ESP YAMAHA VX110 2005 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 40 of 347

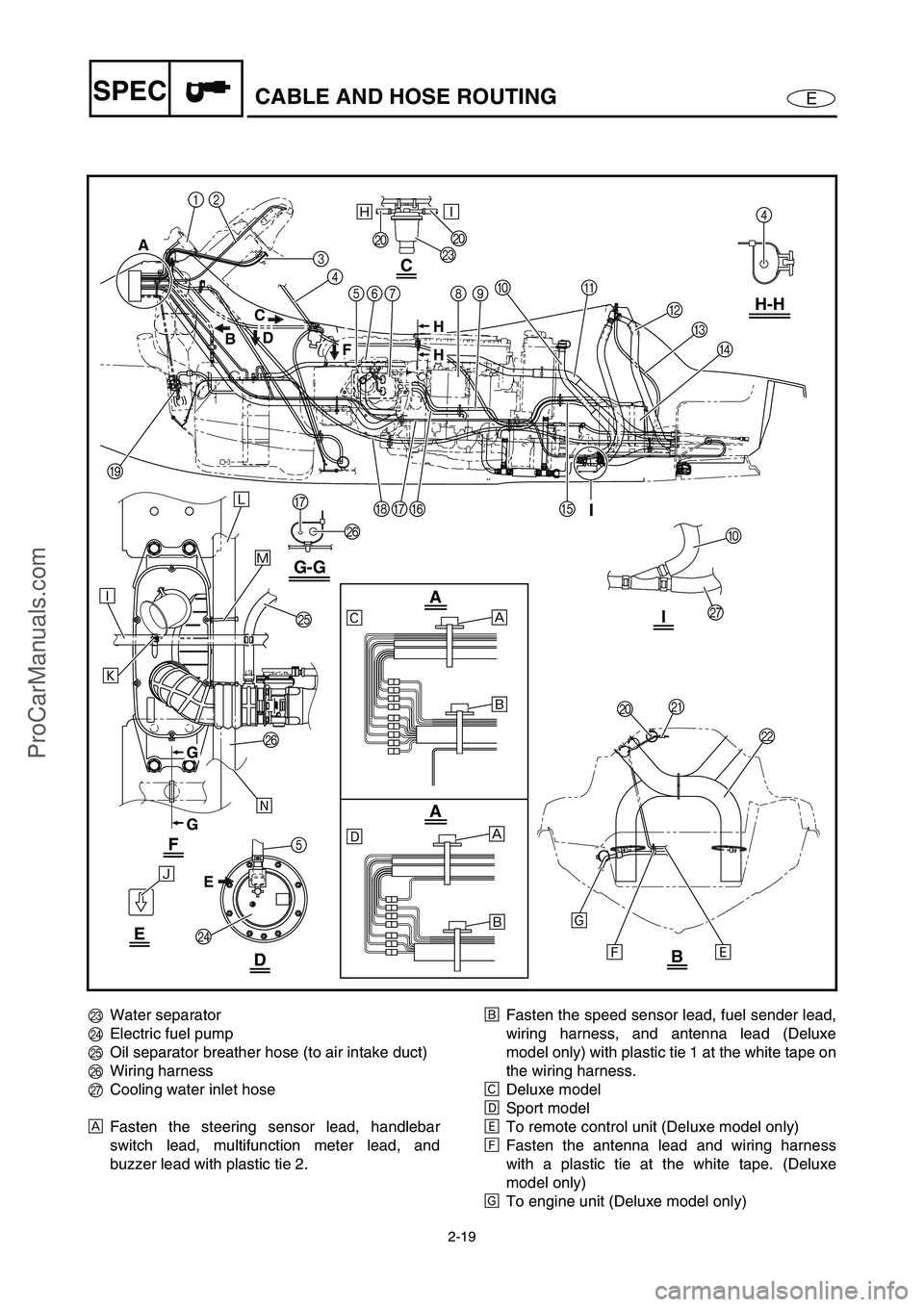

2-19

ESPECCABLE AND HOSE ROUTING

12

Ð

Ò

Ó

Õ

Î

ÍÌ

È

É

È

É

Ñ

Ô

3

4

5678

4

B

O

P

5

N

C

D

A09H-H

EFGH

I

P

G

G-G

A

BD

F C

E

JJ

M

C

F

I

I

E

DB

A

A

ÏÐ

H

H

G

G

JK

0

Q

L

Ê

Ë

MWater separator

NElectric fuel pump

OOil separator breather hose (to air intake duct)

PWiring harness

QCooling water inlet hose

ÈFasten the steering sensor lead, handlebar

switch lead, multifunction meter lead, and

buzzer lead with plastic tie 2.ÉFasten the speed sensor lead, fuel sender lead,

wiring harness, and antenna lead (Deluxe

model only) with plastic tie 1 at the white tape on

the wiring harness.

