ad blue YAMAHA VX110 2005 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 6 of 347

E

A50001-1-4

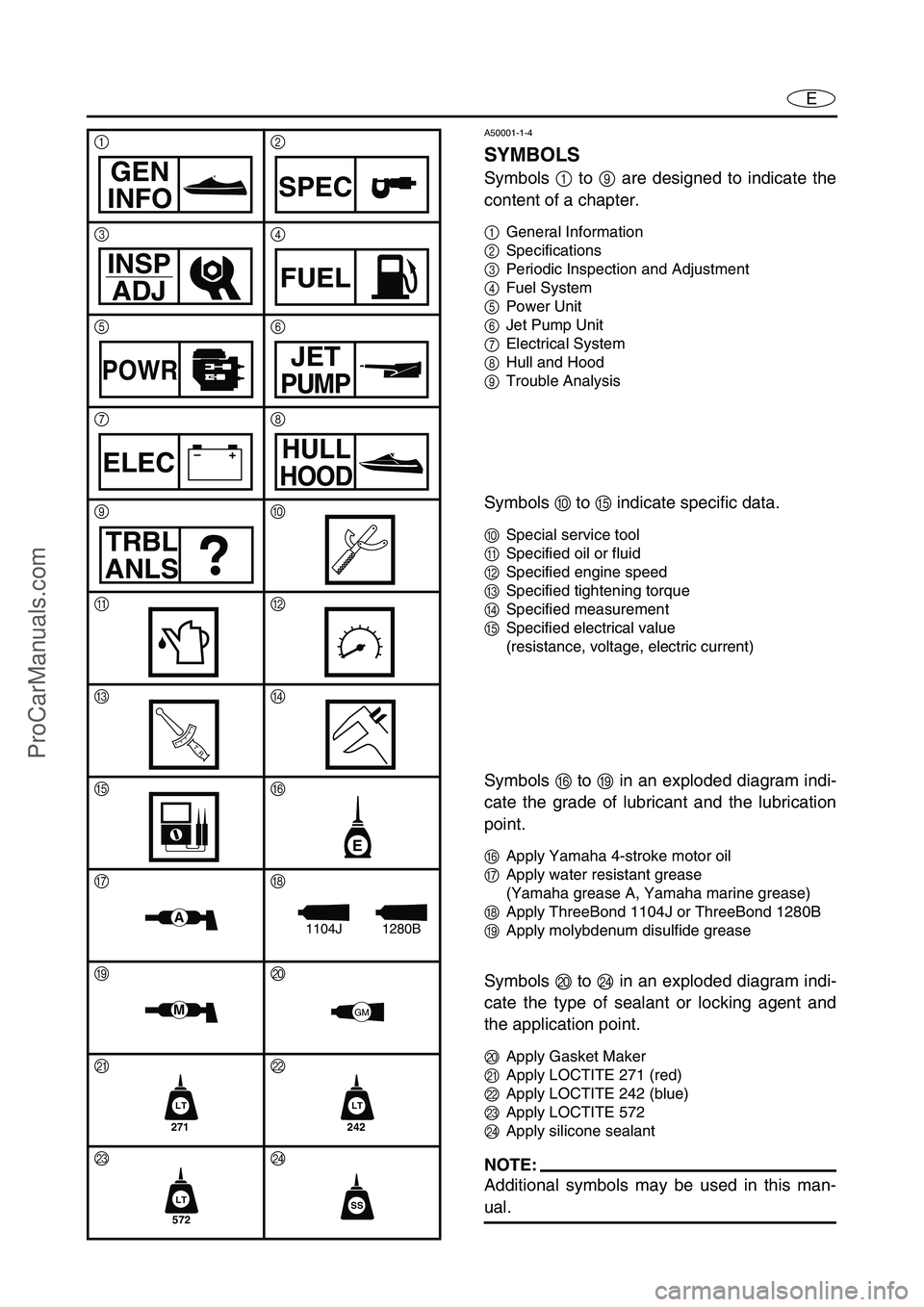

SYMBOLS

Symbols 1 to 9 are designed to indicate the

content of a chapter.

1General Information

2Specifications

3Periodic Inspection and Adjustment

4Fuel System

5Power Unit

6Jet Pump Unit

7Electrical System

8Hull and Hood

9Trouble Analysis

Symbols 0 to E indicate specific data.

