engine YAMAHA TTR90 2001 Betriebsanleitungen (in German)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: TTR90, Model: YAMAHA TTR90 2001Pages: 288, PDF-Größe: 15.39 MB

Page 250 of 288

5 - 6

CHAS

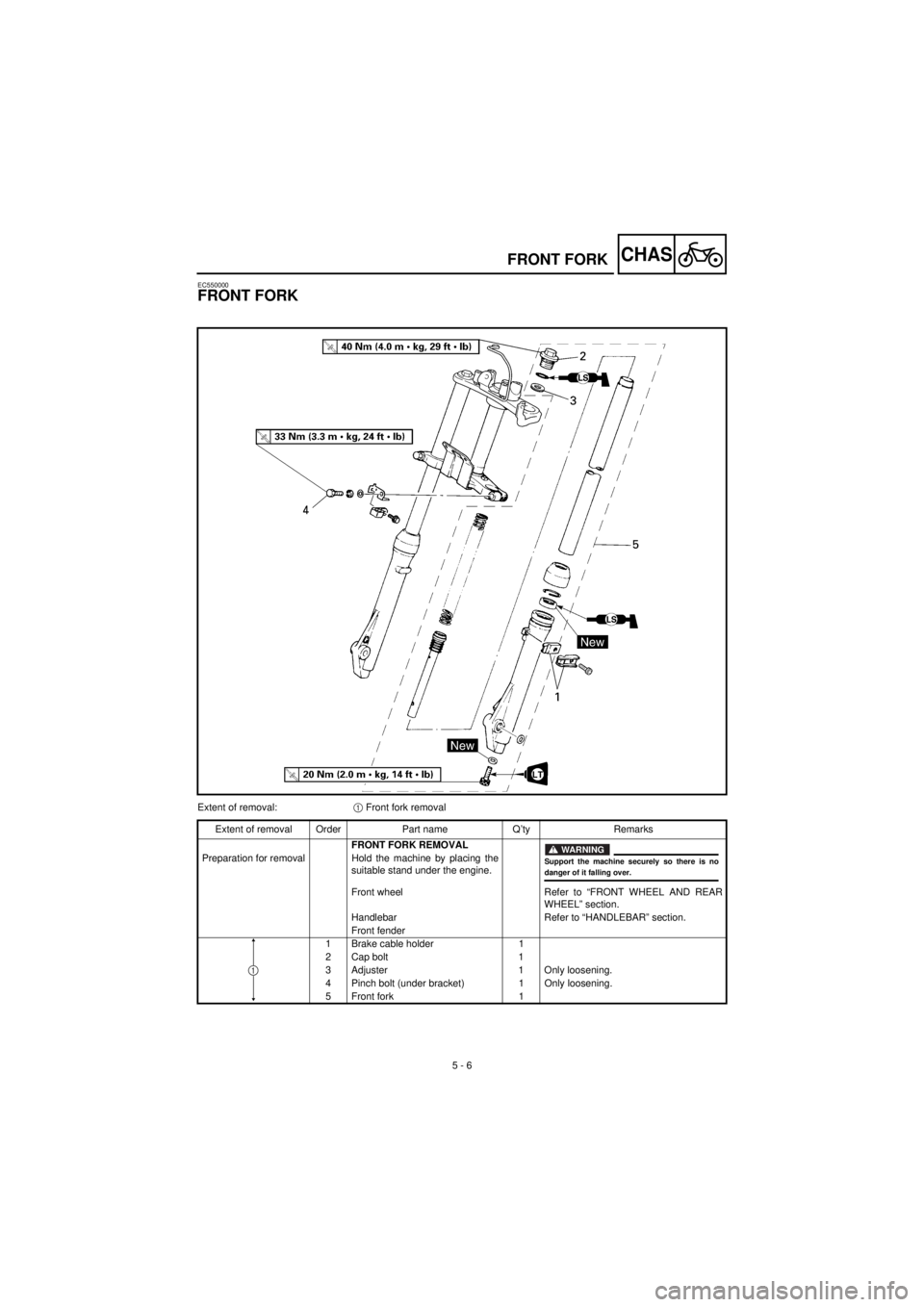

FRONT FORK

EC550000

FRONT FORK

Extent of removal:

1

Front fork removal

Extent of removal Order Part name Q’ty Remarks

FRONT FORK REMOVAL

Preparation for removal Hold the machine by placing the

suitable stand under the engine.

