check engine YAMAHA TW200 2002 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: TW200, Model: YAMAHA TW200 2002Pages: 74, PDF Size: 1.57 MB

Page 6 of 74

EAU00009

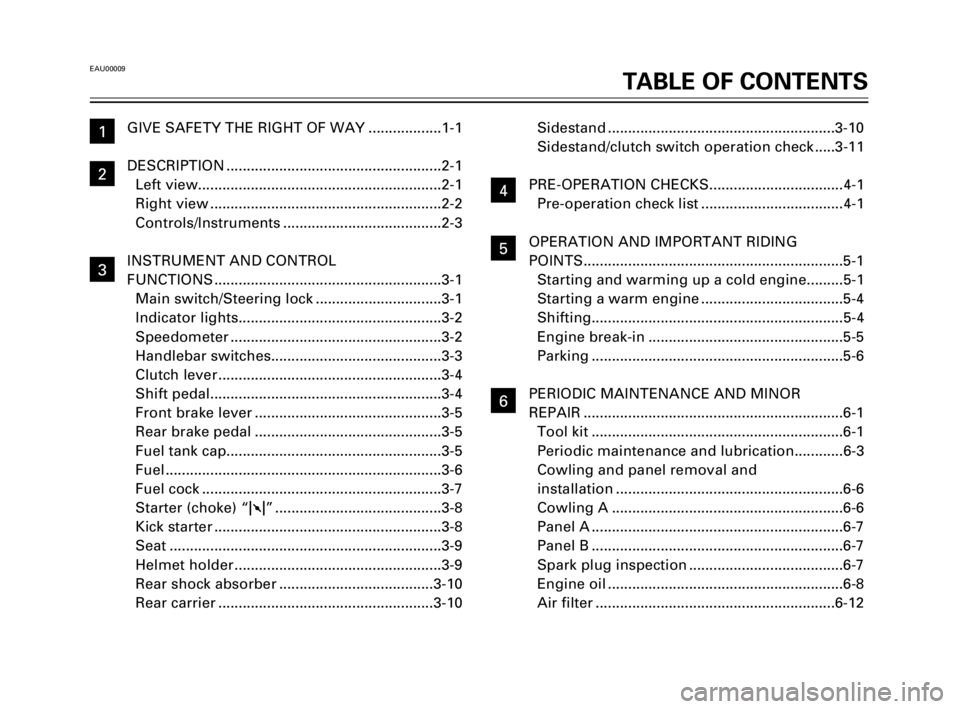

TABLE OF CONTENTS

1

2

3

4

5

6

7

8

9 GIVE SAFETY THE RIGHT OF WAY ..................1-1

DESCRIPTION .....................................................2-1

Left view............................................................2-1

Right view .........................................................2-2

Controls/Instruments .......................................2-3

INSTRUMENT AND CONTROL

FUNCTIONS ........................................................3-1

Main switch/Steering lock ...............................3-1

Indicator lights..................................................3-2

Speedometer ....................................................3-2

Handlebar switches..........................................3-3

Clutch lever .......................................................3-4

Shift pedal.........................................................3-4

Front brake lever ..............................................3-5

Rear brake pedal ..............................................3-5

Fuel tank cap.....................................................3-5

Fuel ....................................................................3-6

Fuel cock ...........................................................3-7

Starter (choke) “1” .........................................3-8

Kick starter ........................................................3-8

Seat ...................................................................3-9

Helmet holder ...................................................3-9

Rear shock absorber ......................................3-10

Rear carrier .....................................................3-10Sidestand ........................................................3-10

Sidestand/clutch switch operation check .....3-11

PRE-OPERATION CHECKS.................................4-1

Pre-operation check list ...................................4-1

OPERATION AND IMPORTANT RIDING

POINTS................................................................5-1

Starting and warming up a cold engine.........5-1

Starting a warm engine ...................................5-4

Shifting..............................................................5-4

Engine break-in ................................................5-5

Parking ..............................................................5-6

PERIODIC MAINTENANCE AND MINOR

REPAIR ................................................................6-1

Tool kit ..............................................................6-1

Periodic maintenance and lubrication............6-3

Cowling and panel removal and

installation ........................................................6-6

Cowling A .........................................................6-6

Panel A ..............................................................6-7

Panel B ..............................................................6-7

Spark plug inspection ......................................6-7

Engine oil ..........................................................6-8

Air filter ...........................................................6-12

1

2

3

4

5

6

5FY-9-E0 (TW200) 7/29/02 10:54 AM Page 5

Page 22 of 74

3-11

EW000044

w

This motorcycle must not be oper-

ated with the sidestand in the

down position. If the stand is not

properly retracted, it could contact

the ground and distract the opera-

tor, resulting in a possible loss of

control. Yamaha has designed into

this motorcycle a lockout system

to assist the operator in fulfilling

the responsibility of retracting the

sidestand. Please check carefully

the operating instructions listed

below and if there is any indication

of a malfunction, return the motor-

cycle to a Yamaha dealer immedi-

ately for repair.

