engine oil YAMAHA TTR90 2000 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: TTR90, Model: YAMAHA TTR90 2000Pages: 287, PDF Size: 6.77 MB

Page 18 of 287

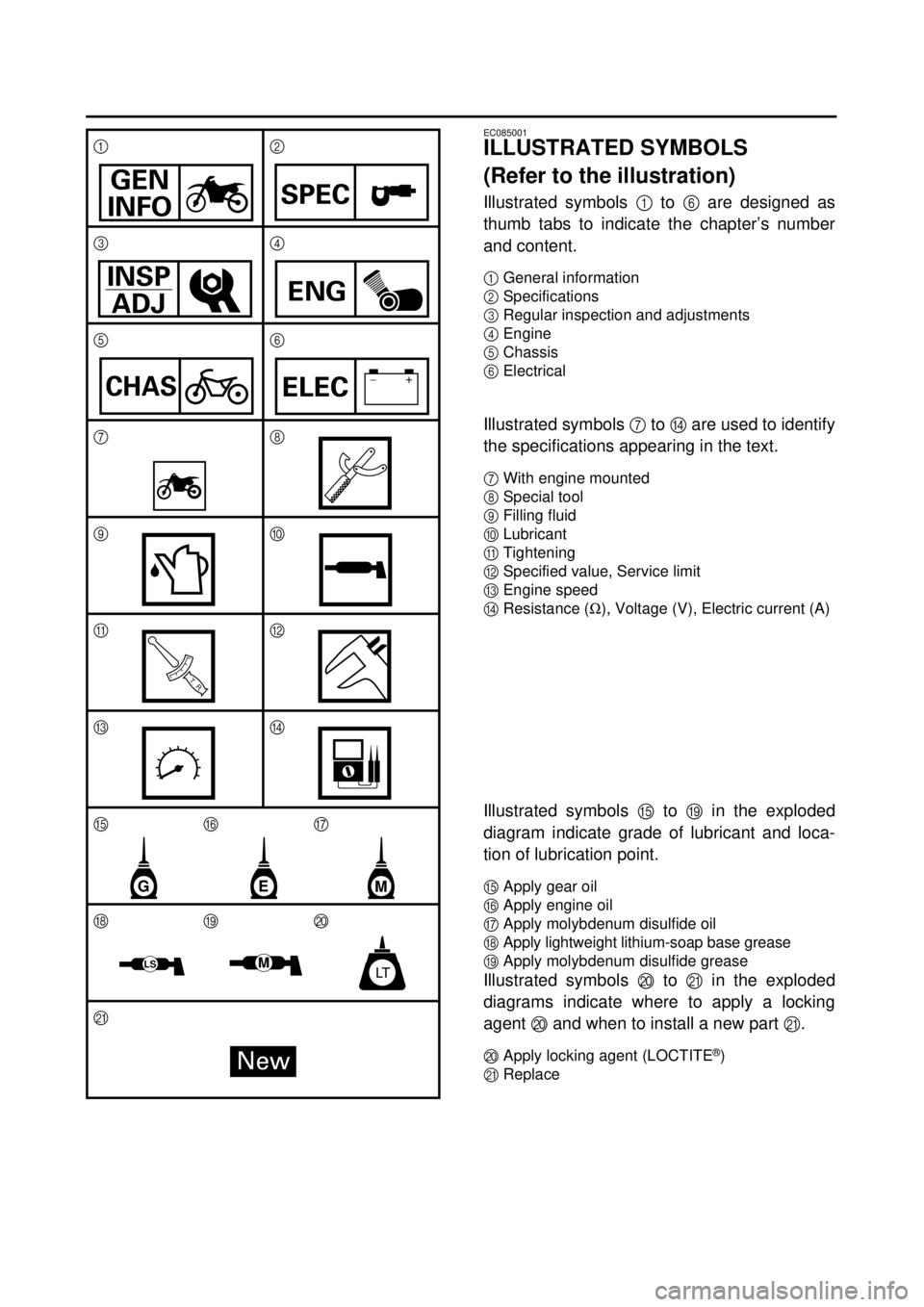

EC085001

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols

1

to

6

are designed as

thumb tabs to indicate the chapter’s number

and content.

1

General information

2

Specifications

3

Regular inspection and adjustments

4

Engine

5

Chassis

6

Electrical

Illustrated symbols

7

to

D

are used to identify

the specifications appearing in the text.

7

With engine mounted

8

Special tool

9

Filling fluid

0

Lubricant

A

Tightening

B

Specified value, Service limit

C

Engine speed

DResistance (W), Voltage (V), Electric current (A)

Illustrated symbols E to I in the exploded

diagram indicate grade of lubricant and loca-

tion of lubrication point.

EApply gear oil

FApply engine oil

GApply molybdenum disulfide oil

HApply lightweight lithium-soap base grease

IApply molybdenum disulfide grease

Illustrated symbols J to K in the exploded

diagrams indicate where to apply a locking

agent J and when to install a new part K.

JApply locking agent (LOCTITE®)

KReplace 12

34

56

78

90

AB

CD

EFG

HIJ

K

GEN

INFOSPEC

INSP

ADJENG

CHAS–+ELEC

T R..

