fuel YAMAHA TTR90 2002 Betriebsanleitungen (in German)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: TTR90, Model: YAMAHA TTR90 2002Pages: 288, PDF-Größe: 15.07 MB

Page 63 of 288

SPEC

2 - 8

Crankshaft:

Crank width “A” 42.95 ~ 43.00 mm

(1.691 ~ 1.693 in)----

Runout limit C ---- 0.03 mm

(0.0012 in)

Big end side clearance “D” 0.10 ~ 0.40 mm

(0.0039 ~ 0.0157 in)0.50 mm

(0.02 in)

Big end radial clearance “E” 0.010 ~ 0.025 mm

(0.0004 ~ 0.0010 in)0.05 mm

(0.002 in)

Clutch:

Friction plate thickness 2.7 ~ 2.9 mm

(0.106 ~ 0.114 in)2.6 mm

(0.102 in)

Quantity 5 ----

Clutch plate thickness 1.1 ~ 1.3 mm (0.043 ~ 0.051 in) ----

Quantity 4 ----

Warp limit ---- 0.2 mm

(0.008 in)

Clutch spring free length 26.2 mm (1.03 in) 24.2 mm

(0.95 in)

Quantity 4 ----

Clutch release method Inner push, cam push ----

Push rod bending limit ---- 0.5 mm

(0.02 in)

Automatic centrifugal clutch: ----

Clutch-in revolution 2,160 ~ 2,560 r/min ----

Clutch-stall revolution 3,300 ~ 3,800 r/min

Shifter:

Shifter type Cam drum and guide bar ----

Kick starter:

Type Ratchet type ----

Kick clip friction force 5.8 ~ 14.7 N

(0.59 ~ 1.50 kg, 1.3 ~ 3.3 lb)

Carburetor:

I. D. mark 5HN1 01 ----

Main jet (M.J) #90 ----

Main air jet (M.A.J) ø 1.1 ----

Jet needle (J.N) 4E9-2 ----

Cutaway (C.A) 2.5 ----

Pilot outlet (P.O) ø 1.0 ´ 2.0 ----

Pilot jet (P.J) #12.5 ----

Valve seat size (V.S) ø 1.5 ----

Starter jet 1 (G.S.1) #37.5 ----

Pilot air screw 1-3/4 turns out

Float height (F.H) 15.5 ~ 16.5 mm (0.61 ~ 0.65 in) ----

Fuel level (F.L) 2 ~ 3 mm (0.08 ~ 0.1 in) ----

Engine idle speed 1,400 ~ 1,600 r/min ----Item Standard Limit

MAINTENANCE SPECIFICATIONS

CC

D

A

E

Page 68 of 288

SPEC

2 - 13

NOTE:

l1. First, tighten the ring nut approximately 38 Nm (3.8 m • kg, 27 ft • lb) by using the ring nut

wrench and turn the steering right and left a few times; then loosen the ring nut one turn.

2. Retighten the ring nut 1 Nm (0.1 m • kg, 0.7 ft • lb).

l-marked portion shall be checked for torque tightening after break-in or before each ride.Part to be tightened Thread size Q’tyTightening torque

Nm m•kg ft•lb

Engine mounting:

Engine and frame (front-upper) M8 ´ 1.25 1 30 3.0 22

Engine and frame (rear-upper) M8 ´ 1.25 1 26 2.6 19

Engine and frame (rear-lower) M10 ´ 1.25 1 40 4.0 29

Starter cable and frame M11 ´ 1.25 1 1 0.1 0.7

Pivot shaft and nut M10 ´ 1.25 1 30 3.0 22

Handle crown and steering shaft M10 ´ 1.25 1 40 4.0 29

Front fork cap bolt M20 ´ 1.0 2 40 4.0 29

Under bracket and front fork M10 ´ 1.25 2 33 3.3 24

Damper rod bolt M8 ´ 1.25 2 20 2.0 14

Handle crown and handlebar holder (lower) M10 ´ 1.25 2 40 4.0 29

Handlebar holder (upper) M6 ´ 1.0 4 13 1.3 9.4

Front brake cable holder and front fork M6 ´ 1.0 2 7 0.7 5.1

Steering ring nut M25 1 Refer to NOTE.

