water pump YAMAHA VX110 2005 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 199 of 347

E

JET

PUMP

1

2

3

4

5

6

7

8

9

CHAPTER 6

JET PUMP UNIT

INTAKE GRATE AND RIDE PLATE ............................................................... 6-1

EXPLODED DIAGRAM ............................................................................. 6-1

REMOVAL AND INSTALLATION CHART ................................................ 6-1

JET PUMP UNIT .............................................................................................. 6-3

EXPLODED DIAGRAM ............................................................................. 6-3

REMOVAL AND INSTALLATION CHART ................................................ 6-3

REVERSE GATE (DELUXE MODEL ONLY) .................................................. 6-5

EXPLODED DIAGRAM ............................................................................. 6-5

REMOVAL AND INSTALLATION CHART ................................................ 6-5

JET THRUST NOZZLE, IMPELLER DUCT, AND

IMPELLER HOUSING 1 ................................................................................. 6-6

EXPLODED DIAGRAM ............................................................................. 6-6

REMOVAL AND INSTALLATION CHART ................................................ 6-6

IMPELLER DUCT AND DRIVE SHAFT .......................................................... 6-8

EXPLODED DIAGRAM ............................................................................. 6-8

REMOVAL AND INSTALLATION CHART ................................................ 6-8

SERVICE POINTS .................................................................................. 6-10

Drive shaft removal ........................................................................... 6-10

Impeller inspection ............................................................................ 6-11

Drive shaft inspection ........................................................................ 6-11

Drive shaft installation ....................................................................... 6-12

TRANSOM PLATE AND HOSES .................................................................. 6-15

EXPLODED DIAGRAM ........................................................................... 6-15

REMOVAL AND INSTALLATION CHART .............................................. 6-15

SERVICE POINTS .................................................................................. 6-17

Bilge strainer inspection .................................................................... 6-17

Bilge hose inspection ........................................................................ 6-17

Cooling water hose inspection .......................................................... 6-17

BEARING HOUSING ..................................................................................... 6-18

EXPLODED DIAGRAM ........................................................................... 6-18

REMOVAL AND INSTALLATION CHART .............................................. 6-18

SERVICE POINTS .................................................................................. 6-21

Driven coupling removal and installation........................................... 6-21

Intermediate drive shaft removal ....................................................... 6-21

Bearing removal ................................................................................ 6-22

Bearing and intermediate drive shaft inspection ............................... 6-22

Driven coupling inspection ................................................................ 6-22

Bearing and oil seals installation ....................................................... 6-23

Intermediate drive shaft installation................................................... 6-24

