wheel YAMAHA VIKING 2015 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: VIKING, Model: YAMAHA VIKING 2015Pages: 182, PDF Size: 3.82 MB

Page 142 of 182

8-32

8

9

10

11

12

13

14

BrakesReplacement of brake components requires

professional knowledge. Brake service should

be performed by a Yamaha dealer.

WARNING

Operating with improperly serviced or ad-

justed brakes could lead to a loss in brak-

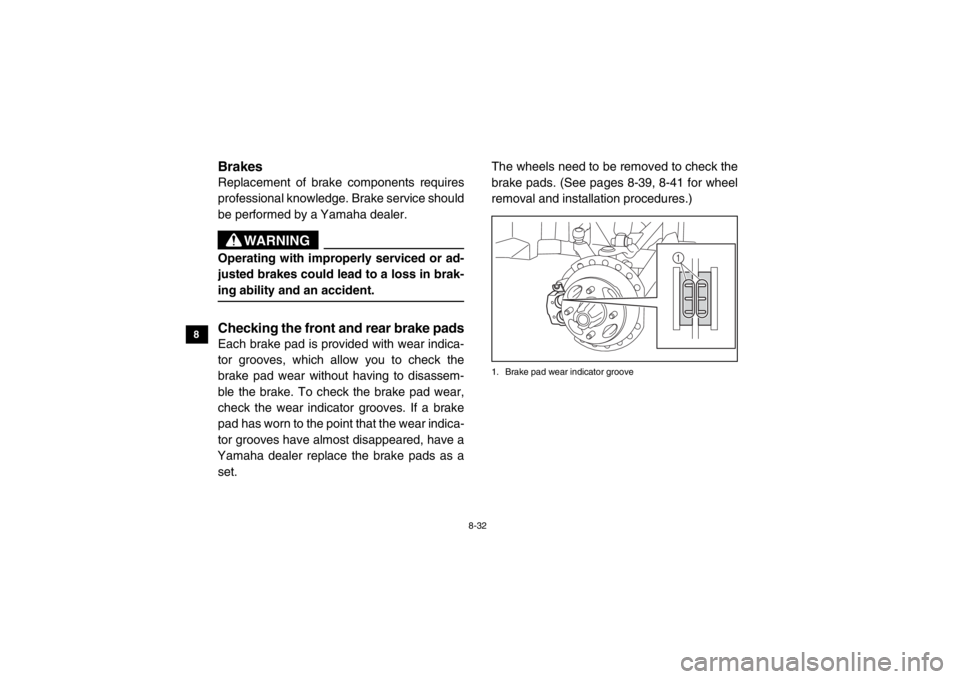

ing ability and an accident.5B410019Checking the front and rear brake padsEach brake pad is provided with wear indica-

tor grooves, which allow you to check the

brake pad wear without having to disassem-

ble the brake. To check the brake pad wear,

check the wear indicator grooves. If a brake

pad has worn to the point that the wear indica-

tor grooves have almost disappeared, have a

Yamaha dealer replace the brake pads as a

set. The wheels need to be removed to check the

brake pads. (See pages 8-39, 8-41 for wheel

removal and installation procedures.)

1. Brake pad wear indicator groove

1

1XP7C_EE.book Page 32 Monday, June 9, 2014 5:17 PM

Page 149 of 182

8-39

1

2

3

4

5

6

78

9

10

11

12

13

14

EVU00920Steering shaft lubricationLubricate the pivot points.

