ECU YAMAHA VMAX 2001 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: VMAX, Model: YAMAHA VMAX 2001Pages: 110, PDF Size: 11.88 MB

Page 27 of 110

INSTRUMENT AND CONTROL FUNCTIONS

3-12

3

EC000012

CAUTION:@ Never exceed the maximum air pres-

sure, otherwise the front fork oil

seals may become damaged. @

EWA00037

WARNING

@ There must be no difference in air

pressure between the left and right

fork legs, otherwise poor handling

and loss of stability may result. @5. Securely install the air valve caps.

EAU01657

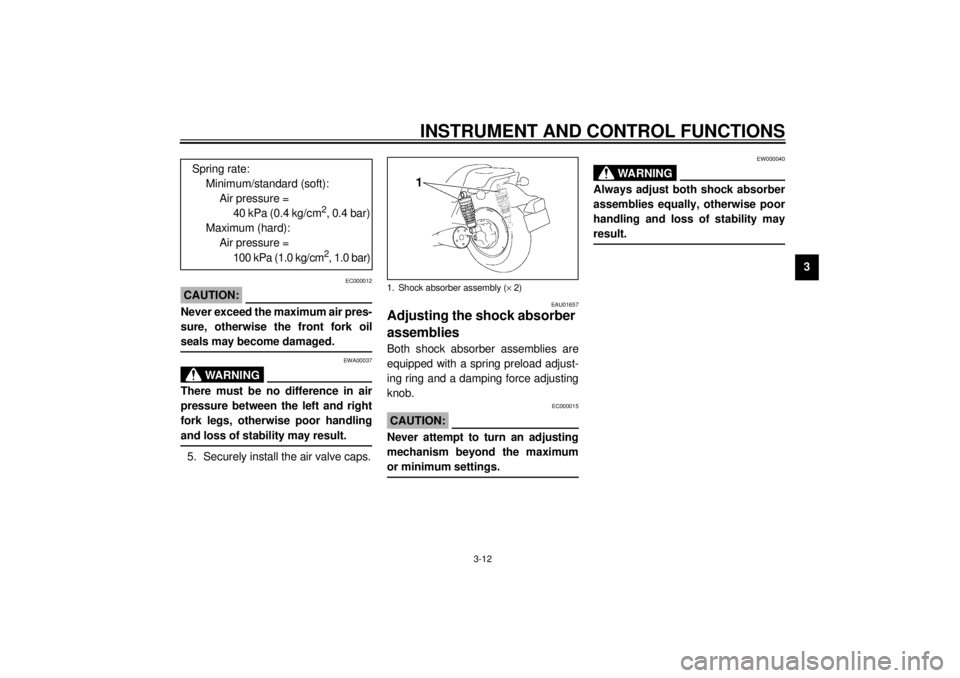

Adjusting the shock absorber

assemblies Both shock absorber assemblies are

equipped with a spring preload adjust-

ing ring and a damping force adjusting

knob.

EC000015

CAUTION:@ Never attempt to turn an adjusting

mechanism beyond the maximum

or minimum settings. @

EW000040

WARNING

@ Always adjust both shock absorber

assemblies equally, otherwise poor

handling and loss of stability may

result. @

Spring rate:

Minimum/standard (soft):

Air pressure =

40 kPa (0.4 kg/cm

2, 0.4 bar)

Maximum (hard):

Air pressure =

100 kPa (1.0 kg/cm2, 1.0 bar)

1. Shock absorber assembly (´ 2)

E_3lr.book Page 12 Wednesday, November 22, 2000 4:10 PM

Page 65 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-22

6

CE-01E

CE-07EEWA00012

WARNING

@ Because loading has an enormous

impact on the handling, braking, per-

formance and safety characteristics

of your motorcycle, you should keep

the following precautions in mind. l

NEVER OVERLOAD THE

MOTORCYCLE! Operation of an

overloaded motorcycle may re-

sult in tire damage, loss of con-

trol, or severe injury. Make sure

that the total weight of rider, pas-

senger, cargo, and accessories

does not exceed the specified

maximum load for the vehicle.

l

Do not carry along loosely

packed items, which can shift

during a ride.

l

Securely pack the heaviest

items close to the center of the

motorcycle and distribute the

weight evenly on both sides.

l

Adjust the suspension and tire

air pressure with regard to the

load.

l

Check the tire condition and air

pressure before each ride.

