light YAMAHA VERSITY 300 2004 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2004, Model line: VERSITY 300, Model: YAMAHA VERSITY 300 2004Pages: 104, PDF Size: 2.82 MB

Page 39 of 104

4

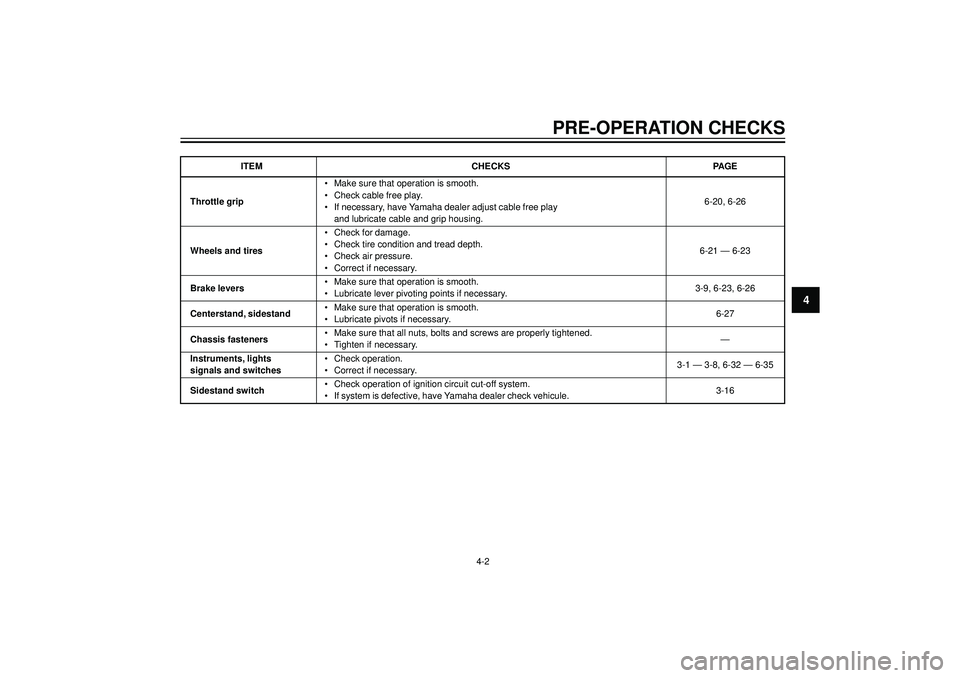

PRE-OPERATION CHECKS

ITEM CHECKS PAGE

•Make sure that operation is smooth.

Throttle grip•Check cable free play.

6-20, 6-26

•If necessary, have Yamaha dealer adjust cable free play

and lubricate cable and grip housing.

•Check for damage.

Wheels and tires•Check tire condition and tread depth.

6-21 — 6-23

•Check air pressure.

•Correct if necessary.

Brake levers•Make sure that operation is smooth.

3-9, 6-23, 6-26

•Lubricate lever pivoting points if necessary.

Centerstand, sidestand•Make sure that operation is smooth.

6-27

•Lubricate pivots if necessary.

Chassis fasteners•Make sure that all nuts, bolts and screws are properly tightened.

—

•Tighten if necessary.

Instruments, lights•Check operation.

3-1 — 3-8, 6-32 — 6-35

signals and switches•Correct if necessary.

Sidestand switch•Check operation of ignition circuit cut-off system.

3-16

•If system is defective, have Yamaha dealer check vehicule.

4-2

Page 45 of 104

OPERATION AND IMPORTANT RIDING POINTS

5

EAU04755

Tips for reducing fuel

consumption

Fuel consumption depends largely on

your riding style. Consider the following

tips to reduce fuel consumption:

•Avoid high engine speeds during

acceleration.

•Avoid high engine speeds with no

load on the engine.

•Turn the engine off instead of

letting it idle for an extended

length of time (e.g., in traffic jams,

at traffic lights or at railroad

crossings).

EAU01128

Engine break-in

There is never a more important period

in the life of your engine than the period

between 0 and 1,600 km. For this

reason, you should read the following

material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1,600 km. The various parts in the

engine wear and polish themselves to

the correct operating clearances.