ProCarManuals.com

Page 206 of 347

6-7

E

JET

PUMP

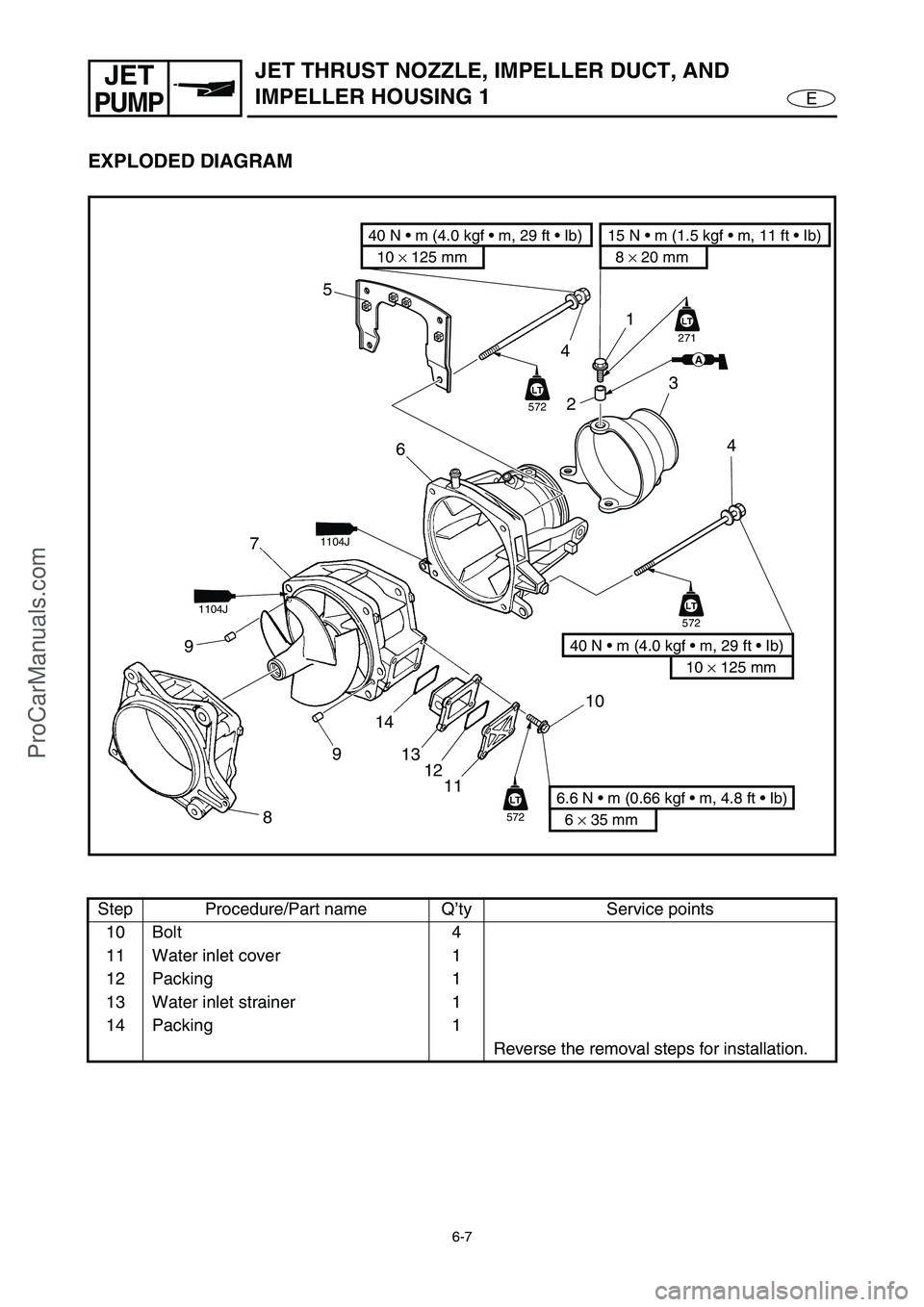

JET THRUST NOZZLE, IMPELLER DUCT, AND

IMPELLER HOUSING 1

EXPLODED DIAGRAM

Step Procedure/Part name Q’ty Service points

10 Bolt 4

11 Water inlet cover 1

12 Packing 1

13 Water inlet strainer 1

14 Packing 1

Reverse the removal steps for installation.

