spark plugs YAMAHA VX110 2005 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 24 of 347

2-3

ESPECMAINTENANCE SPECIFICATIONS

MAINTENANCE SPECIFICATIONS

ENGINE

Item UnitModel

VX110 Sport VX110 Deluxe

Cylinder head

Warpage limit mm (in) 0.1 (0.004)

Compression pressure

*1 kPa

(kgf/cm2, psi)1,150 (11.5, 164)

Cylinder

Bore size mm (in) 76.000–76.015 (2.9921–2.9927)

Taper limit mm (in) 0.08 (0.003)

Out-of-round limit mm (in) 0.05 (0.002)

Wear limit mm (in) 76.100 (2.9961)

Camshaft

Drive system Chain drive

Intake A mm (in) 31.15 (1.226)

Exhaust A mm (in) 30.75 (1.211)

Intake and exhaust B mm (in) 25.00 (0.984)

Camshaft cap inside diameter mm (in) 24.5 (0.9646)

Camshaft journal diameter

Intake mm (in) 24.46–24.47 (0.9630–0.9634)

Exhaust mm (in) 24.44–24.45 (0.9622–0.9626)

Camshaft-journal-to-camshaft-

cap clearancemm (in) 0.05–0.06 (0.0020–0.0024)

Maximum camshaft runout mm (in) 0.03 (0.0012)

Timing chain

Model/number of links 92RH2015-130/130

Tensioning system Automatic

Valves, valve seats, valve guides

Valve clearance (cold)

Intake mm (in) 0.11–0.20 (0.0043–0.0079)

Exhaust mm (in) 0.25–0.34 (0.0098–0.0134)

Valve dimensions

Valve head diameter A

Intake mm (in) 22.9–23.1 (0.9016–0.9094)

Exhaust mm (in) 24.4–24.6 (0.9606–0.9685)

*1 Measuring conditions:

Ambient temperature 20 °C (68 °F), wide open throttle, with spark plugs removed from all

cylinders.

The figures are for reference only.

