clock YAMAHA TTR50 2006 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: TTR50, Model: YAMAHA TTR50 2006Pages: 390, PDF Size: 9.69 MB

Page 46 of 390

1 - 10

GEN

INFO

CONTROL FUNCTIONS

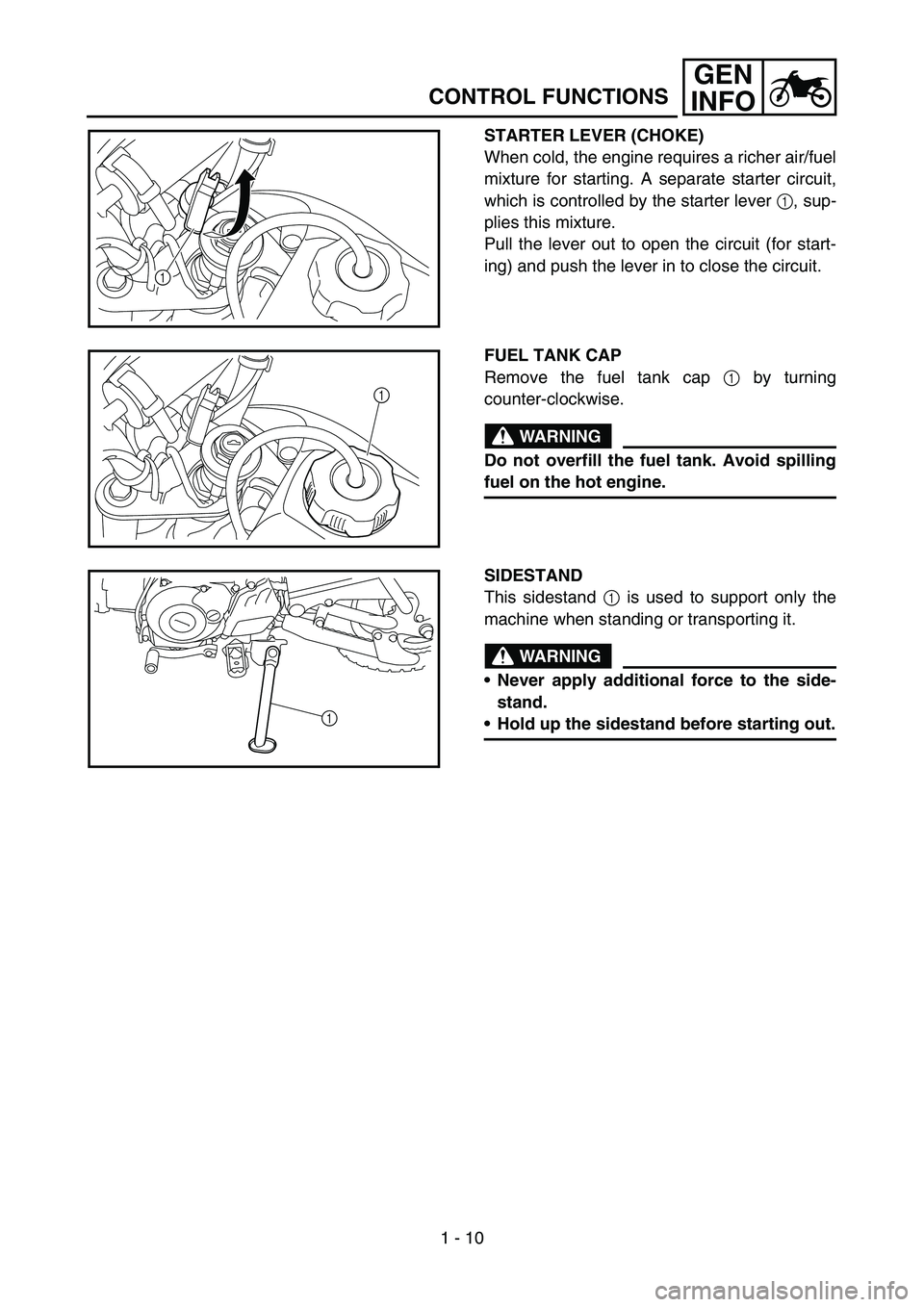

STARTER LEVER (CHOKE)

When cold, the engine requires a richer air/fuel

mixture for starting. A separate starter circuit,

which is controlled by the starter lever 1, sup-

plies this mixture.