GME

MLTLS

New

Page 24 of 287

CHAPTER 4

ENGINE

CARBURETOR

......................................... 4-1

CYLINDER HEAD

..................................... 4-8

CAMSHAFT AND ROCKER ARMS

....... 4-13

VALVES AND VALVE SPRINGS

........... 4-16

CYLINDER AND PISTON

....................... 4-21

CLUTCH

.................................................. 4-27

KICK AXLE

............................................. 4-33

SHIFT SHAFT

......................................... 4-34

OIL PUMP

............................................... 4-36

CDI MAGNETO

....................................... 4-39

CRANKCASE AND CRANKSHAFT

....... 4-41

SHIFT FORK, SHIFT CAM AND

TRANSMISSION

..................................... 4-44

CHAPTER 5

CHASSIS

FRONT WHEEL AND REAR WHEEL

...... 5-1

FRONT FORK

........................................... 5-6

HANDLEBAR

............................................ 5-9

STEERING

.............................................. 5-10

SWINGARM

............................................ 5-11

CHAPTER 6

ELECTRICAL

ELECTRICAL COMPONENTS AND

WIRING DIAGRAM

................................... 6-1

IGNITION SYSTEM

................................... 6-2

CARBURETOR HEATING SYSTEM

........ 6-6

MAINTENANCE RECORD

....................... 6-9

Page 32 of 287

1 - 4

GEN

INFO

IMPORTANT INFORMATION

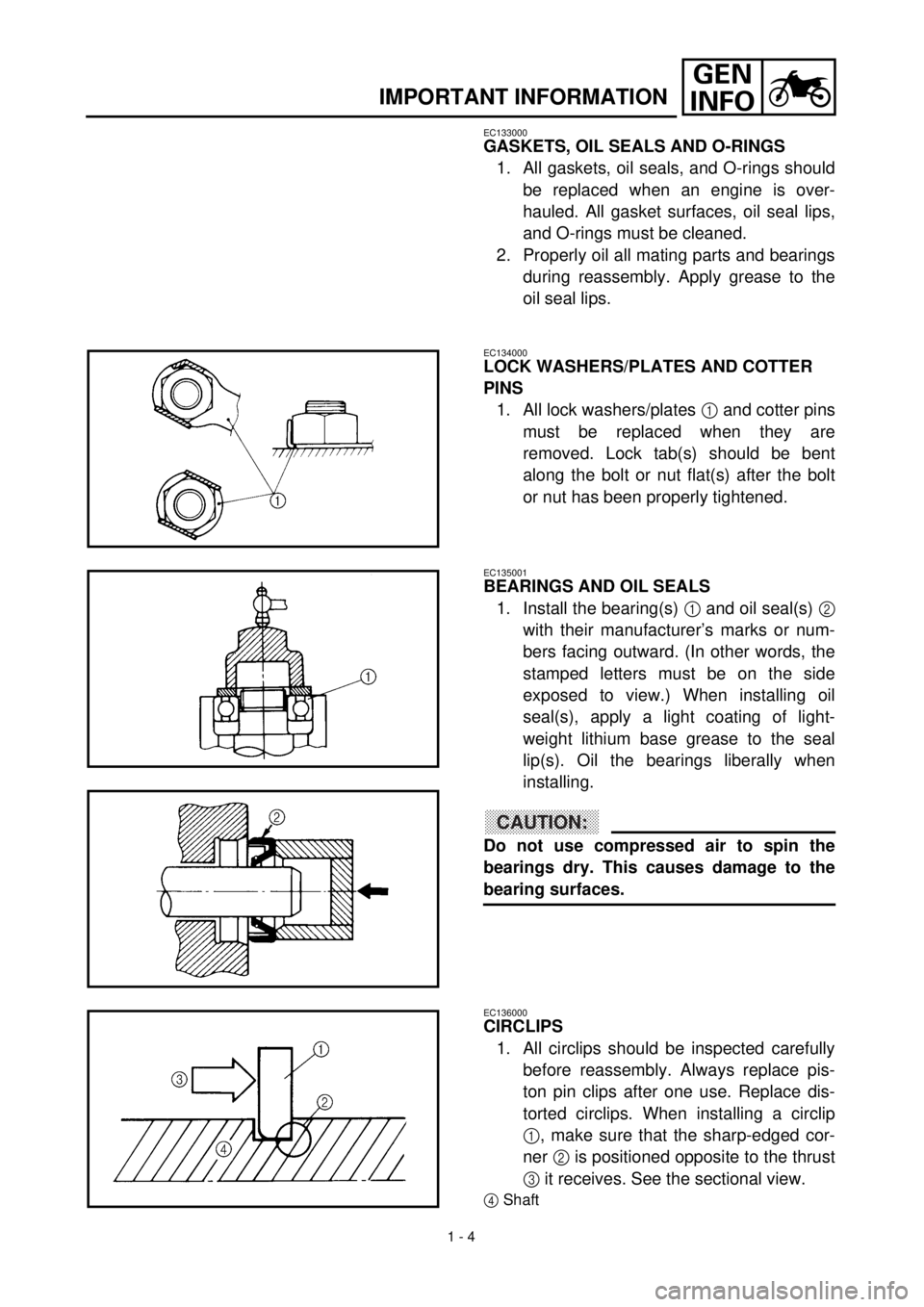

EC133000

GASKETS, OIL SEALS AND O-RINGS

1. All gaskets, oil seals, and O-rings should

be replaced when an engine is over-

hauled. All gasket surfaces, oil seal lips,

and O-rings must be cleaned.

2. Properly oil all mating parts and bearings

during reassembly. Apply grease to the

oil seal lips.

EC134000

LOCK WASHERS/PLATES AND COTTER

PINS

1. All lock washers/plates

1

and cotter pins

must be replaced when they are

removed. Lock tab(s) should be bent

along the bolt or nut flat(s) after the bolt

or nut has been properly tightened.

EC135001

BEARINGS AND OIL SEALS

1. Install the bearing(s)

1

and oil seal(s)

2

with their manufacturer’s marks or num-

bers facing outward. (In other words, the

stamped letters must be on the side

exposed to view.) When installing oil

seal(s), apply a light coating of light-

weight lithium base grease to the seal

lip(s). Oil the bearings liberally when

installing.

CAUTION:

Do not use compressed air to spin the

bearings dry. This causes damage to the

bearing surfaces.

