check engine YAMAHA TTR90 2002 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: TTR90, Model: YAMAHA TTR90 2002Pages: 288, PDF Size: 15.07 MB

Page 132 of 288

3 - 12

INSP

ADJ

DRIVE CHAIN SLACK ADJUSTMENT

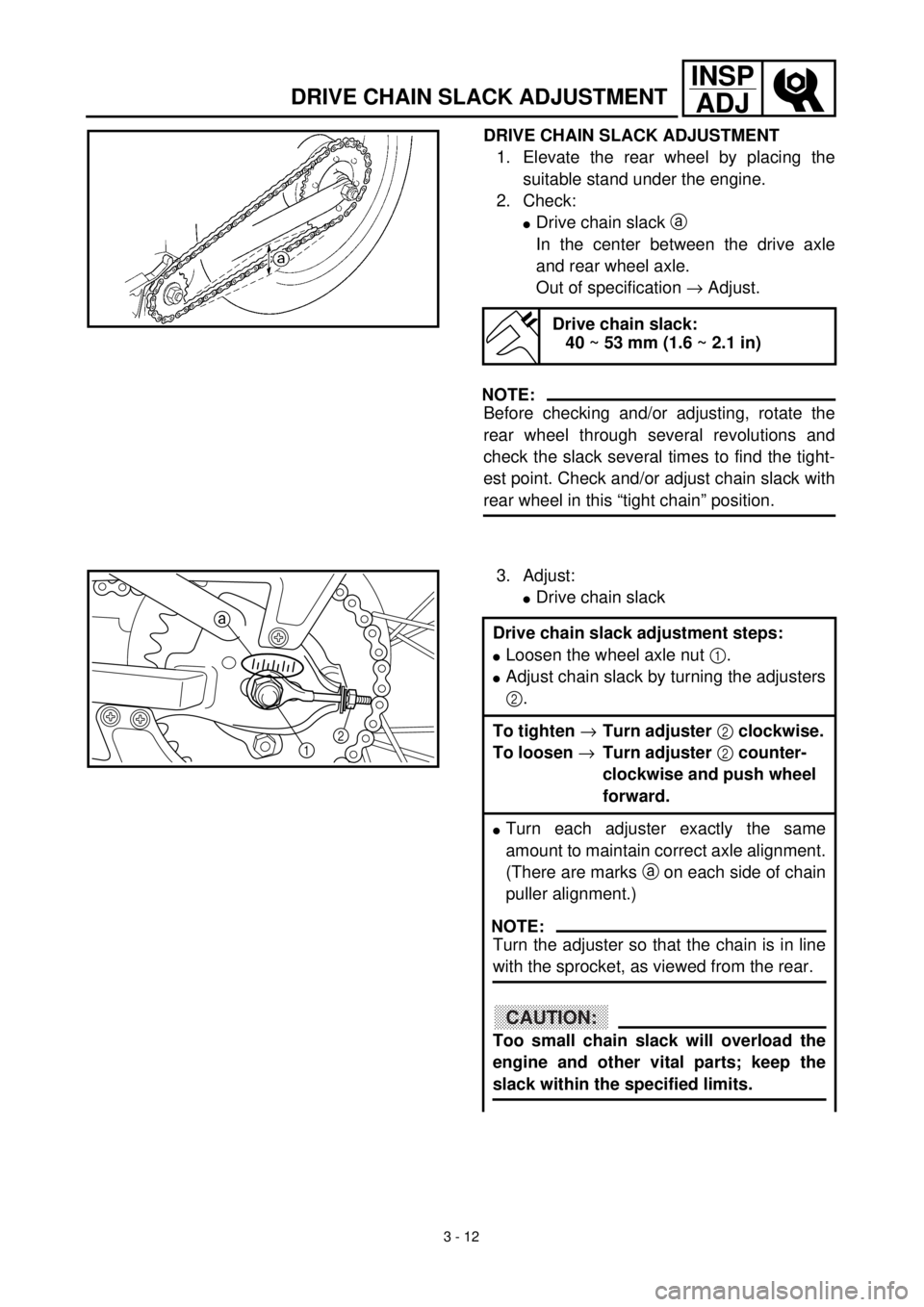

DRIVE CHAIN SLACK ADJUSTMENT

1. Elevate the rear wheel by placing the

suitable stand under the engine.

2. Check:

lDrive chain slack a

In the center between the drive axle

and rear wheel axle.

Out of specification ® Adjust.