0Special service tool

ASpecified oil or fluid

BSpecified engine speed

CSpecified tightening torque

DSpecified measurement

ESpecified electrical value

(resistance, voltage, electric current)

Symbols F to I in an exploded diagram indi-

cate the grade of lubricant and the lubrication

point.

FApply Yamaha 4-stroke motor oil

GApply water resistant grease

(Yamaha grease A, Yamaha marine grease)

HApply ThreeBond 1104J or ThreeBond 1280B

IApply molybdenum disulfide grease

Symbols J to N in an exploded diagram indi-

cate the type of sealant or locking agent and

the application point.

JApply Gasket Maker

KApply LOCTITE 271 (red)

LApply LOCTITE 242 (blue)

MApply LOCTITE 572

NApply silicone sealant

NOTE:

Additional symbols may be used in this man-

ual.

12

34

56

78

90

AB

CD

EF

GH

IJ

KL

MN

GEN

INFOSPEC

INSP

ADJFUEL

POWRJET

PUMP

–+ELECHULL

HOOD

TRBL

ANLS

T R..

E

A1280B1104J

MGM

271

LT

242

LT

572

LTSS

ProCarManuals.com

Page 26 of 347

2-5

ESPECMAINTENANCE SPECIFICATIONS

Piston pins

Outside diameter mm (in) 16.991–17.000 (0.6689–0.6693)

Wear limit mm (in) 16.986 (0.6687)

Piston ring

Top ring

Type Barrel

Dimension (B ×

T) mm (in) 0.90 ×

2.75 (0.04 ×

0.11)

End gap (installed) mm (in) 0.32–0.44 (0.0126–0.0173)

Ring groove clearance mm (in) 0.030–0.065 (0.0012–0.0026)

2nd ring

Type Taper

Dimensions (B ×

T) mm (in) 0.80 ×

2.80 (0.03 ×

0.11)

End gap (installed) mm (in) 0.43–0.58 (0.0169–0.0228)

Ring groove clearance mm (in) 0.020–0.055 (0.0008–0.0022)

Oil ring

Dimensions

(B ×

T)mm (in) 1.50 ×

2.60 (0.06 ×

0.10)

End gap (installed) mm (in) 0.10–0.35 (0.0039–0.0138)

Ring groove clearance mm (in) 0.040–0.160 (0.0016–0.0063)

Connecting rod

Big end oil clearance mm (in) 0.016–0.040 (0.0006–0.0016)

Bearing color code 1. Brown 2. Black 3. Blue 4. Green

Small end inside diameter mm (in) 17.005–17.018 (0.6695–0.6700)

Crankshaft

Crank width A mm (in) 304.8–306.0 (12.00–12.05)

Deflection limit B mm (in) 0.03 (0.0012)

Crankshaft journal oil clearance mm (in) 0.004–0.028 (0.0002–0.0011)

