brake YAMAHA TW125 2000 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: TW125, Model: YAMAHA TW125 2000Pages: 86, PDF Size: 3.94 MB

Page 68 of 86

6-36

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

EAU01495Front wheel installation

1. Install the speedometer gear

unit housing into the wheel

hub. Make sure the projections

are meshed into the slots.

2. Lift up the wheel between the

front fork legs. Make sure that

there is enough gap between

the brake pads before inserting

the brake disc and that the slot

in the speedometer gear unit

housing fits over the stopper

on the front fork outer tube.3. Install the wheel axle and axle

nut. Then, let the motorcycle

down.

4. Tighten the axle nut to the

specified torque.

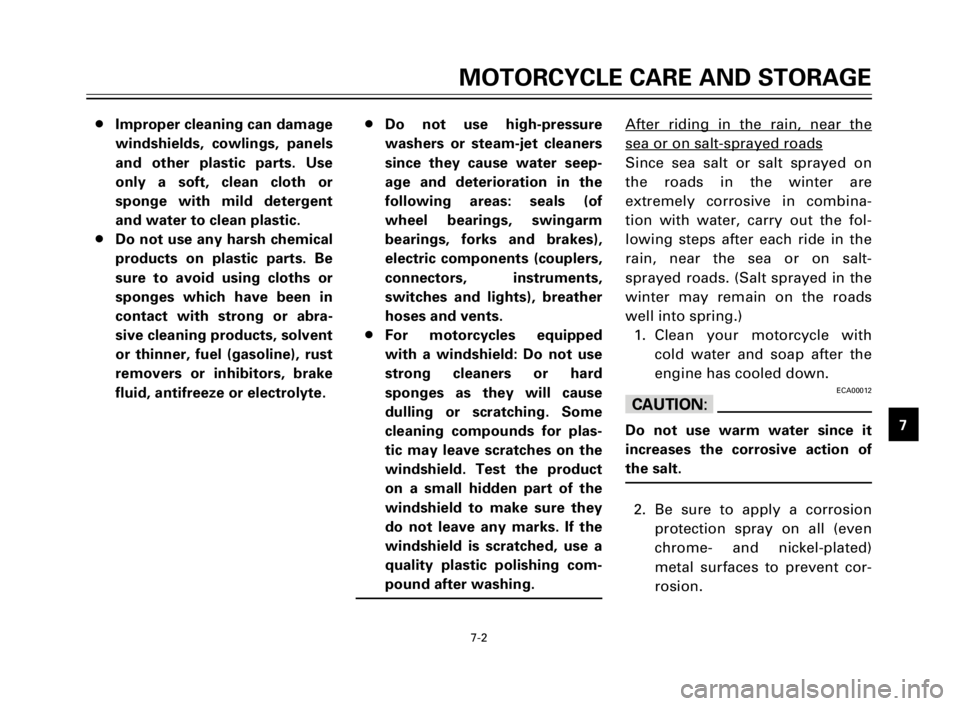

5. Install the speedometer cable.EAU01496Rear wheel removalEW000122

w

8It is advisable to have a

Yamaha dealer service the

wheel.

8Securely support the motorcy-

cle so there is no danger of it

falling over.

1. Loosen the wheel axle nut.

2. Remove the brake adjusting

nut and brake rod from the

brake cam lever.

1. Wheel axle nut

2. Chain adjusting plate

3. Brake adjusting nut

4. Brake rod

21

a

b

34

Tightening torque:

Axle nut:

90 Nm (9.0 m·kg)

5EK-9-E1 (TW125)<3.1> 4/6/0 11:50 PM Page 66

Page 69 of 86

6-37

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9 3. Turn the chain adjusting plates

on each side fully in direction

b.

4. Elevate the rear wheel.

5. Remove the axle nut.

6. Pull out the rear axle.

7. Push the wheel forward and

remove the drive chain.

8. Remove the wheel assembly.

EAU01497Rear wheel installation

1. Install the wheel assembly and

insert the axle from the left-

hand side. Be sure that the

chain adjusting plates are

installed with the punched side

outward and the slot in the

brake shoe plate fits over the

stopper on the swingarm.

2. Install and adjust the drive

chain. (See page 6-24 for

details about adjusting the

drive chain slack.)

3. Install the axle nut and let the

motorcycle down.4. Tighten the axle nut to the

specified torque.

5. Insert the brake rod into the

brake cam lever and install the

brake pedal free play adjusting

nut.

6. Adjust the rear brake pedal

free play. (See page 6-20.)EW000103

w

Check the operation of the brake

light after adjusting the rear brake.

Tightening torque:

Axle nut:

90 Nm (9.0 m·kg)

5EK-9-E1 (TW125)<3.1> 4/6/0 11:50 PM Page 67

Page 73 of 86

7-2

MOTORCYCLE CARE AND STORAGE

1

2

3

4

5

6

7

8

9 8Improper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use

only a soft, clean cloth or

sponge with mild detergent

and water to clean plastic.

8Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abra-

sive cleaning products, solvent

or thinner, fuel (gasoline), rust

removers or inhibitors, brake

fluid, antifreeze or electrolyte.8Do not use high-pressure

washers or steam-jet cleaners

since they cause water seep-

age and deterioration in the

following areas: seals (of

wheel bearings, swingarm

bearings, forks and brakes),

electric components (couplers,

connectors, instruments,

switches and lights), breather

hoses and vents.

8For motorcycles equipped

with a windshield: Do not use

strong cleaners or hard

sponges as they will cause

dulling or scratching. Some

cleaning compounds for plas-

tic may leave scratches on the

windshield. Test the product

on a small hidden part of the

windshield to make sure they

do not leave any marks. If the

windshield is scratched, use a

quality plastic polishing com-

pound after washing.

After riding in the rain, near the

sea or on salt-sprayed roads

Since sea salt or salt sprayed on

the roads in the winter are

extremely corrosive in combina-

tion with water, carry out the fol-

lowing steps after each ride in the

rain, near the sea or on salt-

sprayed roads. (Salt sprayed in the

winter may remain on the roads

well into spring.)

1. Clean your motorcycle with

cold water and soap after the

engine has cooled down.

ECA00012

cC

Do not use warm water since it

increases the corrosive action of

the salt.

2. Be sure to apply a corrosion

protection spray on all (even

chrome- and nickel-plated)

metal surfaces to prevent cor-

rosion.

5EK-9-E1 (TW125)<3.1> 4/6/0 11:50 PM Page 71

Page 74 of 86

7-3

MOTORCYCLE CARE AND STORAGE

1

2

3

4

5

6

7

8

9After cleaning

1. Dry the motorcycle with a

chamois or an absorbing cloth.

2. Immediately dry the drive

chain and lubricate it to pre-

vent it from rusting.

3. Use a chrome polish to shine

chrome, aluminum and stain-

less-steel parts, including the

exhaust system. (Even the

thermally induced discoloring

of stainless-steel exhaust sys-

tems can be removed through

polishing.)

4. To prevent corrosion, it is rec-

ommended to apply a corro-

sion protection spray on all

(even chrome- and nickel-plat-

ed) metal surfaces.

5. Use spray oil as a universal

cleaner to remove any remain-

ing dirt.

6. Touch up minor paint damage

caused by stones, etc.

7. Wax all painted surfaces.8. Let the motorcycle dry com-

pletely before storing it or cov-

ering it.

EWA00001

w

Make sure that there is no oil or

wax on the brakes and tires. If nec-

essary, clean the brake discs and

linings with a regular brake disc

cleaner or acetone, and wash the

tires with warm water and mild

soap. Then, carefully test the

motorcycle for its braking perfor-

mance and cornering behavior.

ECA00013

cC

8Apply spray oil and wax spar-

ingly and wipe off any excess.

8Never apply oil or wax on rub-

ber and plastic parts, but treat

them with a suitable care

product.

8Avoid using abrasive polishing

compounds as they wear

away the paint.

NOTE:

Consult a Yamaha dealer for

advice on what products to use.

5EK-9-E1 (TW125)<3.1> 4/6/0 11:50 PM Page 72

Page 79 of 86

8-3

SPECIFICATIONS

1

2

3

4

5

6

7

8

9

Front150 kPa (1.50 kg/cm2, 1.50 bar)

Rear150 kPa (1.50 kg/cm2, 1.50 bar)

80 kg load ~ Maximum

load*

Front

150 kPa (1.50 kg/cm2, 1.50 bar)

Rear175 kPa (1.75 kg/cm2, 1.75 bar)

Off-road riding

Front

125 kPa (1.25 kg/cm2, 1.25 bar)

Rear125 kPa (1.25 kg/cm2, 1.25 bar)

*Load is total weight of cargo, rider, passenger and accessories.

Wheels

Front

Type Spoke wheel

Size 2.50 ´18

Rear

Type Spoke wheel

Size 14M/C ´MT4.50

Brakes

Front

Type Single disc brake

Operation Right hand operation

Fluid DOT 3 or DOT 4Rear

Type Drum brake

Operation Right foot operation

Suspension

Front

Type Telescopic fork

Rear

Type Swingarm (Monocross

suspension)

Shock absorber

Front Coil spring/oil damper

Rear Coil-gas spring/oil damper

Wheel travel

Front 160 mm

Rear 150 mm

Electrical

Ignition system C.D.I.

Charging system

Type C.D.I. magneto

Standard output 12 V, 11 A @ 5,000 rpm

Battery

Type GM7CZ-3D

Voltage, capacity 12 V, 7 AH

5EK-9-E1 (TW125)<3.1> 4/6/0 11:50 PM Page 77