wheel YAMAHA TTR90 2001 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: TTR90, Model: YAMAHA TTR90 2001Pages: 288, PDF Size: 15.39 MB

Page 134 of 288

3 - 13

INSP

ADJFRONT FORK INSPECTION/REAR SHOCK ABSORBER INSPECTION/

REAR SHOCK ABSORBER SPRING PRELOAD ADJUSTMENT

lTighten the wheel axle nut while pushing

down the drive chain.

T R..

Axle nut:

60 Nm (6.0 m • kg, 43 ft • lb)

EC36C000

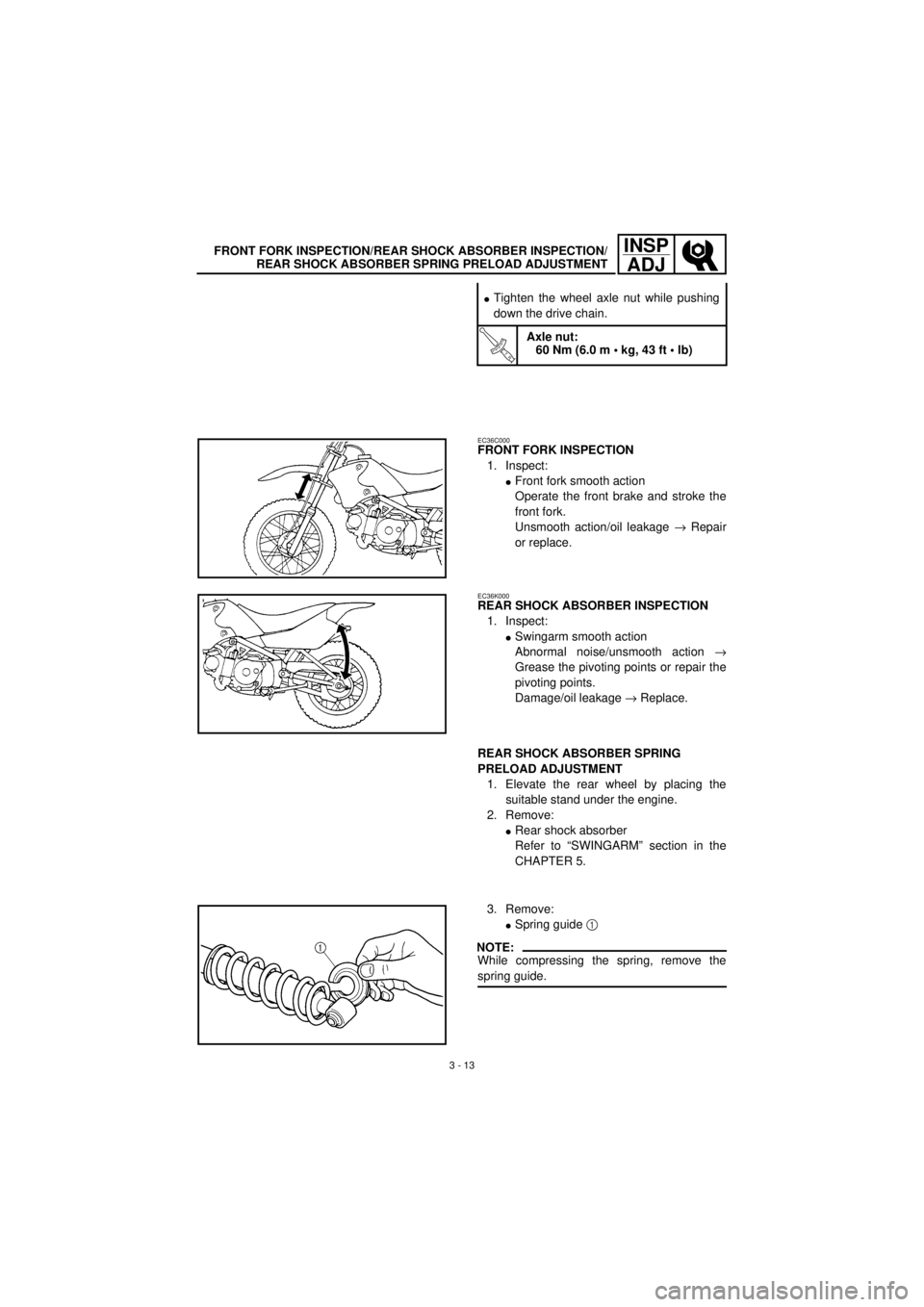

FRONT FORK INSPECTION

1. Inspect:

lFront fork smooth action

Operate the front brake and stroke the

front fork.

Unsmooth action/oil leakage ® Repair

or replace.

EC36K000

REAR SHOCK ABSORBER INSPECTION

1. Inspect:

lSwingarm smooth action

Abnormal noise/unsmooth action ®

Grease the pivoting points or repair the

pivoting points.

Damage/oil leakage ® Replace.

REAR SHOCK ABSORBER SPRING

PRELOAD ADJUSTMENT

1. Elevate the rear wheel by placing the

suitable stand under the engine.

2. Remove:

lRear shock absorber

Refer to “SWINGARM” section in the

CHAPTER 5.

3. Remove:

lSpring guide 1

NOTE:

While compressing the spring, remove the

spring guide.

