tow YAMAHA VX110 2005 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 41 of 347

2-20

ESPECCABLE AND HOSE ROUTING

12

Ð

Ò

Ó

Õ

Î

ÍÌ

È

É

È

É

Ñ

Ô

3

4

5678

4

B

O

P

5

N

C

D

A09H-H

EFGH

I

P

G

G-G

A

BD

F C

E

JJ

M

C

F

I

I

E

DB

A

A

ÏÐ

H

H

G

G

JK

0

Q

L

Ê

Ë

ÏTo ventilation socket

ÐTo fuel tank

ÑPoint the arrow on the cover toward the fuel

tank.

ÒFasten the fuel hose with a plastic tie.

ÓTo fuse box

ÔFasten the wiring harness with a plastic tie at

the white tape.

ÕTo ECM

ProCarManuals.com

Page 43 of 347

2-22

ESPECCABLE AND HOSE ROUTING

A

B

C

D

2

4

2

5

6

7

8

3

2

28

Ñ

Ê

Ó Ò

Ê

ÊÍ

É

Ë

F-FE-E

2

1222

2

2

Õ

ÈÐ

Ô

ÎÌÏ

F

F

E

E

D C

A

B

2

ÍFasten the oil separator breather hose (to air

intake duct) and cooling water hose with a

holder.

ÎFace the ends of the hose clamp towards the

starboard (right) side of the watercraft.

ÏInsert the cooling water hose to the paint mark.

ÐTo install the cooling water hose, align the white

paint mark on the cooling water hose with the

arrow mark of the hose joint.ÑInstall the cooling water hose with the white

paint mark facing up.

ÒTo cooling water pilot outlet

ÓFace the ends of the hose clamp towards the

bow.

ÔInstall the hose onto the cooling water pipe until

the pipe reaches the curve in the hose.

ÕInsert the plastic tie completely into the hole in

the boss on the cylinder block.