ProCarManuals.com

Page 50 of 347

3-1

E

INSP

ADJ

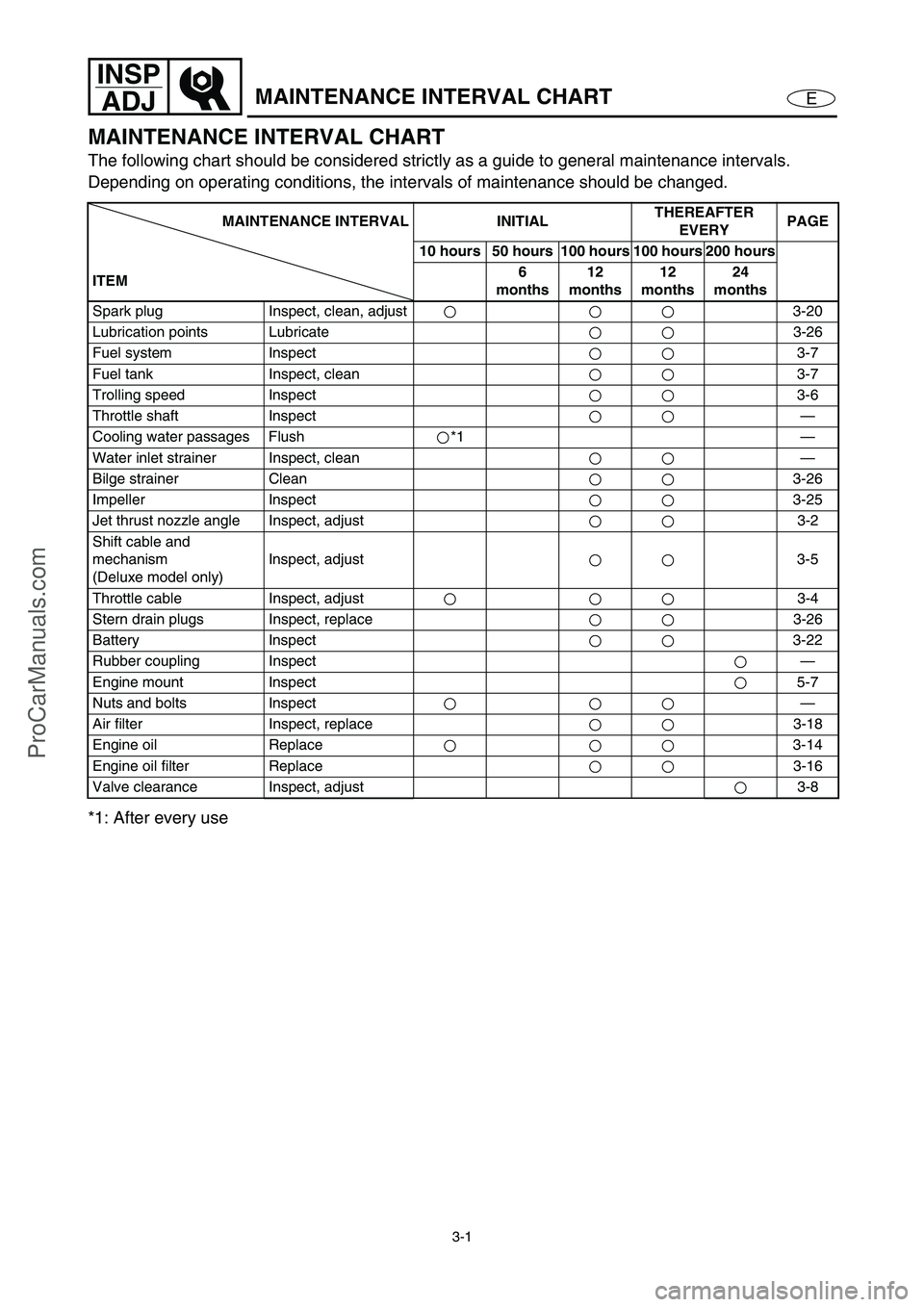

MAINTENANCE INTERVAL CHART

MAINTENANCE INTERVAL CHART

The following chart should be considered strictly as a guide to general maintenance intervals.

Depending on operating conditions, the intervals of maintenance should be changed.

*1: After every use

MAINTENANCE INTERVAL INITIALTHEREAFTER

EVERYPAGE

10 hours 50 hours 100 hours 100 hours 200 hours

ITEM6

months12

months12

months24

months

Spark plug Inspect, clean, adjust 3-20

Lubrication points Lubricate 3-26

Fuel system Inspect3-7

Fuel tank Inspect, clean 3-7

Trolling speed Inspect3-6

Throttle shaft Inspect—

Cooling water passages Flush *1 —

Water inlet strainer Inspect, clean —

Bilge strainer Clean3-26

Impeller Inspect3-25

Jet thrust nozzle angle Inspect, adjust 3-2

Shift cable and

mechanism

(Deluxe model only)Inspect, adjust 3-5

Throttle cable Inspect, adjust 3-4

Stern drain plugs Inspect, replace 3-26

Battery Inspect 3-22

Rubber coupling Inspect—

Engine mount Inspect5-7

Nuts and bolts Inspect—

Air filter Inspect, replace 3-18

Engine oil Replace 3-14

Engine oil filter Replace 3-16

Valve clearance Inspect, adjust 3-8

ProCarManuals.com

Page 57 of 347

3-8

E

INSP

ADJ

FUEL SYSTEM/POWER UNIT

Water separator inspection

1. Inspect:

Water separator 1

Water accumulation →

Drain.

NOTE:

To drain the water, remove the drain plug.

POWER UNIT

Valve clearance adjustment

The following procedure applies to all of the

valves.

NOTE:

Valve clearance adjustment should be made

on a cold engine, at room temperature.