Page 138 of 288

3 - 15

INSP

ADJSPOKES INSPECTION AND TIGHTENING/WHEEL INSPECTION/

STEERING HEAD INSPECTION AND ADJUSTMENT

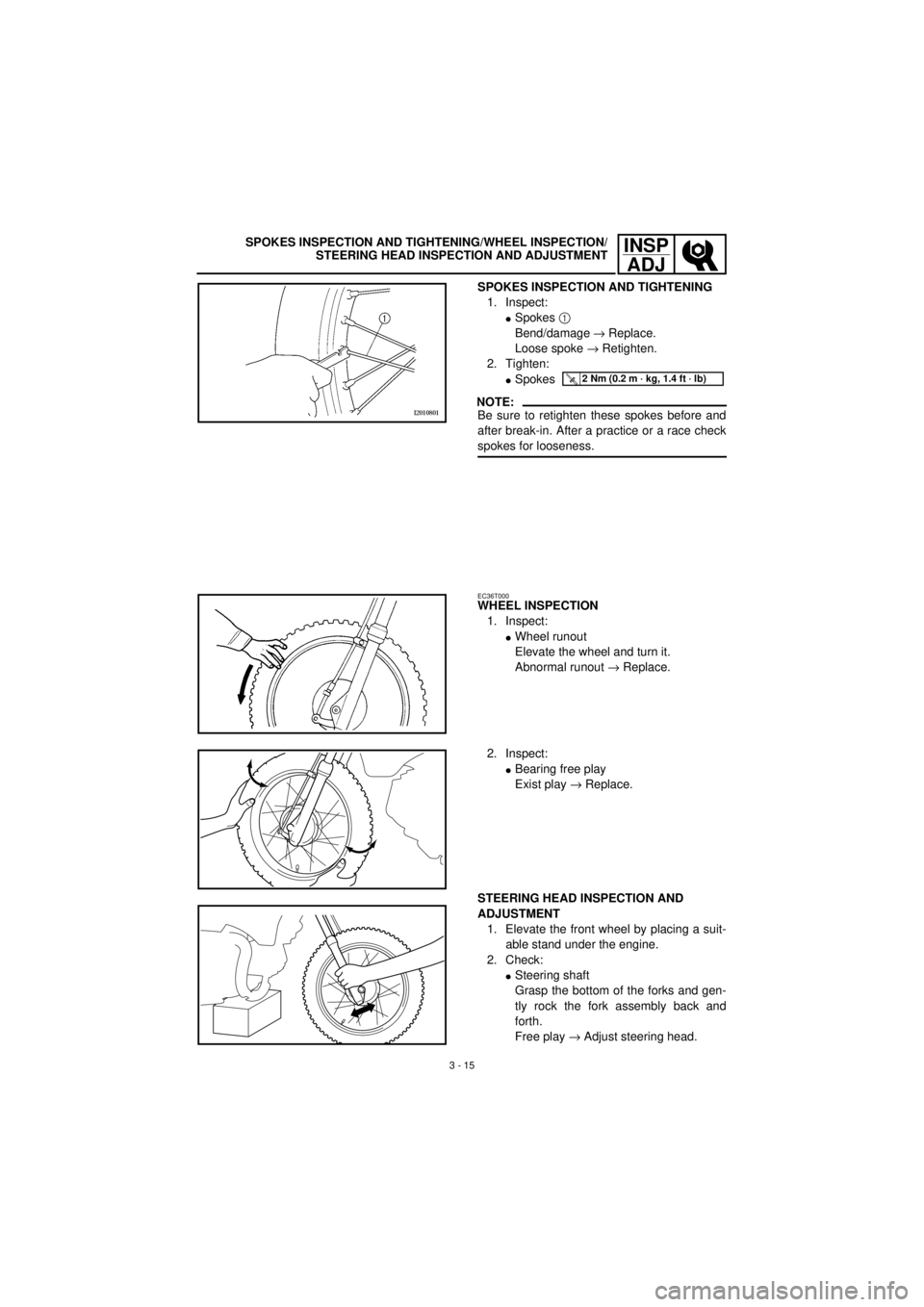

SPOKES INSPECTION AND TIGHTENING

1. Inspect:

lSpokes 1

Bend/damage ® Replace.

Loose spoke ® Retighten.

2. Tighten:

lSpokes

NOTE:

Be sure to retighten these spokes before and

after break-in. After a practice or a race check

spokes for looseness.

T R..2 Nm (0.2 m · kg, 1.4 ft · lb)

EC36T000

WHEEL INSPECTION

1. Inspect:

lWheel runout

Elevate the wheel and turn it.

Abnormal runout ® Replace.

2. Inspect:

lBearing free play

Exist play ® Replace.

STEERING HEAD INSPECTION AND

ADJUSTMENT

1. Elevate the front wheel by placing a suit-

able stand under the engine.

2. Check:

lSteering shaft

Grasp the bottom of the forks and gen-

tly rock the fork assembly back and

forth.

Free play ® Adjust steering head.

