check engine light YAMAHA TTR50 2006 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR50, Model: YAMAHA TTR50 2006Pages: 390, PDF Size: 9.69 MB

Page 50 of 390

GEN

INFO

1 - 12

STARTING AND OPERATION

STARTING AND OPERATION

CAUTION:

Prior to operating the machine, perform

steps listed in pre-operation check list.

WARNING

Never start your engine or let it run for any

length of time in a closed area. The exhaust

fumes are poisonous and can cause loss of

consciousness and death within a short

time. Always operate your machine in an

area with adequate ventilation.

STARTING A COLD ENGINE

WARNING

Before starting the engine, be sure to shift

the transmission into neutral.

NOTE:

This model is equipped with an ignition cir-

cuit cut-off system. In case of electric start-

ing, the engine can be started only when the

transmission is in neutral.

If the engine fails to start by pushing the start

switch, release the switch, wait a few sec-

onds, and then try again. Each starting

attempt should be as short as possible to

preserve the battery. Do not crank the

engine more than 10 seconds on any one

attempt.

1. Turn the fuel cock to “ON ”.

2. Turn the main switch to “ON ”.

3. Shift the transmission into neutral.

4. Operate the starter (choke) and completely close the throttle grip.

5. Slide the “engine stop ” switch to the “”.

6. Start the engine by pushing the start switch.

7. After the engine starts, warm up for one or

two minutes. Make sure the stater (choke) is

returned to the original position before riding. STARTING A WARM ENGINE

To start a warm engine, refer to the

“START-

ING A COLD ENGINE ” section. The starter

(choke) should not be used. The throttle

should be opened slightly.

CAUTION:

See “Engine break-in Section ” prior to

operating engine for the first time.

WARMING UP

To get maximum engine life, always “warm-up ”

the engine before starting off. Never accelerate

hard with a cold engine! To see whether or not

the engine is warm, see if it responds to throttle

normally with the stater (choke) turned off.

WARNING

Before starting off, be sure to turn up or

remove the side stand.

Failure to retract the side stand completely

can result in a serious accident when you

try to turn a corner.

ENGINE BREAK-IN

Break-in is important to better fit the moving

and sliding parts as well as the installed parts.

It is also important to accustom the rider to the

machine better.

Avoid full-throttle run on a new machine for the

first 5 hours.

After the trial run, check for loose parts, oil

leakage and other problems.

Make full inspection and adjustment especially of

slack cables and drive chain and loose spokes.

CAUTION:

After the break-in period, check every fit-

ting and fastener for looseness.

If any loose is found, retighten it securely.