INSTRUMENT AND CONTROL FUNCTIONS

1

2

3

4

5

6

7

8

9

EAU00331

Sidestand/clutch switch

operation check

Check the operation of the side-

stand switch and clutch switch

against the information below.

TURN THE MAIN SWITCH TO “ON”

AND THE ENGINE STOP SWITCH TO

“RUN”.

TRANSMISSION IS IN GEAR AND

SIDESTAND IS UP.

PULL IN CLUTCH LEVER AND

PUSH THE START SWITCH.

ENGINE WILL START.

CLUTCH SWITCH IS OK.

EW000045

w

If improper operation is noted,

consult a Yamaha dealer immedi-

ately.

SIDESTAND IS DOWN.

ENGINE WILL STALL.

SIDESTAND SWITCH IS OK.

5FY-9-E0 (TW200) 7/29/02 10:54 AM Page 21

Page 23 of 74

4-1

EAU01114

PRE-OPERATION CHECKS

1

2

3

4

5

6

7

8

9Owners are personally responsible for their vehicle’s condition. Your motorcycle’s vital functions can start to

deteriorate quickly and unexpectedly, even if it remains unused (for instance, if it is exposed to the elements).

Any damage, fluid leak or loss of tire pressure could have serious consequences. Therefore, it is very important

that, in addition to a thorough visual inspection, you check the following points before each ride.

EAU00340PRE-OPERATION CHECK LIST

ITEM CHECKS PAGE

Brakes9Check operation, condition and free play.

3-5, 6-18 ~ 6-21

9Adjust if necessary.

Clutch9Check operation and free play.

3-4, 6-18

9Adjust if necessary.

9Check for smooth operation.

Throttle grip and housing9Lubricate.6-14, 6-24

9Adjust throttle cable free play if necessary.

Engine oil9Check oil level.

6-8 ~ 6-11

9Fill with oil if necessary.

Drive chain9Check chain slack and condition.

6-21 ~ 6-23

9Adjust if necessary.

Wheels and tires9Check tire pressure, wear, damage and spoke tightness.

6-15 ~ 6-17

9Tighten spokes if necessary.

Brake and shift pedal shafts9Check for smooth operation.

6-24

9Lubricate if necessary.

Brake and clutch lever pivots9Check for smooth operation.

6-25

9Lubricate if necessary.

Sidestand pivot9Check for smooth operation.

6-25

9Lubricate if necessary.

Chassis fasteners9Make sure that all nuts, bolts, and screws are properly tightened.

—

9Tighten if necessary.

5FY-9-E0 (TW200) 7/29/02 10:54 AM Page 22

Page 25 of 74

EAU00373

w

1. Before riding this motorcycle,

become thoroughly familiar

with all operating controls and

their functions. Consult a

Yamaha dealer regarding any

control or function that you do

not thoroughly understand.

2. Never start your engine or let

it run for any length of time in

a closed area. The exhaust

fumes are poisonous and can

cause loss of consciousness

and death within a short time.

Always operate your motorcy-

cle in an area with adequate

ventilation.

3. Before starting out, always be

sure the sidestand is up.

Failure to retract the sidestand

completely can result in a seri-

ous accident when you try to

turn a corner.

EAU00411

Starting and warming up a

cold engine

NOTE:

This motorcycle is equipped with a

starting and an ignition circuit cut-

off switch.

1. The engine can be started only

under the following condi-

tions:

a. The transmission is in neutral.

b. The sidestand is up, the trans-

mission is in gear, and the

clutch is disengaged.

2. The motorcycle must not be

ridden when the sidestand is

down.

EW000054

w

Before going through the follow-

ing steps, check the function of the

sidestand switch and clutch

switch. (Refer to page 3-11.)

5-1

EAU00372

OPERATION AND IMPORTANT RIDING POINTS

1

2

3

4

5

6

7

8

9

5FY-9-E0 (TW200) 7/29/02 10:54 AM Page 24

Page 34 of 74

6-4

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

EVERY

6,000 km 12,000 km

No. ITEM CHECKS AND MAINTENANCE JOBSInitial or or

(1,000 km) 6 months 12 months

(Whichever (Whichever

comes first) comes first)

12 * Wheel bearings9Check bearing for looseness or damage.

√√

9Replace if necessary.

9Check swingarm pivoting point for play.

13 * Swingarm9Correct if necessary. √√

9Lubricate with lithium soap base grease.

9Check chain slack.

14 Drive chain9

Adjust if necessary. Make sure that the rear wheel is properly aligned.Every 500 km and after washing

9Clean and lubricate.the motorcycle or riding in the rain

9Check bearing play and steering for roughness.

15 * Steering bearings9Correct accordingly.

√√

9Lubricate with lithium soap grease every 24,000 km or

24 months (whichever comes first).

16 * Chassis fasteners9

Make sure that all nuts, bolts and screws are properly tightened.√√9Tighten if necessary.

17 Sidestand9Check operation.

√√

9Lubricate and repair if necessary.

18 Sidestand switch9Check operation.

√√√

9Replace if necessary.

19 * Front fork9Check operation and for oil leakage.

√√

9Correct accordingly.

20 *Rear shock absorber 9Check operation and shock absorber for oil leakage.