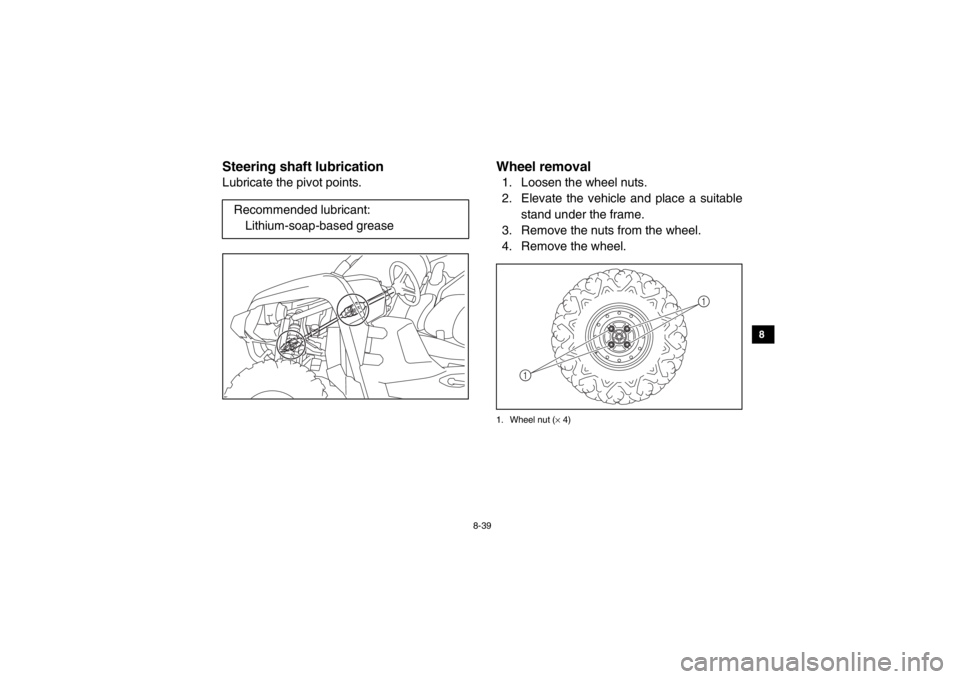

EVU00930Wheel removal1. Loosen the wheel nuts.

2. Elevate the vehicle and place a suitablestand under the frame.

3. Remove the nuts from the wheel.

4. Remove the wheel.1. Wheel nut ( × 4)

Recommended lubricant:

Lithium-soap-based grease

1

1

1XP7C_EE.book Page 39 Monday, June 9, 2014 5:17 PM

Page 151 of 182

8-41

1

2

3

4

5

6

78

9

10

11

12

13

14

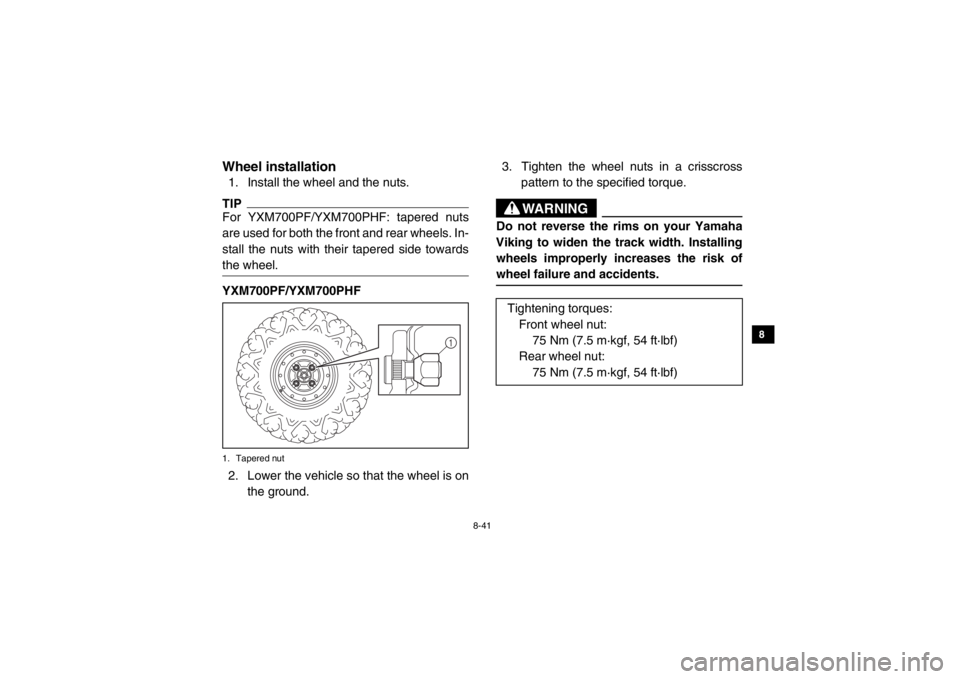

EVU00940Wheel installation1. Install the wheel and the nuts.TIPFor YXM700PF/YXM700PHF: tapered nuts

are used for both the front and rear wheels. In-

stall the nuts with their tapered side towards

the wheel.YXM700PF/YXM700PHF1. Tapered nut2. Lower the vehicle so that the wheel is onthe ground. 3. Tighten the wheel nuts in a crisscross

pattern to the specified torque.

WARNING

Do not reverse the rims on your Yamaha

Viking to widen the track width. Installing wheels improperly increases the risk of

wheel failure and accidents.

1

Tightening torques: Front wheel nut: 75 Nm (7.5 m·kgf, 54 ft·lbf)

Rear wheel nut:

75 Nm (7.5 m·kgf, 54 ft·lbf)

1XP7C_EE.book Page 41 Monday, June 9, 2014 5:17 PM

Page 158 of 182

8-48

8

9

10

11

12

13

14

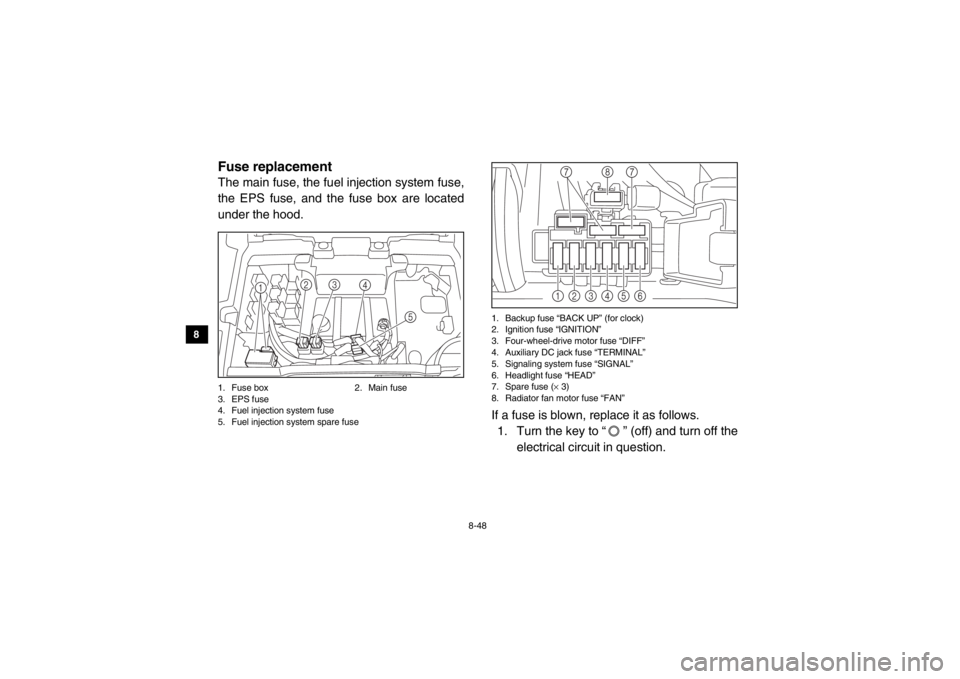

5B410023Fuse replacementThe main fuse, the fuel injection system fuse,

the EPS fuse, and the fuse box are located

under the hood.1. Fuse box 2. Main fuse

3. EPS fuse

4. Fuel injection system fuse

5. Fuel injection system spare fuse 1. Backup fuse “BACK UP” (for clock)

2. Ignition fuse “IGNITION”

3. Four-wheel-drive motor fuse “DIFF”

4. Auxiliary DC jack fuse “TERMINAL”

5. Signaling system fuse “SIGNAL”

6. Headlight fuse “HEAD”

7. Spare fuse (

× 3)

8. Radiator fan motor fuse “FAN”

If a fuse is blown, replace it as follows.