Fuel tank and fuel cock M6 ´ 1.0 2 7 0.7 5.1

Fuel tank and frame M6 ´ 1.0 2 7 0.7 5.1

Grab bar and frame M6 ´ 1.0 4 13 1.3 9.4

Front brake camshaft lever and camshaft M6 ´ 1.0 1 7 0.7 5.1

Rear brake camshaft lever and camshaft M6 ´ 1.0 1 7 0.7 5.1

Front wheel axle nut M10 ´ 1.25 1 35 3.5 25

Rear brake shoe plate tension bar M8 ´ 1.25 2 26 2.6 19

Wheel drive hub and driven sprocket M8 ´ 1.25 4 25 2.5 18

Rear wheel axle nut M12 ´ 1.25 1 60 6.0 43

Wheel nipple (spoke) — 64 2 0.2 1.4

Chain case M5 ´ 0.8 5 4 0.4 2.9

Chain puller locknut M6 ´ 1.0 2 3 0.3 2.2

Footrest and frame M8 ´ 1.25 2 30 3.0 22

MAINTENANCE SPECIFICATIONS

Page 102 of 288

2 - 16

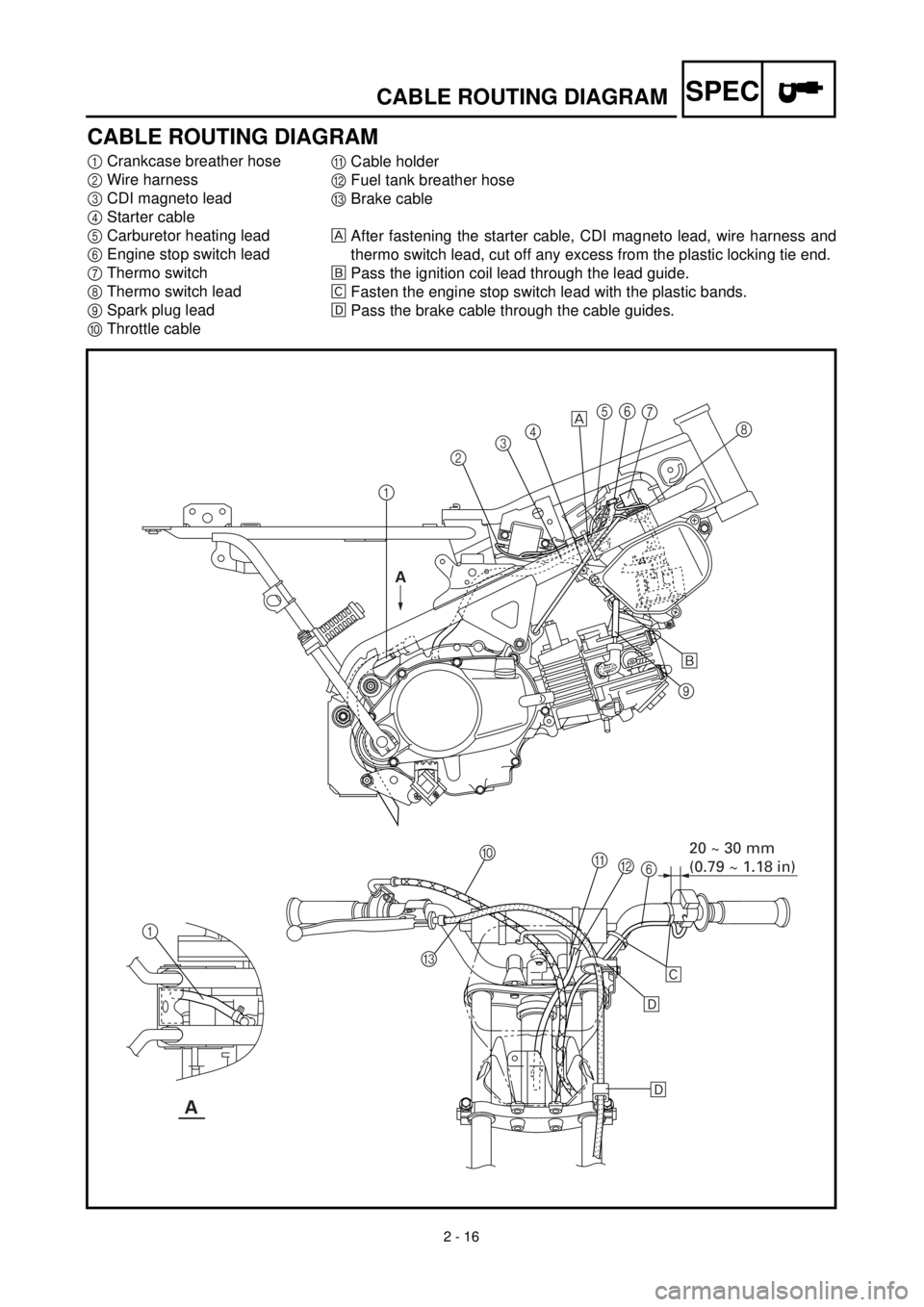

SPECCABLE ROUTING DIAGRAM

CABLE ROUTING DIAGRAM

1Crankcase breather hose

2Wire harness

3CDI magneto lead

4Starter cable

5Carburetor heating lead

6Engine stop switch lead

7Thermo switch

8Thermo switch lead

9Spark plug lead

0Throttle cableACable holder

BFuel tank breather hose

CBrake cable

After fastening the starter cable, CDI magneto lead, wire harness and

thermo switch lead, cut off any excess from the plastic locking tie end.

õPass the ignition coil lead through the lead guide.

‚Fasten the engine stop switch lead with the plastic bands.

ëPass the brake cable through the cable guides.

12345

9

0

B A

6

C 1

õ

‚

ë

ë

A

A

67

8

20 ~ 30 mm

(0.79 ~ 1.18 in)

