wheel YAMAHA TTR90 2001 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: TTR90, Model: YAMAHA TTR90 2001Pages: 288, PDF Size: 15.39 MB

Page 24 of 288

CHAPTER 4

ENGINE

CARBURETOR

......................................... 4-1

CYLINDER HEAD

..................................... 4-8

CAMSHAFT AND ROCKER ARMS

....... 4-13

VALVES AND VALVE SPRINGS

........... 4-16

CYLINDER AND PISTON

....................... 4-21

CLUTCH

.................................................. 4-27

KICK AXLE

............................................. 4-33

SHIFT SHAFT

......................................... 4-34

OIL PUMP

............................................... 4-36

CDI MAGNETO

....................................... 4-39

CRANKCASE AND CRANKSHAFT

....... 4-41

SHIFT FORK, SHIFT CAM AND

TRANSMISSION

..................................... 4-44

CHAPTER 5

CHASSIS

FRONT WHEEL AND REAR WHEEL

...... 5-1

FRONT FORK

........................................... 5-6

HANDLEBAR

............................................ 5-9

STEERING

.............................................. 5-10

SWINGARM

............................................ 5-11

CHAPTER 6

ELECTRICAL

ELECTRICAL COMPONENTS AND

WIRING DIAGRAM

................................... 6-1

IGNITION SYSTEM

................................... 6-2

CARBURETOR HEATING SYSTEM

........ 6-6

MAINTENANCE RECORD

....................... 6-9

Page 37 of 288

GEN

INFO

1 - 7

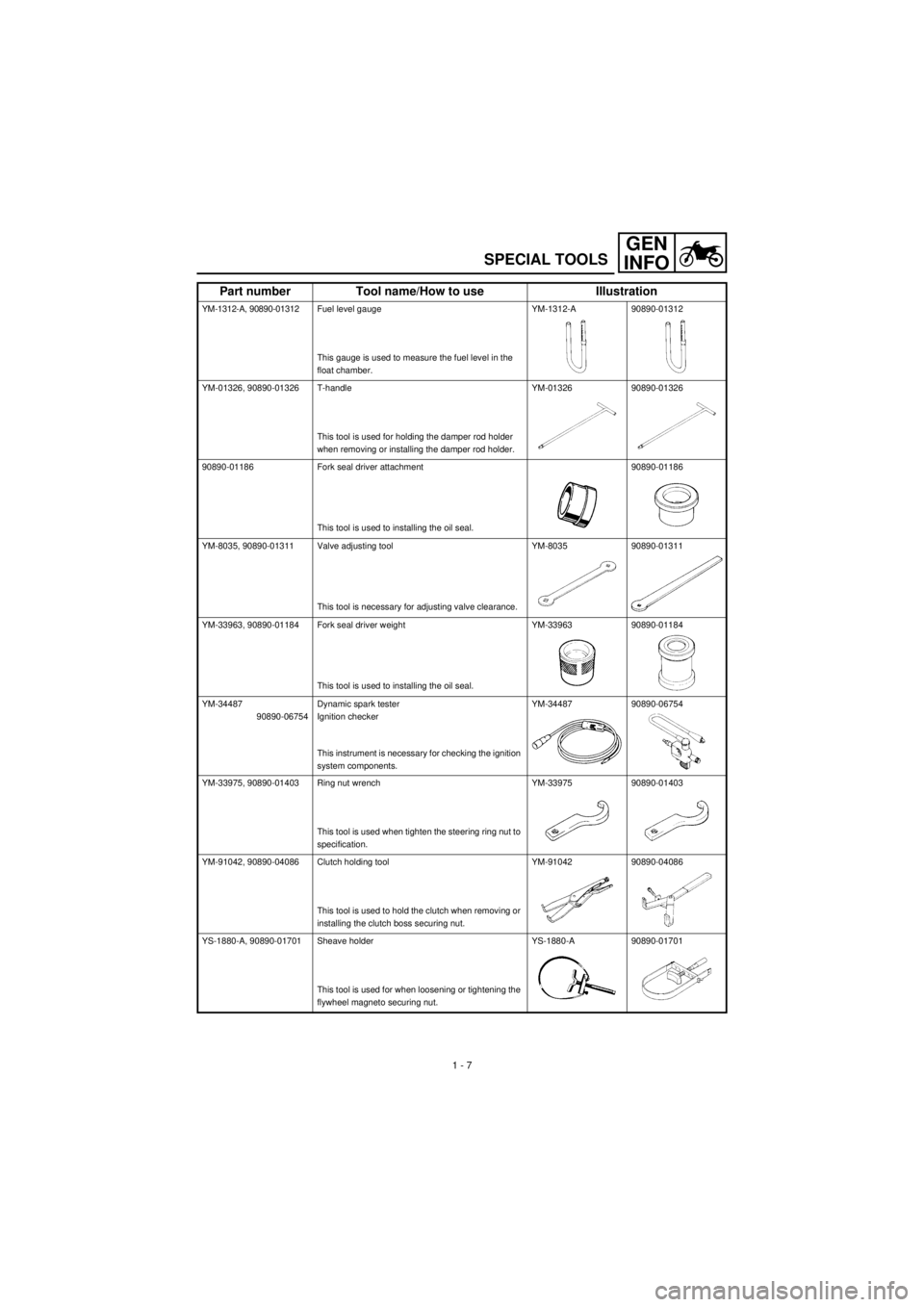

SPECIAL TOOLS

YM-1312-A, 90890-01312Fuel level gauge

This gauge is used to measure the fuel level in the

float chamber.YM-1312-A 90890-01312