Pull the lever out to open the circuit (for start-

ing) and push the lever in to close the circuit.

1

FUEL TANK CAP

Remove the fuel tank cap 1 by turning

counter-clockwise.

WARNING

Do not overfill the fuel tank. Avoid spilling

fuel on the hot engine.

1

SIDESTAND

This sidestand 1 is used to support only the

machine when standing or transporting it.

WARNING

Never apply additional force to the side-

stand.

Hold up the sidestand before starting out.1

Page 61 of 390

SPEC

2 - 6

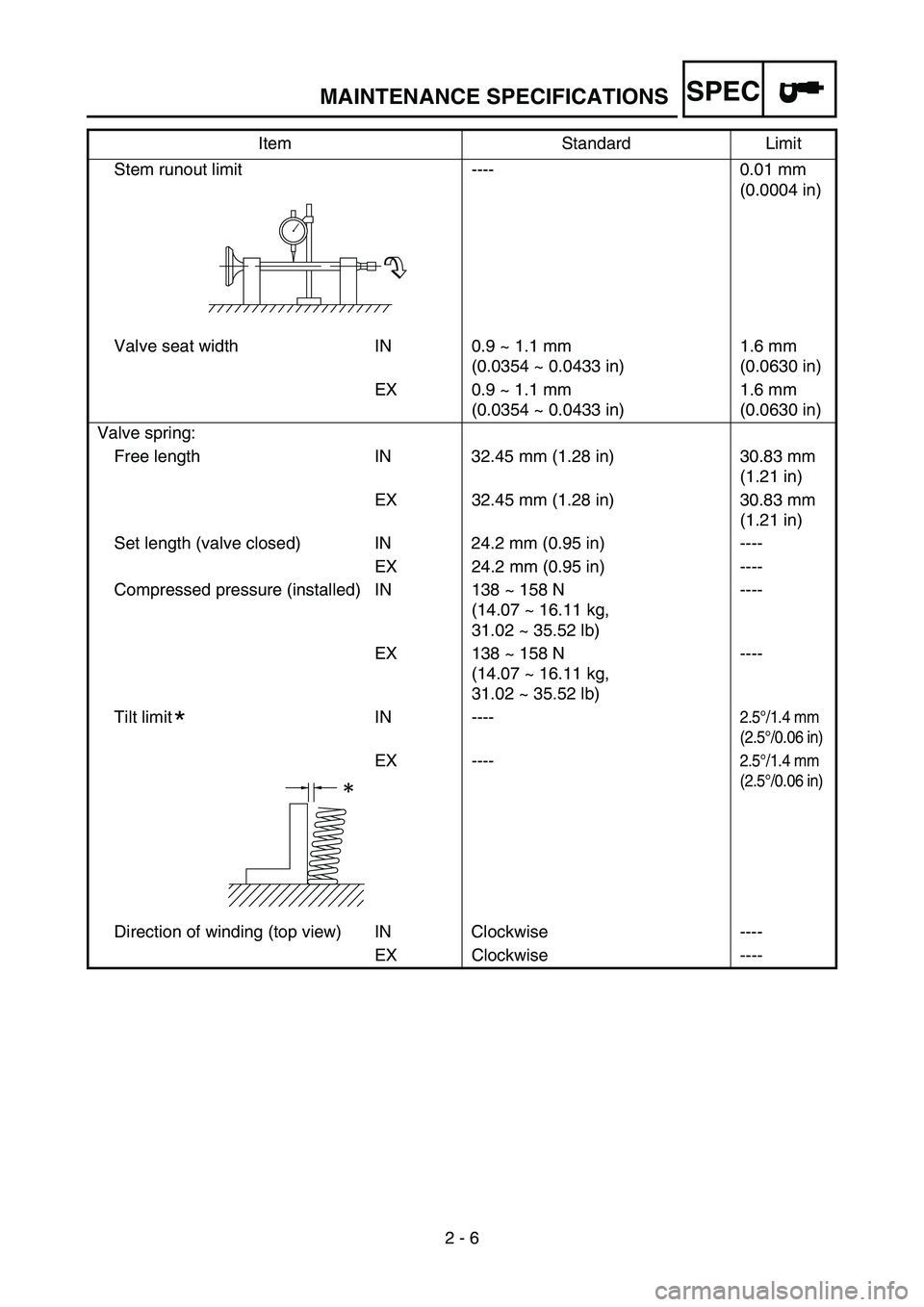

Stem runout limit ---- 0.01 mm

(0.0004 in)

Valve seat width IN 0.9 ~ 1.1 mm (0.0354 ~ 0.0433 in)1.6 mm

(0.0630 in)

EX 0.9 ~ 1.1 mm (0.0354 ~ 0.0433 in) 1.6 mm

(0.0630 in)

Valve spring: Free length IN 32.45 mm (1.28 in) 30.83 mm (1.21 in)

EX 32.45 mm (1.28 in) 30.83 mm (1.21 in)

Set length (valve closed) IN 24.2 mm (0.95 in) ---- EX 24.2 mm (0.95 in) ----

Compressed pressure (installed) IN 138 ~ 158 N (14.07 ~ 16.11 kg,