@

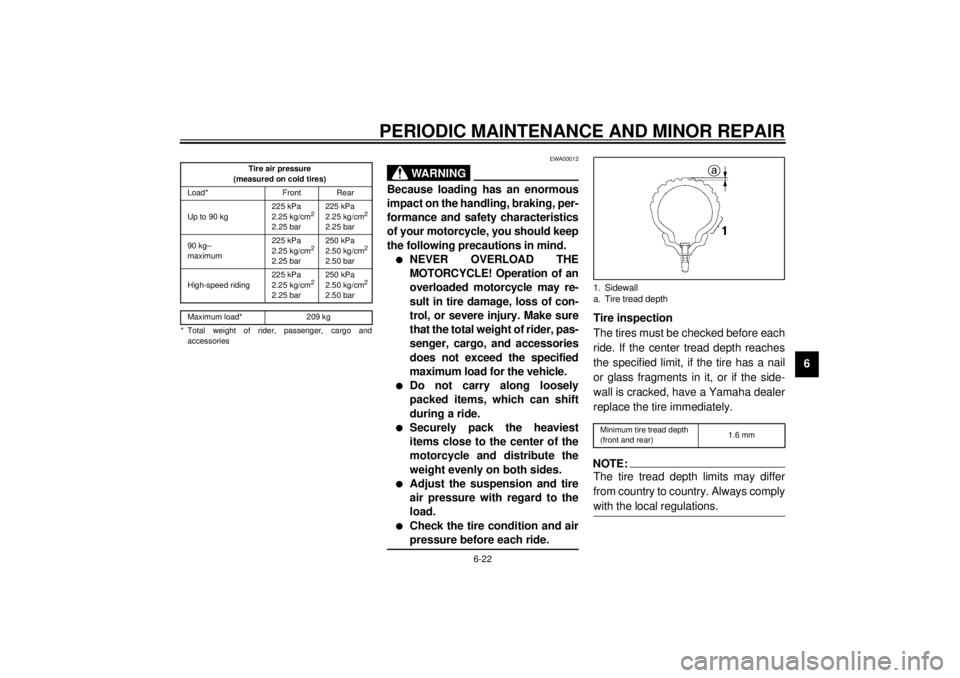

Tire inspection

The tires must be checked before each

ride. If the center tread depth reaches

the specified limit, if the tire has a nail

or glass fragments in it, or if the side-

wall is cracked, have a Yamaha dealer

replace the tire immediately.CE-08ENOTE:@ The tire tread depth limits may differ

from country to country. Always comply

with the local regulations. @

Tire air pressure

(measured on cold tires)