10 × 125 mm

40 N • m (4.0 kgf • m, 29 ft • Ib)

6 × 35 mm

6.6 N • m (0.66 kgf • m, 4.8 ft • Ib)

10

11 12 13 14

9 97

LT

572

LT

LT

572

LT

LT

572

LT

8

10 × 125 mm

40 N • m (4.0 kgf • m, 29 ft • Ib)

1

23

4

4

6 5

8 × 20 mm

15 N • m (1.5 kgf • m, 11 ft • Ib)

LT

271

AA

1104J

1104J

ProCarManuals.com

Page 214 of 347

6-15

E

JET

PUMPTRANSOM PLATE AND HOSES

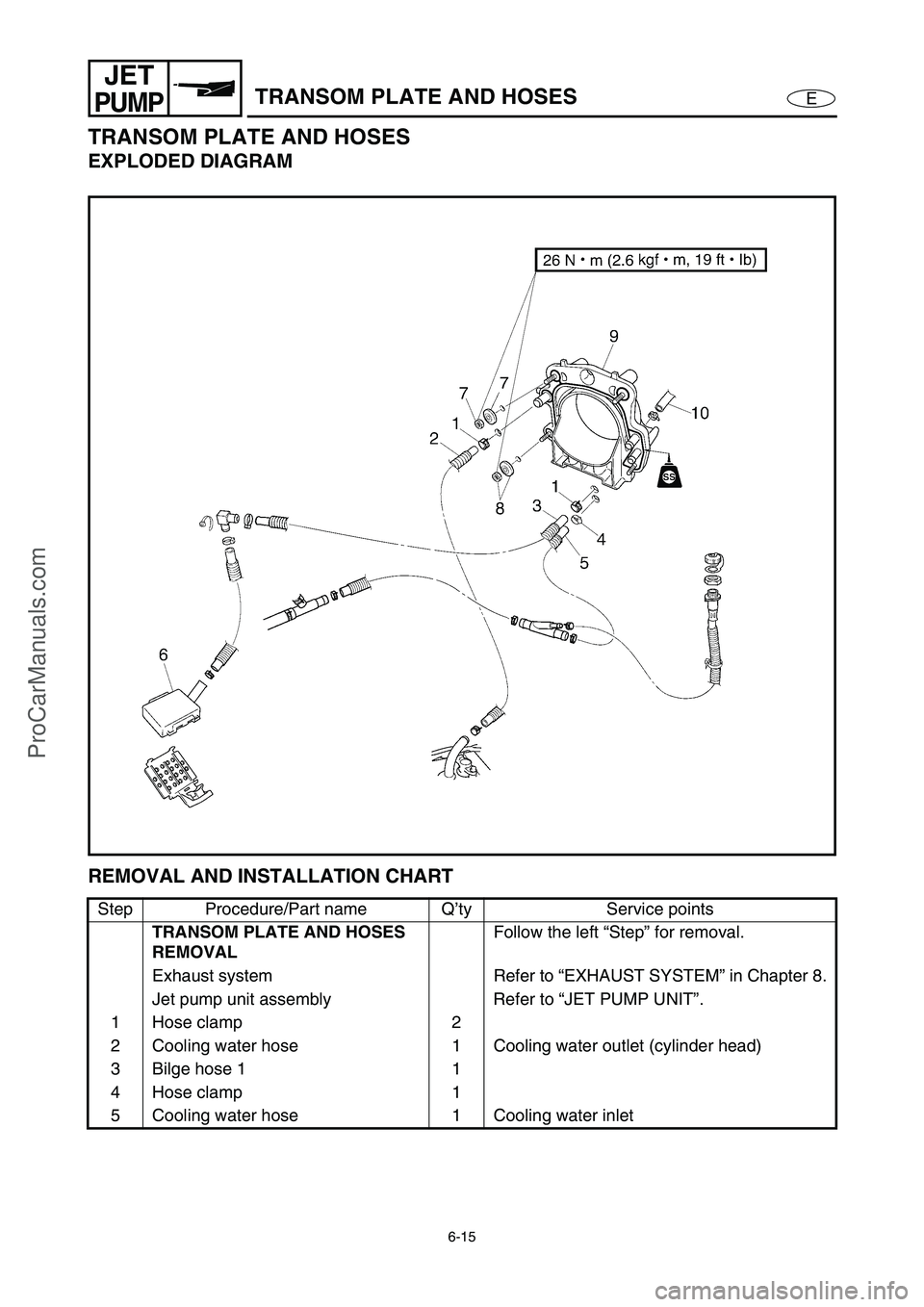

TRANSOM PLATE AND HOSES

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

TRANSOM PLATE AND HOSES

REMOVALFollow the left “Step” for removal.

Exhaust system Refer to “EXHAUST SYSTEM” in Chapter 8.

Jet pump unit assembly Refer to “JET PUMP UNIT”.

1 Hose clamp 2

2 Cooling water hose 1 Cooling water outlet (cylinder head)

3 Bilge hose 1 1

4 Hose clamp 1

5 Cooling water hose 1 Cooling water inlet

ProCarManuals.com

Page 216 of 347

6-17

E

JET

PUMPTRANSOM PLATE AND HOSES

SERVICE POINTS

Bilge strainer inspection

Refer to “JET PUMP UNIT” in

Chapter 3.

Bilge hose inspection

1. Inspect:

Bilge hoses

Cracks/damage/wear →

Replace.

Cooling water hose inspection

1. Inspect:

Cooling water hoses

Cracks/damage/wear →

Replace.

ProCarManuals.com

Page 278 of 347

7-51

E

–+ELECINDICATION SYSTEM

OIL PRESSURE SWITCH

1. Measure:

Oil pressure switch continuity

Out of specification → Replace.