Page 104 of 288

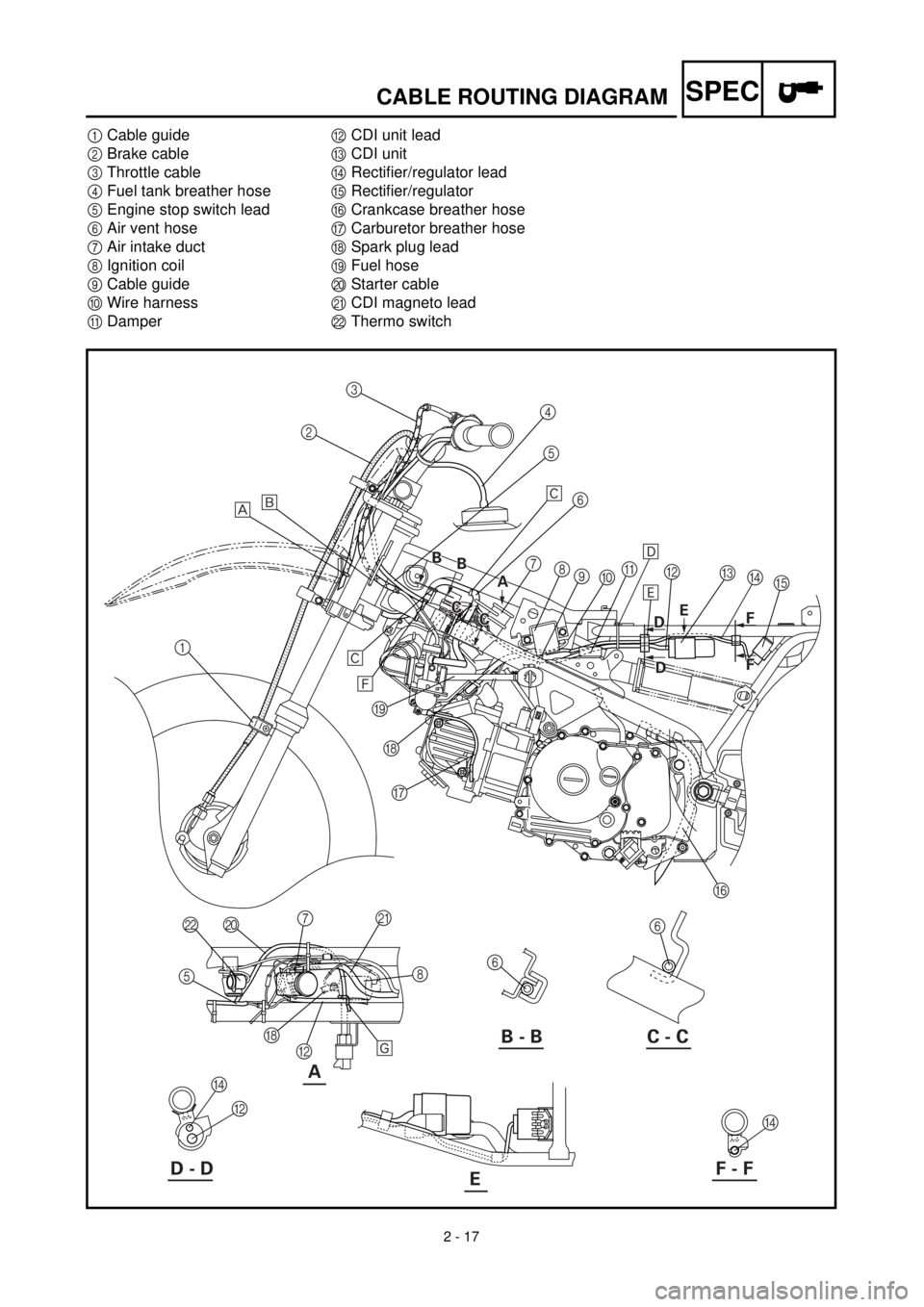

2 - 17

SPECCABLE ROUTING DIAGRAM

1Cable guide

2Brake cable

3Throttle cable

4Fuel tank breather hose

5Engine stop switch lead

6Air vent hose

7Air intake duct

8Ignition coil

9Cable guide

0Wire harness

ADamperBCDI unit lead

CCDI unit

DRectifier/regulator lead

ERectifier/regulator

FCrankcase breather hose

GCarburetor breather hose

HSpark plug lead

IFuel hose

JStarter cable

KCDI magneto lead

LThermo switch

A

123

4

5

6

7

8

9

0A

C

E B

F G H I

6

6 J L

5

H

B8 K

7 ‚

ä

‚

ì

í

B - B C - C

D - DF - FE

õ

ë

D

D

B

D

A A B