Bearing color code 3. Red/Red 4. Red/Brown 5. Red/Black

6. Red/Blue 7. Red/Green

Throttle body

Type/quantity IM-230/1

Manufacturer Mikuni

ID mark 6D300

Trolling speed r/min 1,550–1,750 Item UnitModel

VX110 Sport VX110 Deluxe

T

B

B

T

B

T

BBB

A

ProCarManuals.com

Page 146 of 347

5-47

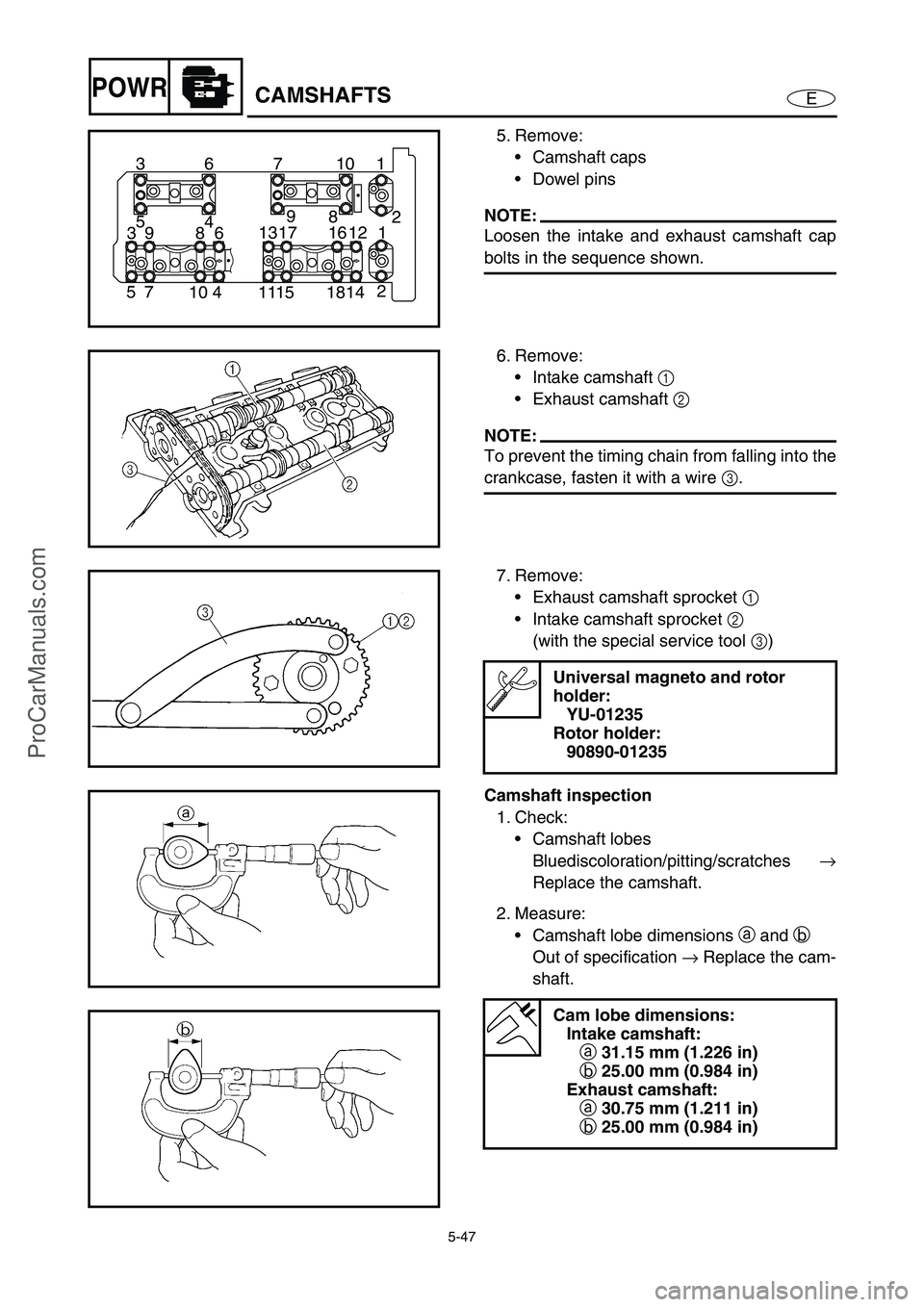

EPOWRCAMSHAFTS

5. Remove:

Camshaft caps

Dowel pins

NOTE:

Loosen the intake and exhaust camshaft cap

bolts in the sequence shown.

1 10 7 6 3

2

14 18 15 11 4 10 7 52 8 9

4 5

1 12 16 17 13

6 8 9 3

6. Remove:

Intake camshaft 1

Exhaust camshaft 2

NOTE:

To prevent the timing chain from falling into the

crankcase, fasten it with a wire 3

.

7. Remove:

Exhaust camshaft sprocket 1

Intake camshaft sprocket 2

(with the special service tool 3

)

Universal magneto and rotor

holder:

YU-01235

Rotor holder:

90890-01235

Camshaft inspection

1. Check:

Camshaft lobes

Bluediscoloration/pitting/scratches →

Replace the camshaft.

2. Measure:

Camshaft lobe dimensions a

and b

Out of specification →

Replace the cam-

shaft.

Cam lobe dimensions:

Intake camshaft:

a 31.15 mm (1.226 in)

b 25.00 mm (0.984 in)

Exhaust camshaft:

a 30.75 mm (1.211 in)

b 25.00 mm (0.984 in)