Lower unit pressure/vacuum

tester:

YB-35956-A

Vacuum/pressure pump gauge

set:

90890-06756

Oil pressure switch continuity

pressure:

128 kPa (1.28 kgf/cm

2, 18.6 psi) –

167 kPa (1.67 kgf/cm2, 24.2 psi)

MULTIFUNCTION METER

Multifunction meter

1. Check:

Multifunction meter

Cracked meter housing → Replace the

multifunction meter.

Meter is fogged/shows signs of water

intrusion → Replace the multifunction

meter.

MULTIFUNCTION METER REMOVAL

Refer to “ENGINE HATCH COVER” in

Chapter 8.

ProCarManuals.com

Page 324 of 347

8-31

E

HULL

HOODEXHAUST SYSTEM

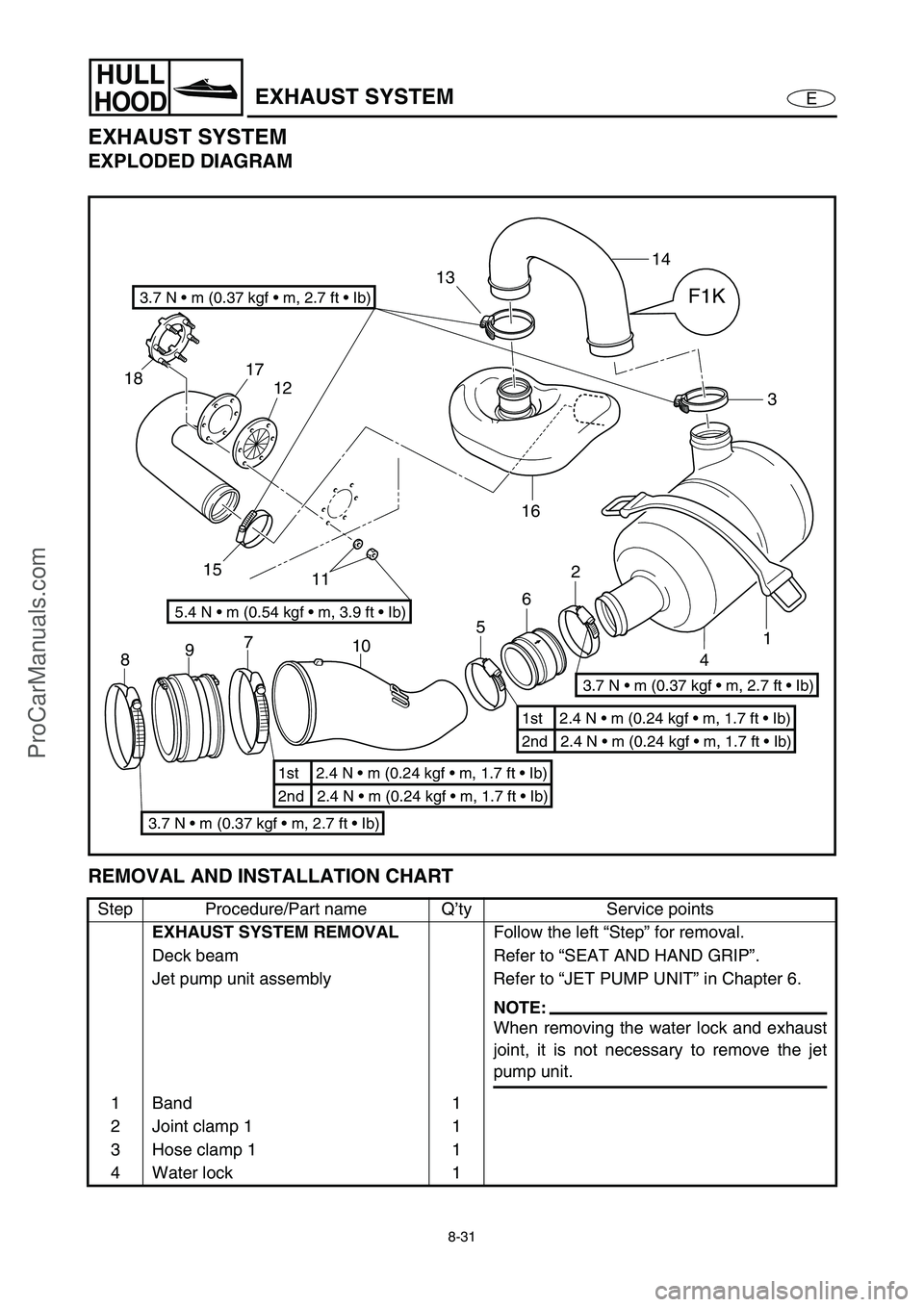

EXHAUST SYSTEM

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

EXHAUST SYSTEM REMOVAL

Follow the left “Step” for removal.

Deck beam Refer to “SEAT AND HAND GRIP”.

Jet pump unit assembly Refer to “JET PUMP UNIT” in Chapter 6.

NOTE:

When removing the water lock and exhaust

joint, it is not necessary to remove the jet

pump unit.

1 Band 1

2 Joint clamp 1 1

3 Hose clamp 1 1

4 Water lock 1

3

1 2

6

7

9

85

4 14

13

15 1817

12

1116

10

F1K3.7 N • m (0.37 kgf • m, 2.7 ft • Ib)

5.4 N • m (0.54 kgf • m, 3.9 ft • Ib)

3.7 N • m (0.37 kgf • m, 2.7 ft • Ib)

3.7 N • m (0.37 kgf • m, 2.7 ft • Ib)

2nd 2.4 N • m (0.24 kgf • m, 1.7 ft • Ib) 1st 2.4 N • m (0.24 kgf • m, 1.7 ft • Ib)

2nd 2.4 N • m (0.24 kgf • m, 1.7 ft • Ib) 1st 2.4 N • m (0.24 kgf • m, 1.7 ft • Ib)

ProCarManuals.com

Page 338 of 347

9-5

E

TRBL

ANLS

TROUBLE ANALYSIS

POWER UNIT

Compression 5

Cylinder head gaskets 5

Cylinder block 5

Crankcase 5

Piston rings 5

Pistons 5

Bearings 5