When the valve clearance is to be measured

or adjusted, the piston must be at top dead

center (TDC) of the compression stroke.

1. Remove:

Ignition coils

Spark plugs

Cylinder head cover

Cylinder head cover gasket

Refer to “CAMSHAFTS” in Chapter 5.

2. Install:

Dial gauge needle

Dial gauge stand 1

(into spark plug hole #1)

Dial gauge 2

Dial gauge stand:

90890-06583

Dial gauge needle:

90890-06584

Dial gauge stand set:

YB-06585/90890-06585

Dial indicator gauge:

YU-03097

Dial gauge set:

90890-012522

1

ProCarManuals.com

Page 103 of 347

5-4

EPOWRENGINE UNIT

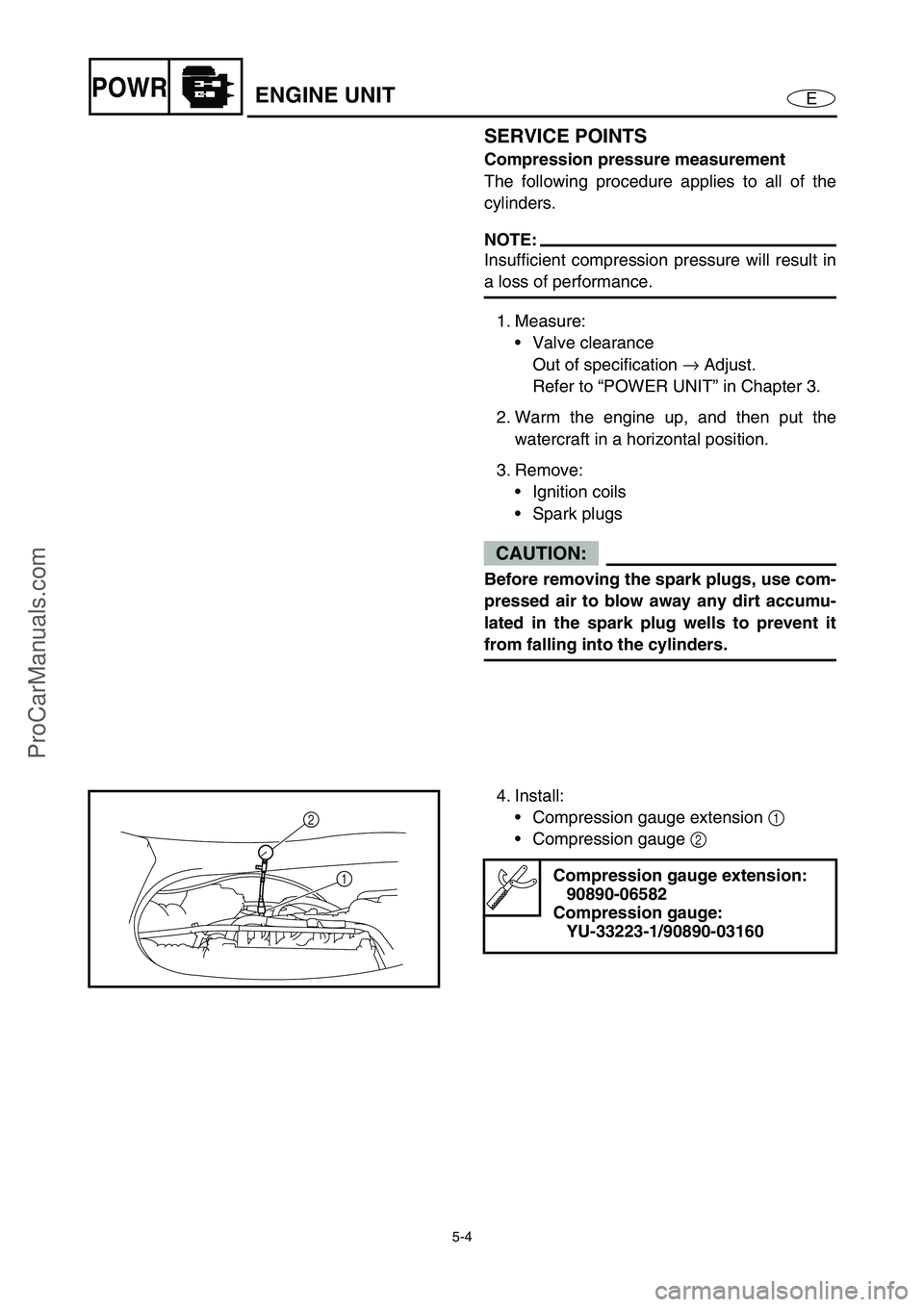

SERVICE POINTS

Compression pressure measurement

The following procedure applies to all of the

cylinders.

NOTE:

Insufficient compression pressure will result in

a loss of performance.

1. Measure:

Valve clearance

Out of specification →

Adjust.

Refer to “POWER UNIT” in Chapter 3.

2. Warm the engine up, and then put the

watercraft in a horizontal position.

3. Remove:

Ignition coils

Spark plugs

CAUTION:

Before removing the spark plugs, use com-

pressed air to blow away any dirt accumu-

lated in the spark plug wells to prevent it

from falling into the cylinders.

4. Install:

Compression gauge extension 1

Compression gauge 2

Compression gauge extension:

90890-06582

Compression gauge:

YU-33223-1/90890-03160

2

1

ProCarManuals.com

Page 225 of 347

E

–+ELEC

1

2

3

4

5

6

7

8

9

CHAPTER 7

ELECTRICAL SYSTEM

ELECTRICAL COMPONENTS........................................................................ 7-1

FUSE BOX ....................................................................................................... 7-2

EXPLODED DIAGRAM ............................................................................. 7-2

REMOVAL AND INSTALLATION CHART ................................................ 7-2

ECM AND RECTIFIER/REGULATOR............................................................. 7-7

EXPLODED DIAGRAM ............................................................................. 7-7

REMOVAL AND INSTALLATION CHART ................................................ 7-7

ELECTRICAL ANALYSIS ............................................................................... 7-9

INSPECTION............................................................................................. 7-9

Digital tester ........................................................................................ 7-9