NOTE:

Before checking and/or adjusting, rotate the

rear wheel through several revolutions and

check the slack several times to find the tight-

est point. Check and/or adjust chain slack with

rear wheel in this “tight chain” position.

Drive chain slack:

40 ~ 53 mm (1.6 ~ 2.1 in)

3. Adjust:

lDrive chain slack

Drive chain slack adjustment steps:

lLoosen the wheel axle nut 1.

lAdjust chain slack by turning the adjusters

2.

To tighten ®Turn adjuster 2 clockwise.

To loosen ®Turn adjuster 2 counter-

clockwise and push wheel

forward.

lTurn each adjuster exactly the same

amount to maintain correct axle alignment.

(There are marks a on each side of chain

puller alignment.)

NOTE:

Turn the adjuster so that the chain is in line

with the sprocket, as viewed from the rear.

CAUTION:

Too small chain slack will overload the

engine and other vital parts; keep the

slack within the specified limits.

12 a

Page 138 of 288

3 - 15

INSP

ADJSPOKES INSPECTION AND TIGHTENING/WHEEL INSPECTION/

STEERING HEAD INSPECTION AND ADJUSTMENT

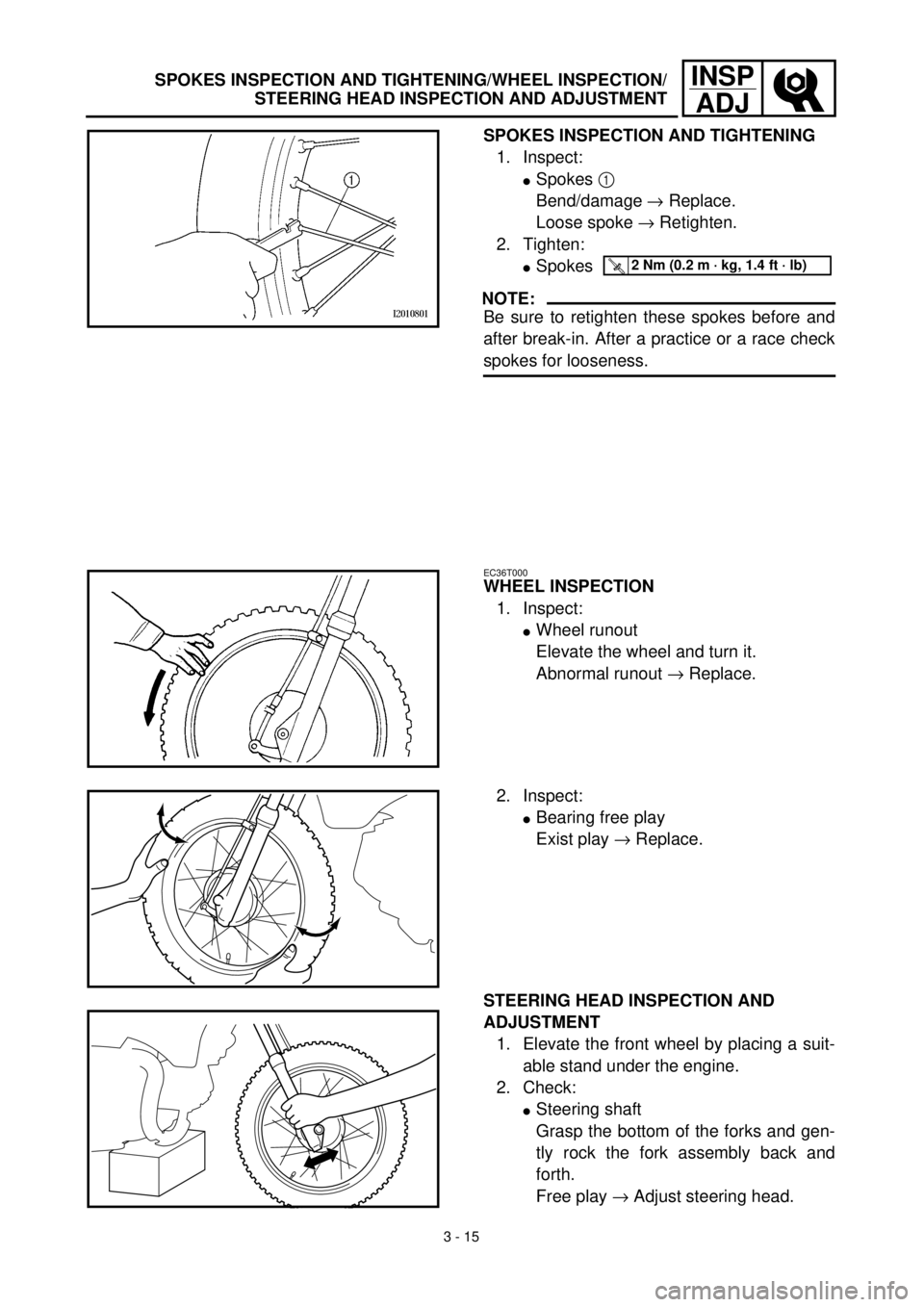

SPOKES INSPECTION AND TIGHTENING

1. Inspect:

lSpokes 1

Bend/damage ® Replace.