Front wheel Refer to “FRONT WHEEL AND REAR

WHEEL” section.

Handlebar Refer to “HANDLEBAR” section.

Front fender

1 Brake cable holder 1

2 Cap bolt 1

3 Adjuster 1 Only loosening.

4 Pinch bolt (under bracket) 1 Only loosening.

5 Front fork 1

WARNING

Support the machine securely so there is nodanger of it falling over.

1

Page 256 of 288

5 - 9

CHAS

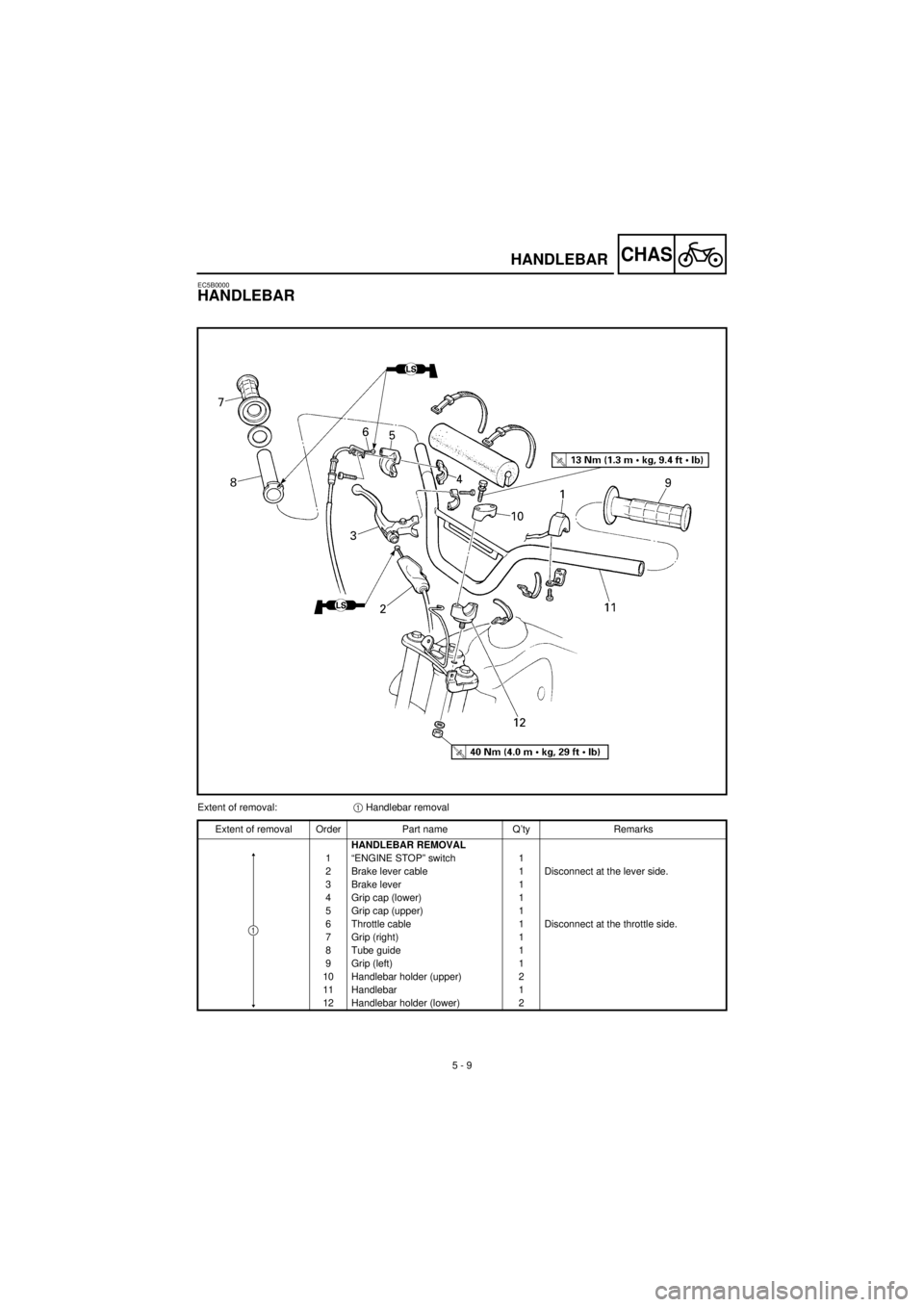

HANDLEBAR

EC5B0000

HANDLEBAR

Extent of removal:

1

Handlebar removal

Extent of removal Order Part name Q’ty Remarks

HANDLEBAR REMOVAL

1 “ENGINE STOP” switch 1

2 Brake lever cable 1 Disconnect at the lever side.

3 Brake lever 1

4 Grip cap (lower) 1

5 Grip cap (upper) 1

6 Throttle cable 1 Disconnect at the throttle side.

7 Grip (right) 1

8 Tube guide 1

9 Grip (left) 1

10 Handlebar holder (upper) 2

11 Handlebar 1

12 Handlebar holder (lower) 2

1

Page 258 of 288

5 - 10

CHAS

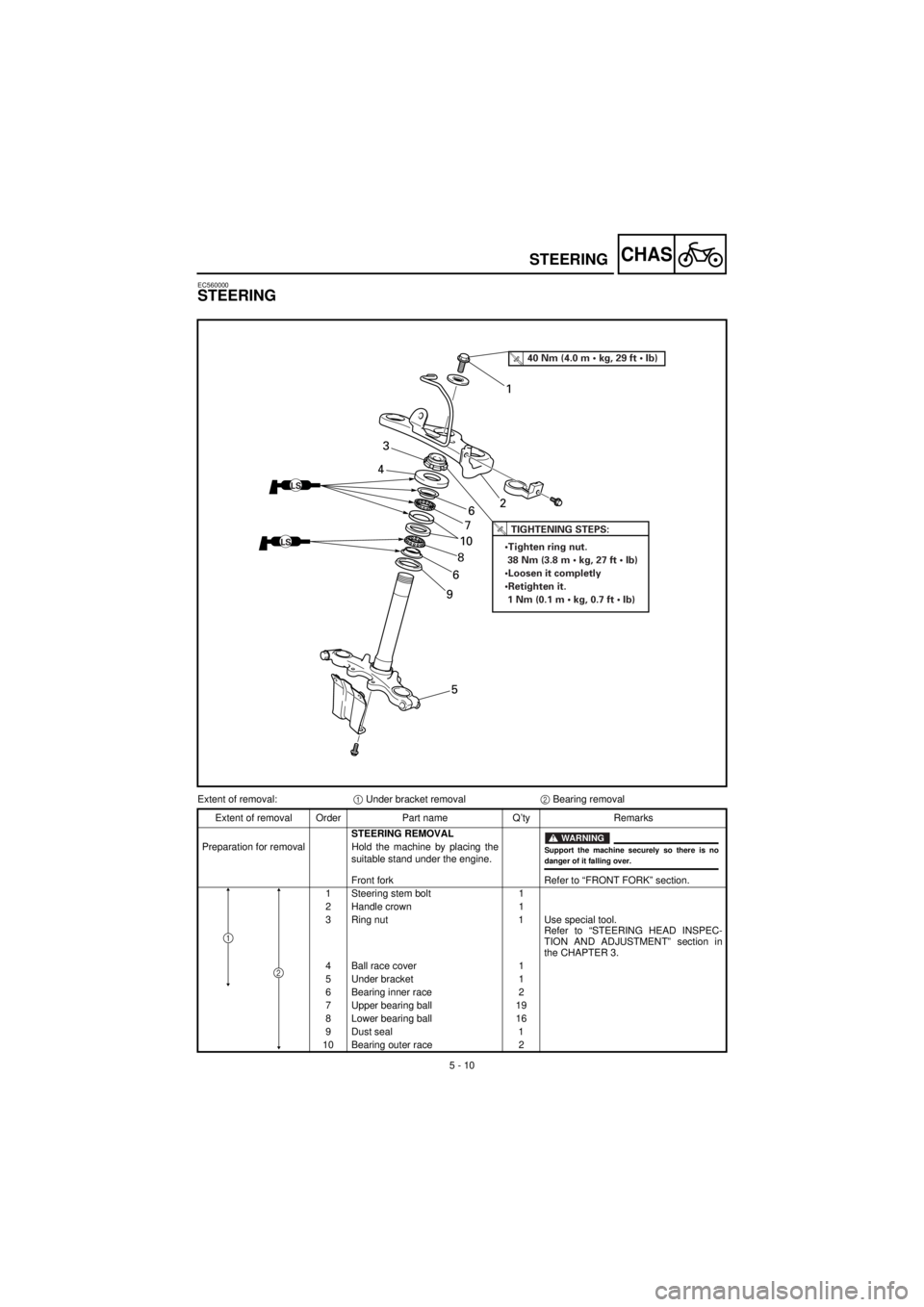

STEERING

EC560000

STEERING

LS

LS

T R..TIGHTENING STEPS:

•Tighten ring nut.

38 Nm (3.8 m • kg, 27 ft • Ib)

•Loosen it completly

•Retighten it.

1 Nm (0.1 m • kg, 0.7 ft • Ib)

T R..40 Nm (4.0 m • kg, 29 ft • Ib)

5 9681076 43

21

Extent of removal:

1

Under bracket removal

2

Bearing removal

Extent of removal Order Part name Q’ty Remarks

STEERING REMOVAL

Preparation for removal Hold the machine by placing the

suitable stand under the engine.

Front fork Refer to “FRONT FORK” section.

1 Steering stem bolt 1

2 Handle crown 1

3 Ring nut 1 Use special tool.

Refer to “STEERING HEAD INSPEC-

TION AND ADJUSTMENT” section in

the CHAPTER 3.

4 Ball race cover 1

5 Under bracket 1

6 Bearing inner race 2

7 Upper bearing ball 19

8 Lower bearing ball 16

9 Dust seal 1

10 Bearing outer race 2

WARNING

Support the machine securely so there is nodanger of it falling over.