Page 120 of 390

3 - 1

INSPADJ

MAINTENANCE INTERVALS

EC300000

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

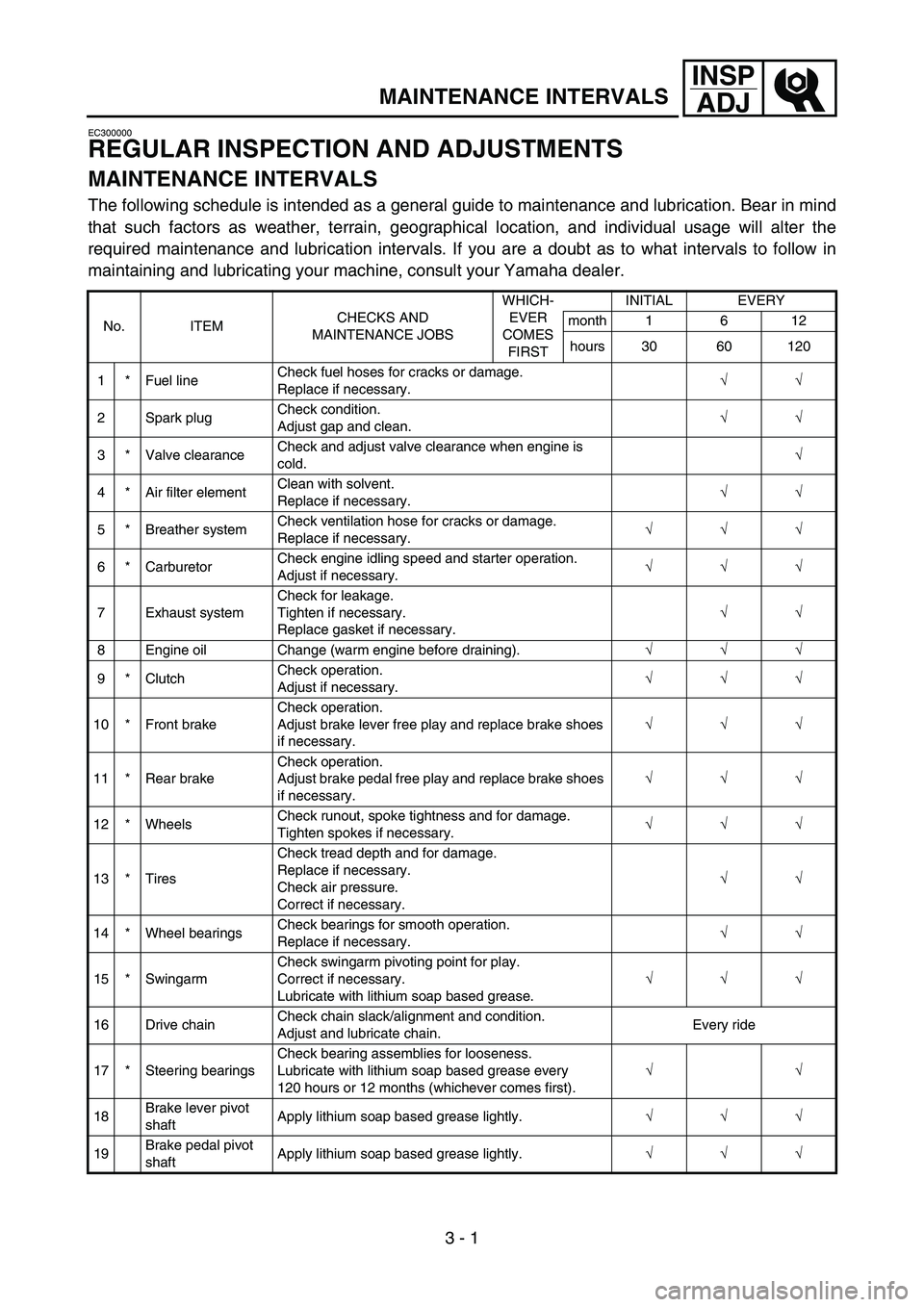

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the

required maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your Yamaha dealer.

No. ITEM CHECKS AND

MAINTENANCE JOBS WHICH-

EVER

COMES

FIRST INITIAL EVERY

month 1 6 12

hours 30 60 120

1 * Fuel line Check fuel hoses for cracks or damage.

Replace if necessary.

√

√

2 Spark plug Check condition.

Adjust gap and clean.

√

√

3 * Valve clearance Check and adjust valve clearance when engine is

cold.

√

4 * Air filter element Clean with solvent.

Replace if necessary.

√

√

5 * Breather system Check ventilation hose for cracks or damage.

Replace if necessary.

√

√

√

6 * Carburetor Check engine idling speed and starter operation.

Adjust if necessary.

√

√

√

7 Exhaust system Check for leakage.

Tighten if necessary.

Replace gasket if necessary.

√

√

8 Engine oil Change (warm engine before draining). √

√

√

9 * Clutch Check operation.

Adjust if necessary.

√

√

√

10 * Front brake Check operation.

Adjust brake lever free play and replace brake shoes

if necessary.

√

√

√

11 * Rear brake Check operation.

Adjust brake pedal free play and replace brake shoes

if necessary. √

√

√

12 * Wheels Check runout, spoke tightness and for damage.

Tighten spokes if necessary.

√

√

√

13 * Tires Check tread depth and for damage.

Replace if necessary.

Check air pressure.

Correct if necessary.

√

√

14 * Wheel bearings Check bearings for smooth operation.