EC136000

CIRCLIPS

1. All circlips should be inspected carefully

before reassembly. Always replace pis-

ton pin clips after one use. Replace dis-

torted circlips. When installing a circlip

1

, make sure that the sharp-edged cor-

ner

2

is positioned opposite to the thrust

3

it receives. See the sectional view.

4

Shaft

Page 36 of 287

GEN

INFO

1 - 6

SPECIAL TOOLS

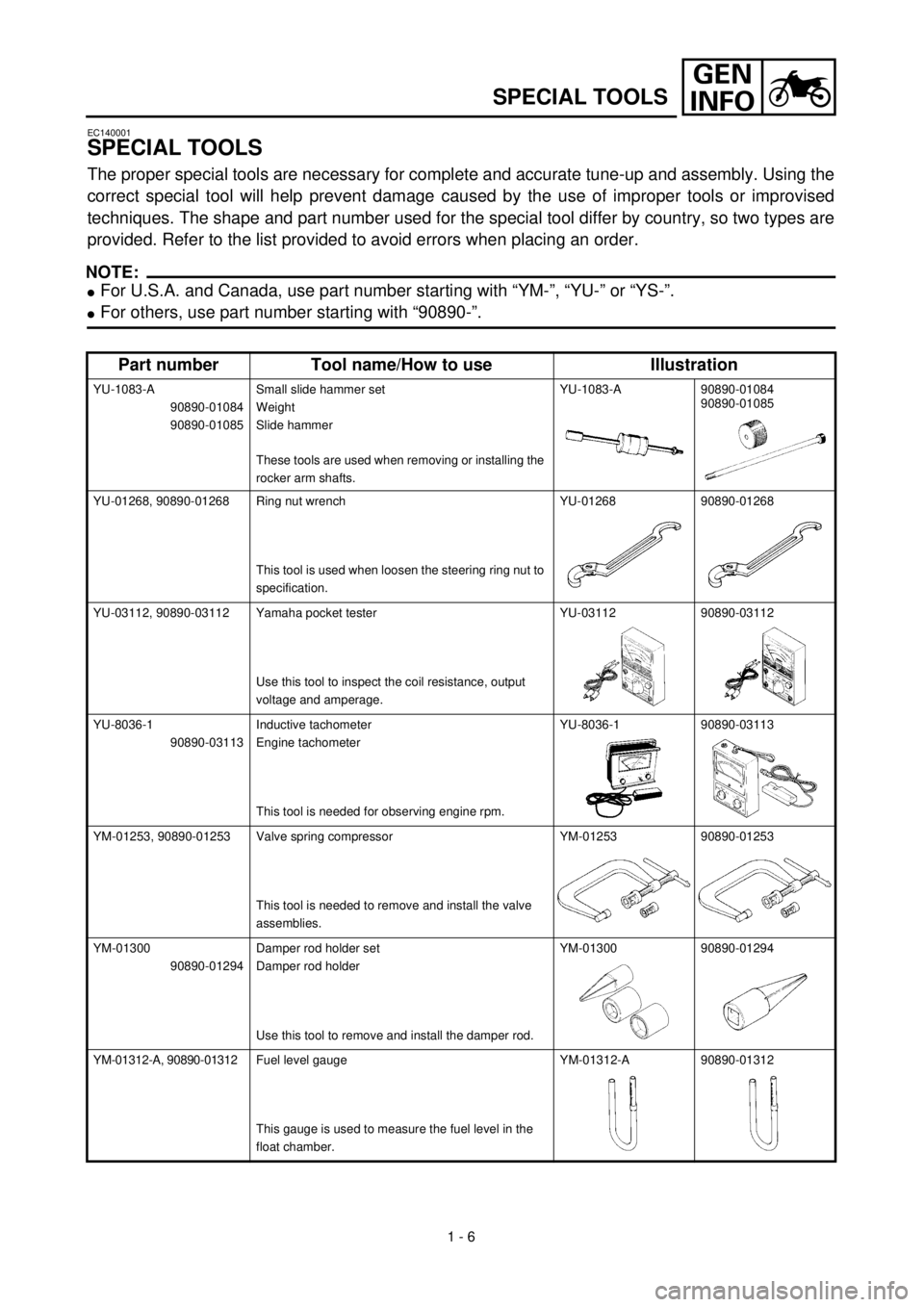

EC140001

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the

correct special tool will help prevent damage caused by the use of improper tools or improvised

techniques. The shape and part number used for the special tool differ by country, so two types are

provided. Refer to the list provided to avoid errors when placing an order.

NOTE:

l

For U.S.A. and Canada, use part number starting with “YM-”, “YU-” or “YS-”.

lFor others, use part number starting with “90890-”.

Part number Tool name/How to use Illustration

YU-1083-A

90890-01084

90890-01085Small slide hammer set

Weight

Slide hammer

These tools are used when removing or installing the

rocker arm shafts.YU-1083-A 90890-01084

90890-01085

YU-01268, 90890-01268 Ring nut wrench

This tool is used when loosen the steering ring nut to

specification.YU-01268 90890-01268

YU-03112, 90890-03112 Yamaha pocket tester

Use this tool to inspect the coil resistance, output

voltage and amperage.YU-03112 90890-03112

YU-8036-1

90890-03113Inductive tachometer

Engine tachometer

This tool is needed for observing engine rpm.YU-8036-1 90890-03113

YM-01253, 90890-01253 Valve spring compressor

This tool is needed to remove and install the valve

assemblies.YM-01253 90890-01253

YM-01300

90890-01294Damper rod holder set

Damper rod holder

Use this tool to remove and install the damper rod.YM-01300 90890-01294

YM-01312-A, 90890-01312Fuel level gauge

This gauge is used to measure the fuel level in the

float chamber.YM-01312-A 90890-01312

Page 52 of 287

GEN

INFO

1 - 12

STARTING AND OPERATION

STARTING AND OPERATION

CAUTION:

Prior to operating the machine, perform

steps listed in pre-operation check list.