Page 212 of 288

4 - 33

ENGKICK AXLE

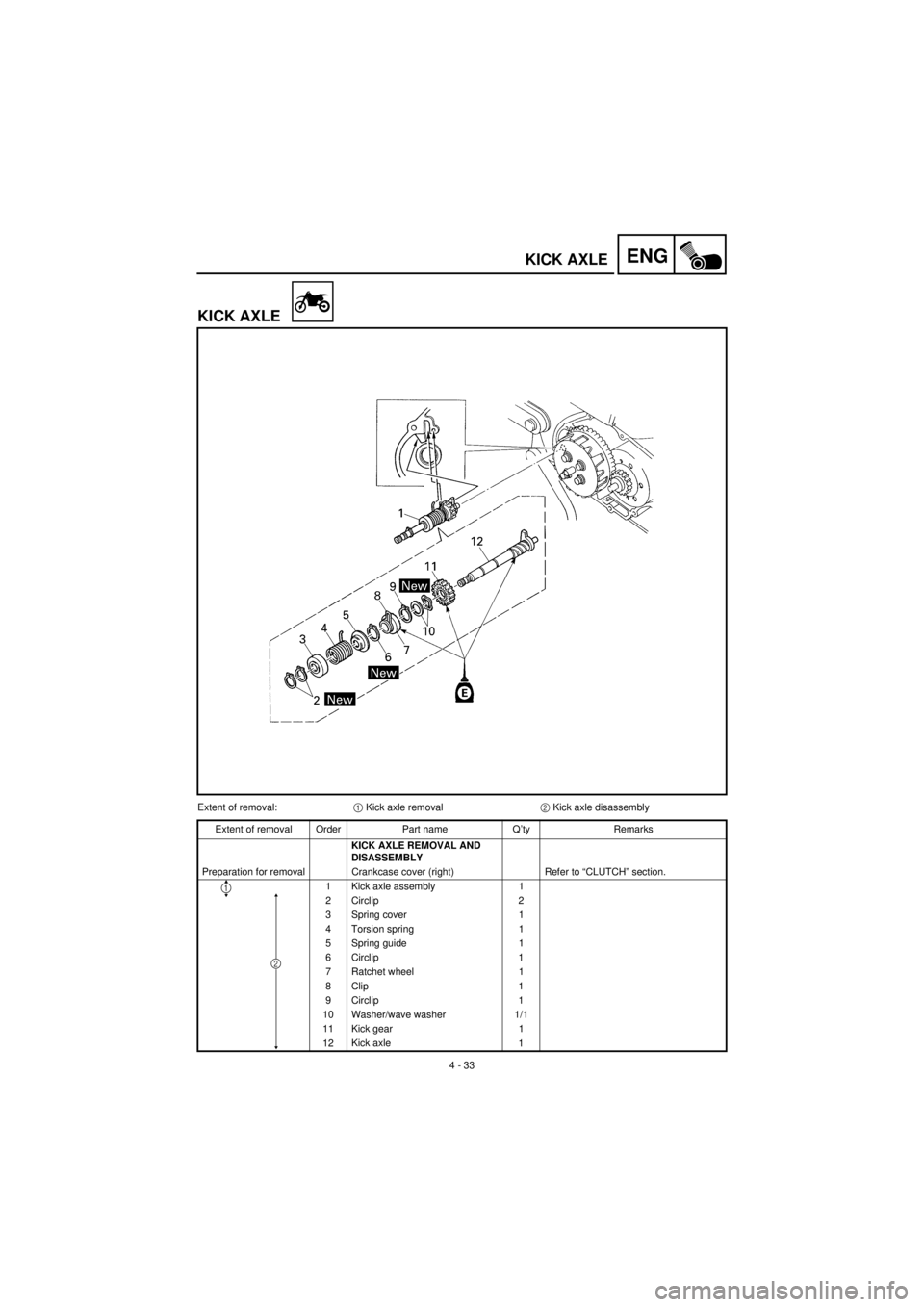

KICK AXLE

Extent of removal:1 Kick axle removal2 Kick axle disassembly

Extent of removal Order Part name Q’ty Remarks

KICK AXLE REMOVAL AND

DISASSEMBLY

Preparation for removal Crankcase cover (right) Refer to “CLUTCH” section.