Loose spoke ® Retighten.

2. Tighten:

lSpokes

NOTE:

Be sure to retighten these spokes before and

after break-in. After a practice or a race check

spokes for looseness.

T R..2 Nm (0.2 m · kg, 1.4 ft · lb)

EC36T000

WHEEL INSPECTION

1. Inspect:

lWheel runout

Elevate the wheel and turn it.

Abnormal runout ® Replace.

2. Inspect:

lBearing free play

Exist play ® Replace.

STEERING HEAD INSPECTION AND

ADJUSTMENT

1. Elevate the front wheel by placing a suit-

able stand under the engine.

2. Check:

lSteering shaft

Grasp the bottom of the forks and gen-

tly rock the fork assembly back and

forth.

Free play ® Adjust steering head.

Page 146 of 288

3 - 19

INSP

ADJ

ELECTRICAL/SPARK PLUG INSPECTION

EC370000

ELECTRICAL

EC371001

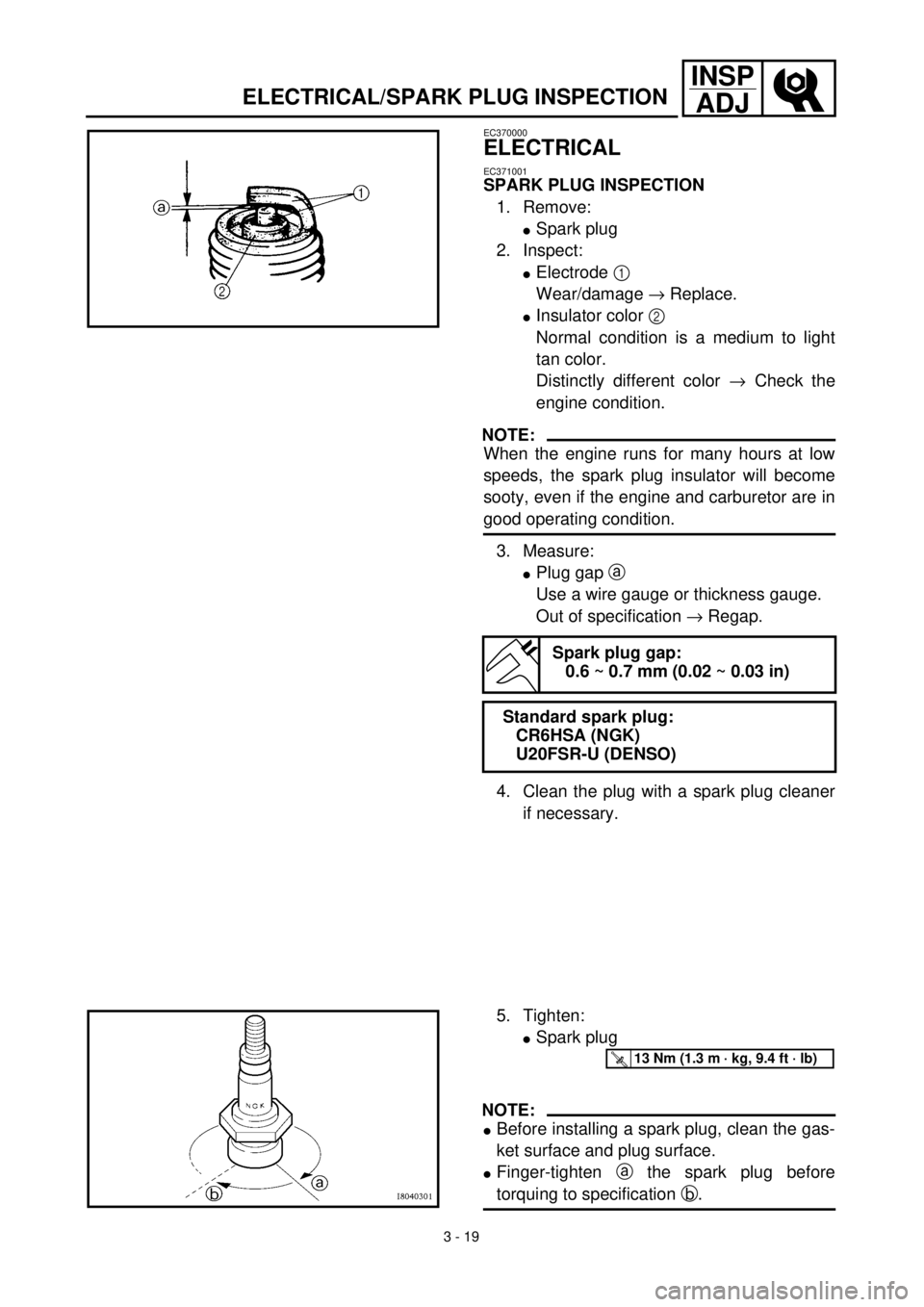

SPARK PLUG INSPECTION

1. Remove:

lSpark plug

2. Inspect:

lElectrode 1

Wear/damage ® Replace.

lInsulator color 2

Normal condition is a medium to light

tan color.

Distinctly different color ® Check the

engine condition.

NOTE:

When the engine runs for many hours at low

speeds, the spark plug insulator will become

sooty, even if the engine and carburetor are in

good operating condition.

3. Measure:

lPlug gap a

Use a wire gauge or thickness gauge.

Out of specification ® Regap.

4. Clean the plug with a spark plug cleaner

if necessary.

Spark plug gap:

0.6 ~ 0.7 mm (0.02 ~ 0.03 in)

Standard spark plug:

CR6HSA (NGK)

U20FSR-U (DENSO)

5. Tighten:

lSpark plug

NOTE:

lBefore installing a spark plug, clean the gas-

ket surface and plug surface.

lFinger-tighten a the spark plug before

torquing to specification b.

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)