B B

B

C

C C

CE

B D

B

D

F F F F

Page 106 of 288

2 - 18

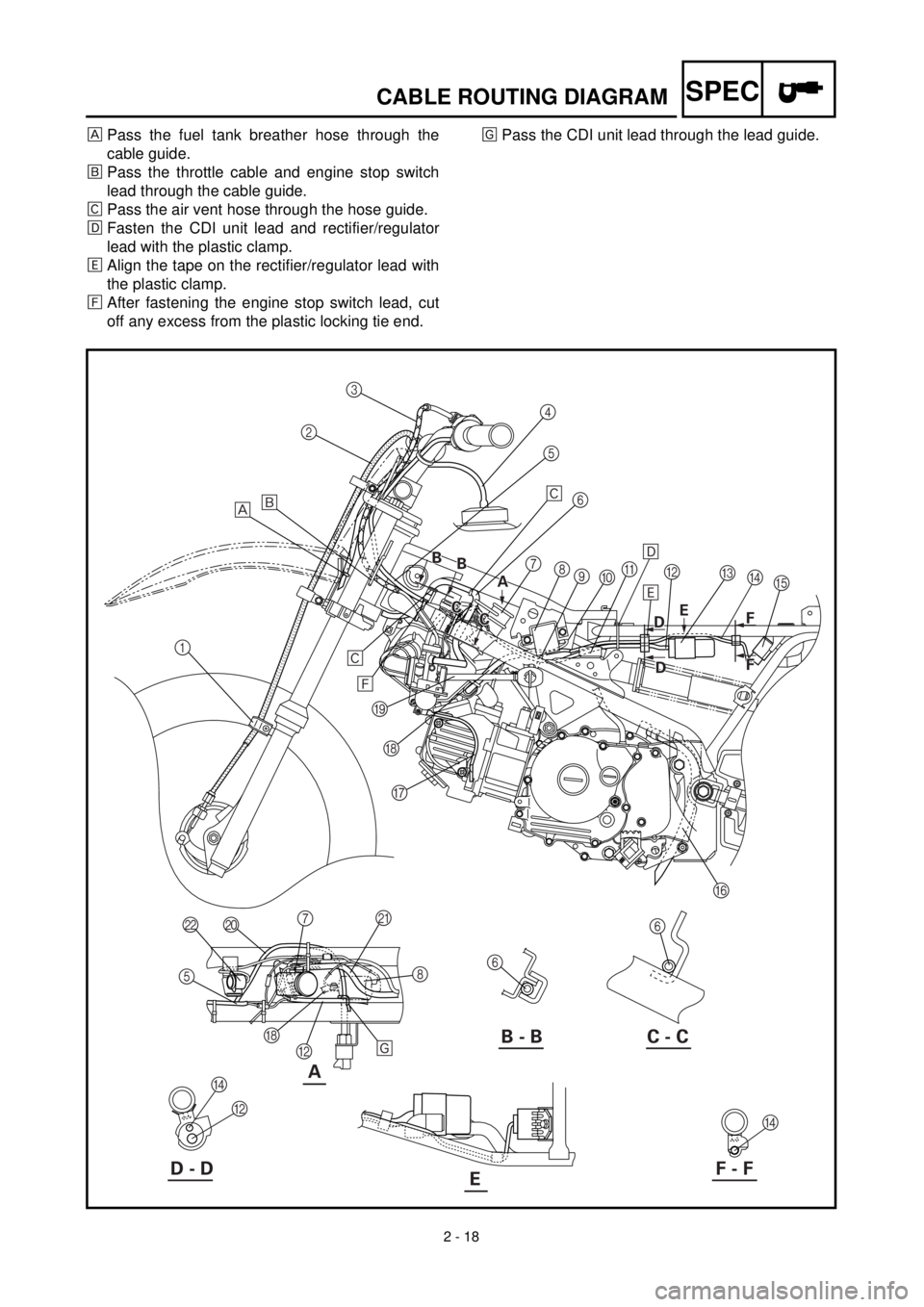

SPECCABLE ROUTING DIAGRAM

Pass the fuel tank breather hose through the

cable guide.

õPass the throttle cable and engine stop switch

lead through the cable guide.

‚Pass the air vent hose through the hose guide.

ëFasten the CDI unit lead and rectifier/regulator

lead with the plastic clamp.

äAlign the tape on the rectifier/regulator lead with

the plastic clamp.

ìAfter fastening the engine stop switch lead, cut

off any excess from the plastic locking tie end.íPass the CDI unit lead through the lead guide.