WARNING

Never start your engine or let it run for any

length of time in a closed area. The exhaust

fumes are poisonous and can cause loss of

consciousness and death within a short

time. Always operate your machine in an

area with adequate ventilation.

STARTING A COLD ENGINE

WARNING

Before starting the engine, be sure to shift

the transmission into neutral.

1. Turn the fuel cock to “ON”.

2. Operate the starter (choke) and com-

pletely close the throttle grip.

3. Slide the “ENGINE STOP” switch to the

“”.

4. Kick the kick starter with full strength to

start the engine.

5. After the engine starts, warm up for one

or two minutes. Make sure the stater

(choke) is returned to the original position

before riding.

STARTING A WARM ENGINE

To start a warm engine, refer to the “Starting a

cold engine” section. The starter (choke)

should not be used. The throttle should be

opened slightly.

CAUTION:

See “Break-in Section” prior to operating

engine for the first time.WARMING UP

To get maximum engine life, always “warm-up”

the engine before starting off. Never acceler-

ate hard with a cold engine! To see whether or

not the engine is warm, see if it responds to

throttle normally with the stater (choke) turned

off.

WARNING

Before starting off, be sure to turn up or

remove the side stand.

Failure to retract the side stand completely

can result in a serious accident when you

try to turn a corner.

ENGINE BREAK-IN

1. Prior to starting, fill fuel tank with gasoline

and oil tank with specified oil.

2. Allow engine to warm up. Check engine

idling speed. Check operating controls

and engine stop switch operation.

3. Operate machine in lower gears at mod-

erate throttle setting for 3 ~ 5 minutes.

Check spark plug condition.

4. Allow engine to cool. Repeat procedure,

running for 5 minutes. Very briefly, shift to

higher gears and check full throttle

response. Check spark plug condition.

5. Allow engine to cool. Repeat procedure,

running for 5 minutes. Full throttle and

higher gears may be used, but avoid sus-

tained full throttle operation. Check spark

plug condition.

6. Allow engine to cool. Remove top end and

inspect. Remove “high” spots on piston

with No.600 grit, wet sandpaper.

Clean, and carefully reassemble.

7. Check entire unit for loose or misadjusted

fittings/controls/fasteners.

8. Re-start engine and check through entire

operating range thoroughly. Stop. Check

spark plug condition. Re-start. After 10 ~

15 minutes operation, machine is ready

to ride.

CAUTION:

After the break-in period, check every fit-

ting and fastener for looseness.

If any loose is found, retighten it securely.

Page 56 of 287

SPEC

2 - 1

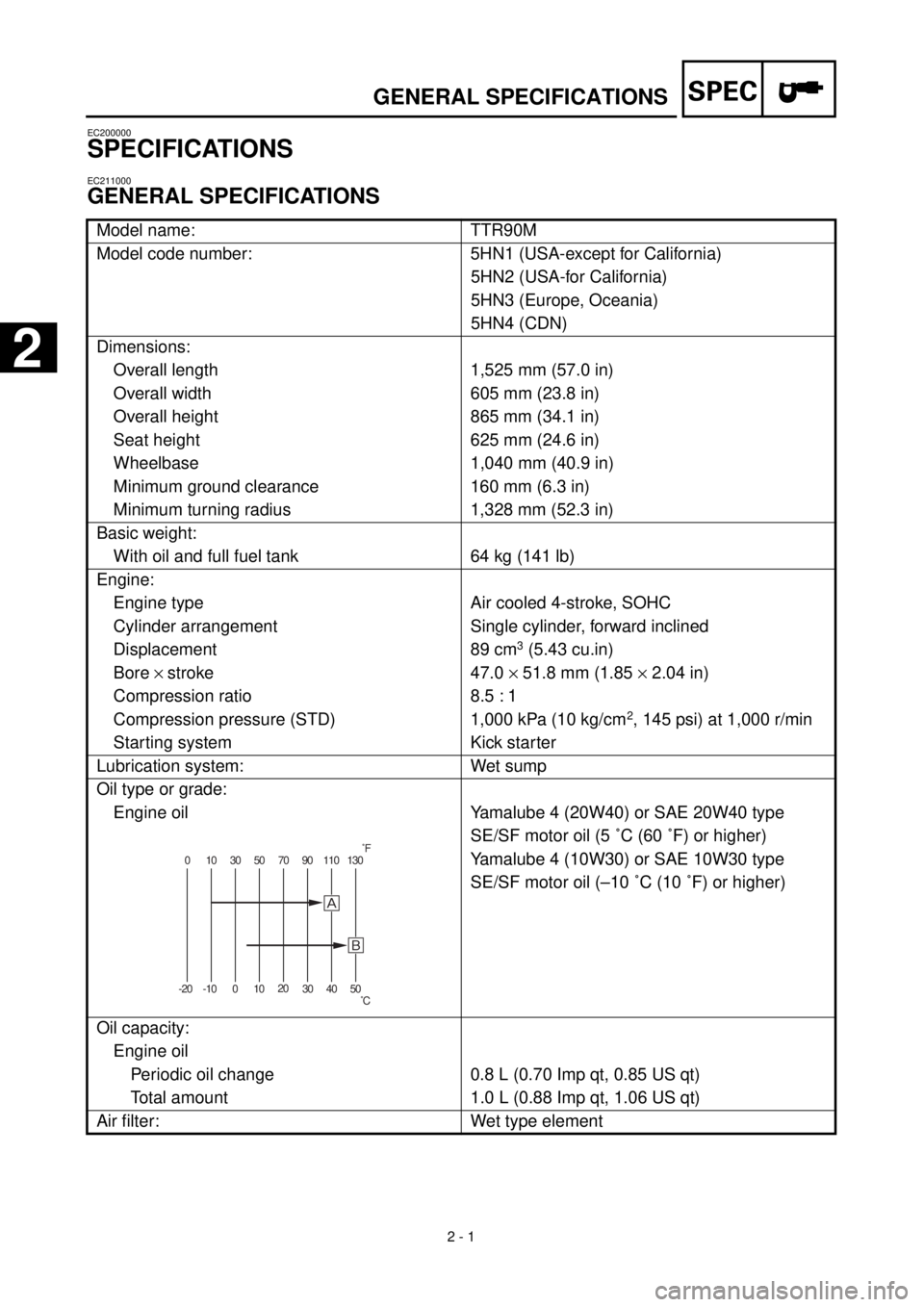

EC200000

SPECIFICATIONS

EC211000

GENERAL SPECIFICATIONS

Model name: TTR90M

Model code number: 5HN1 (USA-except for California)