Load* Front Rear

Up to 90 kg225 kPa

2.25 kg/cm

2

2.25 bar225 kPa

2.25 kg/cm

2

2.25 bar

90 kg–

maximum225 kPa

2.25 kg/cm

2

2.25 bar250 kPa

2.50 kg/cm

2

2.50 bar

High-speed riding225 kPa

2.25 kg/cm

2

2.25 bar250 kPa

2.50 kg/cm

2

2.50 bar

Maximum load* 209 kg

* Total weight of rider, passenger, cargo and

accessories

1. Sidewall

a. Tire tread depthMinimum tire tread depth

(front and rear)1.6 mm

E_3lr.book Page 22 Wednesday, November 22, 2000 4:10 PM

Page 74 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-31

6

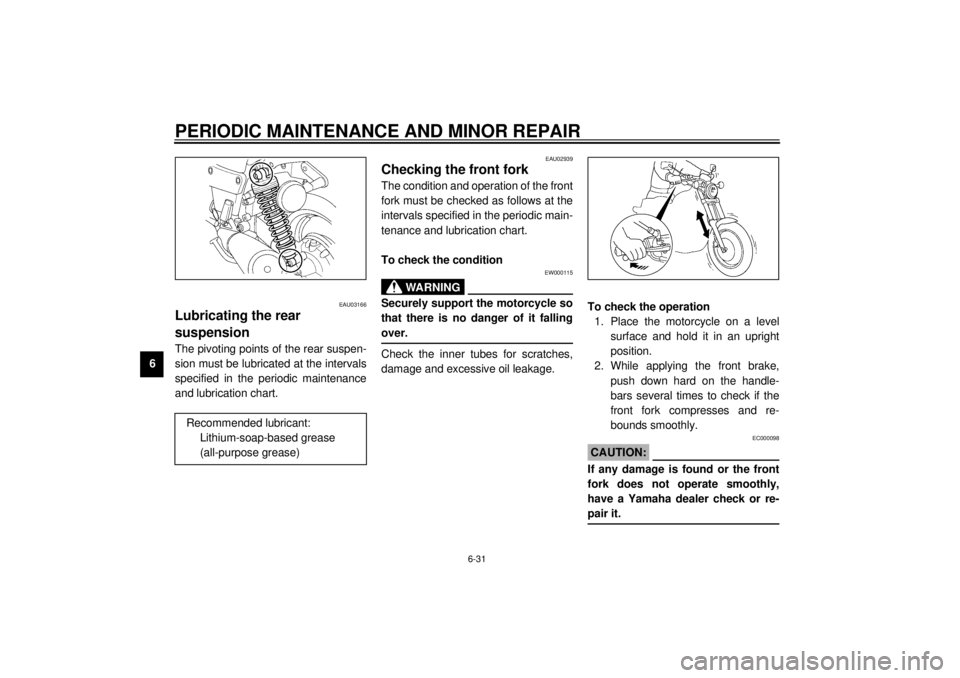

EAU03166

Lubricating the rear

suspension The pivoting points of the rear suspen-

sion must be lubricated at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU02939

Checking the front fork The condition and operation of the front

fork must be checked as follows at the

intervals specified in the periodic main-

tenance and lubrication chart.

To check the condition

EW000115

WARNING

@ Securely support the motorcycle so

that there is no danger of it falling

over. @Check the inner tubes for scratches,

damage and excessive oil leakage.To check the operation

1. Place the motorcycle on a level

surface and hold it in an upright

position.

2. While applying the front brake,

push down hard on the handle-

bars several times to check if the

front fork compresses and re-

bounds smoothly.

EC000098

CAUTION:@ If any damage is found or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-

pair it. @

Recommended lubricant:

Lithium-soap-based grease

(all-purpose grease)