Replace if necessary.

√

√

15 * Swingarm Check swingarm pivoting point for play.

Correct if necessary.

Lubricate with lithium soap based grease. √

√

√

16 Drive chain Check chain slack/alignment and condition.

Adjust and lubricate chain. Every ride

17 * Steering bearings Check bearing assemblies for looseness.

Lubricate with lithium soap based grease every

120 hours or 12 months (whichever comes first).

√

√

18 Brake lever pivot

shaft Apply lithium soap based grease lightly.

√

√

√

19 Brake pedal pivot

shaft Apply lithium soap based grease lightly.

√

√

√

3

Page 121 of 390

3 - 2

INSPADJ

MAINTENANCE INTERVALS

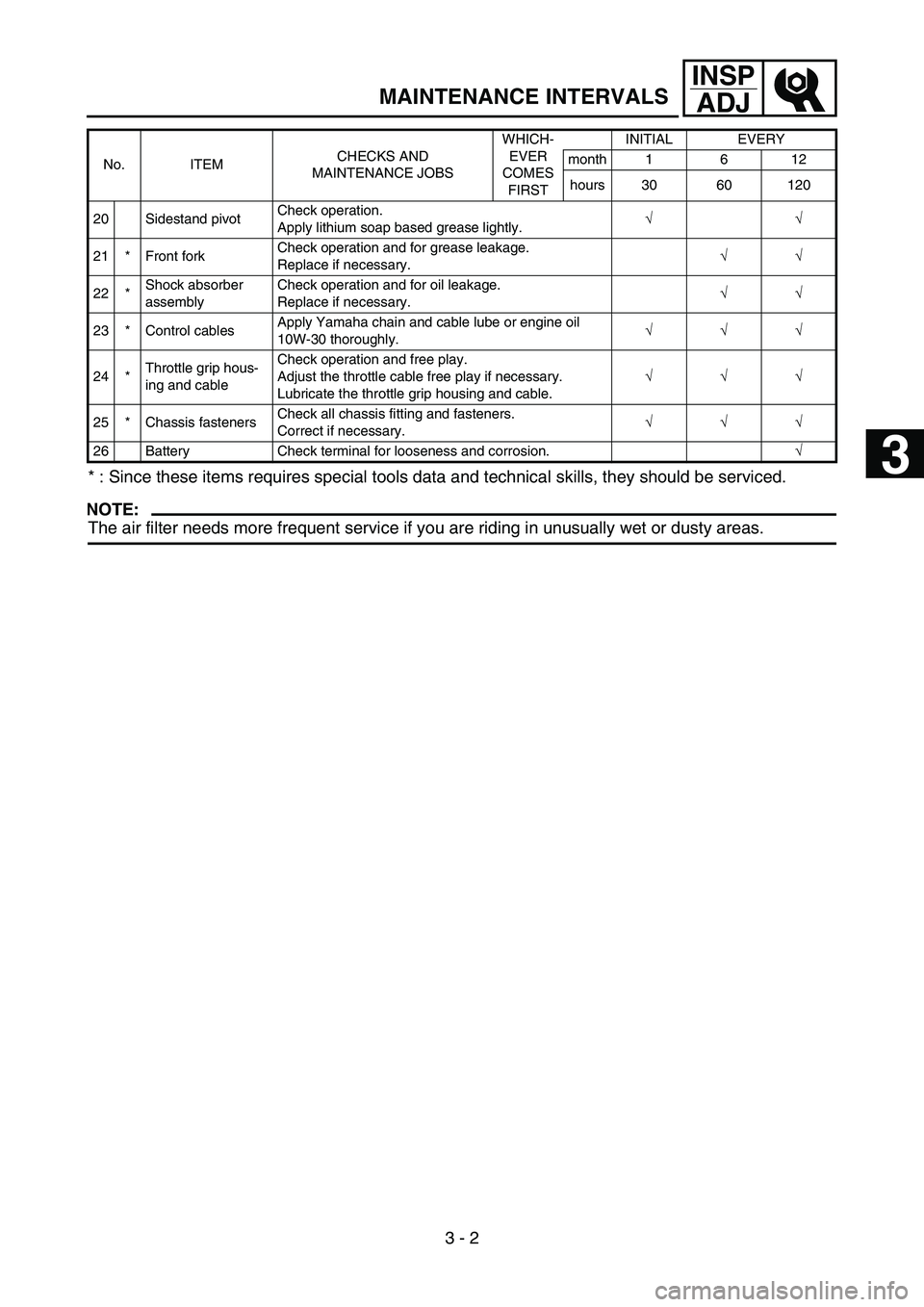

* : Since these items requires special tools data and technical skills, they should be serviced.

NOTE:

The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

20 Sidestand pivot Check operation.

Apply lithium soap based grease lightly.

√

√

21 * Front fork Check operation and for grease leakage.

Replace if necessary.

√

√

22 * Shock absorber

assembly Check operation and for oil leakage.

Replace if necessary.

√

√

23 * Control cables Apply Yamaha chain and cable lube or engine oil

10W-30 thoroughly.

√

√

√

24 * Throttle grip hous-

ing and cable Check operation and free play.

Adjust the throttle cable free play if necessary.

Lubricate the throttle grip housing and cable.

√

√

√

25 * Chassis fasteners Check all chassis fitting and fasteners.

Correct if necessary.