5HN2 (USA-for California)

5HN3 (Europe, Oceania)

5HN4 (CDN)

Dimensions:

Overall length 1,525 mm (57.0 in)

Overall width 605 mm (23.8 in)

Overall height 865 mm (34.1 in)

Seat height 625 mm (24.6 in)

Wheelbase 1,040 mm (40.9 in)

Minimum ground clearance 160 mm (6.3 in)

Minimum turning radius 1,328 mm (52.3 in)

Basic weight:

With oil and full fuel tank 64 kg (141 lb)

Engine:

Engine type Air cooled 4-stroke, SOHC

Cylinder arrangement Single cylinder, forward inclined

Displacement 89 cm

3

(5.43 cu.in)

Bore

´

stroke 47.0

´

51.8 mm (1.85

´

2.04 in)

Compression ratio 8.5 : 1

Compression pressure (STD) 1,000 kPa (10 kg/cm

2

, 145 psi) at 1,000 r/min

Starting system Kick starter

Lubrication system: Wet sump

Oil type or grade:

Engine oil

Yamalube 4 (20W40) or SAE 20W40 type

SE/SF motor oil (5 ˚C (60 ˚F) or higher)

Yamalube 4 (10W30) or SAE 10W30 type

SE/SF motor oil (–10 ˚C (10 ˚F) or higher)

Oil capacity:

Engine oil

Periodic oil change 0.8 L (0.70 Imp qt, 0.85 US qt)

Total amount 1.0 L (0.88 Imp qt, 1.06 US qt)