During this period, prolonged full-

throttle operation or any condition that

might result in engine overheating must

be avoided.

EAU03845*

0 — 1,000 km

Avoid prolonged operation above 1/3

throttle.

1,000 — 1,600 km

Avoid prolonged operation above 1/2

throttle.

ECA00138

After 1,000 km of operation, be sure

to replace the engine oil and final

transmission oil.

1,600 km and beyond

The vehicle can now be operated

normally.

EC000049

If any engine trouble should occur

during the engine break-in period,

immediately have a Yamaha dealer

check the vehicle.

CAUTION:

CAUTION:

5-4

Page 47 of 104

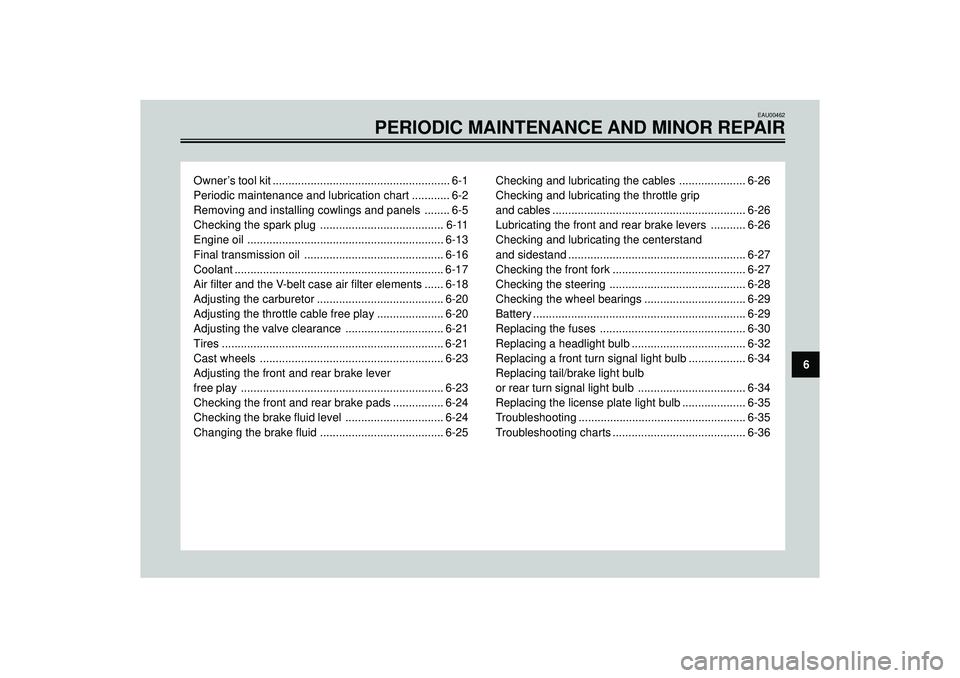

EAU00462

PERIODIC MAINTENANCE AND MINOR REPAIR

Owner’s tool kit ........................................................ 6-1

Periodic maintenance and lubrication chart ............ 6-2

Removing and installing cowlings and panels ........ 6-5

Checking the spark plug ....................................... 6-11

Engine oil .............................................................. 6-13

Final transmission oil ............................................ 6-16

Coolant .................................................................. 6-17

Air filter and the V-belt case air filter elements ...... 6-18

Adjusting the carburetor ........................................ 6-20

Adjusting the throttle cable free play ..................... 6-20

Adjusting the valve clearance ............................... 6-21

Tires ...................................................................... 6-21

Cast wheels .......................................................... 6-23

Adjusting the front and rear brake lever

free play ................................................................ 6-23

Checking the front and rear brake pads ................ 6-24

Checking the brake fluid level ............................... 6-24

Changing the brake fluid ....................................... 6-25Checking and lubricating the cables ..................... 6-26