ProCarManuals.com

Page 165 of 347

5-66

EPOWRVALVES AND VALVE SPRINGS

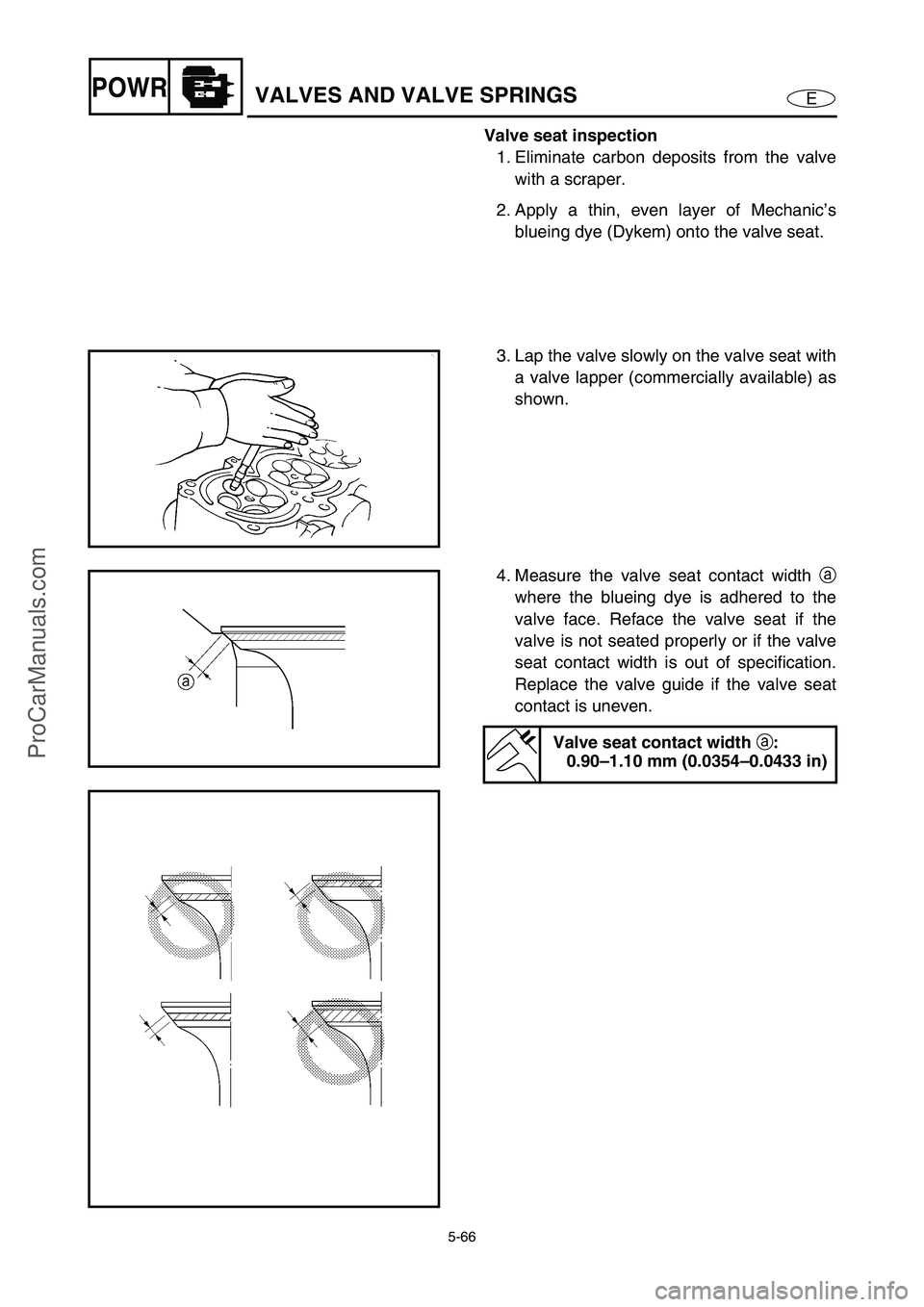

Valve seat inspection

1. Eliminate carbon deposits from the valve

with a scraper.

2. Apply a thin, even layer of Mechanic’s

blueing dye (Dykem) onto the valve seat.

3. Lap the valve slowly on the valve seat with

a valve lapper (commercially available) as

shown.

4. Measure the valve seat contact width a

where the blueing dye is adhered to the

valve face. Reface the valve seat if the

valve is not seated properly or if the valve

seat contact width is out of specification.

Replace the valve guide if the valve seat

contact is uneven.