Air filter: Wet type element

0 10 30 50 70 90 110 130

-20 -10 01020

30 40 50

õ

˚F

˚C

GENERAL SPECIFICATIONS

2

Page 102 of 287

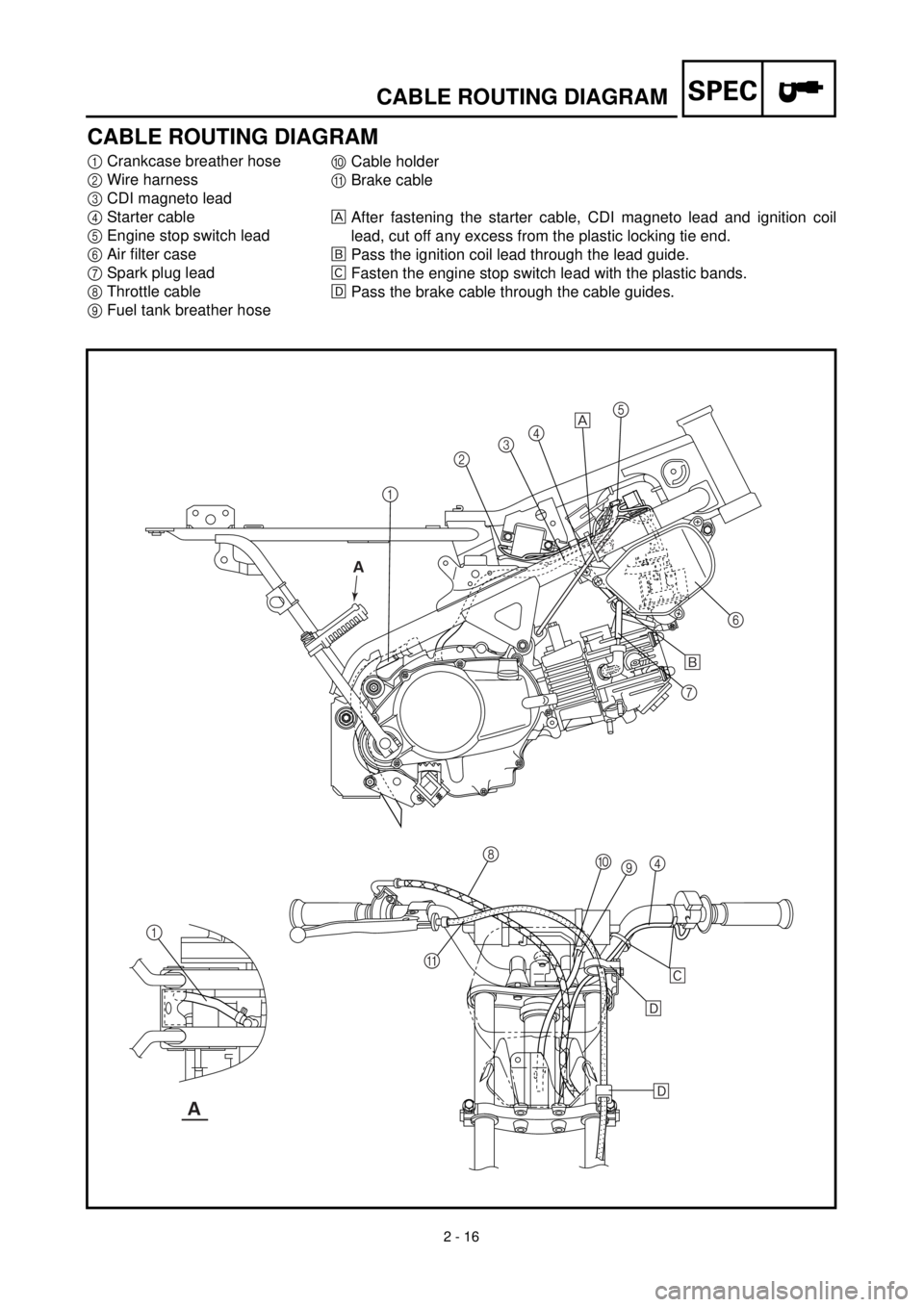

2 - 16

SPEC

CABLE ROUTING DIAGRAM

CABLE ROUTING DIAGRAM

1

Crankcase breather hose

2

Wire harness

3

CDI magneto lead

4

Starter cable

5

Engine stop switch lead

6

Air filter case

7

Spark plug lead

8

Throttle cable

9

Fuel tank breather hose

0

Cable holder

A

Brake cable

After fastening the starter cable, CDI magneto lead and ignition coil

lead, cut off any excess from the plastic locking tie end.

õ

Pass the ignition coil lead through the lead guide.

‚

Fasten the engine stop switch lead with the plastic bands.

ë

Pass the brake cable through the cable guides.

12345

6

7

8

9 0

4

A 1

õ

‚

ë

ë

A

A

Page 104 of 287

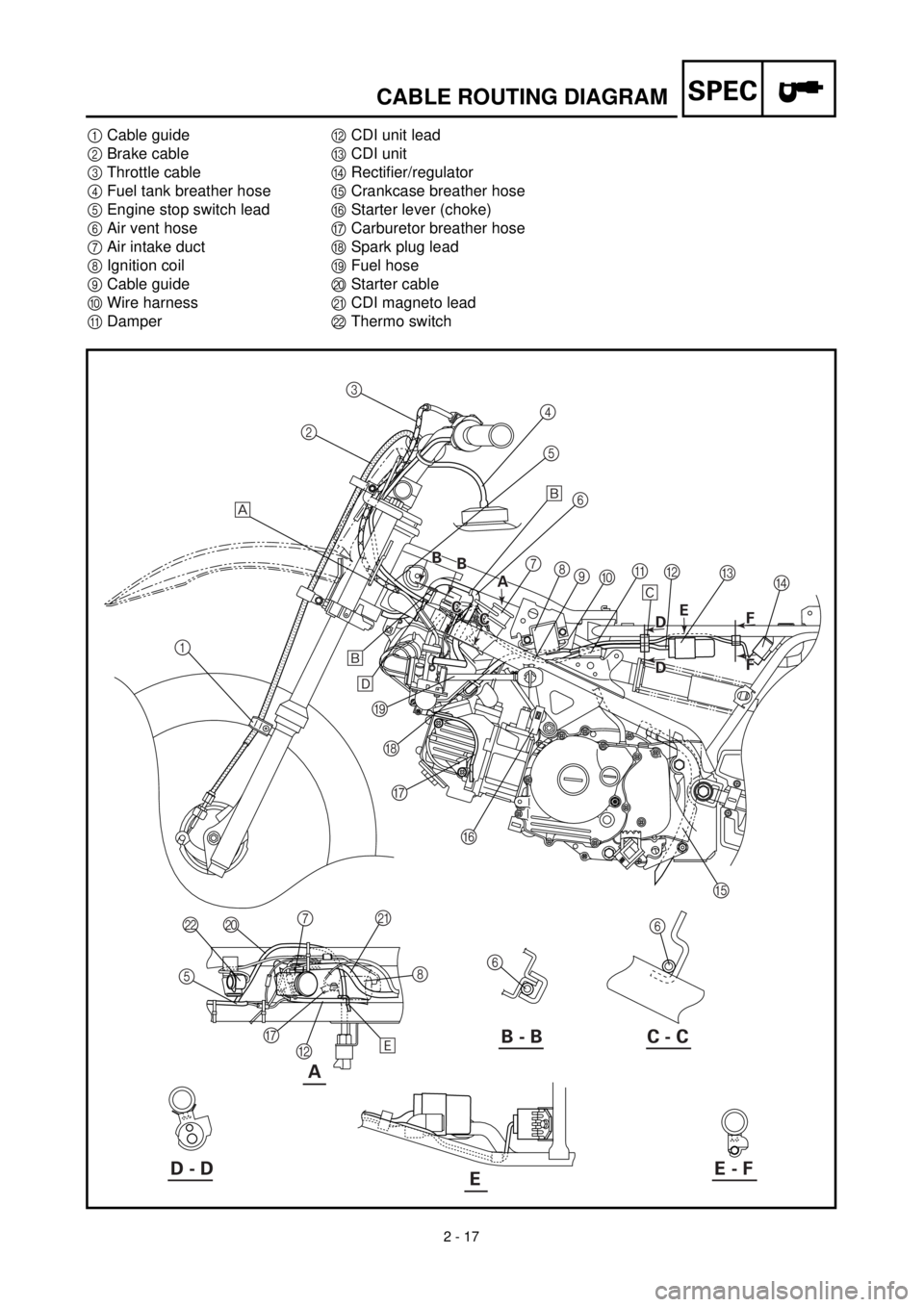

2 - 17

SPEC

CABLE ROUTING DIAGRAM

1

Cable guide

2

Brake cable

3

Throttle cable

4

Fuel tank breather hose

5

Engine stop switch lead

6

Air vent hose

7

Air intake duct

8

Ignition coil

9

Cable guide

0

Wire harness

A

Damper

B

CDI unit lead

C

CDI unit

D

Rectifier/regulator

E

Crankcase breather hose

F

Starter lever (choke)