1. Turn the key to “ ” (off) and turn off the

electrical circuit in question.

1 3

2

4

5

1

2

3

4

5

6

8

7

7

1XP7C_EE.book Page 48 Monday, June 9, 2014 5:17 PM

Page 159 of 182

8-49

1

2

3

4

5

6

78

9

10

11

12

13

14

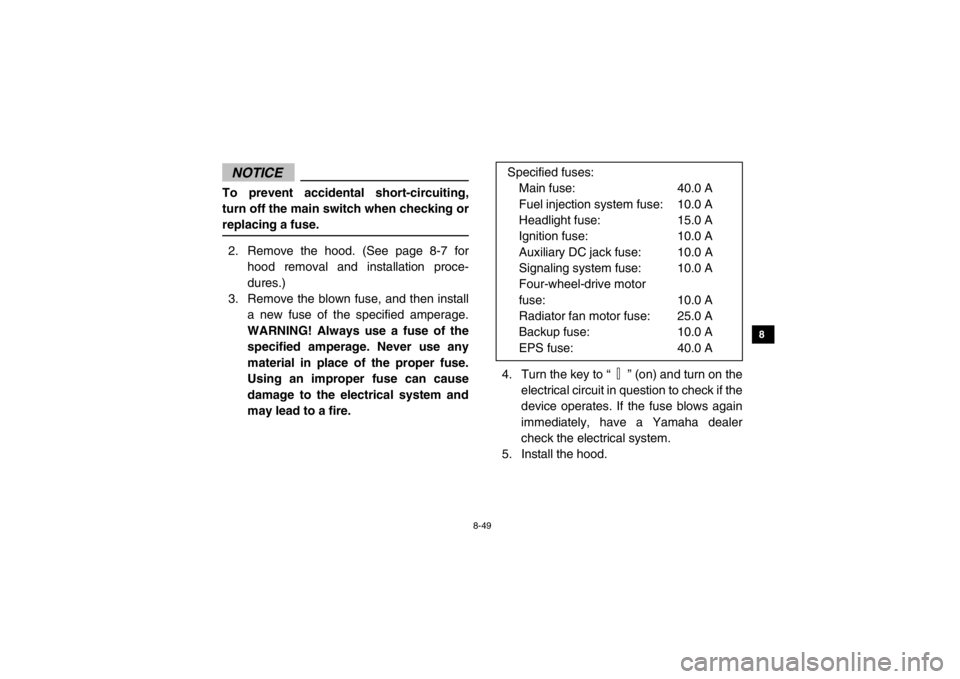

NOTICETo prevent accidental short-circuiting,

turn off the main switch when checking or

replacing a fuse.2. Remove the hood. (See page 8-7 forhood removal and installation proce-

dures.)

3. Remove the blown fuse, and then install a new fuse of the specified amperage.

WARNING! Always use a fuse of the specified amperage. Never use any

material in place of the proper fuse.

Using an improper fuse can cause

damage to the electrical system and

may lead to a fire. 4. Turn the key to “ ” (on) and turn on the

electrical circuit in question to check if the

device operates. If the fuse blows again

immediately, have a Yamaha dealer

check the electrical system.