YM-01326, 90890-01326 T-handle

This tool is used for holding the damper rod holder

when removing or installing the damper rod holder.YM-01326 90890-01326

90890-01186 Fork seal driver attachment

This tool is used to installing the oil seal.90890-01186

YM-8035, 90890-01311 Valve adjusting tool

This tool is necessary for adjusting valve clearance.YM-8035 90890-01311

YM-33963, 90890-01184 Fork seal driver weight

This tool is used to installing the oil seal.YM-33963 90890-01184

YM-34487

90890-06754Dynamic spark tester

Ignition checker

This instrument is necessary for checking the ignition

system components.YM-34487 90890-06754

YM-33975, 90890-01403 Ring nut wrench

This tool is used when tighten the steering ring nut to

specification.YM-33975 90890-01403

YM-91042, 90890-04086 Clutch holding tool

This tool is used to hold the clutch when removing or

installing the clutch boss securing nut.YM-91042 90890-04086

YS-1880-A, 90890-01701 Sheave holder

This tool is used for when loosening or tightening the

flywheel magneto securing nut.YS-1880-A 90890-01701

Part number Tool name/How to use Illustration

Page 38 of 288

GEN

INFO

1 - 8

SPECIAL TOOLS

YU-33270-B, 90890-01362 Flywheel puller

This tool is used to remove the rotor.YU-33270-B 90890-01362

ACC-QUICK-GS-KT

90890-85505Quick gasket

®

YAMAHA Bond No. 1215

This sealant (Bond) is used for crankcase mating

surface, etc.ACC-QUICK-GS-KT 90890-85505

Part number Tool name/How to use Illustration

Page 56 of 288

SPEC

2 - 1

EC200000

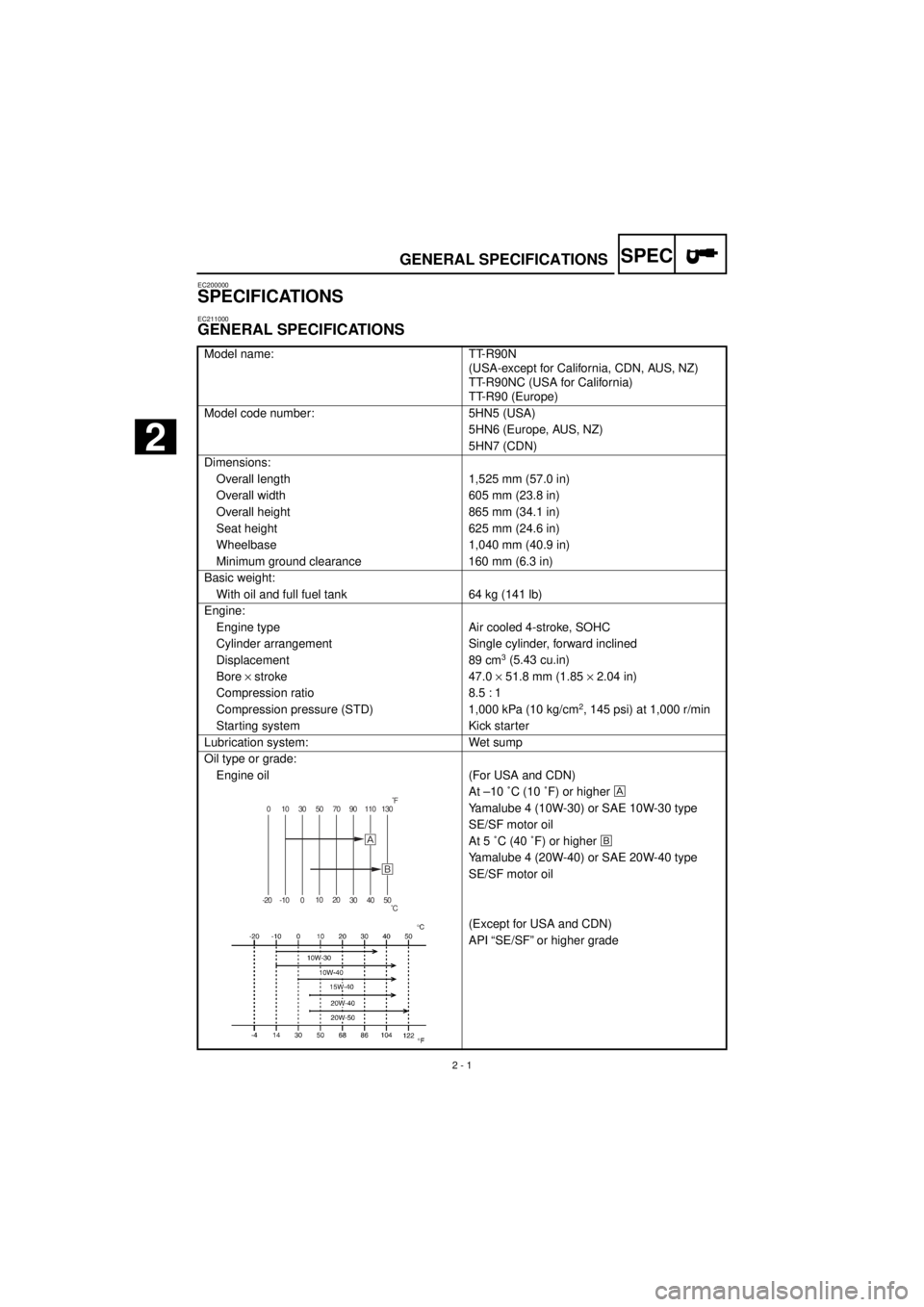

SPECIFICATIONS

EC211000

GENERAL SPECIFICATIONS

