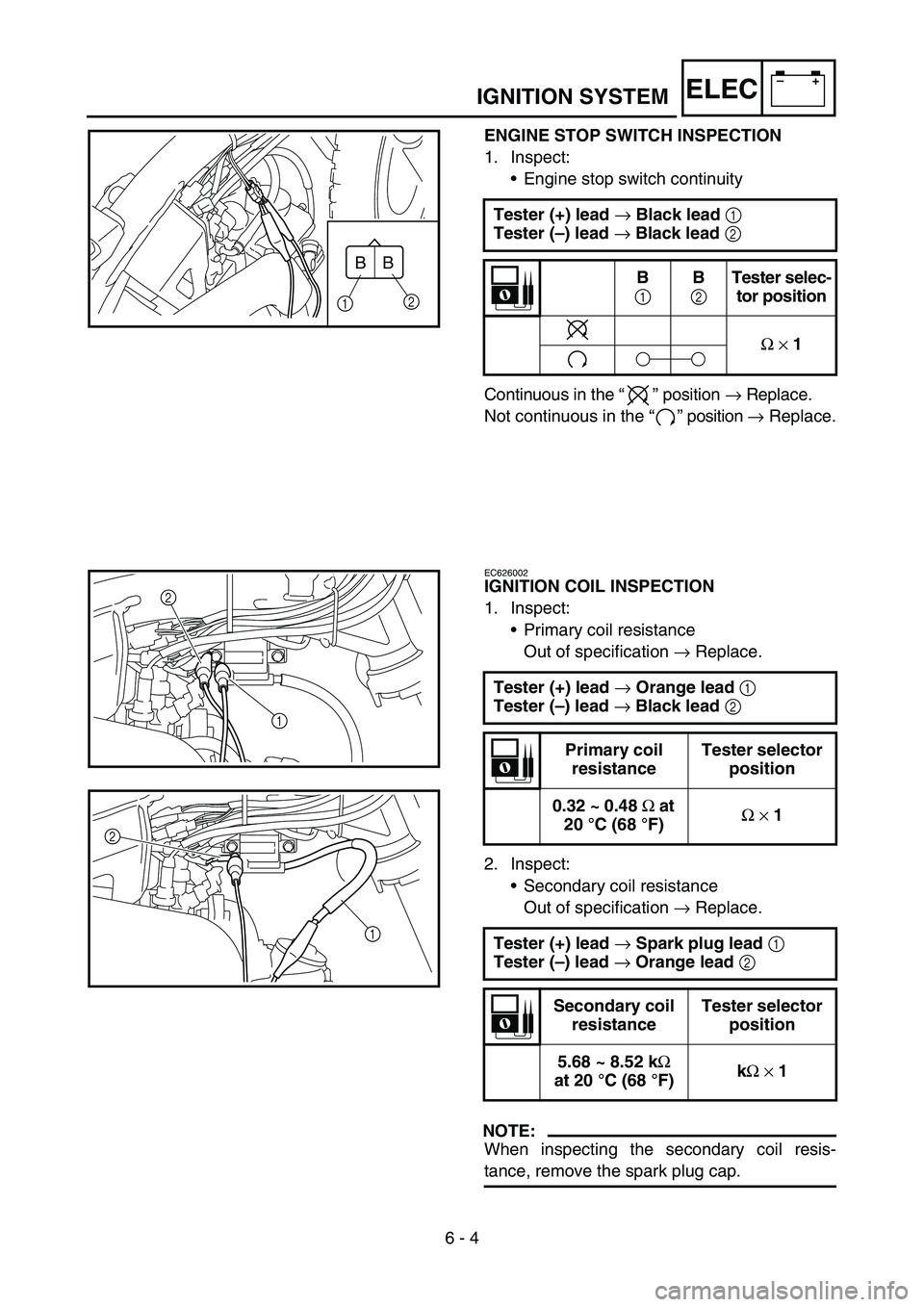

–+ELECIGNITION SYSTEM

ENGINE STOP SWITCH INSPECTION

1. Inspect:

Engine stop switch continuity

Continuous in the “” position → Replace.

Not continuous in the “” position → Replace.

Tester (+) lead

→ Black lead

1

Tester ( –) lead

→ Black lead

2

B

1 B

2 Tester selec-

tor position

Ω

× 1B

B

1 2

EC626002

IGNITION COIL INSPECTION

1. Inspect:

Primary coil resistance

Out of specification → Replace.

2. Inspect: Secondary coil resistance

Out of specification → Replace.