Page 238 of 288

4 - 46

ENGSHIFT FORK, SHIFT CAM AND TRANSMISSION

EC4H3000

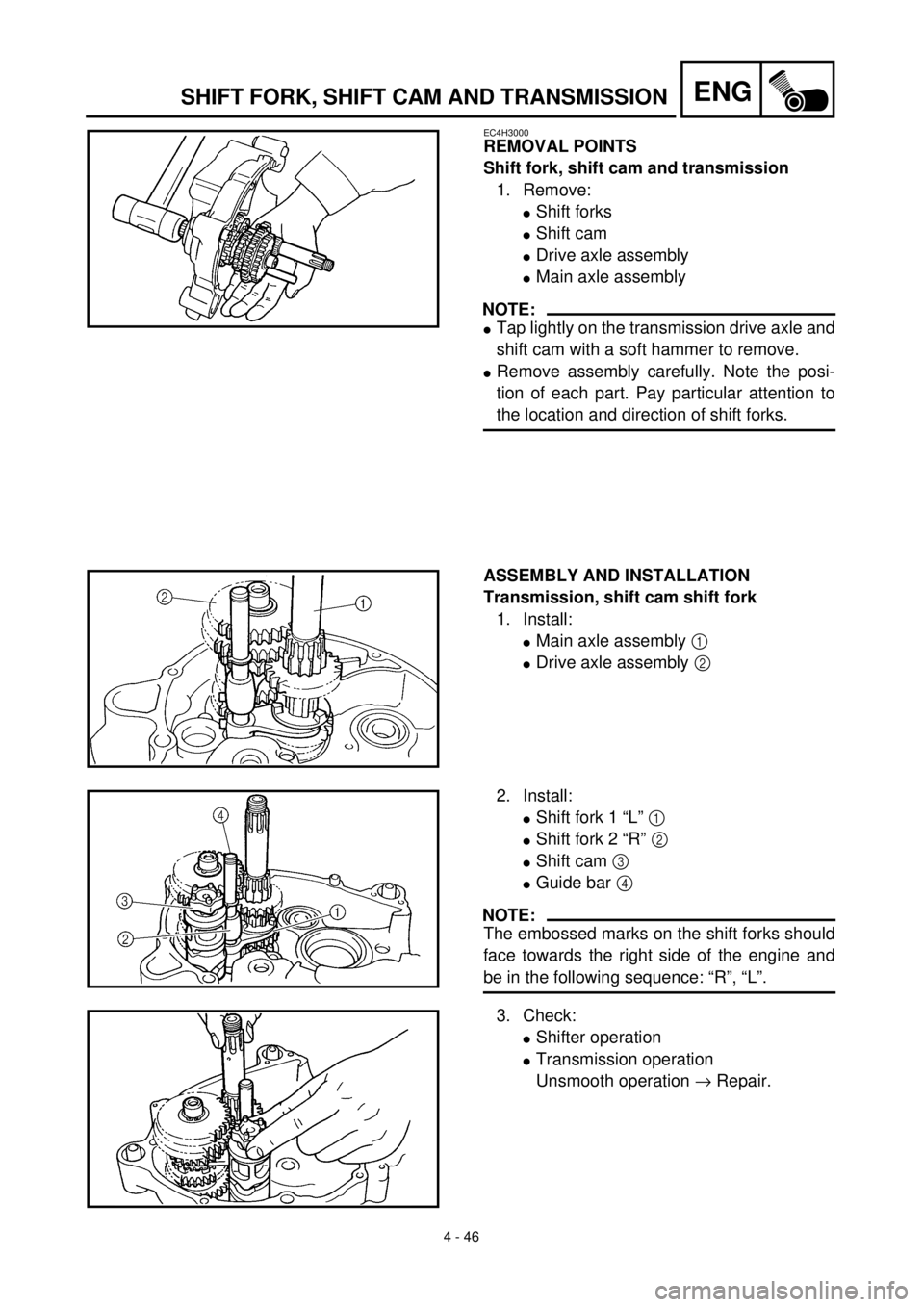

REMOVAL POINTS

Shift fork, shift cam and transmission

1. Remove:

lShift forks

lShift cam

lDrive axle assembly

lMain axle assembly

NOTE:

lTap lightly on the transmission drive axle and

shift cam with a soft hammer to remove.

lRemove assembly carefully. Note the posi-

tion of each part. Pay particular attention to

the location and direction of shift forks.

ASSEMBLY AND INSTALLATION

Transmission, shift cam shift fork

1. Install:

lMain axle assembly 1

lDrive axle assembly 2

2. Install:

lShift fork 1 “L” 1

lShift fork 2 “R” 2

lShift cam 3

lGuide bar 4

NOTE:

The embossed marks on the shift forks should

face towards the right side of the engine and

be in the following sequence: “R”, “L”.

3. Check:

lShifter operation

lTransmission operation

Unsmooth operation ® Repair.

Page 266 of 288

–+ELEC

6 - 2

IGNITION SYSTEM

EC620000

IGNITION SYSTEM

INSPECTION STEPS

Use the following steps for checking the possibility of the malfunctioning engine being attributable to

ignition system failure and for checking the spark plug which will not spark.

NOTE:

lRemove the following parts before inspection.

1) Seat

2) Fuel tank

lUse the following special tools in this inspection.

Spark gap testClean or replace