Model name: TT-R90N

(USA-except for California, CDN, AUS, NZ)

TT-R90NC (USA for California)

TT-R90 (Europe)

Model code number: 5HN5 (USA)

5HN6 (Europe, AUS, NZ)

5HN7 (CDN)

Dimensions:

Overall length 1,525 mm (57.0 in)

Overall width 605 mm (23.8 in)

Overall height 865 mm (34.1 in)

Seat height 625 mm (24.6 in)

Wheelbase 1,040 mm (40.9 in)

Minimum ground clearance 160 mm (6.3 in)

Basic weight:

With oil and full fuel tank 64 kg (141 lb)

Engine:

Engine type Air cooled 4-stroke, SOHC

Cylinder arrangement Single cylinder, forward inclined

Displacement 89 cm

3

(5.43 cu.in)

Bore

´

stroke 47.0

´

51.8 mm (1.85

´

2.04 in)

Compression ratio 8.5 : 1

Compression pressure (STD) 1,000 kPa (10 kg/cm

2

, 145 psi) at 1,000 r/min

Starting system Kick starter

Lubrication system: Wet sump

Oil type or grade:

Engine oil

(For USA and CDN)

At –10 ˚C (10 ˚F) or higher

Yamalube 4 (10W-30) or SAE 10W-30 type

SE/SF motor oil

At 5 ˚C (40 ˚F) or higher

õ

Yamalube 4 (20W-40) or SAE 20W-40 type

SE/SF motor oil

(Except for USA and CDN)

API “SE/SF” or higher grade

0 10 30 50 70 90 110 130

-20 -10 01020

30 40 50

õ

˚F

˚C

GENERAL SPECIFICATIONS

2

Page 58 of 288

SPEC

2 - 3

Brake:

Front brake type Drum brake

Operation Right hand operation

Rear brake type Drum brake

Operation Right foot operation

Suspension:

Front suspension Telescopic fork

Rear suspension Swingarm (monocross suspension)

Shock absorber:

Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/gas, oil damper

Wheel travel:

Front wheel travel 110 mm (4.33 in)

Rear wheel travel 93 mm (3.66 in)

Electrical:

Ignition system CDI magneto

GENERAL SPECIFICATIONS

Page 66 of 288

SPEC

2 - 11

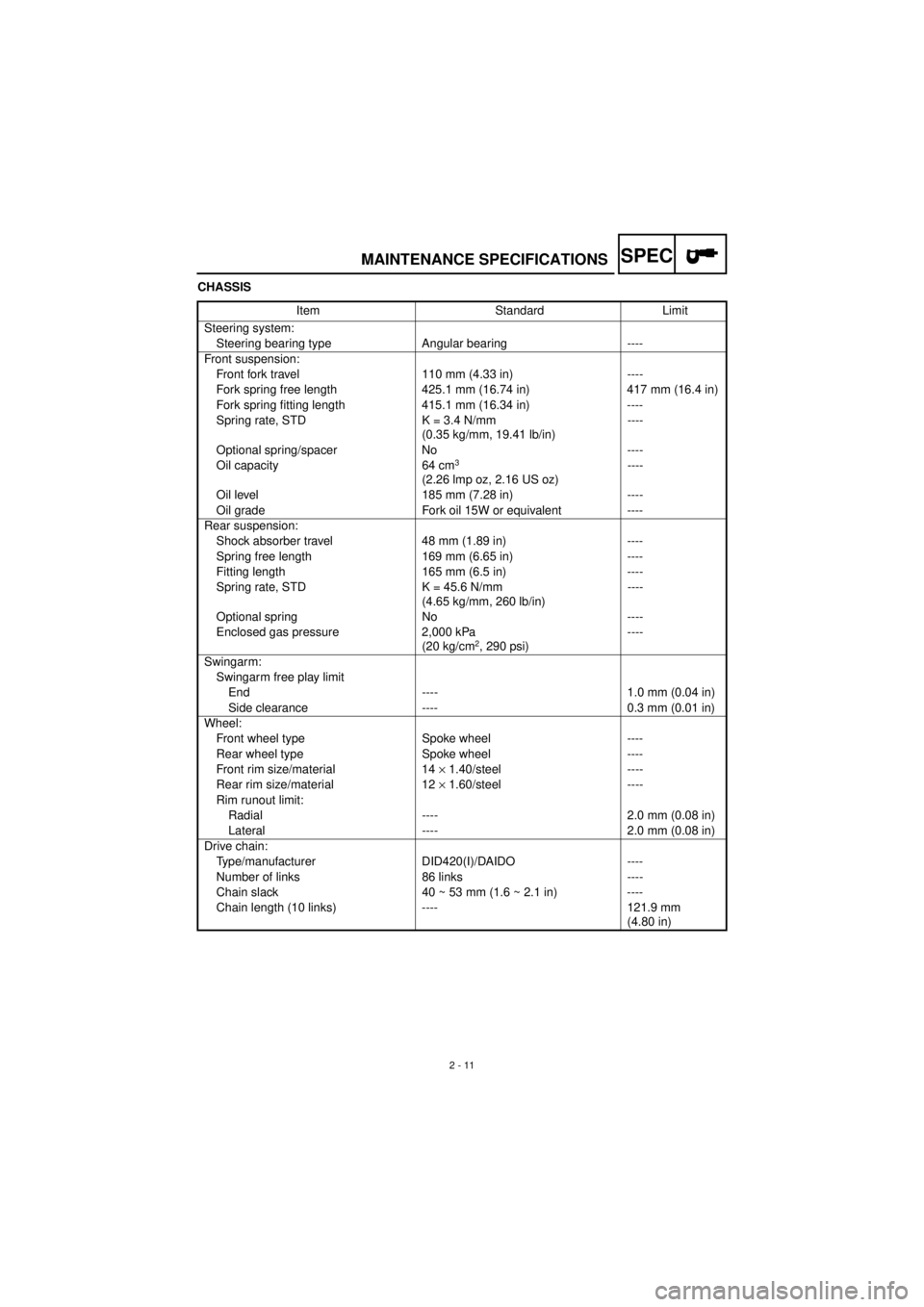

CHASSIS

Item Standard Limit

Steering system:

Steering bearing type Angular bearing ----

Front suspension:

Front fork travel 110 mm (4.33 in) ----

Fork spring free length 425.1 mm (16.74 in) 417 mm (16.4 in)

Fork spring fitting length 415.1 mm (16.34 in) ----

Spring rate, STD K = 3.4 N/mm

(0.35 kg/mm, 19.41 lb/in)----

Optional spring/spacer No ----

Oil capacity 64 cm

3

(2.26 lmp oz, 2.16 US oz) ----

Oil level 185 mm (7.28 in) ----

Oil grade Fork oil 15W or equivalent ----

Rear suspension:

Shock absorber travel 48 mm (1.89 in) ----

Spring free length 169 mm (6.65 in) ----

Fitting length 165 mm (6.5 in) ----

Spring rate, STD K = 45.6 N/mm

(4.65 kg/mm, 260 lb/in)----

Optional spring No ----

Enclosed gas pressure 2,000 kPa

(20 kg/cm

2

, 290 psi)----

Swingarm:

Swingarm free play limit

End ---- 1.0 mm (0.04 in)

Side clearance ---- 0.3 mm (0.01 in)

Wheel:

Front wheel type Spoke wheel ----

Rear wheel type Spoke wheel ----

Front rim size/material 14

´

1.40/steel ----

Rear rim size/material 12

´

1.60/steel ----

Rim runout limit:

Radial ---- 2.0 mm (0.08 in)

Lateral ---- 2.0 mm (0.08 in)

Drive chain:

Type/manufacturer DID420(I)/DAIDO ----

Number of links 86 links ----

Chain slack 40 ~ 53 mm (1.6 ~ 2.1 in) ----

Chain length (10 links) ---- 121.9 mm

(4.80 in)