5. Install the hood. Specified fuses:

Main fuse: 40.0 A

Fuel injection system fuse: 10.0 A

Headlight fuse: 15.0 A

Ignition fuse: 10.0 A

Auxiliary DC jack fuse: 10.0 A

Signaling system fuse: 10.0 A

Four-wheel-drive motor

fuse: 10.0 A

Radiator fan motor fuse: 25.0 A

Backup fuse: 10.0 A

EPS fuse: 40.0 A

1XP7C_EE.book Page 49 Monday, June 9, 2014 5:17 PM

Page 169 of 182

9-1

1

2

3

4

5

6

7

89

10

11

12

13

14

EVU01030

1-CLEANING AND STORAGE

CleaningFrequent, thorough cleaning of your vehicle

will not only enhance its appearance but will

improve its general performance and extend

the useful life of many components.1. Before cleaning the vehicle:

a. Block off the end of the exhaust pipeto prevent water entry. A plastic bag

and strong rubber band may be used.

b. Make sure the spark plug and all filler caps are properly installed.

2. If the engine case is excessively greasy,

apply degreaser with a paint brush. Do

not apply degreaser to the wheel axles. 3. Rinse the dirt and degreaser off with a

garden hose. Use only enough pressure

to do the job. WARNING! Test the

brakes after washing. Apply the

brakes several times at slow speeds

to let friction dry out the linings. Wet

brakes may have reduced stopping

ability, increasing the chance of an ac-

cident. NOTICE: Excessive water

pressure may cause water seepage

and deterioration of wheel bearings,

brakes, transmission seals and elec-

trical devices. Many expensive repair

bills have resulted from improper

high-pressure detergent applications,

such as those available in coin-oper-

ated car washers.1XP7C_EE.book Page 1 Monday, June 9, 2014 5:17 PM

Page 171 of 182

9-3

1

2

3

4

5

6

7

89

10

11

12

13

14

5B410025StorageLong term storage (60 days or more) of your

vehicle will require some preventive proce-

dures to guard against deterioration. Make

any necessary repairs before storing the vehi-

cle.

After thoroughly cleaning the vehicle, prepare

for storage as follows:1. Fill the fuel tank with fresh fuel and add

the specified amount of Yamaha Fuel

Stabilizer and Conditioner or equivalent

product. Operate the vehicle for at least

5 minutes to distribute treated fuel

through the fuel system. 2. Remove the spark plug, pour about one

tablespoon of SAE 10W-40 or 20W-50

motor oil in the spark plug hole and install

the spark plug. Ground the spark plug

wire and turn the engine over several

times to coat the cylinder wall with oil.

3. Lubricate all control cables.

4. Block up the frame to raise all wheels off the ground.

5. Tie a plastic bag over the exhaust pipe outlet to prevent moisture from entering.

6. If storing in a humid or salt-air atmo-

sphere, coat all exposed metal surfaces

with a light film of oil. Do not apply oil to

any rubber parts or the seat covers.

Specified amount:

1 oz of stabilizer to each gallon of fuel (or

7.5 ml of stabilizer to each liter of fuel)1XP7C_EE.book Page 3 Monday, June 9, 2014 5:17 PM

Page 173 of 182

10-1

1

2

3

4

5

6

7

8

910

11

12

13

14

EBU25960

1-SPECIFICATIONS

Dimensions:Overall length:3100 mm (122.0 in)

Overall width: YXM700PF 1570 mm (61.8 in)

YXM700PHF 1570 mm (61.8 in)

YXM700PSF 1625 mm (64.0 in)

Overall height: YXM700PF 1880 mm (74.0 in) (AUS)(NZL)

YXM700PF 1925 mm (75.8 in) (EUR)(FRA)(GBR)

YXM700PHF 1925 mm (75.8 in)

YXM700PSF 1925 mm (75.8 in)

Wheelbase: 2135 mm (84.1 in)

Ground clearance:

300 mm (11.8 in)

Minimum turning radius: 4500 mm (177 in)Weight:Curb weight:

YXM700PF 615 kg (1356 lb) (AUS)(NZL)

YXM700PF 623 kg (1373 lb) (EUR)(FRA)(GBR)

YXM700PHF 623 kg (1373 lb)