A

123

4

5

6

7

8

9

0A

C

E B

F G H I

6

6 J L

5

H

B8 K

7 ‚

ä

‚

ì

í

B - B C - C

D - DF - FE

õ

ë

D

D

B

D

A A B

B B

B

C

C C

CE

B D

B

D

F F F F

Page 108 of 288

3 - 1

INSP

ADJMAINTENANCE INTERVALS/

PERIODIC MAINTENANCE AND LUBRICATION

EC300000

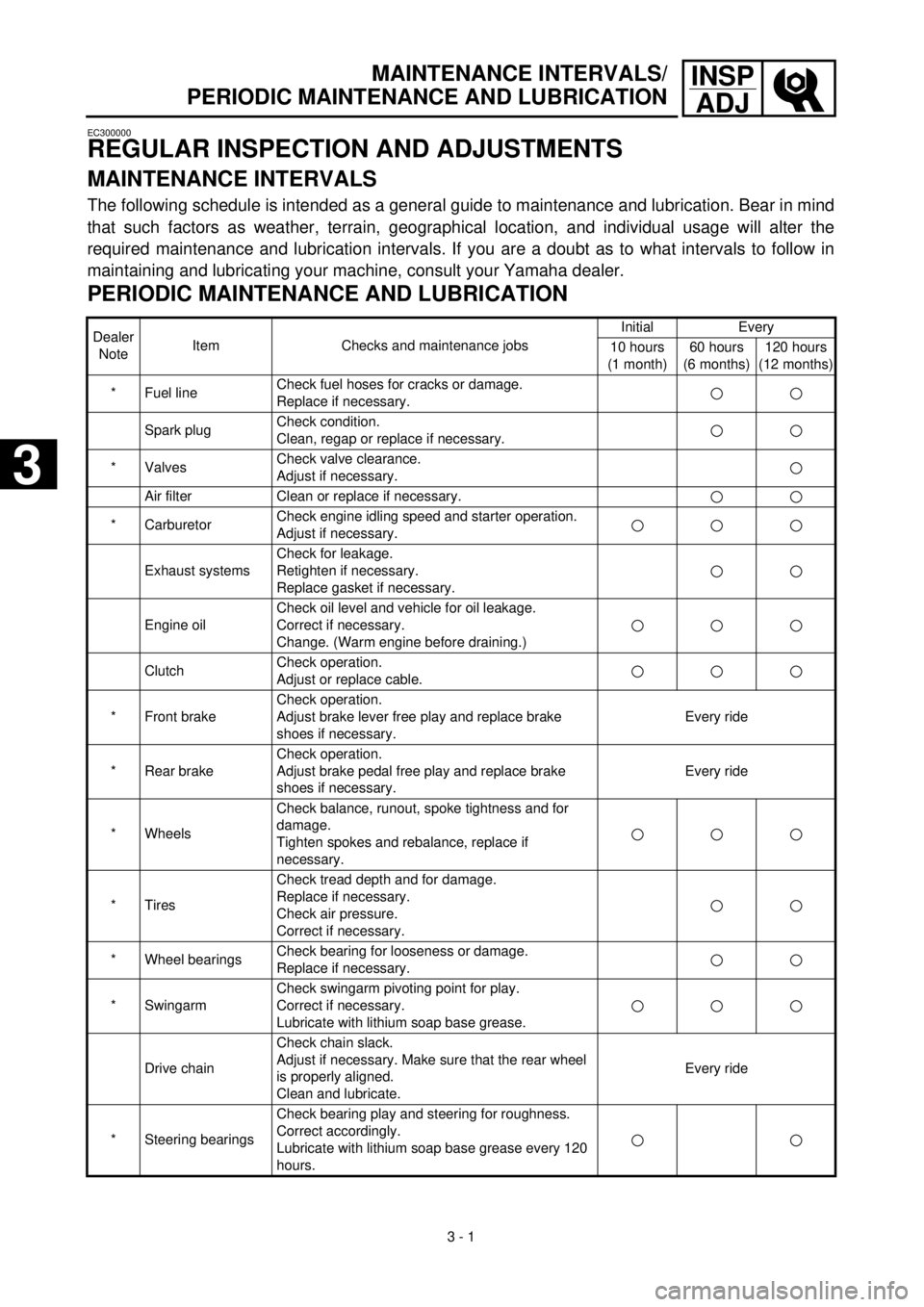

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the

required maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your Yamaha dealer.

PERIODIC MAINTENANCE AND LUBRICATION

Dealer

NoteItem Checks and maintenance jobsInitial Every

10 hours

(1 month)60 hours

(6 months)120 hours

(12 months)

* Fuel lineCheck fuel hoses for cracks or damage.

Replace if necessary.

Spark plugCheck condition.

Clean, regap or replace if necessary.

* ValvesCheck valve clearance.

Adjust if necessary.

Air filter Clean or replace if necessary.

* CarburetorCheck engine idling speed and starter operation.

Adjust if necessary.

Exhaust systemsCheck for leakage.

Retighten if necessary.

Replace gasket if necessary.

Engine oilCheck oil level and vehicle for oil leakage.

Correct if necessary.

Change. (Warm engine before draining.)

ClutchCheck operation.

Adjust or replace cable.

* Front brakeCheck operation.

Adjust brake lever free play and replace brake

shoes if necessary.Every ride

* Rear brakeCheck operation.

Adjust brake pedal free play and replace brake

shoes if necessary.Every ride

* WheelsCheck balance, runout, spoke tightness and for

damage.

Tighten spokes and rebalance, replace if

necessary.

* TiresCheck tread depth and for damage.

Replace if necessary.

Check air pressure.

Correct if necessary.

* Wheel bearingsCheck bearing for looseness or damage.

Replace if necessary.

* SwingarmCheck swingarm pivoting point for play.

Correct if necessary.

Lubricate with lithium soap base grease.

Drive chainCheck chain slack.

Adjust if necessary. Make sure that the rear wheel

is properly aligned.

Clean and lubricate.Every ride

* Steering bearingsCheck bearing play and steering for roughness.

Correct accordingly.

Lubricate with lithium soap base grease every 120

hours.