MAINTENANCE SPECIFICATIONS

Page 68 of 288

SPEC

2 - 13

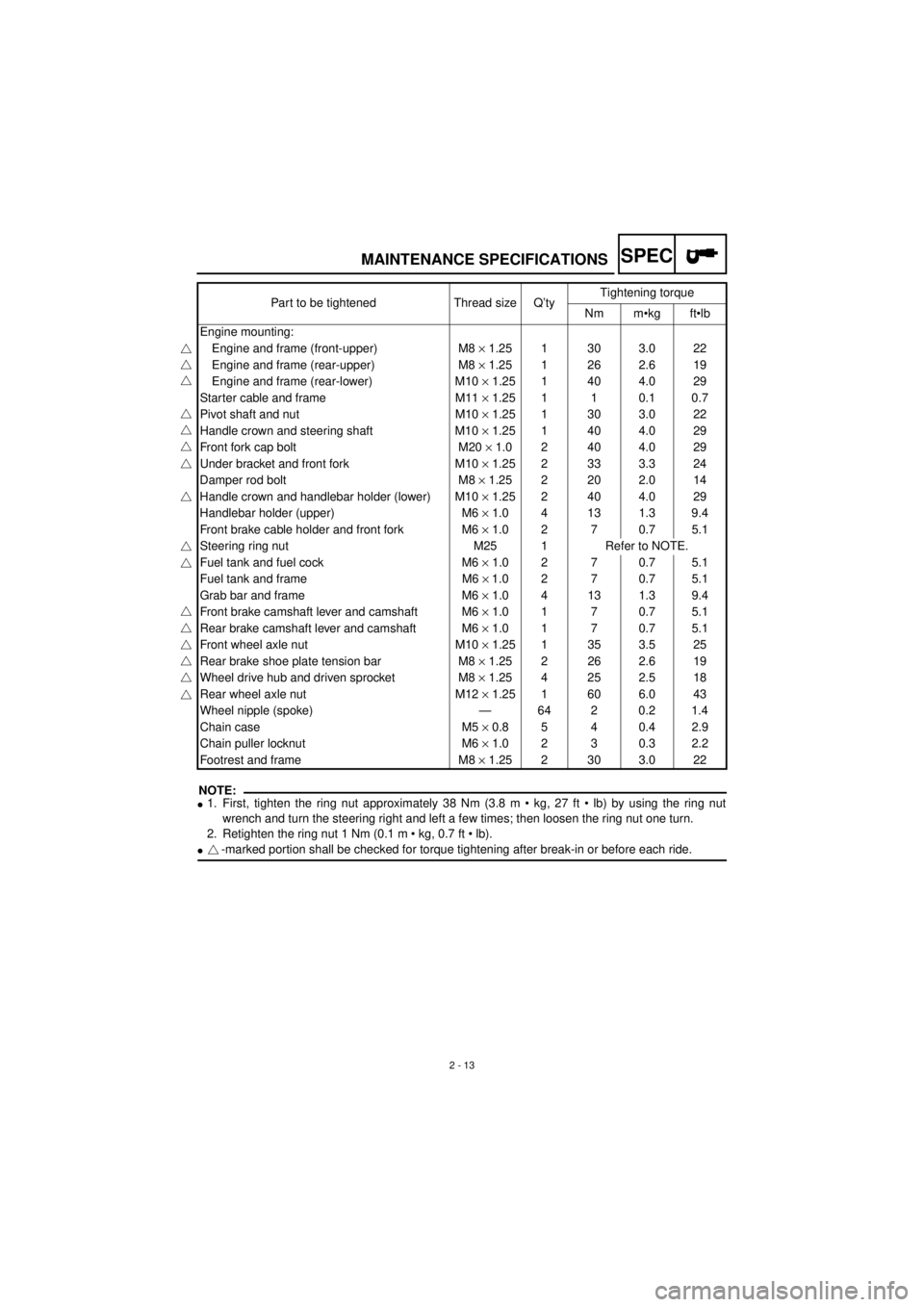

NOTE:

l

1. First, tighten the ring nut approximately 38 Nm (3.8 m • kg, 27 ft • lb) by using the ring nut

wrench and turn the steering right and left a few times; then loosen the ring nut one turn.

2. Retighten the ring nut 1 Nm (0.1 m • kg, 0.7 ft • lb).

l

-marked portion shall be checked for torque tightening after break-in or before each ride.Part to be tightened Thread size Q’tyTightening torque

Nm m•kg ft•lb

Engine mounting:

Engine and frame (front-upper) M8

´

1.25 1 30 3.0 22

Engine and frame (rear-upper) M8

´

1.25 1 26 2.6 19

Engine and frame (rear-lower) M10

´

1.25 1 40 4.0 29

Starter cable and frame M11

´

1.25 1 1 0.1 0.7

Pivot shaft and nut M10

´

1.25 1 30 3.0 22

Handle crown and steering shaft M10

´

1.25 1 40 4.0 29

Front fork cap bolt M20

´

1.0 2 40 4.0 29

Under bracket and front fork M10

´

1.25 2 33 3.3 24

Damper rod bolt M8

´

1.25 2 20 2.0 14

Handle crown and handlebar holder (lower) M10

´

1.25 2 40 4.0 29

Handlebar holder (upper) M6

´

1.0 4 13 1.3 9.4

Front brake cable holder and front fork M6

´

1.0 2 7 0.7 5.1

Steering ring nut M25 1 Refer to NOTE.