YXM700PSF 635 kg (1400 lb)Noise and vibration level:Noise level (77/311/EEC):83.0 dB(A) (EUR)(FRA)(GBR)

A-weighted sound power level:

93.0 dB(A) (EUR)(FRA)(GBR) Vibration on seat (EN1032, ISO5008):

Will not exceed 0.5 m/s² (EUR)(FRA)(GBR)

Vibration on handle (EN1032, ISO5008): Will not exceed 2.5 m/s² (EUR)(FRA)(GBR)

Engine:Engine type:

Liquid cooled 4-stroke, SOHC

Cylinder arrangement: Single cylinder

Displacement: 686 cm³

Bore × stroke:

102.0 × 84.0 mm (4.02 × 3.31 in)

Compression ratio: 10.0 : 1

Starting system: Electric starter

Lubrication system:

Wet sump

1XP7C_EE.book Page 1 Monday, June 9, 2014 5:17 PM

Page 176 of 182

10-4

10

11

12

13

14

Vehicle load: 300 kg – maximum (661 lb – maximum):

Front:70.0 kPa (0.700 kgf/cm

2, 10 psi)

Rear:

120.0 kPa (1.200 kgf/cm2, 17 psi)

Front wheel:Wheel type:YXM700PF Panel wheel

YXM700PHF Panel wheel

YXM700PSF Cast wheel

Rim size: 12 × 6.0ATRear wheel:Wheel type:

YXM700PF Panel wheel

YXM700PHF Panel wheel

YXM700PSF Cast wheel

Rim size: 12 × 7.5ATFront brake:Type:

Disc brake

Operation: Unified brake

Recommended fluid:

DOT 4Rear brake:Type:Disc brake

Operation:

Unified brake Recommended fluid:

DOT 4

Front suspension:Type:

Double wishbone

Spring/shock absorber type: Coil spring/gas-oil damper

Wheel travel: 205 mm (8.1 in)Rear suspension:Type:Double wishbone

Spring/shock absorber type: Coil spring/gas-oil damper

Wheel travel:

205 mm (8.1 in)Electrical system:Ignition system:TCI

Charging system:

AC magnetoBattery:Model:U1-H11L

Voltage, capacity:

12 V, 28.0 AhHeadlight:Bulb type:Halogen bulb

1XP7C_EE.book Page 4 Monday, June 9, 2014 5:17 PM

Page 177 of 182

10-5

1

2

3

4

5

6

7

8

910

11

12

13

14

Bulb voltage, wattage

× quantity:

Headlight:

12 V, 35.0/35.0 W × 2

Tail/brake light:

12 V, 5.0/21.0 W × 2

Neutral indicator light: LED

Reverse indicator light: LED

Coolant temperature warning light:

LED

Engine trouble warning light: LED

Parking brake indicator light: LED

On-Command four-wheel-drive/differential gear lock indica-

tor: LCD

High-range indicator light:

LED

Low-range indicator light: LED

Differential gear lock indicator light: LED

EPS warning light:

LED

Helmet/Seat belt indicator light: 14 V, 0.85 W × 2Fuses:Main fuse:

40.0 A

Fuel injection system fuse: 10.0 A EPS fuse:

40.0 A

Headlight fuse: 15.0 A

Signaling system fuse:

10.0 A

Ignition fuse: 10.0 A

Auxiliary DC jack fuse: 10.0 A

Backup fuse:

10.0 A

Four-wheel-drive motor fuse: 10.0 A

Radiator fan motor fuse: 25.0 A

For Europe only

The figures quoted are emission levels and

are not necessarily safe working levels. Whilst

there is a correlation between the emission

and exposure levels, this cannot be used reli-

ably to determine whether or not further pre-

cautions are required.

Factors that influence the actual level of expo-

sure of work-force include the characteristics

of the work room, the other sources of noise,

etc. i.e. the number of machines and other ad-

1XP7C_EE.book Page 5 Monday, June 9, 2014 5:17 PM