√

√

√

26 Battery Check terminal for looseness and corrosion. √

No. ITEM

CHECKS AND

MAINTENANCE JOBS WHICH-

EVER

COMES FIRST INITIAL EVERY

month 1 6 12

hours 30 60 120

1

2

3

4

5

6

Page 138 of 390

3 - 8

INSPADJ

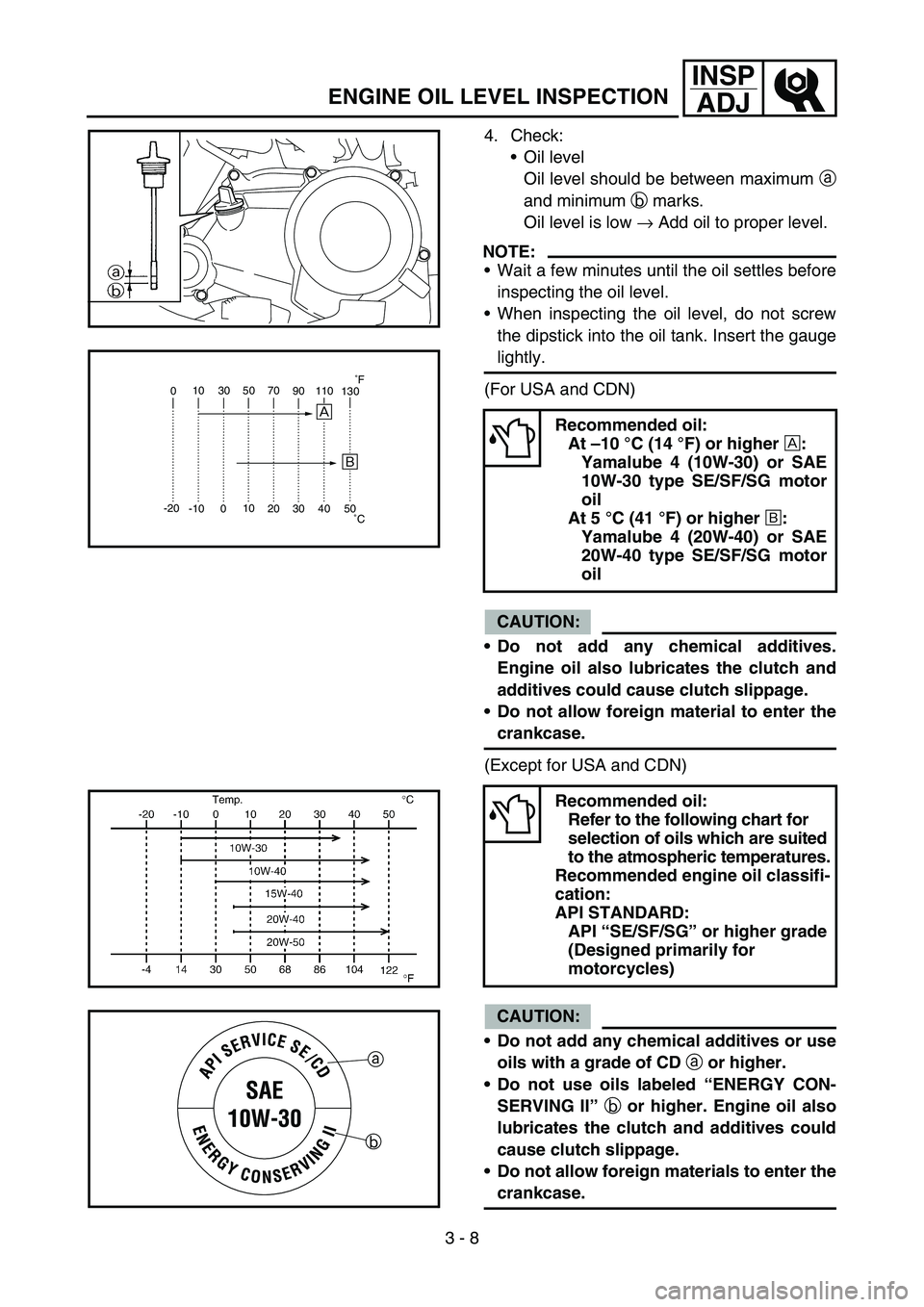

4. Check:

Oil level

Oil level should be between maximum a

and minimum b marks.

Oil level is low → Add oil to proper level.

NOTE:

Wait a few minutes until the oil settles before

inspecting the oil level.

When inspecting the oil level, do not screw

the dipstick into the oil tank. Insert the gauge

lightly.

(For USA and CDN)

CAUTION:

Do not add any chemical additives.

Engine oil also lubricates the clutch and

additives could cause clutch slippage.

Do not allow foreign material to enter the

crankcase.

(Except for USA and CDN)

CAUTION:

Do not add any chemical additives or use

oils with a grade of CD a or higher.

Do not use oils labeled “ENERGY CON-

SERVING II ” b or higher. Engine oil also

lubricates the clutch and additives could

cause clutch slippage.

Do not allow foreign materials to enter the

crankcase.

Recommended oil:

At –10 °C (14 °F) or higher È:

Yamalube 4 (10W-30) or SAE

10W-30 type SE/SF/SG motor

oil

At 5 °C (41 °F) or higher É:

Yamalube 4 (20W-40) or SAE

20W-40 type SE/SF/SG motor

oil

Recommended oil: Refer to the following chart for

selection of oils which are suited

to the atmospheric temperatures.

Recommended engine oil classifi-

cation:

API STANDARD: API “SE/SF/SG ” or higher grade

(Designed primarily for

motorcycles)