Valve seat contact width

a:

0.90–1.10 mm (0.0354–0.0433 in)

ProCarManuals.com

Page 185 of 347

5-86

EPOWRCONNECTING RODS AND PISTONS

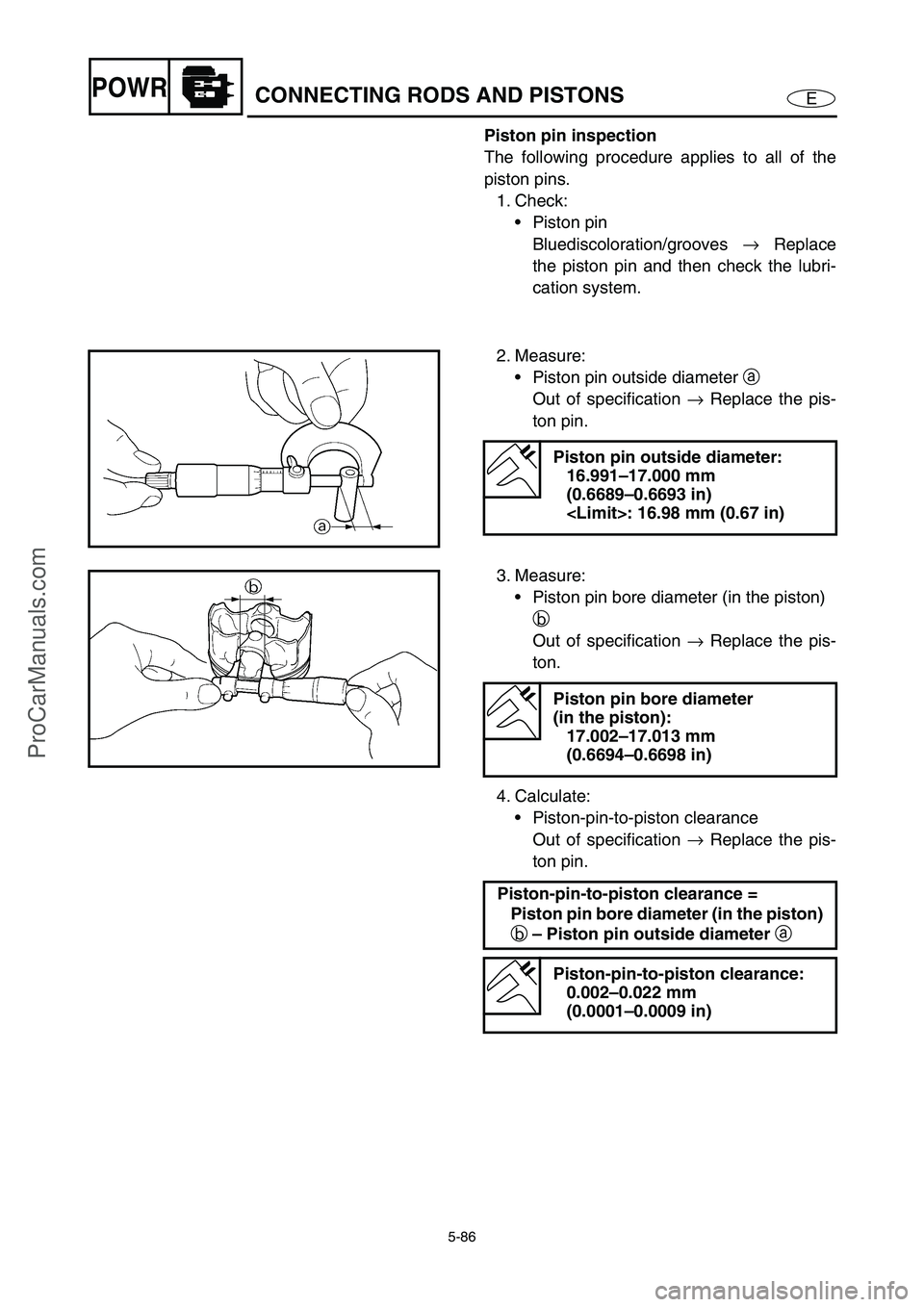

Piston pin inspection

The following procedure applies to all of the

piston pins.

1. Check:

Piston pin

Bluediscoloration/grooves →

Replace

the piston pin and then check the lubri-

cation system.

2. Measure:

Piston pin outside diameter a

Out of specification →

Replace the pis-

ton pin.

Piston pin outside diameter:

16.991–17.000 mm

(0.6689–0.6693 in)

3. Measure:

Piston pin bore diameter (in the piston)

b

Out of specification →

Replace the pis-

ton.

4. Calculate:

Piston-pin-to-piston clearance

Out of specification →

Replace the pis-

ton pin.