E_3lr.book Page 31 Wednesday, November 22, 2000 4:10 PM

Page 75 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-32

6

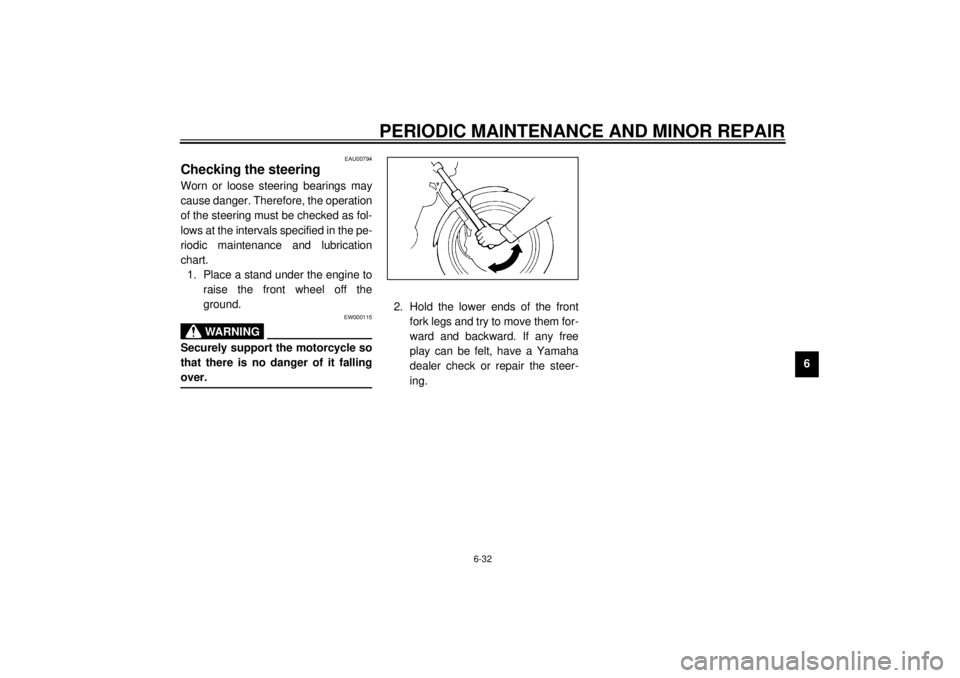

EAU00794

Checking the steering Worn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the pe-

riodic maintenance and lubrication

chart.

1. Place a stand under the engine to

raise the front wheel off the

ground.

EW000115

WARNING

@ Securely support the motorcycle so

that there is no danger of it falling

over. @

2. Hold the lower ends of the front

fork legs and try to move them for-

ward and backward. If any free

play can be felt, have a Yamaha

dealer check or repair the steer-

ing.

E_3lr.book Page 32 Wednesday, November 22, 2000 4:10 PM

Page 81 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-38

6

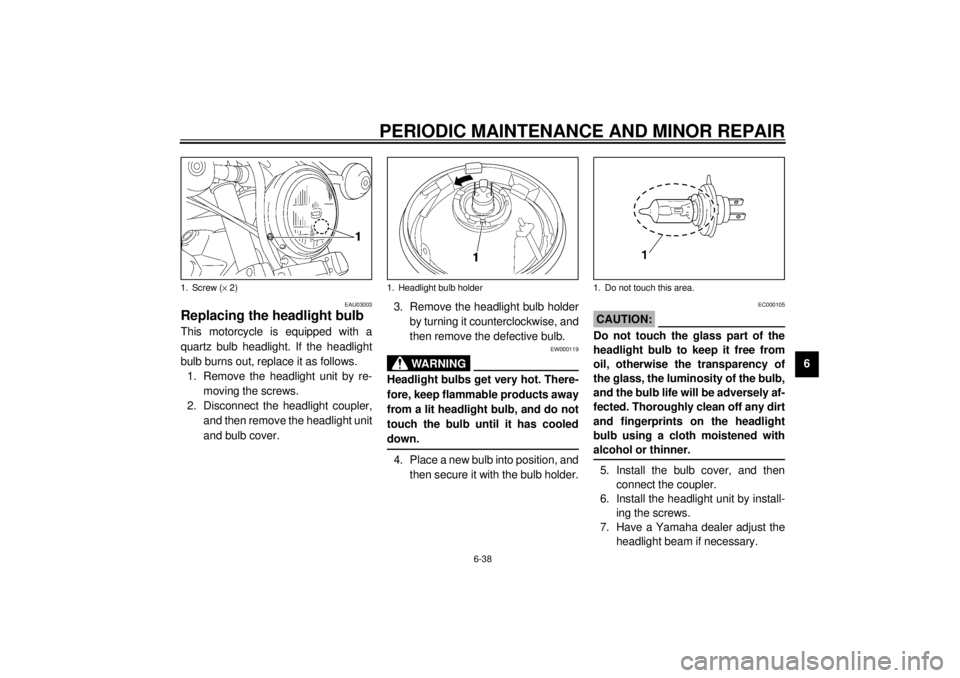

EAU03003

Replacing the headlight bulb This motorcycle is equipped with a

quartz bulb headlight. If the headlight

bulb burns out, replace it as follows.