Checking and lubricating the throttle grip

and cables ............................................................. 6-26

Lubricating the front and rear brake levers ........... 6-26

Checking and lubricating the centerstand

and sidestand ........................................................ 6-27

Checking the front fork .......................................... 6-27

Checking the steering ........................................... 6-28

Checking the wheel bearings ................................ 6-29

Battery ................................................................... 6-29

Replacing the fuses .............................................. 6-30

Replacing a headlight bulb .................................... 6-32

Replacing a front turn signal light bulb .................. 6-34

Replacing tail/brake light bulb

or rear turn signal light bulb .................................. 6-34

Replacing the license plate light bulb .................... 6-35

Troubleshooting ..................................................... 6-35

Troubleshooting charts .......................................... 6-36

6

Page 51 of 104

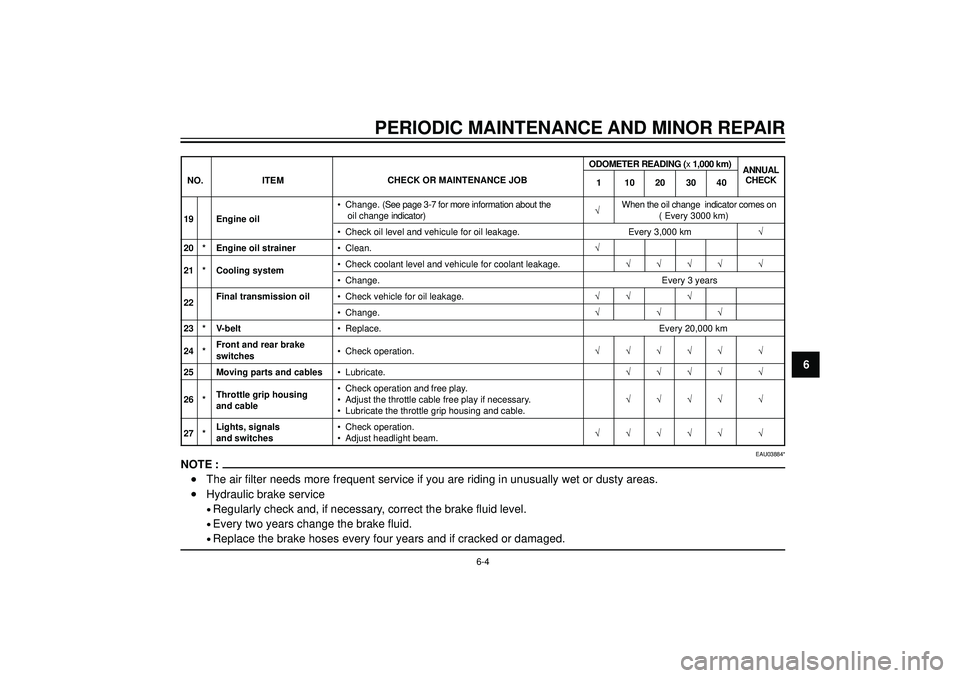

PERIODIC MAINTENANCE AND MINOR REPAIR

6

•Change. (See page 3-7 for more information about the√When the oil change indicator comes on19 Engine oil oil change indicator)( Every 3000 km)

•Check oil level and vehicule for oil leakage. Every 3,000 km√

20 * Engine oil strainer•Clean.√

21 * Cooling system•Check coolant level and vehicule for coolant leakage.√√√√ √•Change. Every 3 years

22Final transmission oil•Check vehicle for oil leakage.√√ √•Change.√√√

23 * V-belt•Replace. Every 20,000 km

24 *Front and rear brake

•Check operation.√√√√√ √

switches

25 Moving parts and cables•Lubricate.√√√√ √

Throttle grip housing•Check operation and free play.

26 *

and cable•Adjust the throttle cable free play if necessary.√√√√ √

•Lubricate the throttle grip housing and cable.

27 *Lights, signals•Check operation.

√√√√√ √

and switches•Adjust headlight beam.

ODOMETER READING (x 1,000 km)

NO. ITEMCHECK OR MAINTENANCE JOB

1

ANNUAL

CHECK

10 20 30 40

EAU03884*

NOTE :

•The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

•Hydraulic brake service

•Regularly check and, if necessary, correct the brake fluid level.