G

Carburetor breather hose

H

Spark plug lead

I

Fuel hose

J

Starter cable

K

CDI magneto lead

L

Thermo switch

A

123

4

5

6

7

8

9

0A

C

D B

E F G H I

6

6 J L

5

G

B8 K

7 õ

‚

õ

ë

ä

B - B C - C

D - DE - FE

A A B

B B

B

C

C C

CE

B D

B D

F

F F F

Page 108 of 287

3 - 1

INSP

ADJ

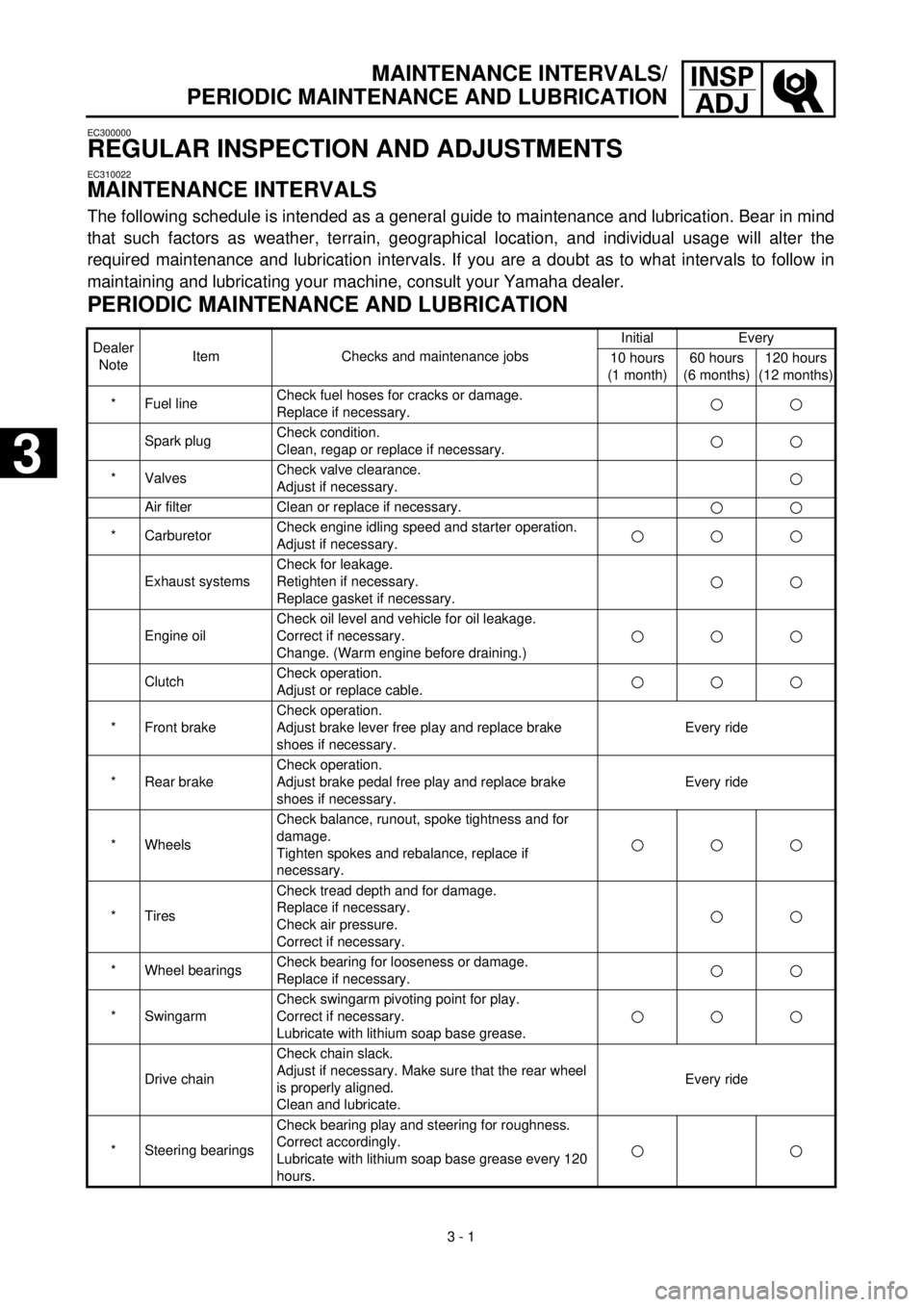

MAINTENANCE INTERVALS/

PERIODIC MAINTENANCE AND LUBRICATION

EC300000

REGULAR INSPECTION AND ADJUSTMENTS

EC310022

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the

required maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your Yamaha dealer.

PERIODIC MAINTENANCE AND LUBRICATION

Dealer

NoteItem Checks and maintenance jobsInitial Every

10 hours

(1 month)60 hours

(6 months)120 hours

(12 months)

* Fuel lineCheck fuel hoses for cracks or damage.

Replace if necessary.

Spark plugCheck condition.

Clean, regap or replace if necessary.

* ValvesCheck valve clearance.

Adjust if necessary.

Air filter Clean or replace if necessary.

* CarburetorCheck engine idling speed and starter operation.

Adjust if necessary.

Exhaust systemsCheck for leakage.

Retighten if necessary.

Replace gasket if necessary.

Engine oilCheck oil level and vehicle for oil leakage.

Correct if necessary.

Change. (Warm engine before draining.)

ClutchCheck operation.

Adjust or replace cable.

* Front brakeCheck operation.

Adjust brake lever free play and replace brake

shoes if necessary.Every ride

* Rear brakeCheck operation.

Adjust brake pedal free play and replace brake

shoes if necessary.Every ride

* WheelsCheck balance, runout, spoke tightness and for

damage.

Tighten spokes and rebalance, replace if

necessary.

* TiresCheck tread depth and for damage.

Replace if necessary.

Check air pressure.

Correct if necessary.

* Wheel bearingsCheck bearing for looseness or damage.

Replace if necessary.

* SwingarmCheck swingarm pivoting point for play.

Correct if necessary.

Lubricate with lithium soap base grease.

Drive chainCheck chain slack.