1. Remove the headlight unit by re-

moving the screws.

2. Disconnect the headlight coupler,

and then remove the headlight unit

and bulb cover.3. Remove the headlight bulb holder

by turning it counterclockwise, and

then remove the defective bulb.

EW000119

WARNING

@ Headlight bulbs get very hot. There-

fore, keep flammable products away

from a lit headlight bulb, and do not

touch the bulb until it has cooled

down. @4. Place a new bulb into position, and

then secure it with the bulb holder.

EC000105

CAUTION:@ Do not touch the glass part of the

headlight bulb to keep it free from

oil, otherwise the transparency of

the glass, the luminosity of the bulb,

and the bulb life will be adversely af-

fected. Thoroughly clean off any dirt

and fingerprints on the headlight

bulb using a cloth moistened with

alcohol or thinner. @5. Install the bulb cover, and then

connect the coupler.

6. Install the headlight unit by install-

ing the screws.

7. Have a Yamaha dealer adjust the

headlight beam if necessary.

1. Screw (´ 2)

1. Headlight bulb holder

1. Do not touch this area.

E_3lr.book Page 38 Wednesday, November 22, 2000 4:10 PM

Page 83 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-40

6

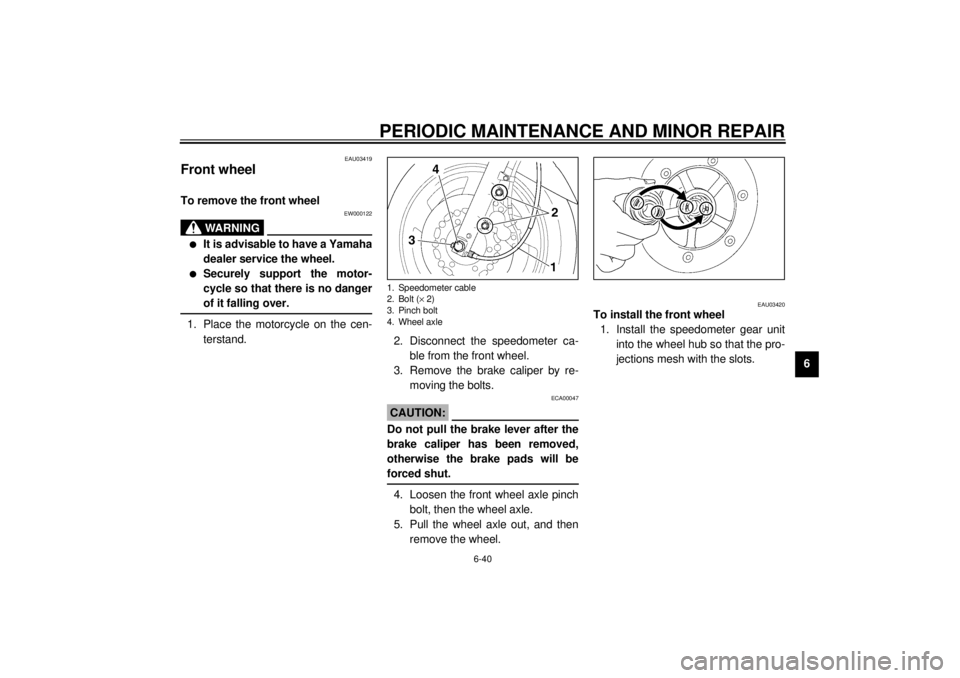

EAU03419

Front wheel To remove the front wheel

EW000122

WARNING

@ l

It is advisable to have a Yamaha

dealer service the wheel.

l

Securely support the motor-

cycle so that there is no danger

of it falling over.

@1. Place the motorcycle on the cen-

terstand.

2. Disconnect the speedometer ca-

ble from the front wheel.

3. Remove the brake caliper by re-

moving the bolts.

ECA00047

CAUTION:@ Do not pull the brake lever after the

brake caliper has been removed,

otherwise the brake pads will be

forced shut. @4. Loosen the front wheel axle pinch

bolt, then the wheel axle.