1 Kick axle assembly 1

2 Circlip 2

3 Spring cover 1

4 Torsion spring 1

5 Spring guide 1

6 Circlip 1

7 Ratchet wheel 1

8 Clip 1

9 Circlip 1

10 Washer/wave washer 1/1

11 Kick gear 1

12Kick axle

1

1

2

Page 226 of 288

4 - 40

ENGCDI MAGNETO

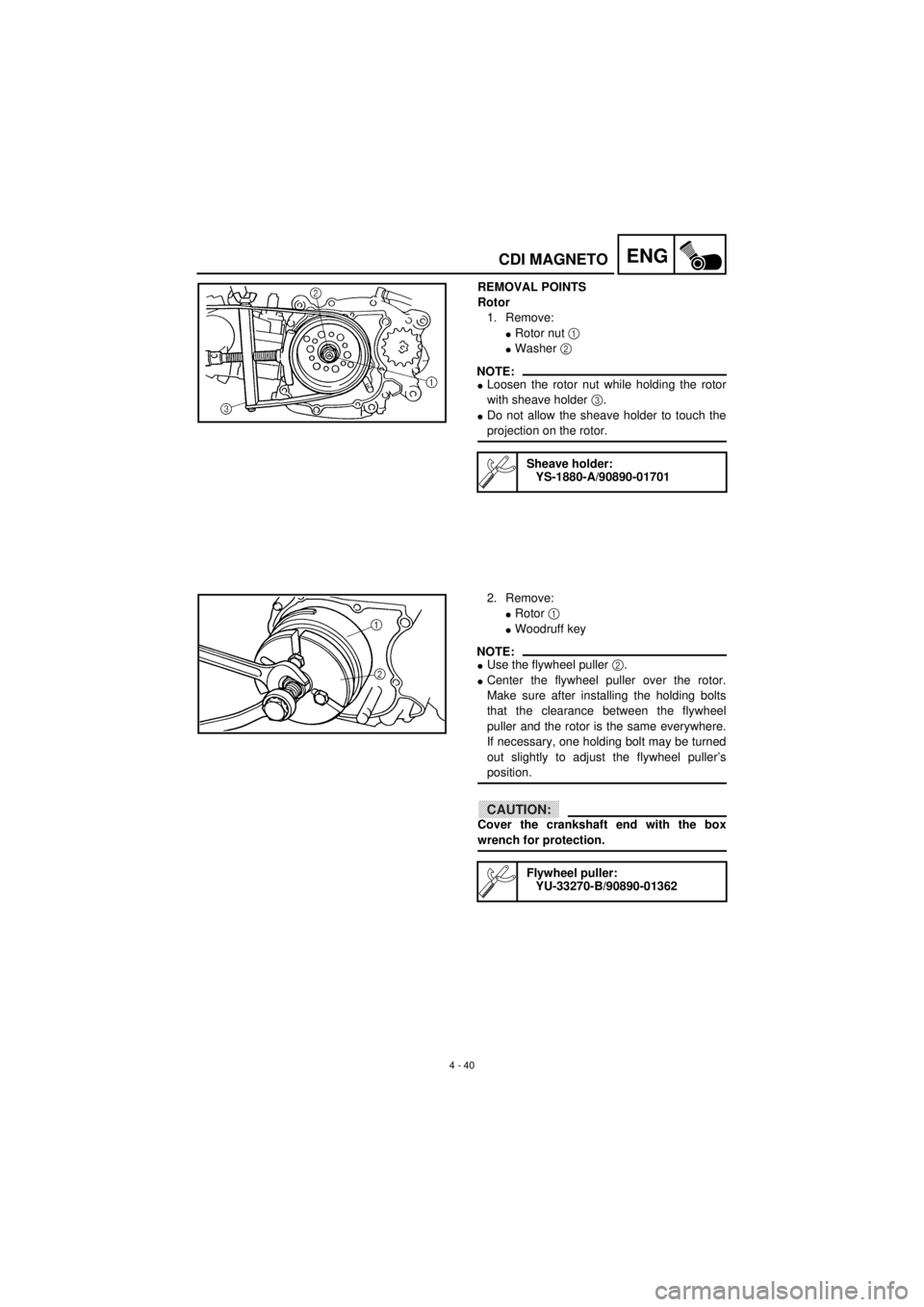

REMOVAL POINTS

Rotor

1. Remove:

lRotor nut 1

lWasher 2

NOTE:

lLoosen the rotor nut while holding the rotor

with sheave holder 3.

lDo not allow the sheave holder to touch the

projection on the rotor.

Sheave holder:

YS-1880-A/90890-01701

2. Remove:

lRotor 1

lWoodruff key

NOTE:

lUse the flywheel puller 2.

lCenter the flywheel puller over the rotor.

Make sure after installing the holding bolts

that the clearance between the flywheel

puller and the rotor is the same everywhere.

If necessary, one holding bolt may be turned

out slightly to adjust the flywheel puller’s

position.

CAUTION:

Cover the crankshaft end with the box

wrench for protection.

Flywheel puller:

YU-33270-B/90890-01362

Page 236 of 288

4 - 45

ENG

SHIFT FORK, SHIFT CAM AND TRANSMISSION

Extent of removal Order Part name Q’ty Remarks

10 3th pinion gear 1

11 Main axle 1

12 Circlip 1

13 Washer 1

14 Collar 1

15 1st wheel gear 1

16 3rd wheel gear 1

17 Circlip 1

18 Washer 1

19 2nd wheel gear 1

20 Drive axle 1

2

3

Page 240 of 288

5 - 1

CHAS

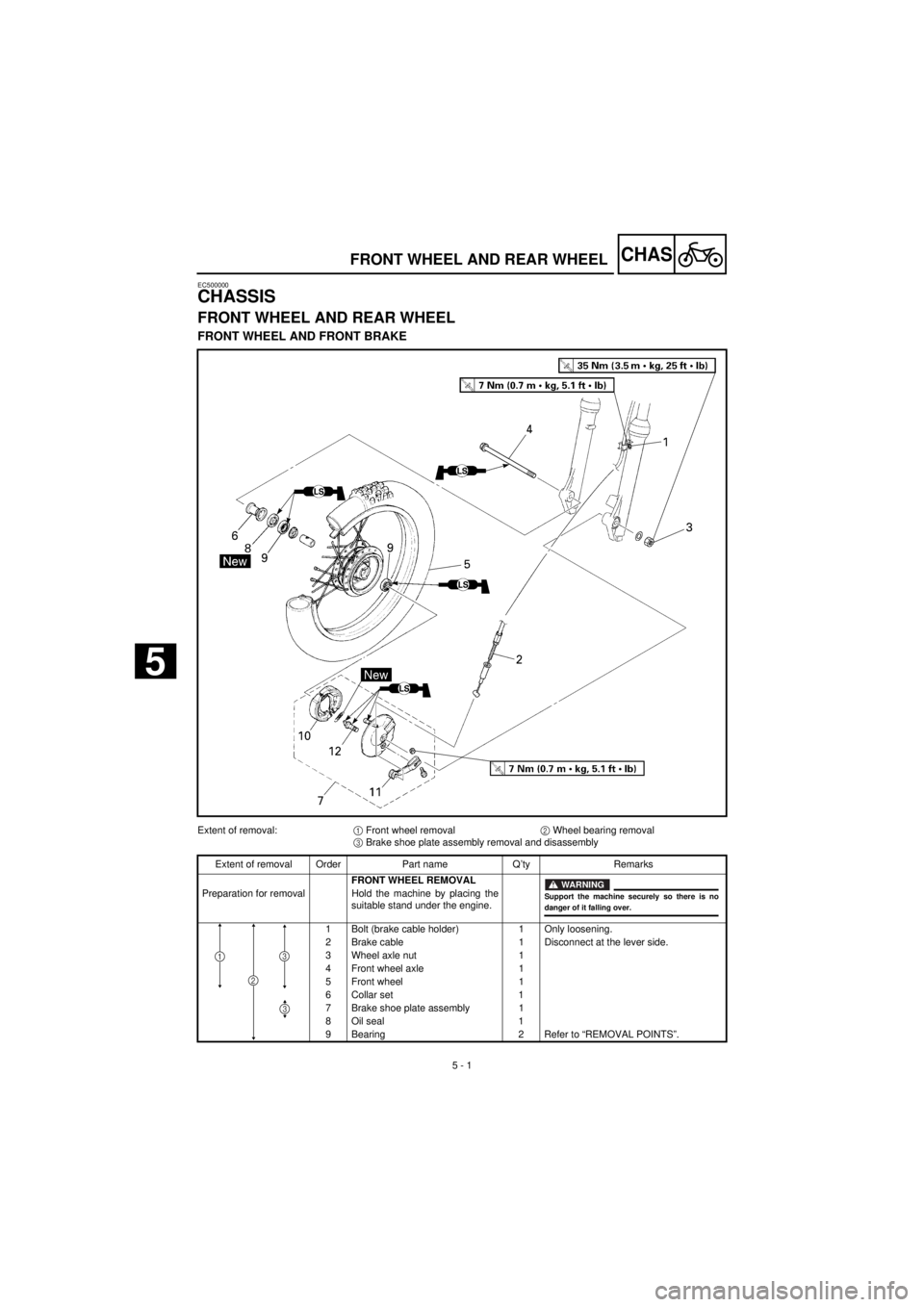

EC500000

CHASSIS

FRONT WHEEL AND REAR WHEEL

FRONT WHEEL AND FRONT BRAKE

Extent of removal:

1

Front wheel removal

2

Wheel bearing removal

3

Brake shoe plate assembly removal and disassembly

Extent of removal Order Part name Q’ty Remarks

FRONT WHEEL REMOVAL

Preparation for removal Hold the machine by placing the

suitable stand under the engine.

1 Bolt (brake cable holder) 1 Only loosening.

2 Brake cable 1 Disconnect at the lever side.

3 Wheel axle nut 1

4 Front wheel axle 1

5 Front wheel 1

6 Collar set 1

7 Brake shoe plate assembly 1

8 Oil seal 1

9Bearing

2Refer to “REMOVAL POINTS”.

WARNING

Support the machine securely so there is nodanger of it falling over.