•Every two years change the brake fluid.

•Replace the brake hoses every four years and if cracked or damaged.

6-4

Page 54 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6

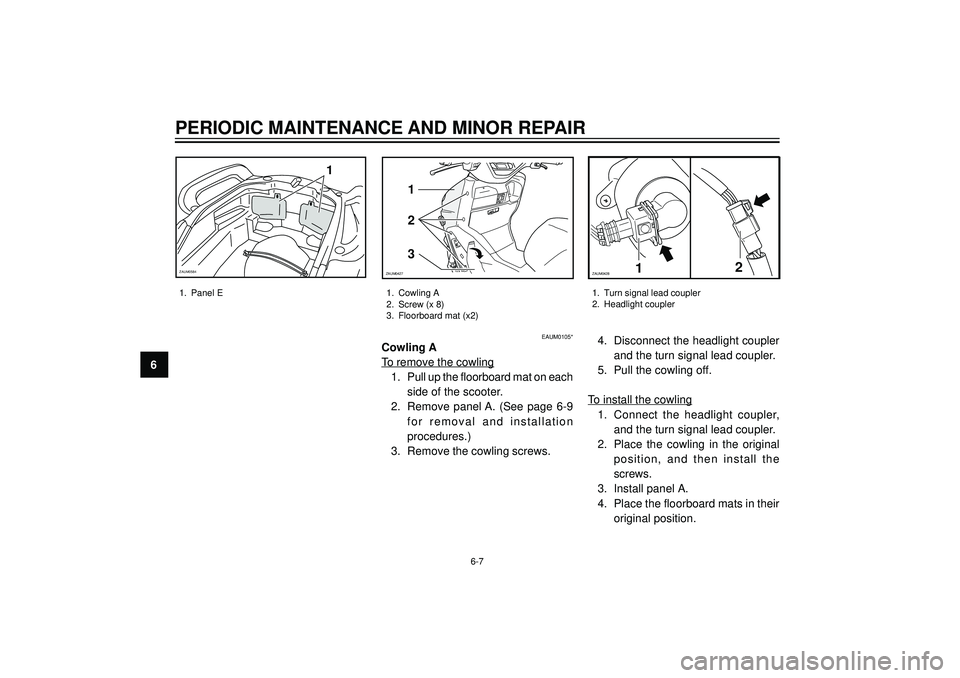

1. Cowling A

2. Screw (x 8)

3. Floorboard mat (x2)1. Turn signal lead coupler

2. Headlight coupler

6-7

3 2 1

ZAUM042712ZAUM0428

EAUM0105*

Cowling A

To remove the cowling

1. Pull up the floorboard mat on each

side of the scooter.

2. Remove panel A. (See page 6-9

for removal and installation

procedures.)

3. Remove the cowling screws.4. Disconnect the headlight coupler

and the turn signal lead coupler.

5. Pull the cowling off.

To install the cowling

1. Connect the headlight coupler,

and the turn signal lead coupler.

2. Place the cowling in the original

position, and then install the

screws.

3. Install panel A.

4. Place the floorboard mats in their

original position.