Fuel tank and fuel cock M6

´

1.0 2 7 0.7 5.1

Fuel tank and frame M6

´

1.0 2 7 0.7 5.1

Grab bar and frame M6

´

1.0 4 13 1.3 9.4

Front brake camshaft lever and camshaft M6

´

1.0 1 7 0.7 5.1

Rear brake camshaft lever and camshaft M6

´

1.0 1 7 0.7 5.1

Front wheel axle nut M10

´

1.25 1 35 3.5 25

Rear brake shoe plate tension bar M8

´

1.25 2 26 2.6 19

Wheel drive hub and driven sprocket M8

´

1.25 4 25 2.5 18

Rear wheel axle nut M12

´

1.25 1 60 6.0 43

Wheel nipple (spoke) — 64 2 0.2 1.4

Chain case M5

´

0.8 5 4 0.4 2.9

Chain puller locknut M6

´

1.0 2 3 0.3 2.2

Footrest and frame M8

´

1.25 2 30 3.0 22

MAINTENANCE SPECIFICATIONS

Page 108 of 288

3 - 1

INSP

ADJ

MAINTENANCE INTERVALS/

PERIODIC MAINTENANCE AND LUBRICATION

EC300000

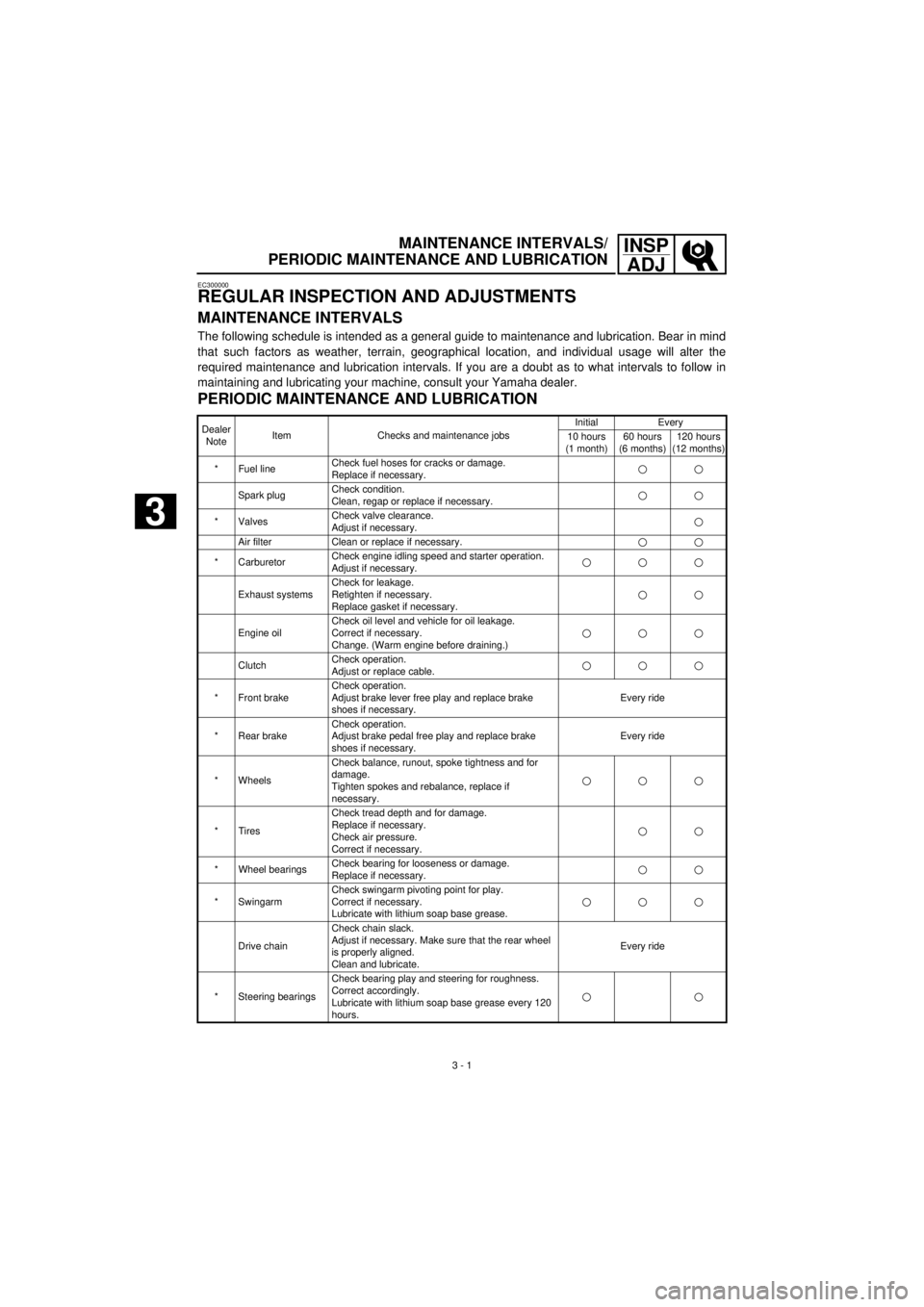

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the

required maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your Yamaha dealer.

PERIODIC MAINTENANCE AND LUBRICATION

Dealer

NoteItem Checks and maintenance jobsInitial Every

10 hours

(1 month)60 hours

(6 months)120 hours

(12 months)

* Fuel lineCheck fuel hoses for cracks or damage.

Replace if necessary.

Spark plugCheck condition.

Clean, regap or replace if necessary.

* ValvesCheck valve clearance.

Adjust if necessary.

Air filter Clean or replace if necessary.

* CarburetorCheck engine idling speed and starter operation.

Adjust if necessary.

Exhaust systemsCheck for leakage.

Retighten if necessary.

Replace gasket if necessary.

Engine oilCheck oil level and vehicle for oil leakage.

Correct if necessary.

Change. (Warm engine before draining.)

ClutchCheck operation.

Adjust or replace cable.

* Front brakeCheck operation.

Adjust brake lever free play and replace brake

shoes if necessary.Every ride

* Rear brakeCheck operation.

Adjust brake pedal free play and replace brake

shoes if necessary.Every ride

* WheelsCheck balance, runout, spoke tightness and for

damage.

Tighten spokes and rebalance, replace if

necessary.

* TiresCheck tread depth and for damage.

Replace if necessary.

Check air pressure.

Correct if necessary.

* Wheel bearingsCheck bearing for looseness or damage.

Replace if necessary.

* SwingarmCheck swingarm pivoting point for play.

Correct if necessary.

Lubricate with lithium soap base grease.

Drive chainCheck chain slack.

Adjust if necessary. Make sure that the rear wheel

is properly aligned.

Clean and lubricate.Every ride

* Steering bearingsCheck bearing play and steering for roughness.

Correct accordingly.

Lubricate with lithium soap base grease every 120

hours.