31.02 ~ 35.52 lb)----

EX 138 ~ 158 N (14.07 ~ 16.11 kg,

31.02 ~ 35.52 lb) ----

Tilt limit IN ----

2.5 °/1.4 mm

(2.5 °/0.06 in)

EX ----2.5 °/1.4 mm

(2.5 °/0.06 in)

Direction of winding (top view) IN Clockwise ----

EX Clockwise ----

Item Standard Limit

*

MAINTENANCE SPECIFICATIONS

Page 144 of 390

3 - 11

INSPADJ

VALVE CLEARANCE ADJUSTMENT

3. Check:

Valve clearance

Out of specification → Adjust.

Valve clearance (cold):

Intake valve: 0.05 ~ 0.09 mm

(0.0020 ~ 0.0035 in)

Exhaust valve: 0.08 ~ 0.12 mm

(0.0031 ~ 0.0047 in)

Checking steps:

Turn the crankshaft counterclockwise with

a wrench.

When the piston is at T.D.C. on the com-

pression stroke, align the “I” mark a on

the camshaft sprocket with the stationary

pointer b on the cylinder head.

Align the “I” mark c on the rotor with the

stationary pointer d on the crankcase

cover.

Measure the valve clearance using a

thickness gauge 1.

Out of specification → Adjust clearance.

Thickness gauge:

YM-34483/90890-03079

a

b

d

c

1

Page 156 of 390

3 - 17

INSPADJ

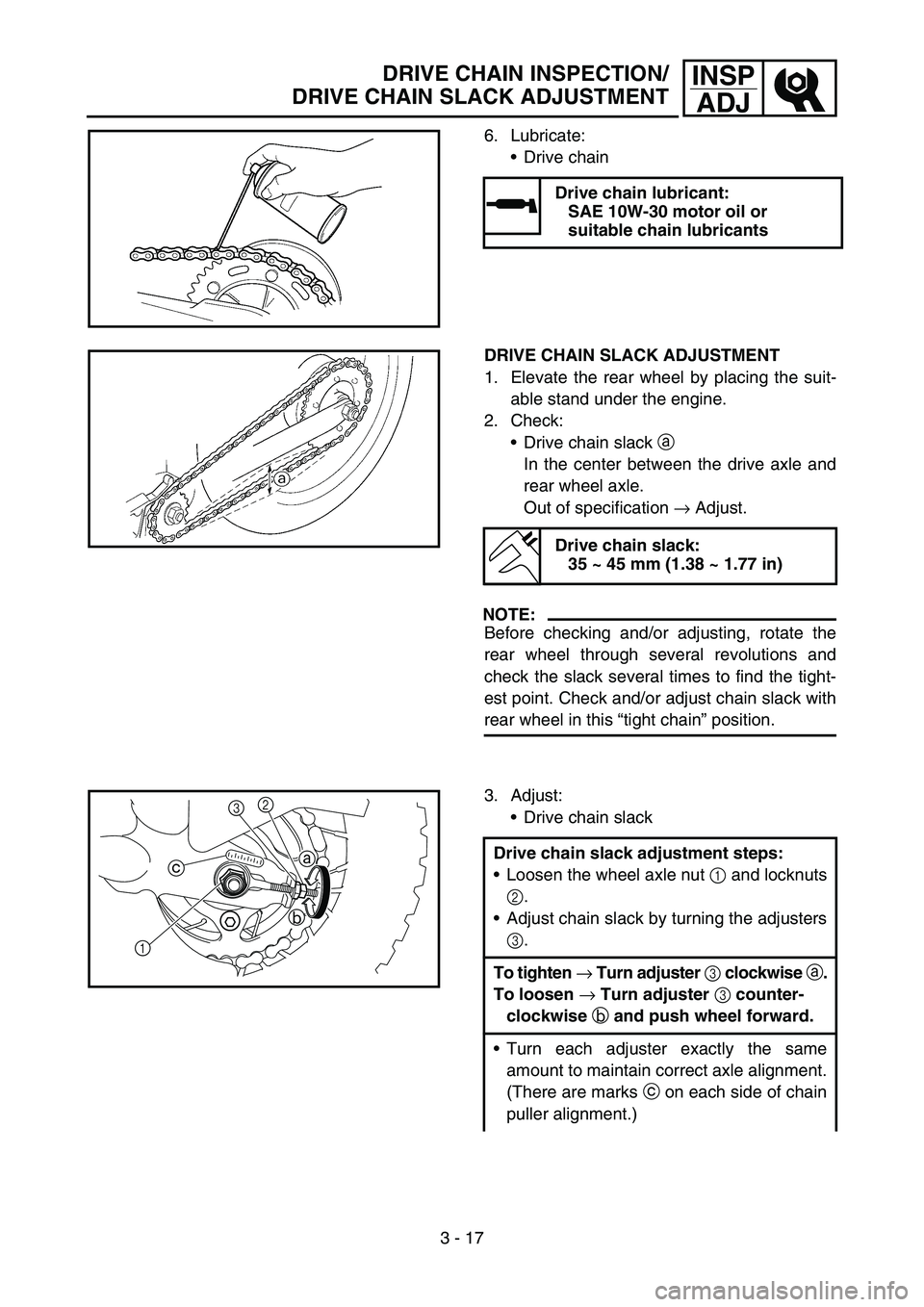

6. Lubricate:

Drive chain

Drive chain lubricant:

SAE 10W-30 motor oil or

suitable chain lubricants

DRIVE CHAIN SLACK ADJUSTMENT

1. Elevate the rear wheel by placing the suit-

able stand under the engine.

2. Check: Drive chain slack a

In the center between the drive axle and

rear wheel axle.

Out of specification → Adjust.

NOTE:

Before checking and/or adjusting, rotate the

rear wheel through several revolutions and

check the slack several times to find the tight-

est point. Check and/or adjust chain slack with

rear wheel in this “tight chain ” position.

Drive chain slack:

35 ~ 45 mm (1.38 ~ 1.77 in)

3. Adjust:

Drive chain slack

Drive chain slack adjustment steps:

Loosen the wheel axle nut 1 and locknuts

2 .

Adjust chain slack by turning the adjusters

3 .

To tighten → Turn adjuster 3 clockwise a.

To loosen → Turn adjuster 3 counter-

clockwise b and push wheel forward.

Turn each adjuster exactly the same

amount to maintain correct axle alignment.