1

ZAUM0584

1. Panel E

Page 59 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

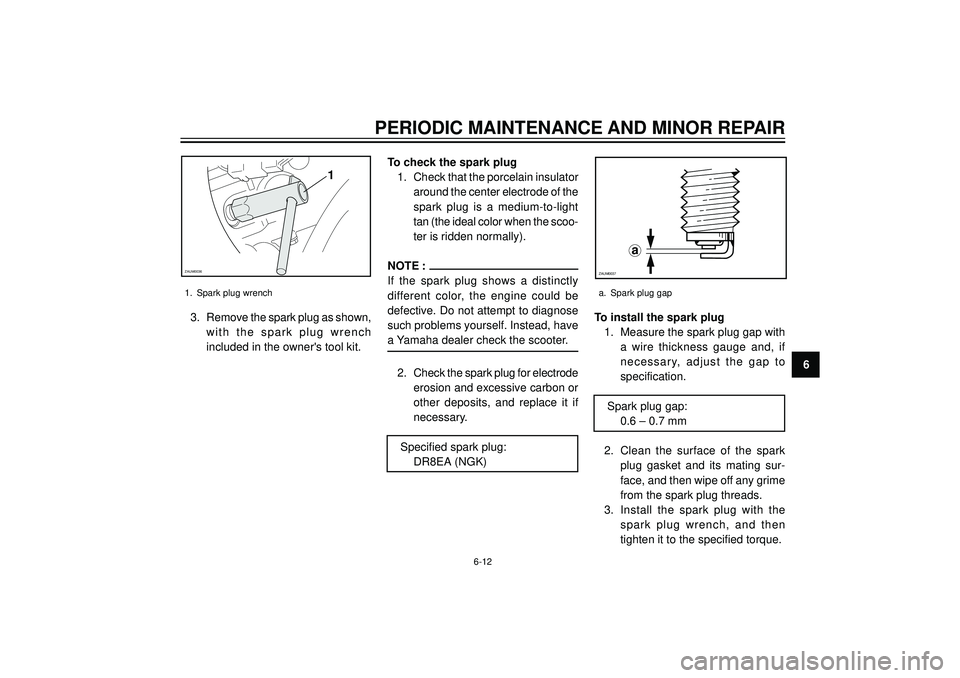

6 3. Remove the spark plug as shown,

with the spark plug wrench

included in the owner's tool kit.To check the spark plug

1. Check that the porcelain insulator

around the center electrode of the

spark plug is a medium-to-light

tan (the ideal color when the scoo-

ter is ridden normally).

NOTE :

If the spark plug shows a distinctly

different color, the engine could be

defective. Do not attempt to diagnose

such problems yourself. Instead, have

a Yamaha dealer check the scooter.

2. Check the spark plug for electrode

erosion and excessive carbon or

other deposits, and replace it if

necessary.

Specified spark plug:

DR8EA (NGK)To install the spark plug

1. Measure the spark plug gap with

a wire thickness gauge and, if

necessary, adjust the gap to

specification.

Spark plug gap:

0.6 – 0.7 mm

2. Clean the surface of the spark

plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

3. Install the spark plug with the

spark plug wrench, and then

tighten it to the specified torque.

1. Spark plug wrencha. Spark plug gap

6-12

1

ZAUM0036

a

ZAUM0037

Page 60 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6Tightening torque:

Spark plug:

17.5 Nm (1.75 m

•kg)

NOTE :

If a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4 – 1/2 turn

past finger tight. However, the spark

plug should be tightened to the

specified torque as soon as possible.

4. Install the spark plug cap.

5. Install the cowling.

6-13

EAUM0103*

Engine oil

The engine oil level should be checked

before each ride. In addition, the oil

must be changed at the intervals

specified in the periodic maintenance

and lubrication chart and when the oil

change indicator comes on.To check the engine oil level

1. Place the scooter on the

centerstand.

NOTE :

Make sure that the scooter is positioned

straight up when checking the oil level.