Low resistance measurement ........................................................... 7-10

Peak voltage measurement .............................................................. 7-10

Peak voltage adapter ........................................................................ 7-11

Test harness .................................................................................... 7-11

IGNITION SYSTEM ....................................................................................... 7-12

WIRING DIAGRAM ................................................................................. 7-12

IGNITION SPARK ................................................................................... 7-14

IGNITION SYSTEM PEAK VOLTAGE .................................................... 7-15

BATTERY ................................................................................................ 7-17

FUSE ....................................................................................................... 7-17

SPARK PLUGS ....................................................................................... 7-17

IGNITION COIL ....................................................................................... 7-18

ENGINE STOP SWITCH ......................................................................... 7-18

ENGINE TEMPERATURE SENSOR ...................................................... 7-19

SENSOR ASSEMBLY ............................................................................. 7-19

THERMOSWITCH (ENGINE).................................................................. 7-20

THERMOSWITCH (EXHAUST) .............................................................. 7-21

MAIN AND FUEL PUMP RELAY............................................................. 7-22

ELECTRONIC CONTROL THROTTLE VALVE RELAY ......................... 7-23

THROTTLE POSITION SENSOR ........................................................... 7-24

ACCELERATOR POSITION SENSOR ................................................... 7-26

CAM POSITION SENSOR ...................................................................... 7-29

SLANT DETECTION SWITCH ................................................................ 7-30

ProCarManuals.com

Page 228 of 347

7-1

E

–+ELECELECTRICAL COMPONENTS

ELECTRICAL COMPONENTS

O

N

M

L

K

J

I

H

G

F

E

D

C

B

A

0

91

2

3

4

5

6

7

8

1Thermoswitch (engine)