2

31

3

FRONT WHEEL AND REAR WHEEL

5

Page 242 of 288

5 - 2

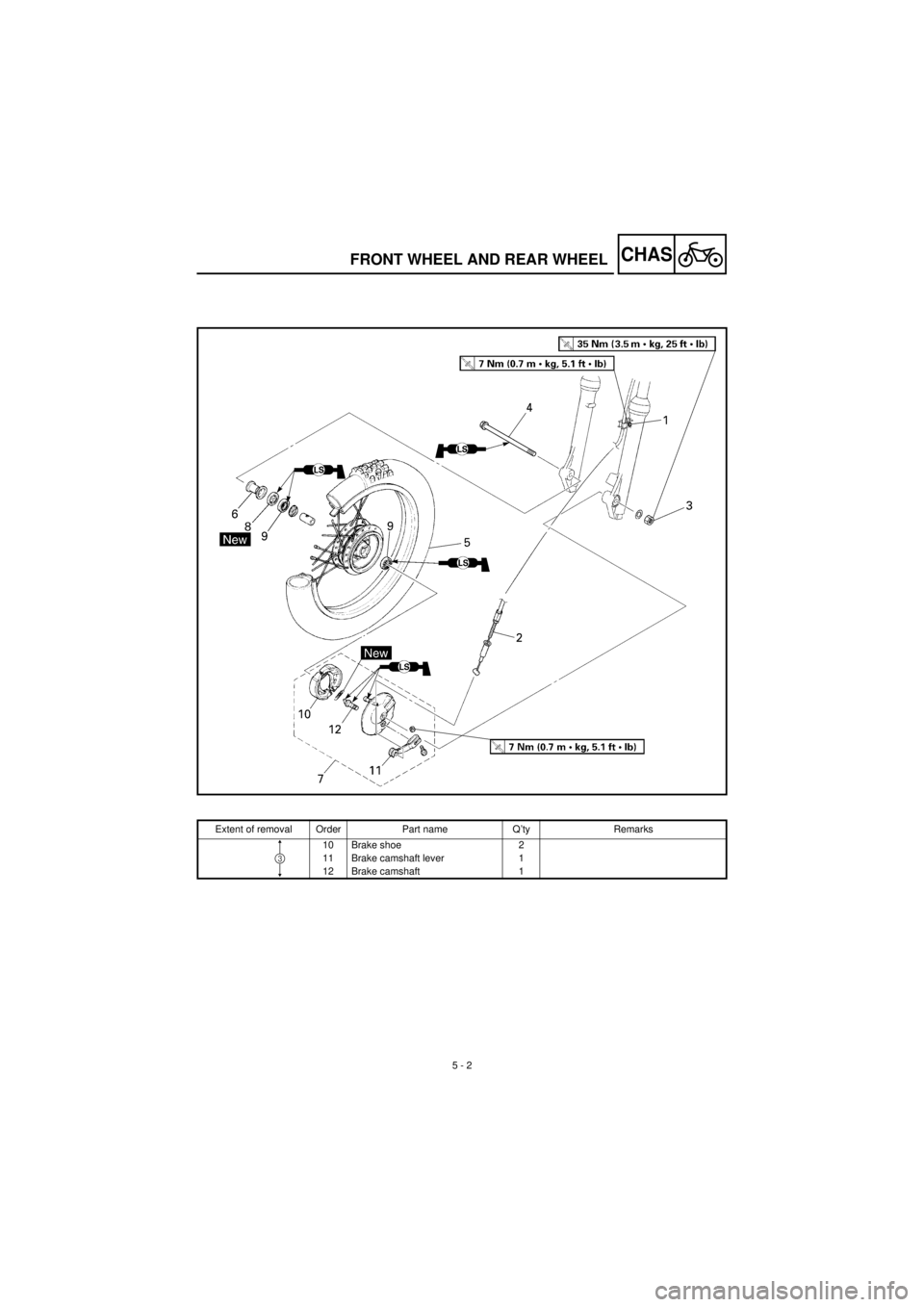

CHAS

Extent of removal Order Part name Q’ty Remarks

10 Brake shoe 2

11 Brake camshaft lever 1

12 Brake camshaft 1

3

FRONT WHEEL AND REAR WHEEL

Page 244 of 288

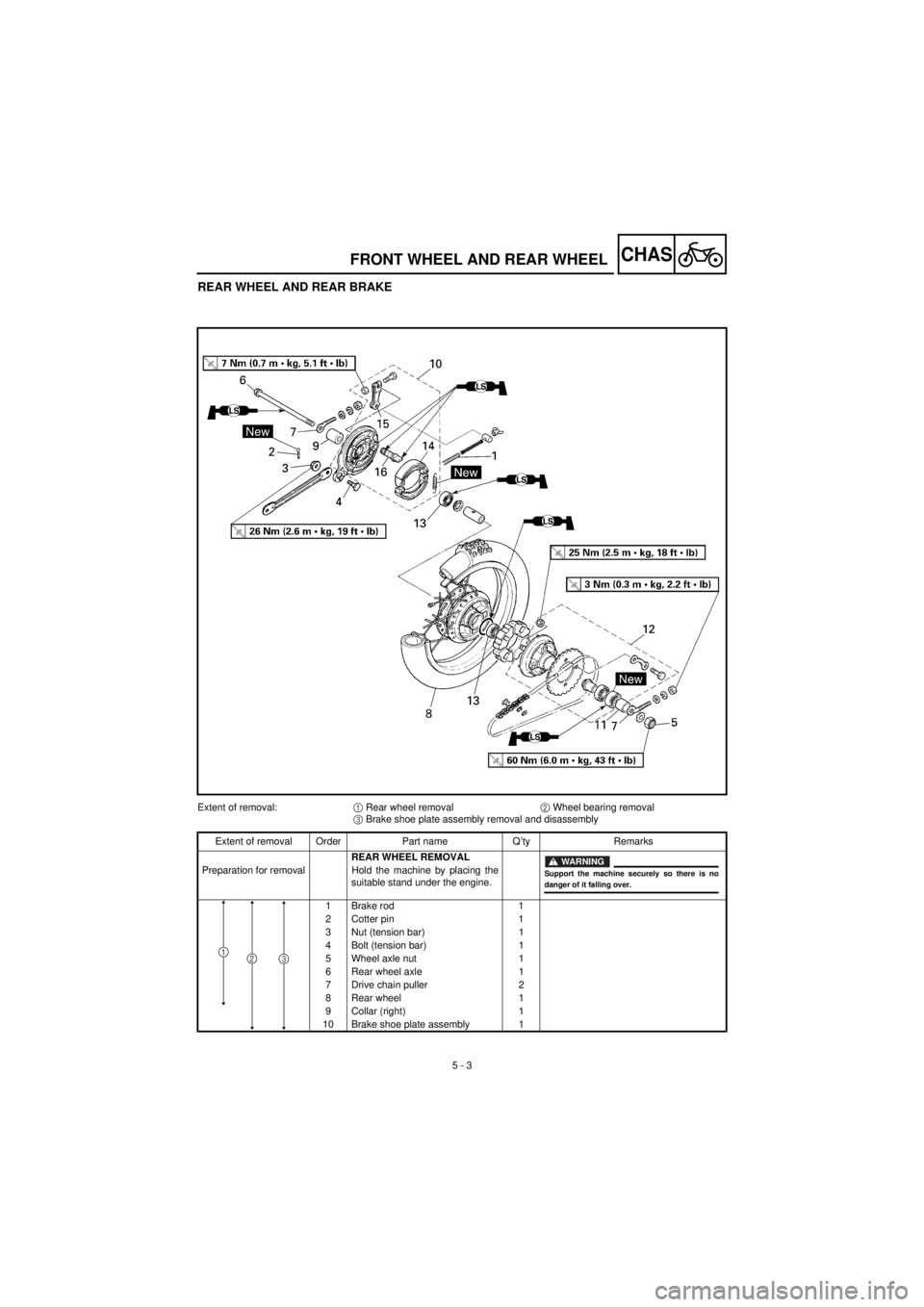

5 - 3

CHAS

FRONT WHEEL AND REAR WHEEL

REAR WHEEL AND REAR BRAKE

Extent of removal:

1

Rear wheel removal

2

Wheel bearing removal

3

Brake shoe plate assembly removal and disassembly

Extent of removal Order Part name Q’ty Remarks

REAR WHEEL REMOVAL

Preparation for removal Hold the machine by placing the

suitable stand under the engine.

1 Brake rod 1

2 Cotter pin 1

3 Nut (tension bar) 1

4 Bolt (tension bar) 1

5 Wheel axle nut 1

6 Rear wheel axle 1

7 Drive chain puller 2

8 Rear wheel 1

9 Collar (right) 1

10 Brake shoe plate assembly 1

WARNING

Support the machine securely so there is nodanger of it falling over.

231

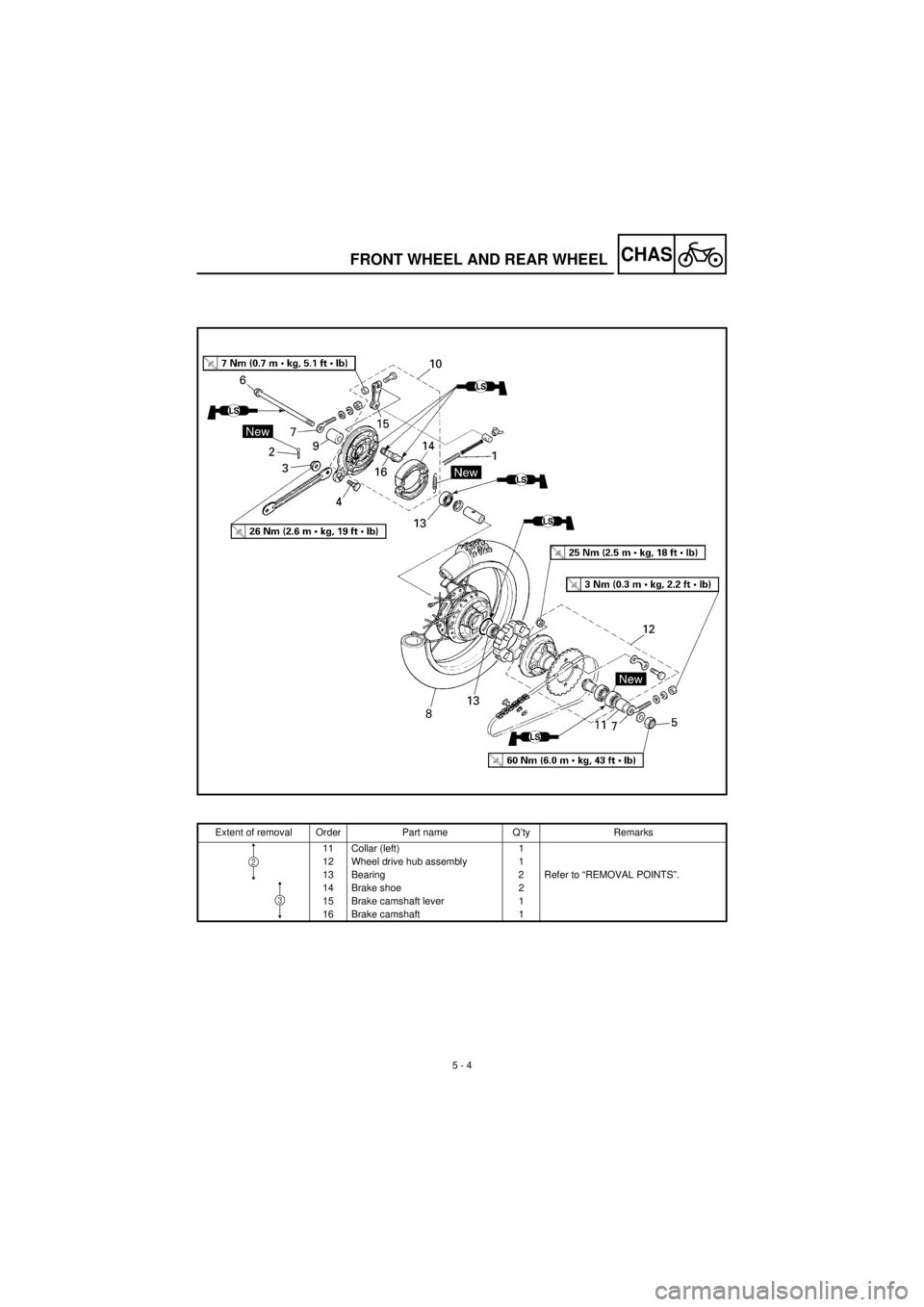

Page 246 of 288

5 - 4

CHAS

FRONT WHEEL AND REAR WHEEL

Extent of removal Order Part name Q’ty Remarks

11 Collar (left) 1

12 Wheel drive hub assembly 1

13 Bearing 2 Refer to “REMOVAL POINTS”.

14 Brake shoe 2

15 Brake camshaft lever 1

16 Brake camshaft 1

3

2

Page 248 of 288

5 - 5