3

3

Page 109 of 288

3 - 2

INSP

ADJ

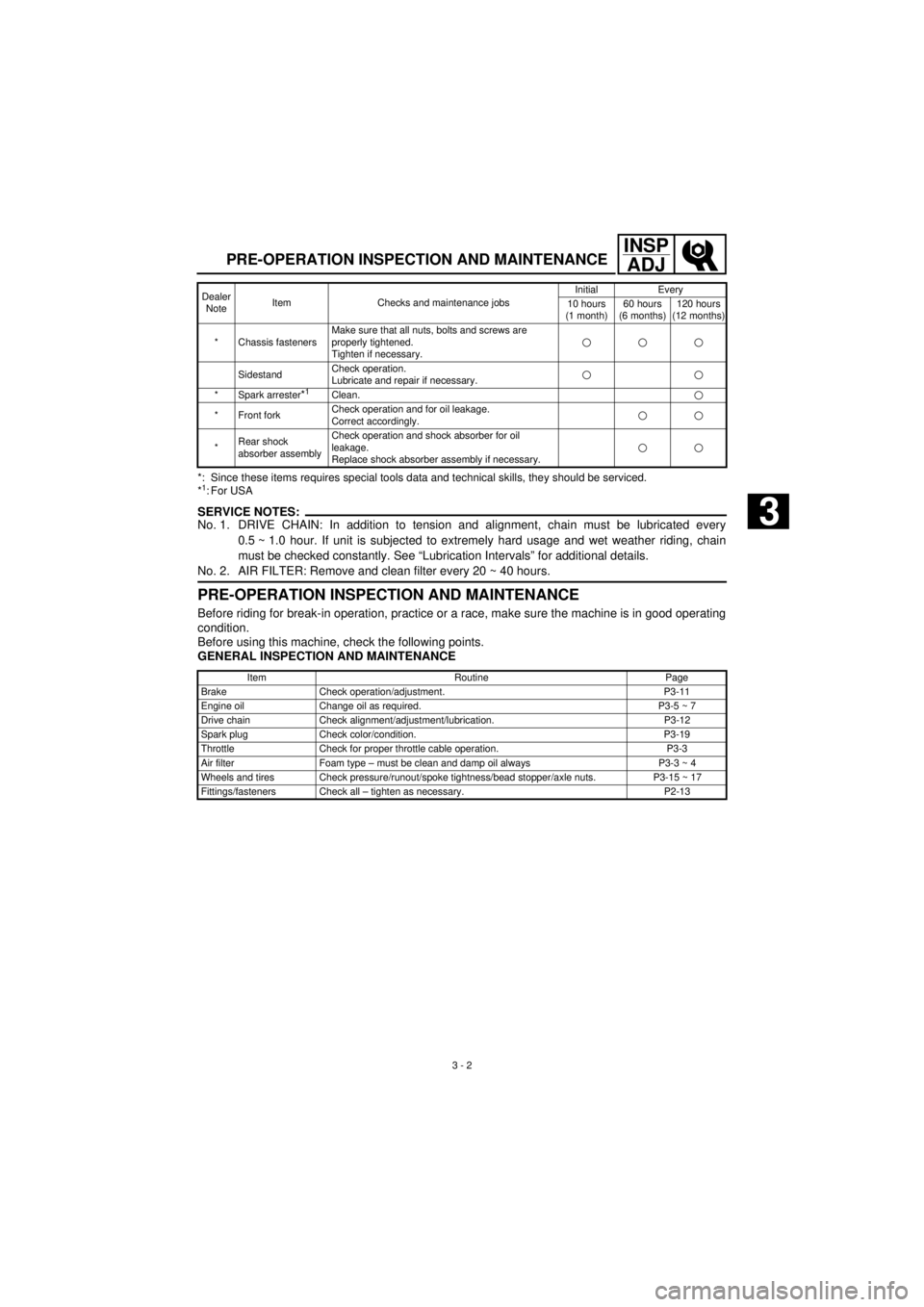

PRE-OPERATION INSPECTION AND MAINTENANCE

*: Since these items requires special tools data and technical skills, they should be serviced.

*

1

: For USA

SERVICE NOTES:

No. 1. DRIVE CHAIN: In addition to tension and alignment, chain must be lubricated every

0.5 ~ 1.0 hour. If unit is subjected to extremely hard usage and wet weather riding, chain

must be checked constantly. See “Lubrication Intervals” for additional details.

No. 2. AIR FILTER: Remove and clean filter every 20 ~ 40 hours.

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

* Chassis fastenersMake sure that all nuts, bolts and screws are

properly tightened.

Tighten if necessary.

SidestandCheck operation.

Lubricate and repair if necessary.

* Spark arrester

*

1

Clean.

* Front forkCheck operation and for oil leakage.

Correct accordingly.

*Rear shock

absorber assemblyCheck operation and shock absorber for oil

leakage.

Replace shock absorber assembly if necessary.

Item Routine Page

Brake Check operation/adjustment. P3-11

Engine oil Change oil as required. P3-5 ~ 7

Drive chain Check alignment/adjustment/lubrication. P3-12

Spark plug Check color/condition. P3-19

Throttle Check for proper throttle cable operation. P3-3

Air filter Foam type – must be clean and damp oil always P3-3 ~ 4

Wheels and tires Check pressure/runout/spoke tightness/bead stopper/axle nuts. P3-15 ~ 17