ÊDeluxe model

ËSport model

ÌTo remote control unit (Deluxe model only)

ÍFasten the antenna lead and wiring harness

with a plastic tie at the white tape. (Deluxe

model only)

ÎTo engine unit (Deluxe model only)

ProCarManuals.com

Page 41 of 347

2-20

ESPECCABLE AND HOSE ROUTING

12

Ð

Ò

Ó

Õ

Î

ÍÌ

È

É

È

É

Ñ

Ô

3

4

5678

4

B

O

P

5

N

C

D

A09H-H

EFGH

I

P

G

G-G

A

BD

F C

E

JJ

M

C

F

I

I

E

DB

A

A

ÏÐ

H

H

G

G

JK

0

Q

L

Ê

Ë

ÏTo ventilation socket

ÐTo fuel tank

ÑPoint the arrow on the cover toward the fuel

tank.

ÒFasten the fuel hose with a plastic tie.

ÓTo fuse box

ÔFasten the wiring harness with a plastic tie at

the white tape.

ÕTo ECM

ProCarManuals.com

Page 42 of 347

2-21

ESPECCABLE AND HOSE ROUTING

A

B

C

D

2

4

2

5

6

7

8

3

2

28

Ñ

Ê

Ó Ò

Ê

ÊÍ

É

Ë

F-FE-E

2

1222

2

2

Õ

ÈÐ

Ô

ÎÌÏ

F

F

E

E

D C

A

B

2

1Cooling water inlet hose

2Cooling water hose

3Cooling water outlet hose

4Flushing hose

5Cylinder head breather hose

6Oil separator breather hose (to oil tank)

7Oil separator breather hose (to air intake duct)

8Cooling water pilot outlet hoseÈTo install the cooling water outlet hose, align the

white paint mark on the cooling water hose with

the projection of the hose joint.

ÉTo transom plate

ÊFasten the cooling water outlet hose with a plas-

tic tie.

Ë25–45 mm (0.98–1.77 in)

ÌFasten the oil separator breather (to oil tank)

hose and cooling water hose with a holder.

ProCarManuals.com

Page 43 of 347

2-22

ESPECCABLE AND HOSE ROUTING

A

B

C

D

2

4

2

5

6

7

8

3

2

28

Ñ

Ê

Ó Ò

Ê

ÊÍ

É

Ë

F-FE-E

2

1222

2

2

Õ

ÈÐ

Ô

ÎÌÏ

F

F

E

E

D C

A

B

2

ÍFasten the oil separator breather hose (to air

intake duct) and cooling water hose with a

holder.

ÎFace the ends of the hose clamp towards the

starboard (right) side of the watercraft.

ÏInsert the cooling water hose to the paint mark.

ÐTo install the cooling water hose, align the white

paint mark on the cooling water hose with the

arrow mark of the hose joint.ÑInstall the cooling water hose with the white

paint mark facing up.

ÒTo cooling water pilot outlet

ÓFace the ends of the hose clamp towards the

bow.

ÔInstall the hose onto the cooling water pipe until

the pipe reaches the curve in the hose.

ÕInsert the plastic tie completely into the hole in

the boss on the cylinder block.

ProCarManuals.com

Page 44 of 347

2-23

ESPECCABLE AND HOSE ROUTING

13

90A

C B

88

4567

2

E

D

F

È

É

Í

Ê

Ë

Ì A-A

AA

Î

1Oil separator breather hose (to air intake duct)

2Wiring harness

3Ignition coil lead #1

4Ignition coil lead #2

5Ignition coil lead #3

6Ignition coil lead #4

7Cam position sensor

8Ignition coil

9ECM

0Rectifier/regulator

AOil pressure switch couplerBThermoswitch (exhaust) coupler

CGround lead plate

DWiring harness

EThermoswitch (exhaust) lead

FOil pressure switch lead

ÈFasten the oil separator breather hose (to air

intake duct) at the paint mark with a holder.