Adjust if necessary. Make sure that the rear wheel

is properly aligned.

Clean and lubricate.Every ride

* Steering bearingsCheck bearing play and steering for roughness.

Correct accordingly.

Lubricate with lithium soap base grease every 120

hours.

3

3

Page 109 of 287

3 - 2

INSP

ADJ

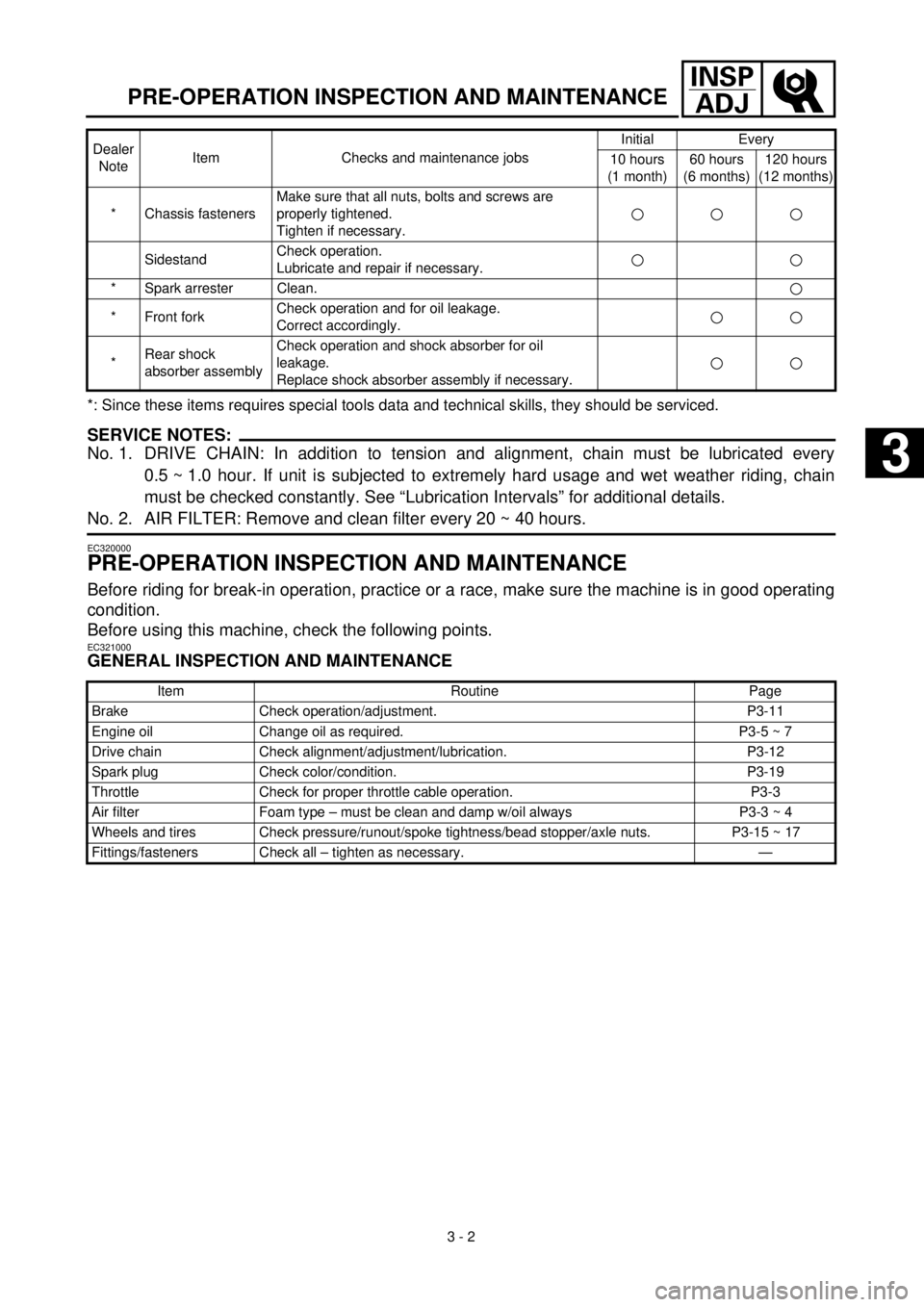

PRE-OPERATION INSPECTION AND MAINTENANCE

*: Since these items requires special tools data and technical skills, they should be serviced.

SERVICE NOTES:

No. 1. DRIVE CHAIN: In addition to tension and alignment, chain must be lubricated every

0.5 ~ 1.0 hour. If unit is subjected to extremely hard usage and wet weather riding, chain

must be checked constantly. See “Lubrication Intervals” for additional details.

No. 2. AIR FILTER: Remove and clean filter every 20 ~ 40 hours.

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

EC321000

GENERAL INSPECTION AND MAINTENANCE

* Chassis fastenersMake sure that all nuts, bolts and screws are

properly tightened.

Tighten if necessary.

SidestandCheck operation.

Lubricate and repair if necessary.

* Spark arrester Clean.

* Front forkCheck operation and for oil leakage.

Correct accordingly.

*Rear shock

absorber assemblyCheck operation and shock absorber for oil

leakage.

Replace shock absorber assembly if necessary.

Item Routine Page

Brake Check operation/adjustment. P3-11

Engine oil Change oil as required. P3-5 ~ 7

Drive chain Check alignment/adjustment/lubrication. P3-12

Spark plug Check color/condition. P3-19

Throttle Check for proper throttle cable operation. P3-3

Air filter Foam type – must be clean and damp w/oil always P3-3 ~ 4

Wheels and tires Check pressure/runout/spoke tightness/bead stopper/axle nuts. P3-15 ~ 17

Fittings/fasteners Check all – tighten as necessary. —Dealer

NoteItem Checks and maintenance jobsInitial Every

10 hours

(1 month)60 hours

(6 months)120 hours

(12 months)

3