0 10 30 50 70

90110

130

-20 -10 010

20 30 40 50

È

É

˚C

˚

F

a

b

ENGINE OIL LEVEL INSPECTION

Page 168 of 390

3 - 23

INSPADJ

ELECTRICAL/SPARK PLUG INSPECTION

EC370000

ELECTRICAL

EC371001

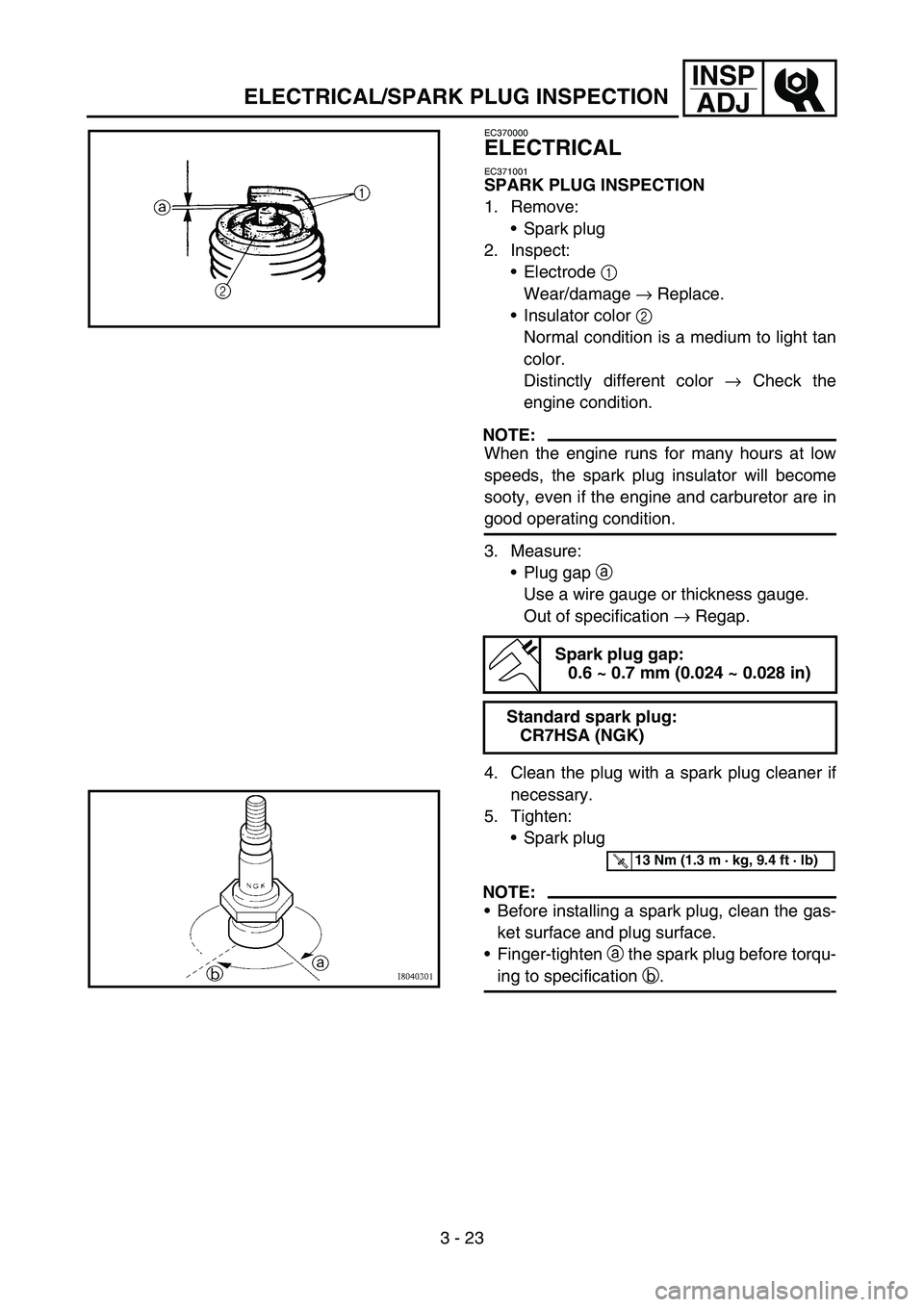

SPARK PLUG INSPECTION

1. Remove:

Spark plug

2. Inspect: Electrode 1

Wear/damage → Replace.

Insulator color 2

Normal condition is a medium to light tan

color.

Distinctly different color → Check the

engine condition.

NOTE:

When the engine runs for many hours at low

speeds, the spark plug insulator will become

sooty, even if the engine and carburetor are in

good operating condition.

3. Measure: Plug gap a

Use a wire gauge or thickness gauge.

Out of specification → Regap.

4. Clean the plug with a spark plug cleaner if necessary.

5. Tighten: Spark plug

NOTE:

Before installing a spark plug, clean the gas-

ket surface and plug surface.

Finger-tighten a the spark plug before torqu-

ing to specification b.

Spark plug gap:

0.6 ~ 0.7 mm (0.024 ~ 0.028 in)

Standard spark plug: CR7HSA (NGK)

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)