2

1

Page 260 of 288

5 - 11

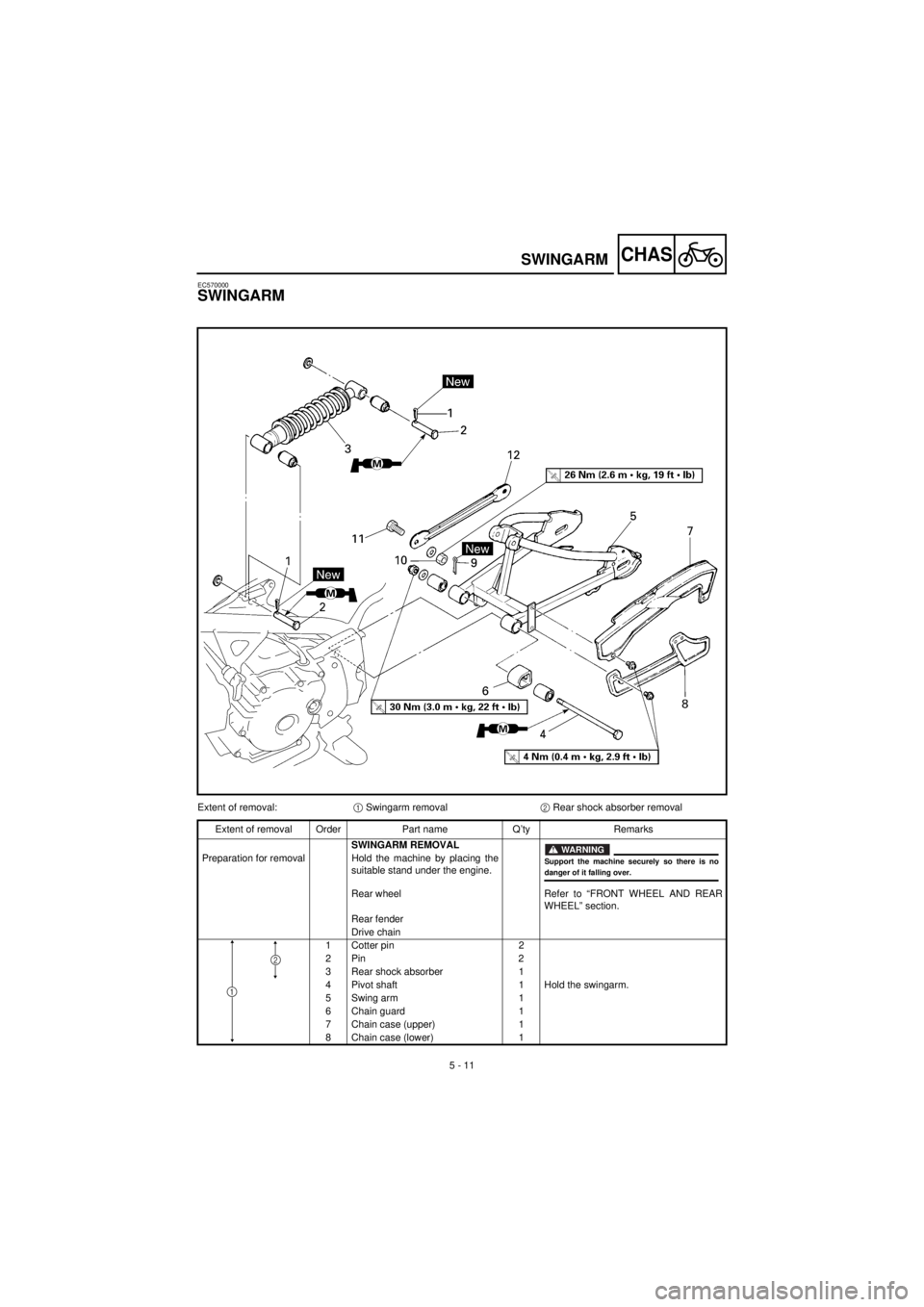

CHASSWINGARM

EC570000

SWINGARM

Extent of removal:1 Swingarm removal2 Rear shock absorber removal

Extent of removal Order Part name Q’ty Remarks

SWINGARM REMOVAL

Preparation for removal Hold the machine by placing the

suitable stand under the engine.

Rear wheel Refer to “FRONT WHEEL AND REAR

WHEEL” section.

Rear fender

Drive chain

1 Cotter pin 2

2 Pin 2

3 Rear shock absorber 1

4 Pivot shaft 1 Hold the swingarm.

5 Swing arm 1

6 Chain guard 1

7 Chain case (upper) 1

8 Chain case (lower) 1

WARNING

Support the machine securely so there is nodanger of it falling over.