5. Pull the wheel axle out, and then

remove the wheel.

EAU03420

To install the front wheel

1. Install the speedometer gear unit

into the wheel hub so that the pro-

jections mesh with the slots.

1. Speedometer cable

2. Bolt (´ 2)

3. Pinch bolt

4. Wheel axle

E_3lr.book Page 40 Wednesday, November 22, 2000 4:10 PM

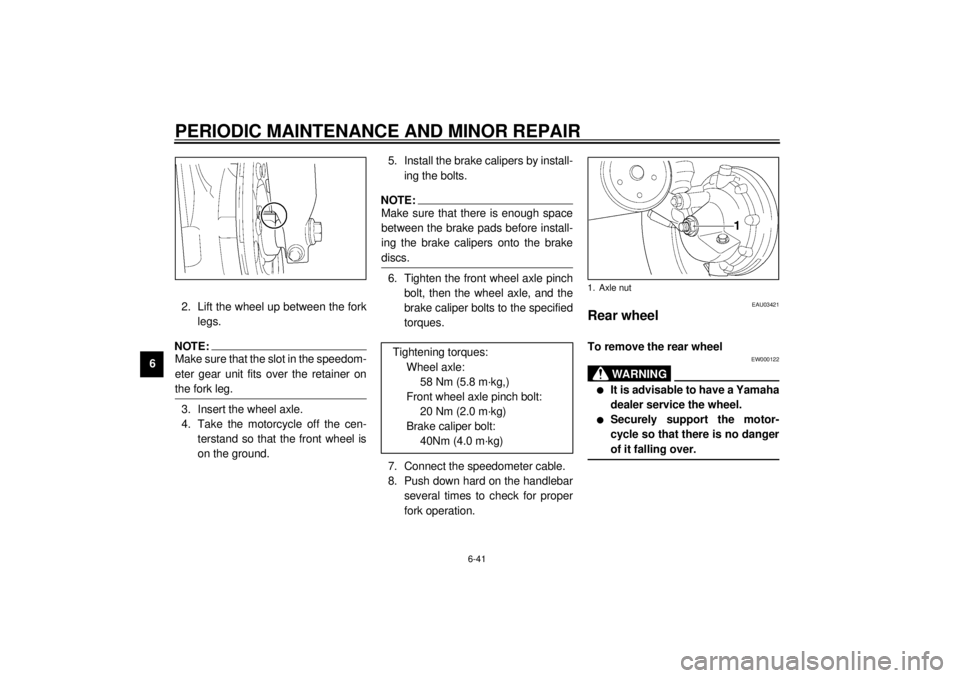

Page 84 of 110

PERIODIC MAINTENANCE AND MINOR REPAIR

6-41

62. Lift the wheel up between the fork

legs.

NOTE:@ Make sure that the slot in the speedom-

eter gear unit fits over the retainer on

the fork leg. @3. Insert the wheel axle.

4. Take the motorcycle off the cen-

terstand so that the front wheel is

on the ground.5. Install the brake calipers by install-

ing the bolts.

NOTE:@ Make sure that there is enough space

between the brake pads before install-

ing the brake calipers onto the brake

discs. @6. Tighten the front wheel axle pinch

bolt, then the wheel axle, and the

brake caliper bolts to the specified

torques.

7. Connect the speedometer cable.

8. Push down hard on the handlebar

several times to check for proper

fork operation.

EAU03421

Rear wheel To remove the rear wheel

EW000122

WARNING

@ l

It is advisable to have a Yamaha

dealer service the wheel.

l

Securely support the motor-

cycle so that there is no danger

of it falling over.

@

Tightening torques:

Wheel axle:

58 Nm (5.8 m·kg,)

Front wheel axle pinch bolt:

20 Nm (2.0 m·kg)

Brake caliper bolt:

40Nm (4.0 m·kg)

1. Axle nut

E_3lr.book Page 41 Wednesday, November 22, 2000 4:10 PM