É15–25 mm (0.59–0.98 in)

ÊTo fuse box

ËTo multifunction meter

ProCarManuals.com

Page 45 of 347

2-24

ESPECCABLE AND HOSE ROUTING

13

90A

C B

88

4567

2

E

D

F

È

É

Í

Ê

Ë

Ì A-A

AA

Î

ÌTo generator

ÍFasten the thermoswitch (exhaust) lead at the

protective sleeve, the oil pressure switch lead at

the corrugated tube, and the wiring harness at

the tape on the harness with a plastic tie.

Î60–80 mm (2.36–3.15 in)

ProCarManuals.com

Page 46 of 347

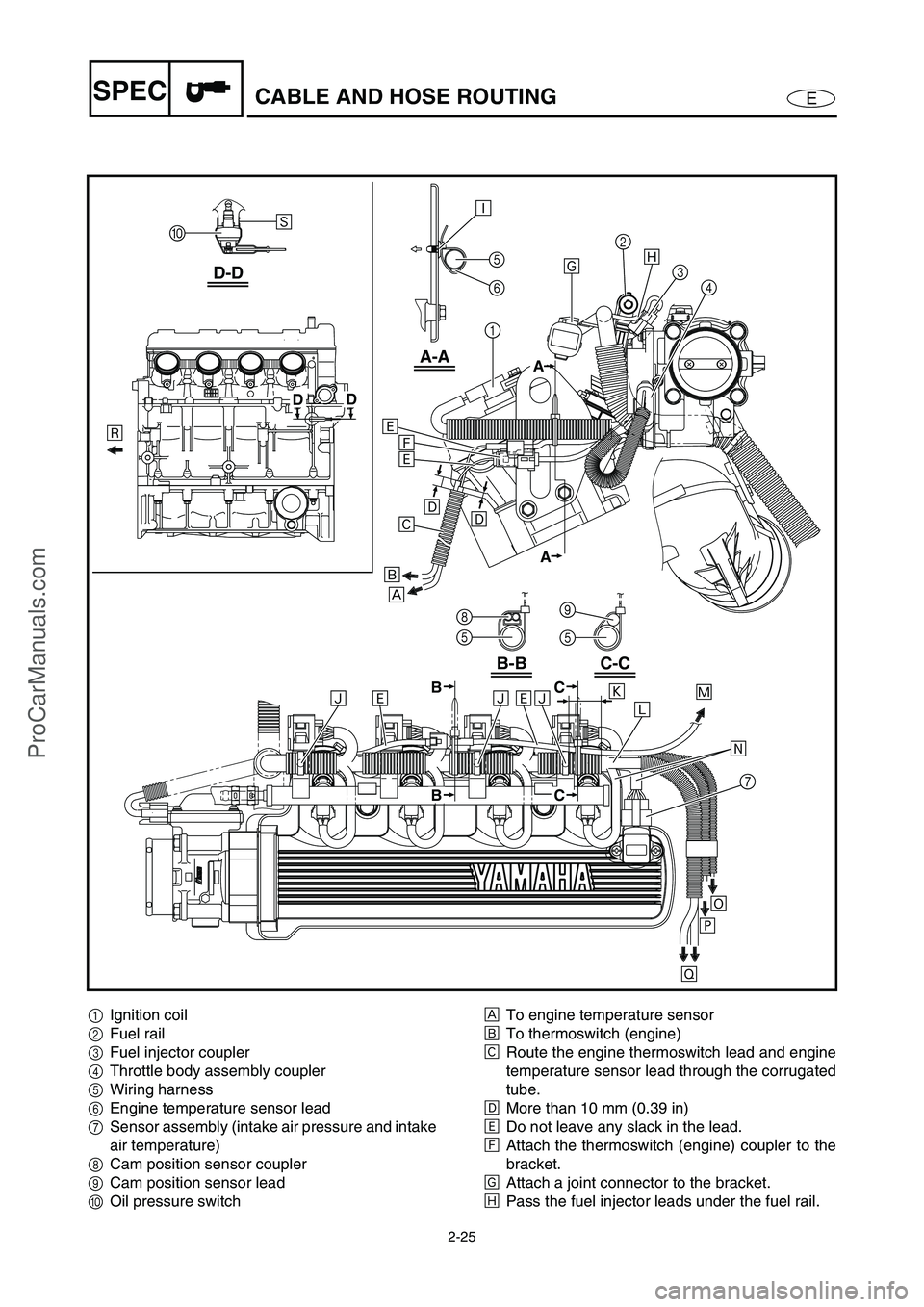

2-25

ESPECCABLE AND HOSE ROUTING

D-D

A-A

B-B

0

8

5

C-C

9

5 Ú

Ù

É

È

Ð

DD

5

6

A

A

1

2

7

34

Î

Ó ÒÌÑÑÌÑ

Ì

Ì

Ë Ë

Ê

Ø×Ö Ô

Õ

Í

Ï

C

CB

B

1Ignition coil

2Fuel rail

3Fuel injector coupler

4Throttle body assembly coupler

5Wiring harness

6Engine temperature sensor lead

7Sensor assembly (intake air pressure and intake

air temperature)

8Cam position sensor coupler

9Cam position sensor lead

0Oil pressure switchÈTo engine temperature sensor

ÉTo thermoswitch (engine)

ÊRoute the engine thermoswitch lead and engine

temperature sensor lead through the corrugated

tube.

ËMore than 10 mm (0.39 in)

ÌDo not leave any slack in the lead.

ÍAttach the thermoswitch (engine) coupler to the

bracket.

ÎAttach a joint connector to the bracket.

ÏPass the fuel injector leads under the fuel rail.