1

2

Page 264 of 288

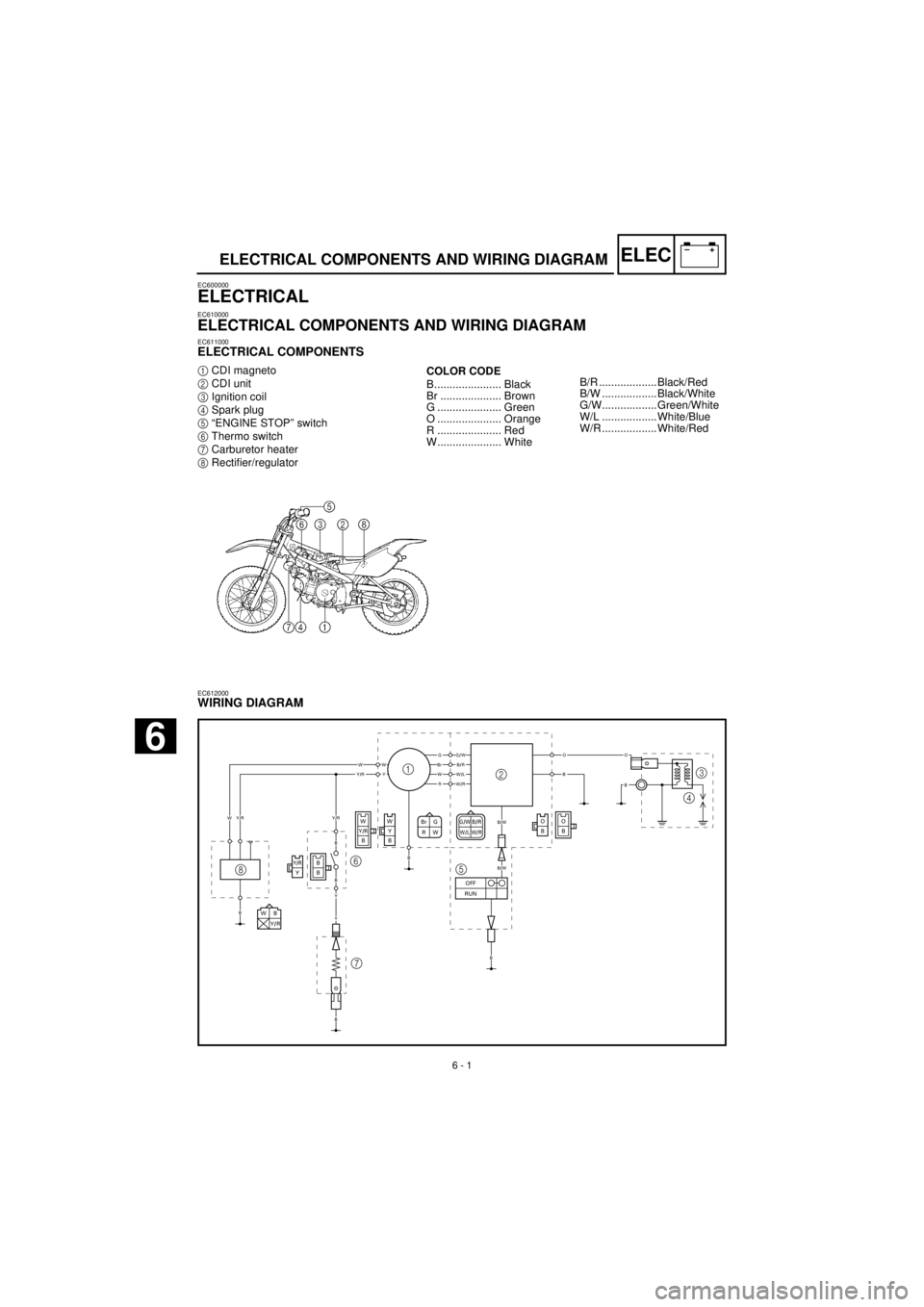

6 - 1

–+ELEC

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC611000

ELECTRICAL COMPONENTS

1

CDI magneto

2

CDI unit

3

Ignition coil

4

Spark plug

5

“ENGINE STOP” switch

6

Thermo switch

7

Carburetor heater

8

Rectifier/regulator

COLOR CODE

B...................... Black

Br .................... Brown

G ..................... Green

O ..................... Orange

R ..................... Red

W..................... White

EC612000

WIRING DIAGRAM

G/WB/RW/LW/RBr G

RW

WB

Y/R

O

BO

B

B

BY/RY

WY/RB

W

Y

B

GG/W

B/W

B/W

BrB/RWWWY

OO

BBW/LY/RR

W

B

B

B

W/R

Y/R

OFF

RUN

B

Y/R

B

B

Y

Y

1

23

4

5 6

7 8

B/R ................... Black/Red

B/W .................. Black/White

G/W.................. Green/White

W/L .................. White/Blue