NOTE:

When inspecting the secondary coil resis-

tance, remove the spark plug cap.Tester (+) lead

→ Orange lead

1

Tester ( –) lead

→ Black lead

2

Primary coil

resistance Tester selector

position

0.32 ~ 0.48 Ω at

20 °C (68 °F) Ω

× 1

Tester (+) lead → Spark plug lead

1

Tester ( –) lead

→ Orange lead

2

Secondary coil

resistance Tester selector

position

5.68 ~ 8.52 k Ω

at 20 °C (68 °F) k

Ω

× 1

1

2

1

2

Page 362 of 390

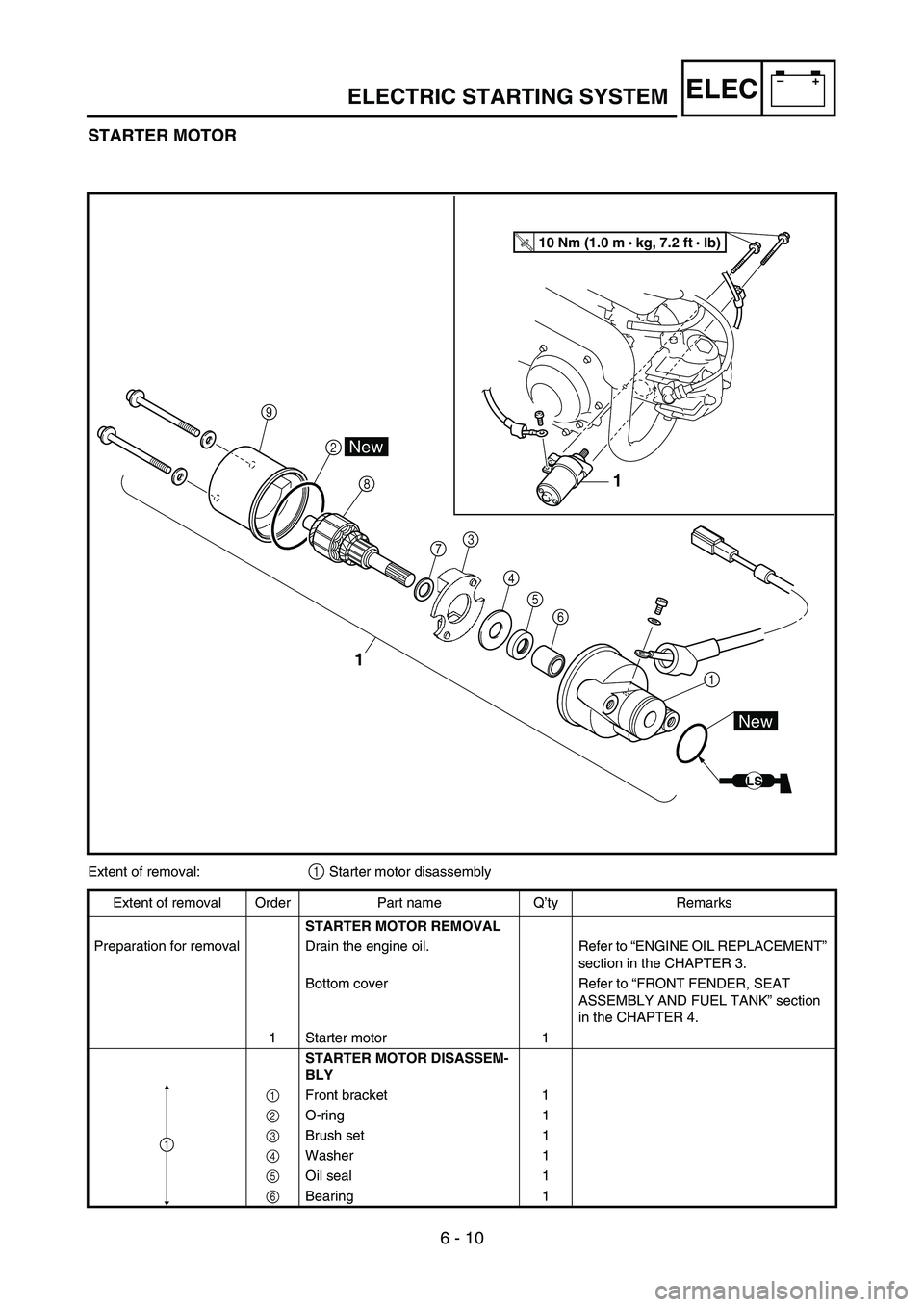

6 - 10

–+ELEC

STARTER MOTOR

1

3

45 6

8

2

\b

1

1

LS

New

New

T R..10 Nm (1.0 m •

kg, 7.2 ft • Ib)

7

Extent of removal:1 Starter motor disassembly

Extent of removal Order Part name Q ’ty Remarks

STARTER MOTOR REMOVAL

Preparation for removal Drain the engine oil. Refer to “ENGINE OIL REPLACEMENT ”

section in the CHAPTER 3.

Bottom cover Refer to “FRONT FENDER, SEAT

ASSEMBLY AND FUEL TANK ” section

in the CHAPTER 4.

1 Starter motor 1 STARTER MOTOR DISASSEM-

BLY

1 Front bracket 1

2 O-ring 1

3 Brush set 1

4 Washer 1

5 Oil seal 1

6 Bearing 1

1

ELECTRIC STARTING SYSTEM