(There are marks c on each side of chain

puller alignment.)

1 b

c

a

23

DRIVE CHAIN INSPECTION/

DRIVE CHAIN SLACK ADJUSTMENT

Page 210 of 390

4 - 12

ENGCYLINDER HEAD

REMOVAL POINTS

Cylinder head

1. Align:“I” mark

(with stationary pointer)

Checking steps:

Turn the crankshaft counterclockwise with

a wrench.

Align the “I” mark a on the rotor with the

stationary pointer b on the crankcase

cover. When the “I” mark is aligned with

the stationary pointer, the piston is at the

Top Dead Center (T.D.C.).

NOTE:

In order to be sure that the piston is at Top

Dead Center, the “I” mark c on the cam-

shaft sprocket must align with the station-

ary pointer d on the cylinder head as

shown in the illustration.

If there is no valve clearance, rotate the

crankshaft counterclockwise one turn.

b

a

c

d

2. Loosen:

Camshaft sprocket bolt 1

3. Remove:

Timing chain tensioner

Camshaft sprocket 2

NOTE:

Fasten a safety wire to the timing chain 3 to

prevent it from falling into the crankcase.

Remove the bolt 1 while holding the rotor

nut with a wrench.

12

3

Page 212 of 390

4 - 13

ENGCYLINDER HEAD

4. Remove:Cylinder head

NOTE:

Loosen the bolts and nuts in their proper

loosening sequence.

Start by loosening each bolt and nut 1/2 turn

until all are loose.1

2

5

64

3

ASSEMBLY AND INSTALLATION

1. Install:

Cylinder head

2. Tighten: Nuts

Bolts

NOTE:

Apply the engine oil on the contact surfaces

of the nuts and copper washers.

Apply the engine oil on the thread and con-

tact surface of the bolts.

Follow the numerical order shown in the illus-

tration. Tighten the bolts and nuts in two

stages.

6

5

2

13

4

T R..22 Nm (2.2 m · kg, 16 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

3. Install:

Camshaft sprocket 1

Installation steps:

Turn the crankshaft counterclockwise until

the “I” mark a on the rotor is aligned with

the stationary pointer b on the crankcase

cover.

Align the “I” mark c on the camshaft

sprocket with the stationary pointer d on

the cylinder head.

Fit the timing chain 2 onto camshaft

sprocket and install the camshaft sprocket

on the camshaft.

NOTE:

When installing the camshaft sprocket, keep

the timing chain as tense as possible on the

exhaust side.

b

a

1

2

c

d

Page 258 of 390

4 - 36

ENG

Clutch free play adjustment

1. Adjust:Clutch free play

Adjustment steps:

Loosen the locknut 1.

Turn the clutch adjuster 2 counterclock-

wise until it becomes slightly difficult to

turn.

Turn the clutch adjuster 2 clockwise 1/8

turn.

Hold the clutch adjuster 2 and tighten the

locknut 1.

T R..

Locknut:

6 Nm (0.6 m kg, 4.3 ft lb)

1

2

CLUTCH

Page 276 of 390

4 - 45

ENG

INSPECTION

Starter clutch

1. Inspect:Starter idle gear teeth a

Starter drive gear teeth b

Starter wheel gear teeth c

Burrs/chips/roughness/wear → Replace.

2. Check:

Starter clutch operation.

Checking steps:

Install the starter wheel gear onto the

starter clutch and hold the starter clutch.

When turning the starter wheel gear clock-

wise È, the starter clutch and the starter

wheel gear should be engage, otherwise

the starter clutch is faulty and must be

replaced.

When turning the starter wheel gear coun-

terclockwise É, it should turn freely, other-

wise the starter clutch is faulty and must

be replaced.

É

È

ASSEMBLY AND INSTALLATION

Starter clutch

1. Install:Starter clutch 1

1T R..14 Nm (1.4 m · kg, 10 ft · lb)

2. Unloosen the starter clutch assembly by

using the center punch.

AC MAGNETO AND STARTER CLUTCH