W/R .................. White/Red

6

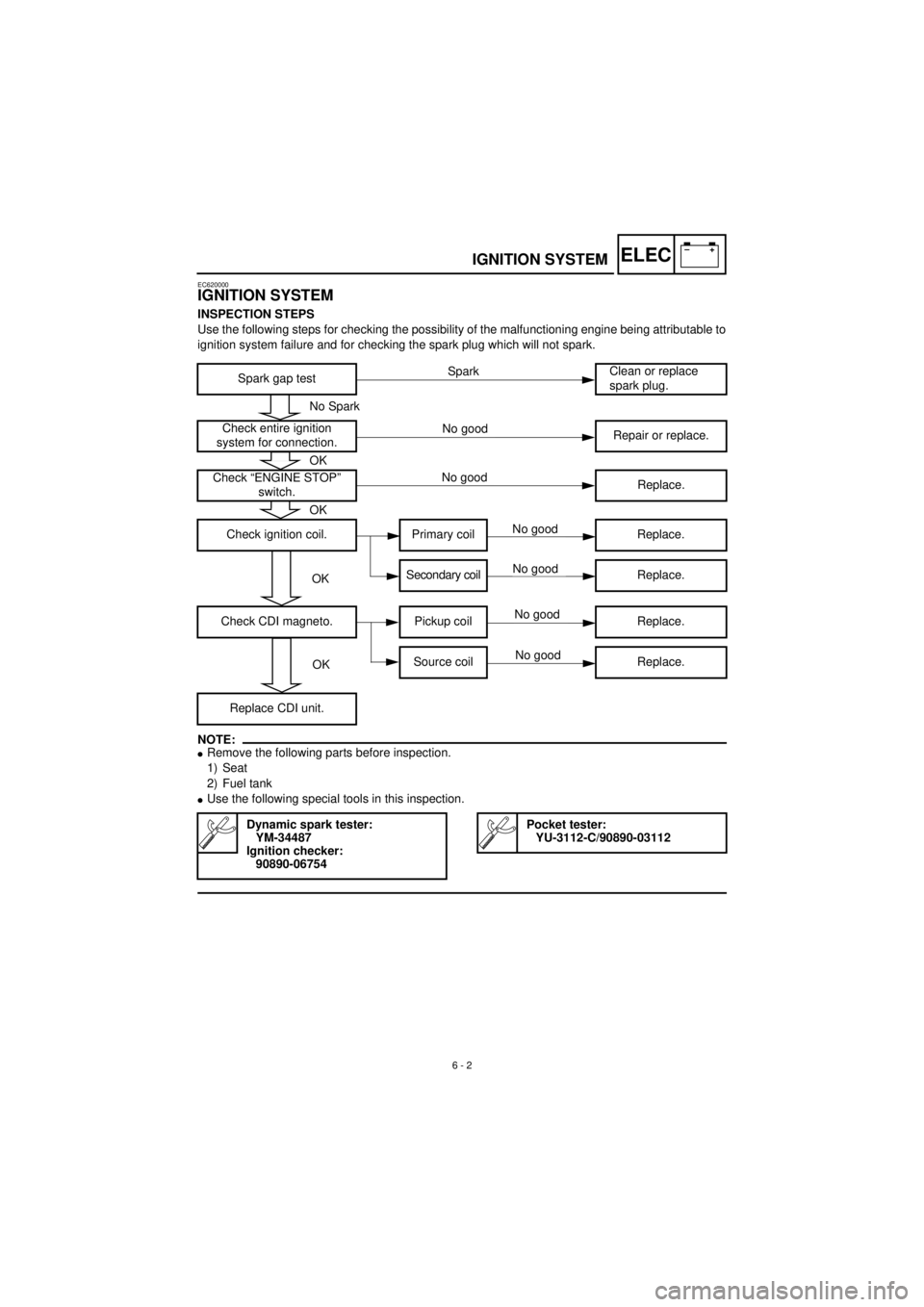

Page 266 of 288

–+ELEC

6 - 2

IGNITION SYSTEM

EC620000

IGNITION SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning engine being attributable to

ignition system failure and for checking the spark plug which will not spark.

NOTE:

l

Remove the following parts before inspection.

1) Seat

2) Fuel tank

l

Use the following special tools in this inspection.

Spark gap testClean or replace

spark plug.

Check entire ignition

system for connection.Repair or replace.

Check “ENGINE STOP”

switch.Replace.

Check ignition coil. Primary coil Replace.

Secondary coilReplace.

Check CDI magneto. Pickup coil Replace.

Source coil Replace.

Replace CDI unit.

Dynamic spark tester:

YM-34487

Ignition checker:

90890-06754

Pocket tester:

YU-3112-C/90890-03112

No Spark

OK

OK

OK

OK

Spark

No good

No good

No good

No good

No good

No good

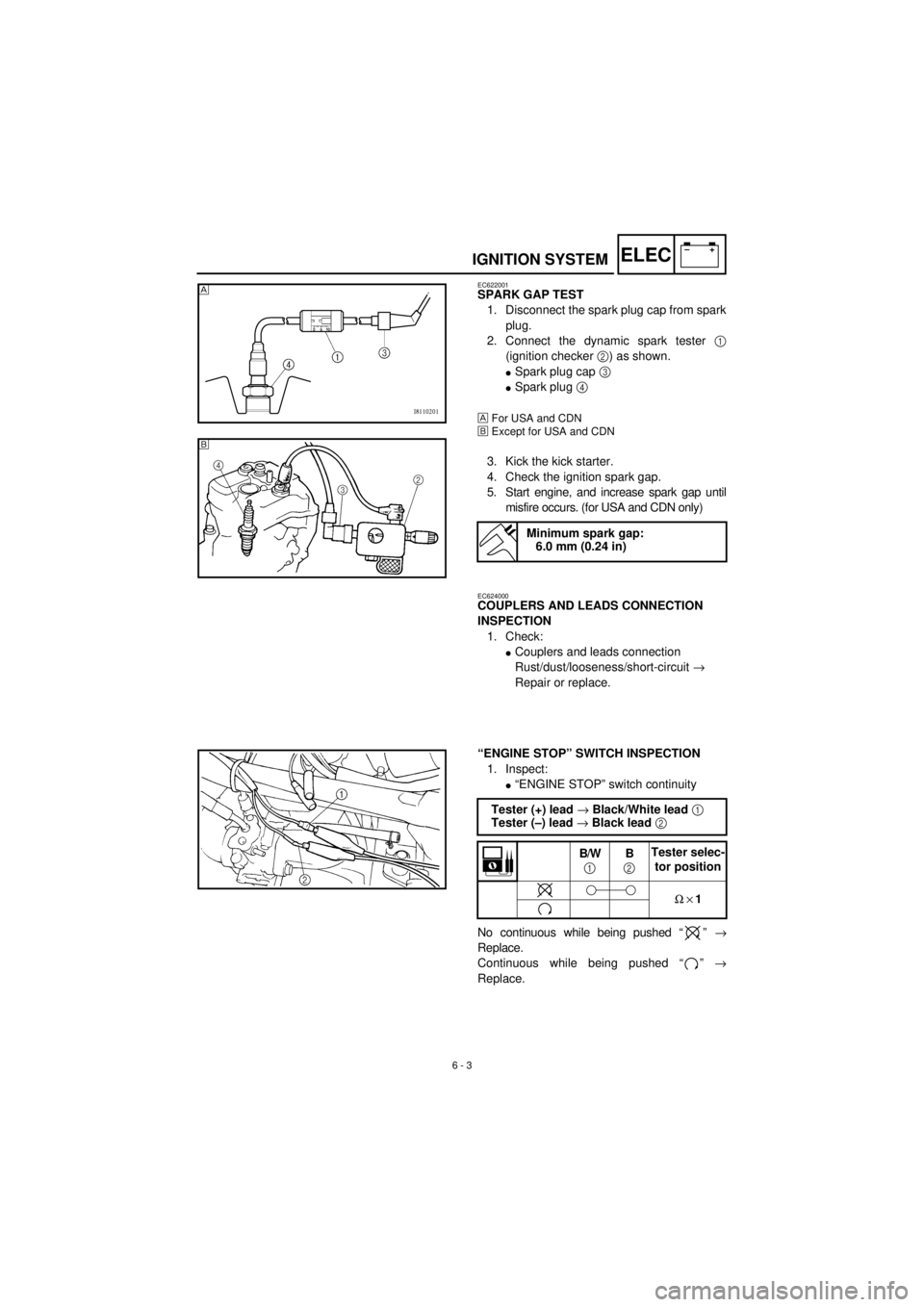

Page 270 of 288

6 - 3

–+ELEC

IGNITION SYSTEM

EC622001

SPARK GAP TEST

1. Disconnect the spark plug cap from spark

plug.

2. Connect the dynamic spark tester

1

(ignition checker

2

) as shown.

l

Spark plug cap

3

l

Spark plug

4

For USA and CDN

õ

Except for USA and CDN

3. Kick the kick starter.

4. Check the ignition spark gap.

5. Start engine, and increase spark gap until

misfire occurs. (for USA and CDN only)

Minimum spark gap:

6.0 mm (0.24 in)

õ

EC624000

COUPLERS AND LEADS CONNECTION

INSPECTION

1. Check:

l

Couplers and leads connection

Rust/dust/looseness/short-circuit

®

Repair or replace.

“ENGINE STOP” SWITCH INSPECTION

1. Inspect:

l

“ENGINE STOP” switch continuity

No continuous while being pushed “ ”

®

Replace.

Continuous while being pushed “ ”

®

Replace.

Tester (+) lead

®

Black/White lead

1

Tester (–) lead

®

Black lead

2

B/W

1

B

2

Tester selec-

tor position

W

´

1