CHAS

FRONT WHEEL AND REAR WHEEL

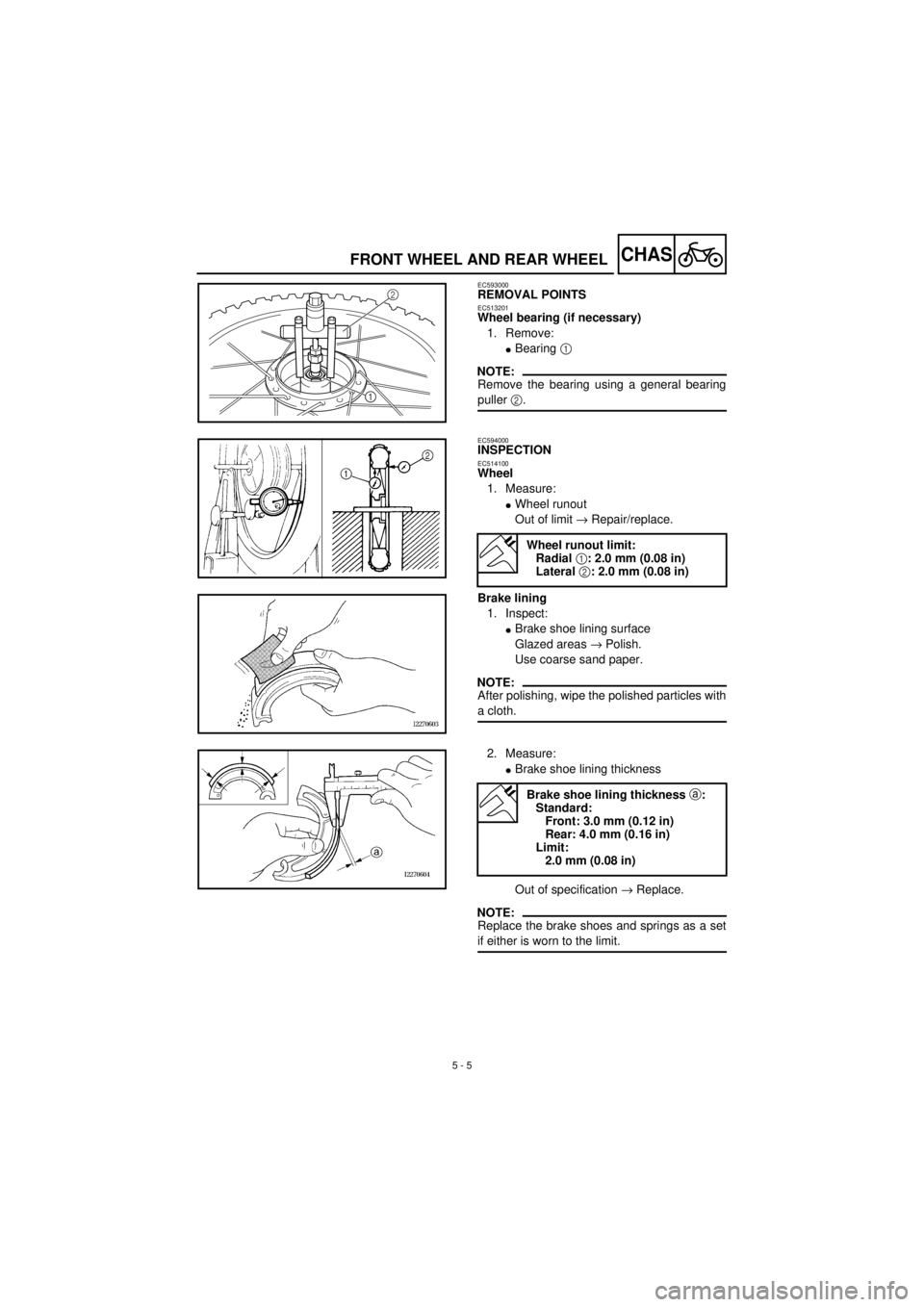

EC593000

REMOVAL POINTS

EC513201

Wheel bearing (if necessary)

1. Remove:

l

Bearing

1

NOTE:

Remove the bearing using a general bearing

puller

2

.

1 1

2

1

EC594000

INSPECTION

EC514100

Wheel

1. Measure:

l

Wheel runout

Out of limit

®

Repair/replace.

Wheel runout limit:

Radial

1

: 2.0 mm (0.08 in)

Lateral

2

: 2.0 mm (0.08 in)

Brake lining

1. Inspect:

l

Brake shoe lining surface

Glazed areas

®

Polish.

Use coarse sand paper.

NOTE:

After polishing, wipe the polished particles with

a cloth.

2. Measure:

l

Brake shoe lining thickness

Out of specification

®

Replace.

NOTE:

Replace the brake shoes and springs as a set

if either is worn to the limit.

Brake shoe lining thickness

a

:

Standard:

Front: 3.0 mm (0.12 in)

Rear: 4.0 mm (0.16 in)

Limit:

2.0 mm (0.08 in)