Piston pin bore diameter

(in the piston):

17.002–17.013 mm

(0.6694–0.6698 in)

Piston-pin-to-piston clearance =

Piston pin bore diameter (in the piston)

b – Piston pin outside diameter

a

Piston-pin-to-piston clearance:

0.002–0.022 mm

(0.0001–0.0009 in)

ProCarManuals.com

Page 188 of 347

5-89

EPOWRCONNECTING RODS AND PISTONS

For example, if the connecting rod “P1” and the

crankshaft web “P

1” numbers are “5” and “1”

respectively, then the bearing size for “P

1” is:

Bearing size of P

1:

“P

1” (connecting rod) –

“P

1” (crankshaft web)

5 – 1 = 4 (green)

BEARING COLOR CODE

1brown

2 black

3blue

4 green5 G

P4P3P2P1

Connecting rod and piston installation

The following procedure applies to all of the

pistons and connecting rods.

1. Install:

Oil ring

2nd ring

Top ring

NOTE:

Be sure to install the piston rings so that the

manufacturer’s marks or numbers face up.

2. Install:

Piston 1

Connecting rod 2

Piston pin 3

Piston pin clips 4

NOTE:

Apply engine oil onto the piston pin.

When installing the connecting rod to the pis-

ton, make sure that the “Y” mark a

on the

connecting rod faces towards the left when

the exhaust valve recesses b

on the piston

face upward. Refer to the illustration.

Reinstall each piston into its original cylinder

(numbering order starting from the front: #1

to #4).

ProCarManuals.com

Page 195 of 347

5-96

EPOWRCRANKSHAFT

Tighten the bolts to specification in the

order of the numbers on the crankcase.

Refer to “Crankcase assembly”—

“CRANKCASE”.

Remove the lower crankcase and the

crankshaft journal lower bearings.

Measure the compressed Plastigauge

width c

on each crankshaft journal.

If the crankshaft journal oil clearance is

out of specification, select replacement

crankshaft journal bearings.

c

4. Select:

Crankshaft journal bearings (J

1–J5)

NOTE:

The numbers stamped into the crankshaft

web and the numbers stamped into the lower

crankcase are used to determine the

replacement crankshaft journal bearing

sizes.

“J

1–J5” refer to the bearings shown in the

crankshaft illustration.

If “J

1–J5” are the same, use the same size

for all of the bearings.

For example, if the crankcase “J

1” and crank-

shaft web “J

1” numbers are “8” and “2” respec-

tively, then the bearing size for “J

1” is:

Bearing size of J

1:

“J

1” (crankcase) – “J1” (crankshaft web)

– 1

8 – 2 – 1 = 5 (Red/black)