A slight tilt to the side can result in a

false reading.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

Page 64 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6

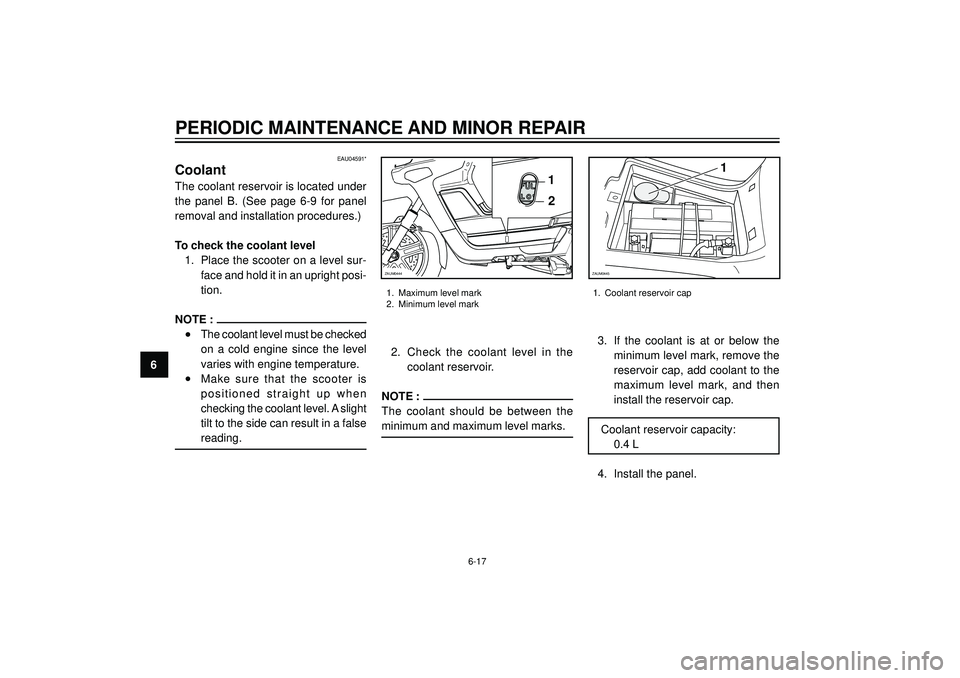

EAU04591*

Coolant

The coolant reservoir is located under

the panel B. (See page 6-9 for panel

removal and installation procedures.)

To check the coolant level

1. Place the scooter on a level sur-

face and hold it in an upright posi-

tion.

NOTE :

•The coolant level must be checked

on a cold engine since the level

varies with engine temperature.

•Make sure that the scooter is

positioned straight up when

checking the coolant level. A slight

tilt to the side can result in a false

reading.2. Check the coolant level in the

coolant reservoir.

NOTE :

The coolant should be between the

minimum and maximum level marks.

1. Maximum level mark

2. Minimum level mark

3. If the coolant is at or below the

minimum level mark, remove the

reservoir cap, add coolant to the

maximum level mark, and then

install the reservoir cap.

Coolant reservoir capacity:

0.4 L

4. Install the panel.

1. Coolant reservoir cap

6-17

1

2

ZAUM0444

1

ZAUM0445

Page 78 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6

1. Backup fuse

2. Headlight fuse

3. Radiator fan fuse

4. Signaling system fuse

5. Ignition fuse

6. Auxiliary DC jack fuse

7. Spare fuse (x2)

8. Fuse tongs

CAUTION:

6-31

12345 776

8

ZAUM0460

The fuse block, which contains the fu-

ses for the individual circuits, is located

in the storage compartment A. (See

page 3-12 for storage compartment

opening and closing procedures.)If a fuse is blown, replace it as follows.

1. Turn the key to "

" and turn off

the electrical circuit in question.

2. Remove the blown fuse, and then

install a new fuse of the specified

amperage.

Specified fuses:

Main fuse Box

Main fuse: 30 A

Fuse block

Backup fuse 3 A

Headlight fuse: 15 A

Radiator fan fuse: 15 A

Signaling system fuse: 15 A

Ignition fuse: 7.5 A

Auxiliary DC jack fuse: 3 A3. Turn the key to "

" and turn on

the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows

again, have a Yamaha dealer

check the electrical system.

EC000103

Do not use a fuse of a higher

amperage rating than recommended

to avoid causing extensive damage

to the electrical system and possibly

a fire.

Page 79 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU04285

Replacing the headlight bulb

This scooter is equipped with a quartz

bulb headlight. If the headlight bulb

burns out, replace it as follows.

1. Remove cowling A together with

the headlight unit. (See page 6-7

for cowling removal and installa-

tion procedures.)

WARNING

1. Bulb cover

2. Headlight coupler

3. Remove the headlight bulb holder

by pushing it inward and turning

it counterclockwise, and then

remove the defective bulb.

EW000119

Headlight bulbs get very hot.

Therefore, keep flammable products

away from a lit headlight bulb, and

do not touch the bulb until it has

cooled down. 2. Disconnect the headlight coupler,

and then remove the bulb cover.

6-32

2 1ZAUM0461

1

ZAUM0462

1. Headlight bulb holder