2Fuse box

3Slant detection switch

4Starter motor

5Engine temperature sensor

6Spark plugs and ignition coils

7Cam position sensor

8Battery

9Speed sensor

0Sensor assembly (intake air

pressure and intake air tem-

perature)AOil pressure switch

BFuel injectors

CThermoswitch (exhaust)

DRectifier/regulator

EECM

FThrottle body assembly

GLighting coil and pickup coil

HEngine stop switch, engine

shut-off switch, and start

switch

ISteering sensor

JBuzzerKAccelerator position sensor

LElectric fuel pump

MFuel sender

NMultifunction meter

ORemote control unit (Deluxe

model only)

ProCarManuals.com

Page 237 of 347

7-10

E

–+ELECELECTRICAL ANALYSIS

Low resistance measurement

NOTE:

When measuring a resistance of 10 Ω

or less

using a digital tester, the correct measure-

ment cannot be obtained because of the

tester’s internal resistance.

To obtain the correct value, subtract the

internal resistance from the displayed mea-

surement.

The internal resistance of the tester can be

obtained by connecting both of its terminals.

Correct value =

Displayed measurement –

Internal resistance

Peak voltage measurement

NOTE:

When checking the condition of the ignition

system it is vital to know the peak voltage.

Cranking speed is dependant on many fac-

tors (e.g., fouled or weak spark plugs, a

weak battery). If one of these is defective,

the peak voltage will be lower than specifica-

tion.

If the peak voltage measurement is not

within specification the engine will not oper-

ate properly.

A low peak voltage will also cause compo-

nents to prematurely wear.

ProCarManuals.com

Page 244 of 347

7-17

E

–+ELEC

NOTE:

To crank the engine, connect the engine shut-

off cord (lanyard) to the engine shut-off switch,

and then press the start switch and engine

stop switch simultaneously.

4. Measure:

Rectifier/regulator output voltage

Below specification →

Replace the recti-

fier/regulator.

NOTE:

Do not use the peak voltage adapter to mea-

sure the output voltage.

Disconnect the output lead of the tester har-

ness.

Test harness (6 pins):

YB-06848

Test harness FSW-6A (6 pins):

90890-06848

Rectifier/regulator output

voltage:

Red (R) – Black (B)

r/minUnloaded

3,500

V 13.0

BATTERY

Refer to “ELECTRICAL” in Chapter 3.

FUSE

Refer to “STARTING SYSTEM”.

SPARK PLUGS

Refer to “POWER UNIT” in Chapter 3.

IGNITION SYSTEM

ProCarManuals.com

Page 339 of 347

9-6

E

TRBL

ANLS

TROUBLE ANALYSIS

JET PUMP UNIT

Duct 6

Impeller 6

Intake grate 6

Bearings 6

Water inlet hose 6

Bilge hose 6

Bilge strainer 3

Bilge hose joint 6

ELECTRICAL

Ignition system, fuel control system

Pickup coils 7

ECM 7

Ignition coils 7

Slant detection switch 7

Engine stop switch 7

Engine shut-off switch 7

Spark plugs 3

Main and fuel pump relay 7

Electronic control throttle

valve relay7

Thermoswitch 7

Sensor assembly 7

Engine temperature

sensor7

Throttle body assembly

(throttle position sensor)7

Accelerator position

sensor7

Cam position sensor 7 Trouble mode Check elements

ENGINE WILL NOT START

HARD STARTING

ROUGH IDLING

HIGH IDLING

ENGINE STALLS

POOR ACCELERATION

ENGINE WILL NOT STOP

POOR PERFORMANCE

LIMITED ENGINE SPEED

OVERHEATING

LOW OIL PRESSURE

LOOSE STEERING

BILGE INCREASE

IRREGULAR WARNING INDICATION

POOR BATTERY CHARGING

Relative partReference

chapter

ProCarManuals.com