BEARING COLOR CODE

3 Red/red

4Red/brown

5 Red/black

6 Red/blue

7Red/green

J5J4J3J2J1

J1J2J3J4J5

J5J4J3J2J1

ProCarManuals.com

Page 240 of 347

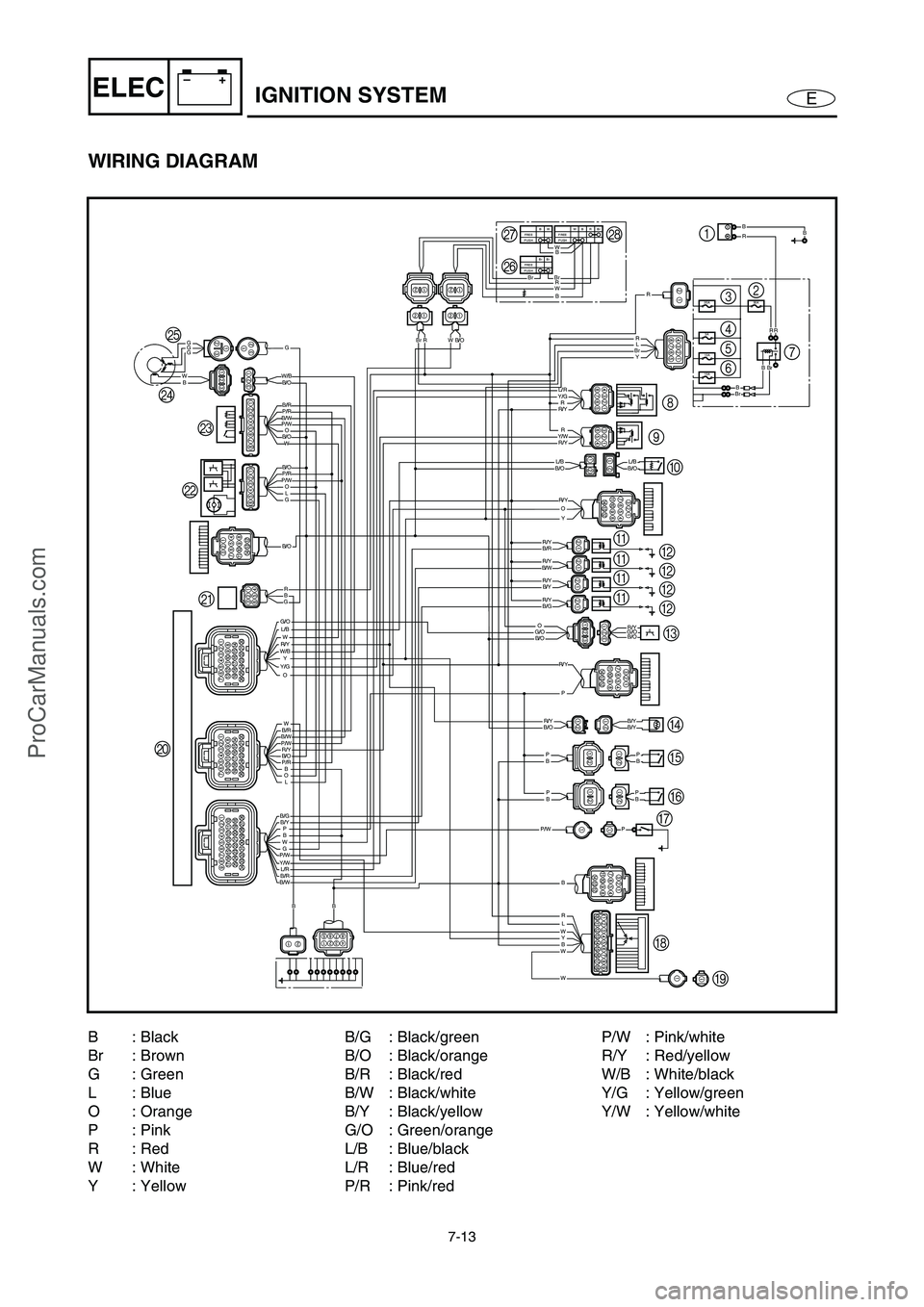

7-13

E

–+ELECIGNITION SYSTEM

WIRING DIAGRAM

10A

10A

3A

30A20A

WBrBRFREE

PUSHBWFREE

PUSH

Br BrFREE

PUSH

BW

W

BrBrBrBrR

W

B/W

B/O

B/O

B/O

B/R

P/R

P/R

W/B

P/W

P/W

B/O

L/B

B/WB/R

B/OP/W

P/R

W

W

WLR

Y

G

O

O

W

GG

BW

GG

O

OLG

W

Y

W

G/O

W/BR/Y

Y/G

BL

PBWP/W

B/GB/Y

Y/WL/RB/RB/W

B

B

BBP

P

P

BBP

RR

BBR

R/Y

B/OL/BB/OL/B

B/G

G/OB/OG/O

P/W

B/OB/YB/YR/Y

R/Y

R/Y

R/YB/YR/Y

R/Y

B/O

B/RR/Y

R/Y

R/YY/W

Y/GL/R

Y

P

P

O

O R

R

R

BB

BrRB/O

BBr

B/W

Y BrL R B

R

GB

R/YBBr

4

0 98

B

B B

B

H

I JK LM NOQ

PR

3

5

67 2 1

A

A A

A

C

D

E

F

G

B: Black

Br : Brown

G: Green

L: Blue

O : Orange

P: Pink

R: Red

W: White

Y : YellowB/G : Black/green

B/O : Black/orange

B/R : Black/red

B/W : Black/white

B/Y : Black/yellow

G/O : Green/orange

L/B : Blue/black

L/R : Blue/red

P/R : Pink/redP/W : Pink/white

R/Y : Red/yellow

W/B : White/black

Y/G : Yellow/green

Y/W : Yellow/white

ProCarManuals.com

Page 247 of 347

7-20

E

–+ELECIGNITION SYSTEM

THERMOSWITCH (ENGINE)

1. Check:

Thermoswitch (engine) continuity

(at the specified temperature)

Out of specification →

Replace.

1 No continuity

È Temperature

2 Continuity

É Time

NOTE:

The thermoswitch (engine) connector is blue.

Thermoswitch (engine) continuity

temperature:

a 84–90 °C (183–194 °F)

b 70–84 °C (158–183 °F)

Checking steps:

Suspend the thermoswitch (engine) in a

container filled with water.

Place a thermometer in the water.

Slowly heat the water.

Measure the continuity when the speci-

fied temperature is reached.