ProCarManuals.com

Page 47 of 347

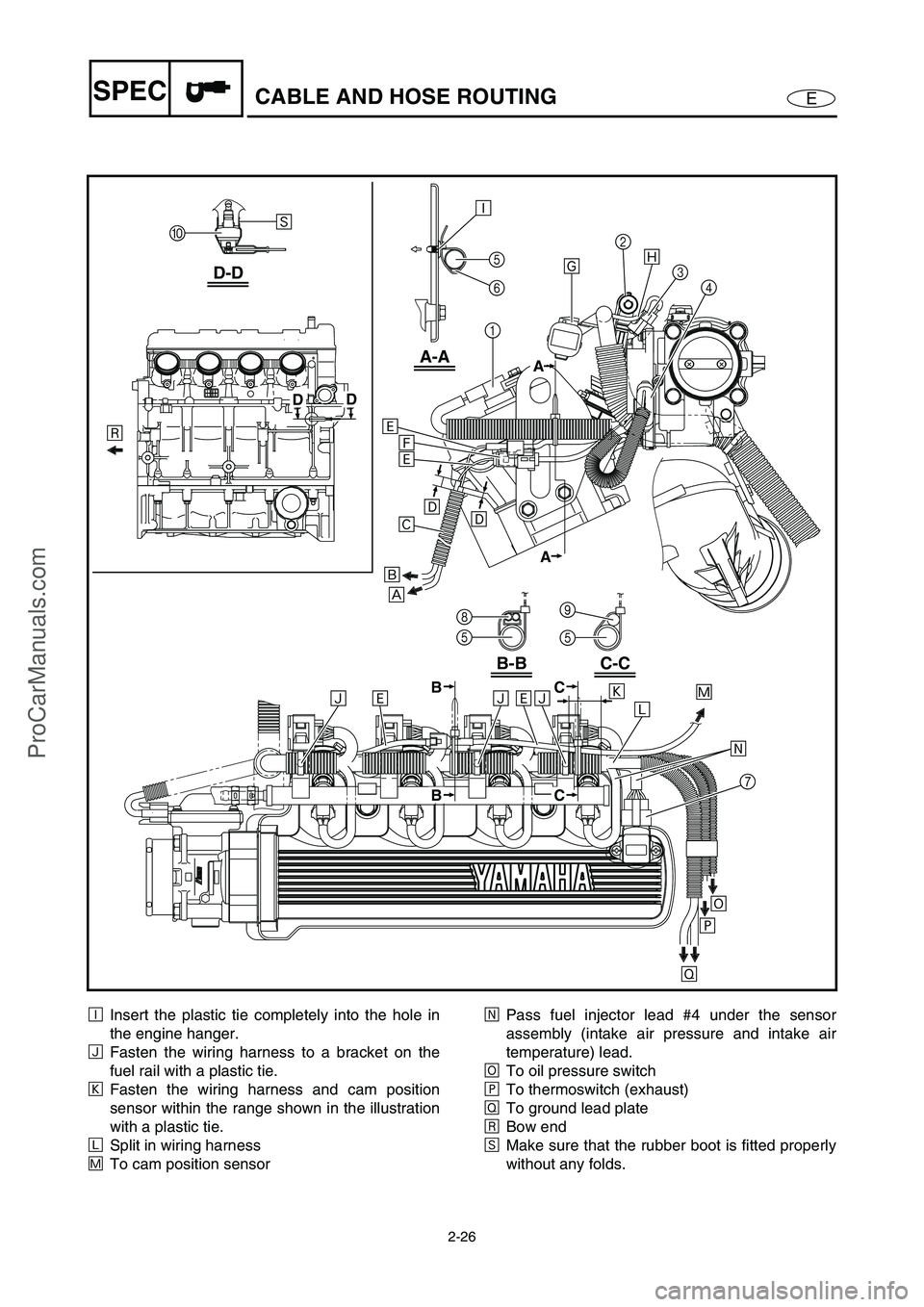

2-26

ESPECCABLE AND HOSE ROUTING

D-D

A-A

B-B

0

8

5

C-C

9

5 Ú

Ù

É

È

Ð

DD

5

6

A

A

1

2

7

34

Î

Ó ÒÌÑÑÌÑ

Ì

Ì

Ë Ë

Ê

Ø×Ö Ô

Õ

Í

Ï

C

CB

B

ÐInsert the plastic tie completely into the hole in

the engine hanger.

ÑFasten the wiring harness to a bracket on the

fuel rail with a plastic tie.

ÒFasten the wiring harness and cam position

sensor within the range shown in the illustration

with a plastic tie.

ÓSplit in wiring harness

ÔTo cam position sensorÕPass fuel injector lead #4 under the sensor

assembly (intake air pressure and intake air

temperature) lead.

ÖTo oil pressure switch

×To thermoswitch (exhaust)

ØTo ground lead plate

ÙBow end

ÚMake sure that the rubber boot is fitted properly

without any folds.