spark plug.

Check entire ignition

system for connection.Repair or replace.

Check “ENGINE STOP”

switch.Replace.

Check ignition coil. Primary coil Replace.

Secondary coil Replace.

Check CDI magneto. Pickup coil Replace.

Source coil Replace.

Replace CDI unit.

Dynamic spark tester:

YM-34487

Ignition checker:

90890-06754Pocket tester:

YU-3112-C/90890-03112

No Spark

OK

OK

OK

OK

Spark

No good

No good

No good

No good

No good

No good

Page 270 of 288

6 - 3

–+ELECIGNITION SYSTEM

EC622001

SPARK GAP TEST

1. Disconnect the spark plug cap from spark

plug.

2. Connect the dynamic spark tester 1

(ignition checker 2) as shown.

lSpark plug cap 3

lSpark plug 4

For USA and CDN

õExcept for USA and CDN

3. Kick the kick starter.

4. Check the ignition spark gap.

5. Start engine, and increase spark gap until

misfire occurs. (for USA and CDN only)

Minimum spark gap:

6.0 mm (0.24 in)

õ

EC624000

COUPLERS AND LEADS CONNECTION

INSPECTION

1. Check:

lCouplers and leads connection

Rust/dust/looseness/short-circuit ®

Repair or replace.

“ENGINE STOP” SWITCH INSPECTION

1. Inspect:

l“ENGINE STOP” switch continuity

No continuous while being pushed “ ” ®

Replace.

Continuous while being pushed “ ” ®

Replace.Tester (+) lead ® Black/White lead 1

Tester (–) lead ® Black lead 2

B/W

1B

2Tester selec-

tor position

W ´ 1