ProCarManuals.com

Page 257 of 347

7-30

E

–+ELEC

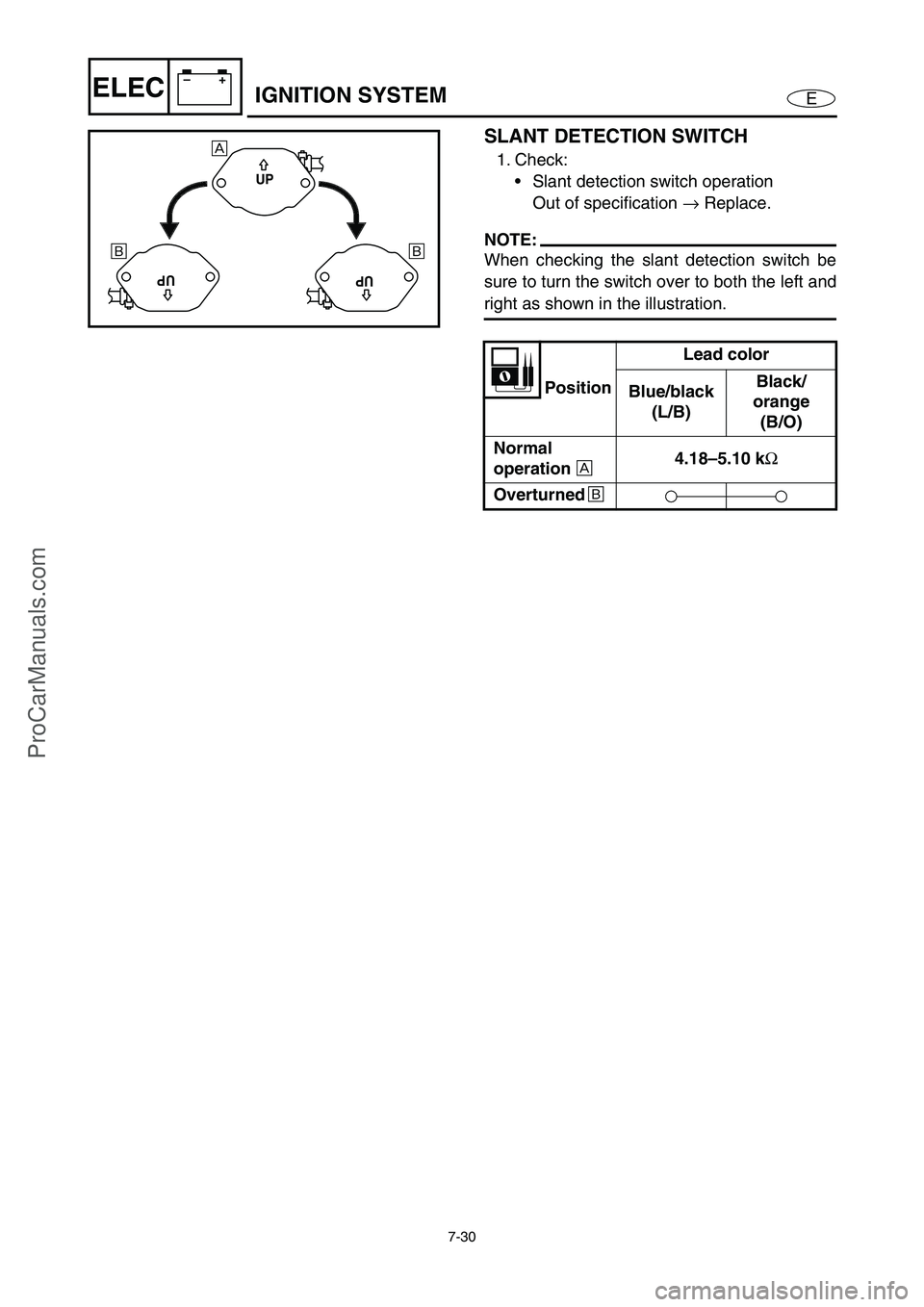

SLANT DETECTION SWITCH

1. Check:

Slant detection switch operation

Out of specification →

Replace.

NOTE:

When checking the slant detection switch be

sure to turn the switch over to both the left and

right as shown in the illustration.

PositionLead color

Blue/black

(L/B)Black/

orange

(B/O)

Normal

operation

È 4.18–5.10 k

Ω

Overturned

É

UP

UPUP

È

É É

IGNITION SYSTEM

ProCarManuals.com