3

3

Page 148 of 288

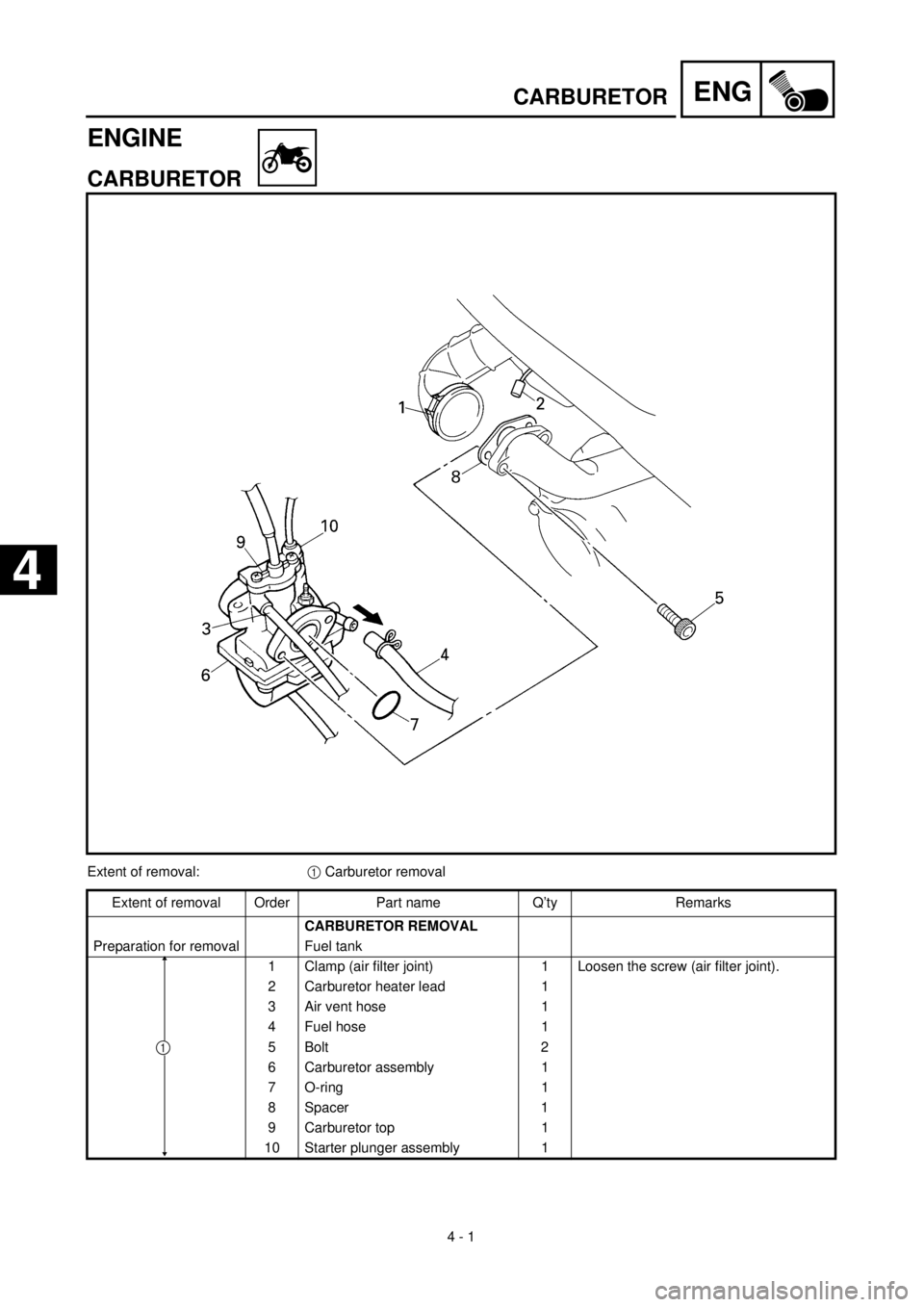

4 - 1

ENG

ENGINE

CARBURETOR

Extent of removal:1 Carburetor removal

Extent of removal Order Part name Q’ty Remarks

CARBURETOR REMOVAL

Preparation for removal Fuel tank

1 Clamp (air filter joint) 1 Loosen the screw (air filter joint).

2 Carburetor heater lead 1

3 Air vent hose 1

4 Fuel hose 1

5 Bolt 2

6 Carburetor assembly 1

7 O-ring 1

8 Spacer 1

9 Carburetor top 1

10 Starter plunger assembly 1

1

CARBURETOR

4

Page 158 of 288

4 - 6

ENGCARBURETOR

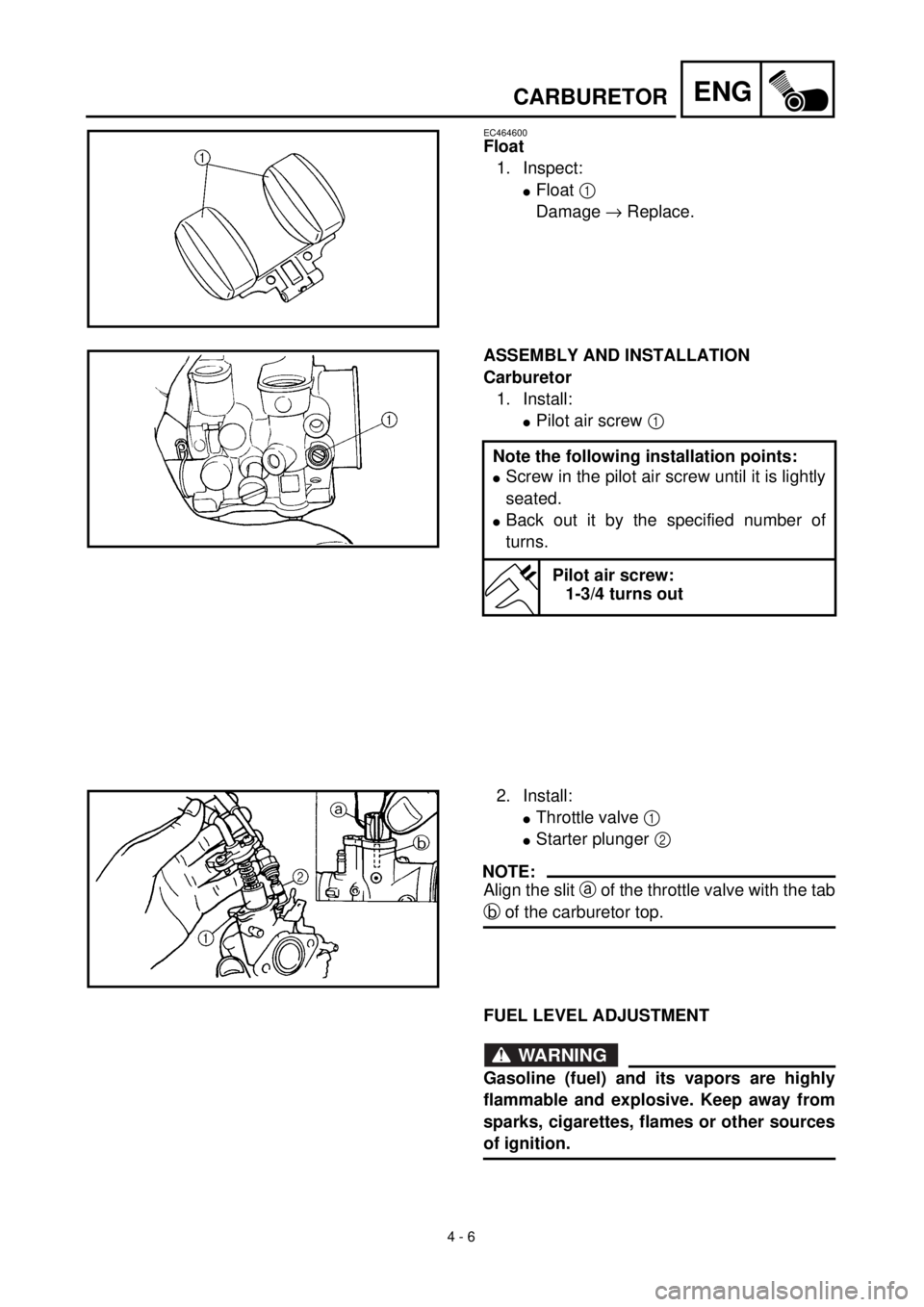

EC464600

Float

1. Inspect:

lFloat 1

Damage ® Replace.

ASSEMBLY AND INSTALLATION

Carburetor