Valve(s) and valve seat(s) 5

Valve clearance adjusting

pad(s)3

Camshaft(s) 5

Timing chain 5

Oil pump 5

Engine oil 3

Oil filter 3

Oil pressure switch 7

Bearing housing 5

Drive couplings 5

Rubber coupling 5

Pilot water hose 5

Water hose 5

Water passage 5 Trouble mode Check elements

ENGINE WILL NOT START

HARD STARTING

ROUGH IDLING

HIGH IDLING

ENGINE STALLS

POOR ACCELERATION

ENGINE WILL NOT STOP

POOR PERFORMANCE

LIMITED ENGINE SPEED

OVERHEATING

LOW OIL PRESSURE

LOOSE STEERING

BILGE INCREASE

IRREGULAR WARNING INDICATION

POOR BATTERY CHARGING

Relative partReference

chapter

ProCarManuals.com

Page 339 of 347

9-6

E

TRBL

ANLS

TROUBLE ANALYSIS

JET PUMP UNIT

Duct 6

Impeller 6

Intake grate 6

Bearings 6

Water inlet hose 6

Bilge hose 6

Bilge strainer 3

Bilge hose joint 6

ELECTRICAL

Ignition system, fuel control system

Pickup coils 7

ECM 7

Ignition coils 7

Slant detection switch 7

Engine stop switch 7

Engine shut-off switch 7

Spark plugs 3

Main and fuel pump relay 7

Electronic control throttle

valve relay7

Thermoswitch 7

Sensor assembly 7

Engine temperature

sensor7

Throttle body assembly

(throttle position sensor)7

Accelerator position

sensor7

Cam position sensor 7 Trouble mode Check elements

ENGINE WILL NOT START

HARD STARTING

ROUGH IDLING

HIGH IDLING

ENGINE STALLS

POOR ACCELERATION

ENGINE WILL NOT STOP

POOR PERFORMANCE

LIMITED ENGINE SPEED

OVERHEATING

LOW OIL PRESSURE

LOOSE STEERING

BILGE INCREASE

IRREGULAR WARNING INDICATION

POOR BATTERY CHARGING

Relative partReference

chapter

ProCarManuals.com