√√

assembly9Replace shock absorber assembly if necessary.

Rear shock absorber9Check operation.

21 * assembly pivoting9Lubricate with lithium soap base grease every 24,000 km or√√

points24 months (whichever comes first).

22 * Carburetor9Check engine idling speed and starter operation.

√√√

9Adjust if necessary.

5FY-9-E0 (TW200) 7/29/02 10:54 AM Page 33

Page 35 of 74

6-5

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

*: Since these items require special tools, data and technical skills, they should be serviced by a Yamaha dealer.EAU00479

NOTE:

The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

EVERY

6,000 km 12,000 km

No. ITEM CHECKS AND MAINTENANCE JOBSInitial or or

(1,000 km) 6 months 12 months

(Whichever (Whichever

comes first) comes first)

9Check oil level and vehicle for oil leakage.

23 Engine oil9Correct if necessary.√√√

9Change. (Warm engine before draining.)

24Engine oil filter element9Clean or replace if necessary.√√

25

*

Engine oil strainer9Clean or replace if necessary.√√

5FY-9-E0 (TW200) 7/29/02 10:54 AM Page 34

Page 38 of 74

6-8

PERIODIC MAINTENANCE AND MINOR REPAIR

6 break down and erode. If electrode

erosion becomes excessive, or if

carbon and other deposits are

excessive, you should replace the

spark plug with the specified plug.

Before installing the spark plug,

measure the electrode gap with a

wire thickness gauge; adjust the

gap to specification as necessary.

When installing the plug, always

clean the gasket surface and use a

new gasket. Wipe off any grime

from the threads and tighten the

spark plug to the specified torque.Specified spark plug:

DR8EA (NGK) or

X24ESR-U (DENSO)Spark plug gap:

0.6 ~ 0.7 mm

Tightening torque:

Spark plug:

17.5 Nm (1.75 m0kg)

NOTE:

If a torque wrench is not available

when you are installing a spark

plug, a good estimate of the cor-

rect torque is 1/4 to 1/2 turn past

finger tight. Have the spark plug

tightened to the specified torque as

soon as possible.EAU00517Engine oil

1. Oil level measurement

a. Place the motorcycle on a level

place and hold it in an upright

position. Warm up the engine

for several minutes.

NOTE:

Be sure the motorcycle is posi-

tioned straight up when checking

the oil level. A slight tilt toward the

side can result in false readings.

5FY-9-E0 (TW200) 7/29/02 10:54 AM Page 37

Page 39 of 74

6-9

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

1

2. Engine oil replacement

a. Warm up the engine for a few

minutes.

b. Stop the engine. Place an oil

pan under the engine and

remove the oil filler cap.

1. Oil filler cap

2

3 1

b. With the engine stopped,

check the oil level through the

level window located at the

lower part of the right side

crankcase cover.

NOTE:

Wait a few minutes until the oil

level settles before checking.

c. The oil level should be

between the maximum and

minimum marks. If the level is

low, add sufficient oil to raise

it to the proper level.

1. Level window

2. Maximum level mark

3. Minimum level mark

1

c. Remove the drain plug and

drain bolt.

1. Drain plug

5FY-9-E0 (TW200) 7/29/02 10:54 AM Page 38

Page 41 of 74

6-11

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9i. Fill the engine with oil. Install

the oil filler cap and tighten.

EC000066

cC

8Do not put in any chemical

additives. Engine oil also lubri-

cates the clutch and additives

could cause clutch slippage.

8Be sure no foreign material

enters the crankcase.

Recommended oil:

See page 8-1

Oil quantity:

Total amount:

1.3 L

Periodic oil change:

1.0 L

With oil filter replacement:

1.1 LTightening torque:

Drain plug:

10 Nm (1.0 m0kg)

Filter cover screw:

10 Nm (1.0 m0kg)

Drain bolt (filter cover):

10 Nm (1.0 m0kg)j. Start the engine and warm up

for a few minutes. While

warming up, check for oil leak-

age. If oil leakage is found,

stop the engine immediately

and check for the cause.

5FY-9-E0 (TW200) 7/29/02 10:54 AM Page 40

Page 52 of 74

6-22

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9 To check the chain slack the motor-

cycle must be held straight up with

both wheels on the ground and

without rider. Check the slack at

the position shown in the illustra-

tion. Normal slack is approximately

30 ~ 40 mm. If the slack exceeds 40

mm, adjust.

EAU01302

Drive chain slack adjustment

1. Loosen the rear brake adjust-

ing nut.

2. Remove the cotter pin from

the axle nut.

3. Loosen the axle nut.

4. Turn both left and right chain

adjusting plates the same

amount. Make sure that they

are in the same position for

proper wheel alignment.

1

2

3 4

1. Adjusting nut

2. Axle nut

3. Cotter pin

4. Chain adjusting plate

EC000096

cC

Too little chain slack will overload

the engine and other vital parts.

Keep the slack within the specified

limits.

5. After adjusting, be sure to

tighten the axle nut to the

specified torque.

Tightening torque:

Axle nut:

90 Nm (9.0 m0kg)

5FY-9-E0 (TW200) 7/29/02 10:54 AM Page 51