1. Install:

lPilot air screw 1

Note the following installation points:

lScrew in the pilot air screw until it is lightly

seated.

lBack out it by the specified number of

turns.

Pilot air screw:

1-3/4 turns out

2. Install:

lThrottle valve 1

lStarter plunger 2

NOTE:

Align the slit a of the throttle valve with the tab

b of the carburetor top.

FUEL LEVEL ADJUSTMENT

WARNING

Gasoline (fuel) and its vapors are highly

flammable and explosive. Keep away from

sparks, cigarettes, flames or other sources

of ignition.

Page 160 of 288

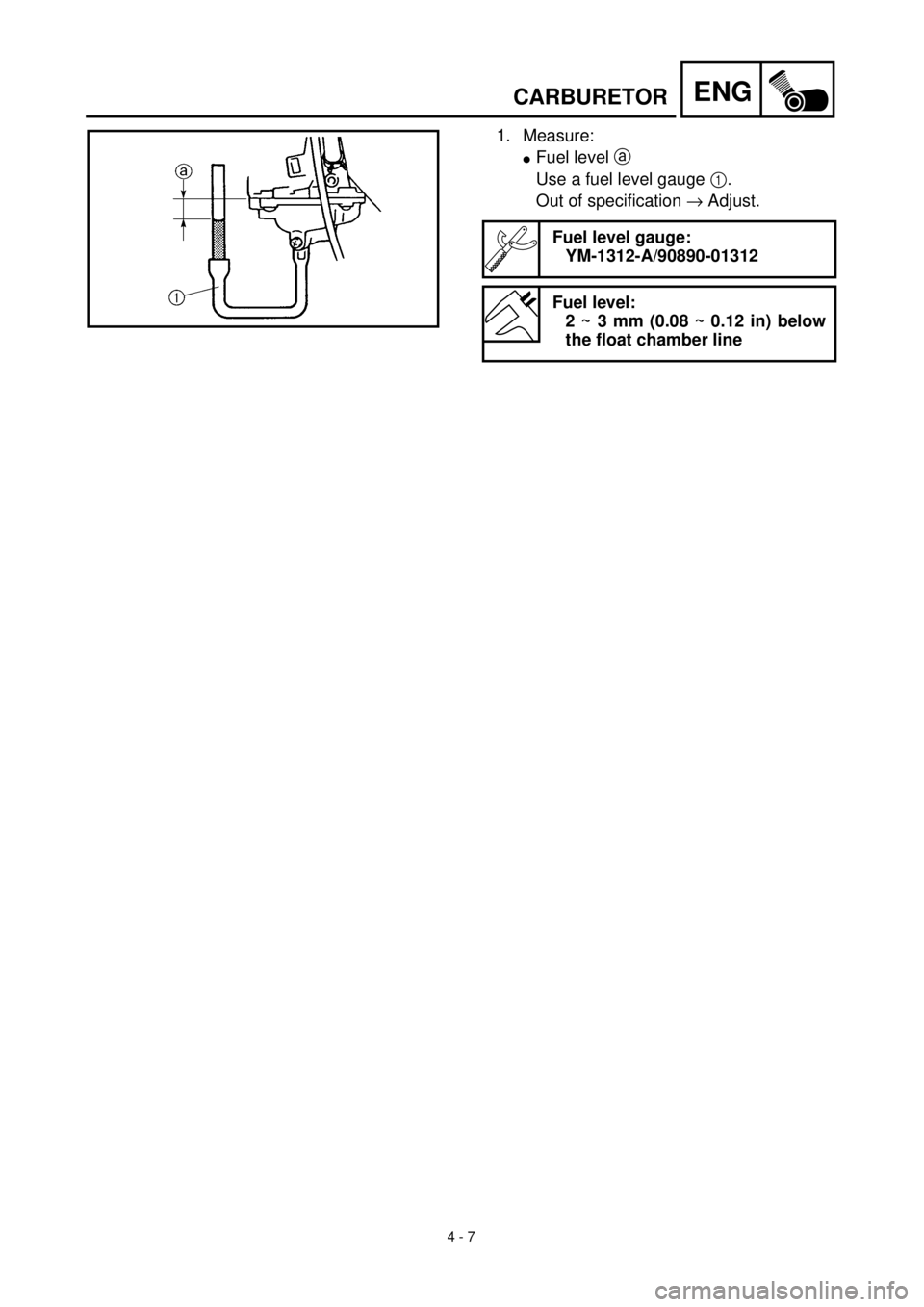

4 - 7

ENGCARBURETOR

1. Measure:

lFuel level a

Use a fuel level gauge 1.