ProCarManuals.com

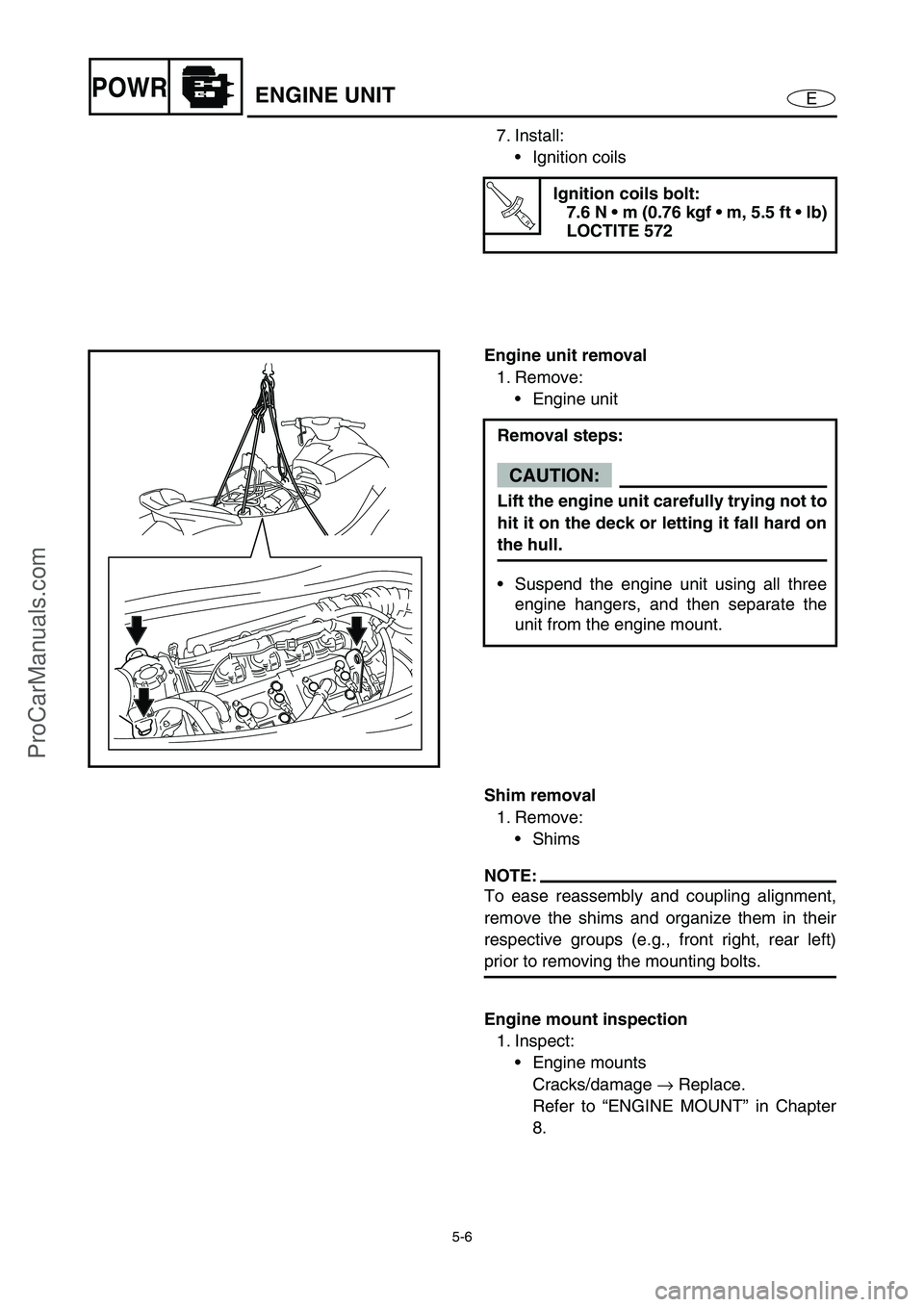

Page 105 of 347

5-6

EPOWRENGINE UNIT

7. Install:

Ignition coils

T R..

Ignition coils bolt:

7.6 N m (0.76 kgf m, 5.5 ft lb)

LOCTITE 572

Engine unit removal

1. Remove:

Engine unit

Removal steps:

CAUTION:

Lift the engine unit carefully trying not to

hit it on the deck or letting it fall hard on

the hull.

Suspend the engine unit using all three

engine hangers, and then separate the

unit from the engine mount.

Shim removal

1. Remove:

Shims

NOTE:

To ease reassembly and coupling alignment,

remove the shims and organize them in their

respective groups (e.g., front right, rear left)

prior to removing the mounting bolts.

Engine mount inspection

1. Inspect:

Engine mounts

Cracks/damage →

Replace.

Refer to “ENGINE MOUNT” in Chapter

8.

ProCarManuals.com

Page 188 of 347

5-89

EPOWRCONNECTING RODS AND PISTONS

For example, if the connecting rod “P1” and the

crankshaft web “P

1” numbers are “5” and “1”

respectively, then the bearing size for “P

1” is:

Bearing size of P

1:

“P

1” (connecting rod) –

“P

1” (crankshaft web)

5 – 1 = 4 (green)

BEARING COLOR CODE

1brown

2 black

3blue

4 green5 G

P4P3P2P1

Connecting rod and piston installation

The following procedure applies to all of the

pistons and connecting rods.

1. Install:

Oil ring

2nd ring

Top ring

NOTE:

Be sure to install the piston rings so that the

manufacturer’s marks or numbers face up.

2. Install:

Piston 1

Connecting rod 2

Piston pin 3

Piston pin clips 4

NOTE:

Apply engine oil onto the piston pin.

When installing the connecting rod to the pis-

ton, make sure that the “Y” mark a

on the

connecting rod faces towards the left when

the exhaust valve recesses b

on the piston

face upward. Refer to the illustration.

Reinstall each piston into its original cylinder

(numbering order starting from the front: #1

to #4).

ProCarManuals.com