Fittings/fasteners Check all – tighten as necessary. P2-13Dealer

NoteItem Checks and maintenance jobsInitial Every

10 hours

(1 month)60 hours

(6 months)120 hours

(12 months)

3

Page 132 of 288

3 - 12

INSP

ADJ

DRIVE CHAIN SLACK ADJUSTMENT

DRIVE CHAIN SLACK ADJUSTMENT

1. Elevate the rear wheel by placing the

suitable stand under the engine.

2. Check:

lDrive chain slack a

In the center between the drive axle

and rear wheel axle.

Out of specification ® Adjust.

NOTE:

Before checking and/or adjusting, rotate the

rear wheel through several revolutions and

check the slack several times to find the tight-

est point. Check and/or adjust chain slack with

rear wheel in this “tight chain” position.

Drive chain slack:

40 ~ 53 mm (1.6 ~ 2.1 in)

3. Adjust:

lDrive chain slack

Drive chain slack adjustment steps:

lLoosen the wheel axle nut 1.

lAdjust chain slack by turning the adjusters

2.

To tighten ®Turn adjuster 2 clockwise.

To loosen ®Turn adjuster 2 counter-

clockwise and push wheel

forward.

lTurn each adjuster exactly the same

amount to maintain correct axle alignment.

(There are marks a on each side of chain

puller alignment.)

12 a

NOTE:

Turn the adjuster so that the chain is in line

with the sprocket, as viewed from the rear.

CAUTION:

Too small chain slack will overload the

engine and other vital parts; keep the

slack within the specified limits.