Out of specification ® Adjust.

Fuel level gauge:

YM-1312-A/90890-01312

Fuel level:

2 ~ 3 mm (0.08 ~ 0.12 in) below

the float chamber line

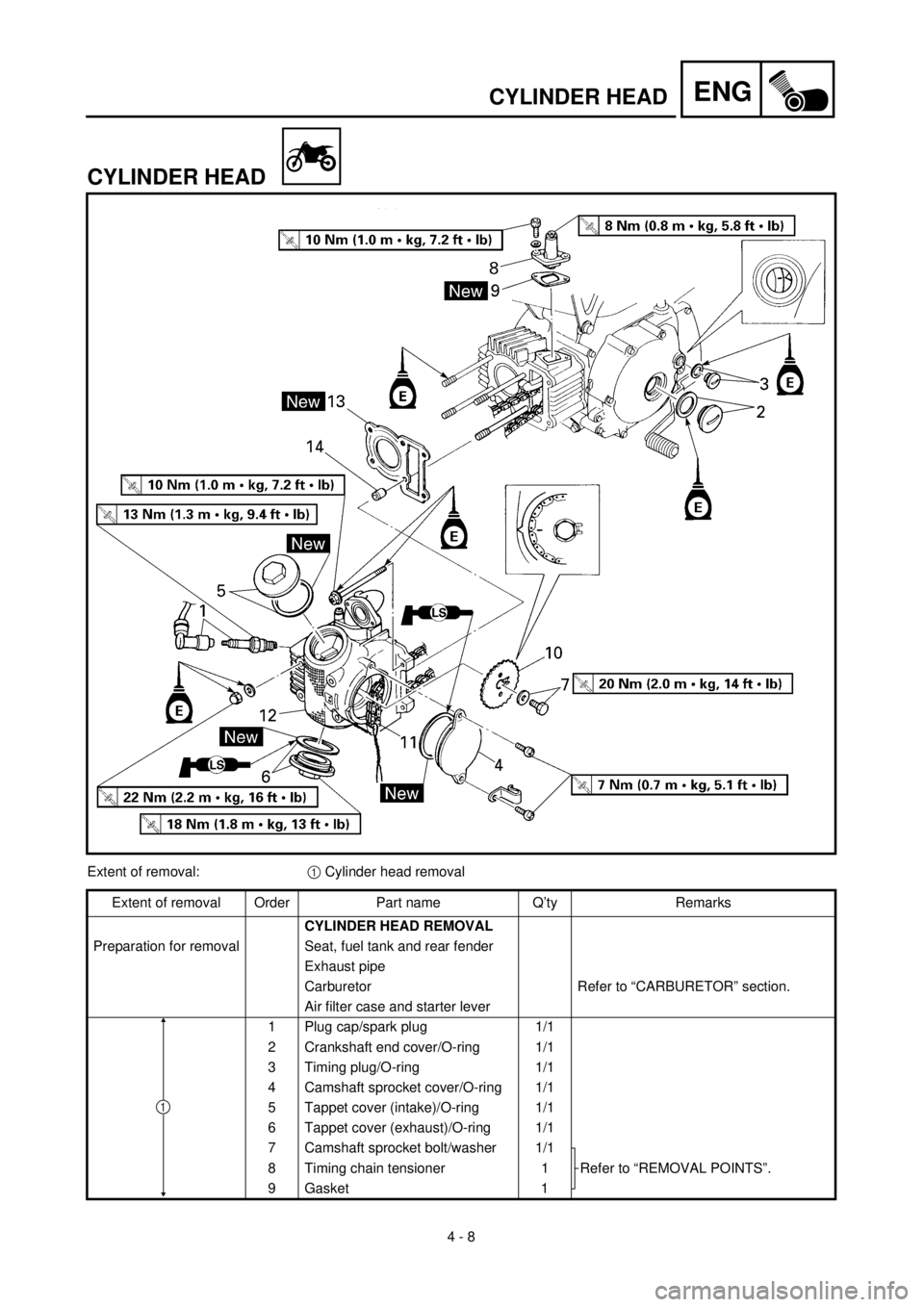

Page 162 of 288

4 - 8

ENGCYLINDER HEAD

CYLINDER HEAD

Extent of removal:1 Cylinder head removal

Extent of removal Order Part name Q’ty Remarks

CYLINDER HEAD REMOVAL

Preparation for removal Seat, fuel tank and rear fender

Exhaust pipe

Carburetor Refer to “CARBURETOR” section.

Air filter case and starter lever

1 Plug cap/spark plug 1/1

2 Crankshaft end cover/O-ring 1/1

3 Timing plug/O-ring 1/1

4 Camshaft sprocket cover/O-ring 1/1

5 Tappet cover (intake)/O-ring 1/1

6 Tappet cover (exhaust)/O-ring 1/1

7 Camshaft sprocket bolt/washer 1/1

Refer to “REMOVAL POINTS”. 8 Timing chain tensioner 1

9 Gasket 1

1