ProCarManuals.com

Page 78 of 347

4-1

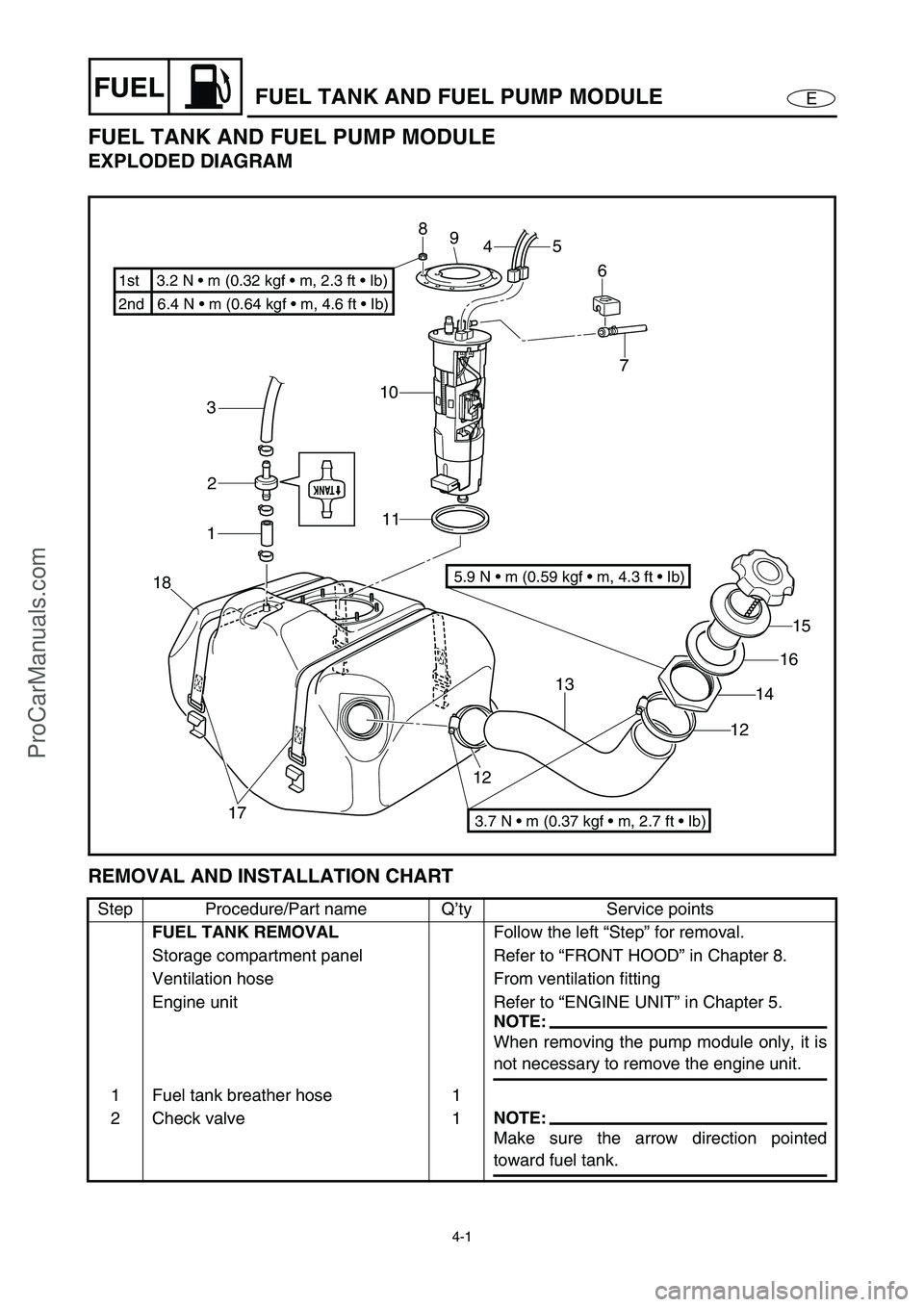

EFUELFUEL TANK AND FUEL PUMP MODULE

FUEL TANK AND FUEL PUMP MODULE

EXPLODED DIAGRAM

REMOVAL AND INSTALLATION CHART

Step Procedure/Part name Q’ty Service points

FUEL TANK REMOVAL

Follow the left “Step” for removal.

Storage compartment panel Refer to “FRONT HOOD” in Chapter 8.

Ventilation hose From ventilation fitting

Engine unit Refer to “ENGINE UNIT” in Chapter 5.

NOTE:

When removing the pump module only, it is

not necessary to remove the engine unit.

1 Fuel tank breather hose 1

2 Check valve 1

NOTE:

Make sure the arrow direction pointed

toward fuel tank.

7

10

11 3

2

1

18

17121315

16

14

12 6 5

4 8

9

2nd 6.4 N • m (0.64 kgf m, 4.6 ft Ib) 1st 3.2 N m (0.32 kgf m, 2.3 ft Ib)

3.7 N m (0.37 kgf m, 2.7 ft Ib)

5.9 N m (0.59 kgf m, 4.3 ft Ib)

ProCarManuals.com

Page 187 of 347

5-88

EPOWRCONNECTING RODS AND PISTONS

NOTE:

• Do not move the connecting rod or crank-

shaft until the clearance measurement

has been completed.

Lubricate the bolts threads and nut seats

with molybdenum disulfide grease.

Make sure the “Y” mark c on the con-

necting rod faces towards the front side of

the crankshaft.

Make sure the characters d on both the

connecting rod and connecting rod cap

are aligned.

Tighten the connecting rod nuts.

Refer to “Connecting rod and piston

installation”.

Remove the connecting rod and big end

bearings.

Refer to “Connecting rod and piston

removal”.

Measure the compressed Plastigauge

width e on the crankshaft pin.

If the big end oil clearance is out of speci-

fication, select replacement big end bear-

ings.

cd

e

2. Select:

Big end bearings (P

1–P4)

NOTE:

The numbers stamped into the crankshaft web

and the numbers on the connecting rods are

used to determine the replacement big end

bearing sizes.

P4

P3P2

P1

ProCarManuals.com

Page 188 of 347

5-89

EPOWRCONNECTING RODS AND PISTONS

For example, if the connecting rod “P1” and the

crankshaft web “P

1” numbers are “5” and “1”

respectively, then the bearing size for “P

1” is:

Bearing size of P

1:

“P

1” (connecting rod) –

“P

1” (crankshaft web)

5 – 1 = 4 (green)

BEARING COLOR CODE

1brown

2 black

3blue

4 green5 G

P4P3P2P1

Connecting rod and piston installation

The following procedure applies to all of the

pistons and connecting rods.

1. Install:

Oil ring

2nd ring

Top ring

NOTE:

Be sure to install the piston rings so that the

manufacturer’s marks or numbers face up.

2. Install:

Piston 1

Connecting rod 2

Piston pin 3

Piston pin clips 4

NOTE:

Apply engine oil onto the piston pin.

When installing the connecting rod to the pis-

ton, make sure that the “Y” mark a

on the

connecting rod faces towards the left when

the exhaust valve recesses b

on the piston

face upward. Refer to the illustration.

Reinstall each piston into its original cylinder

(numbering order starting from the front: #1

to #4).

ProCarManuals.com

Page 190 of 347

5-91

EPOWRCONNECTING RODS AND PISTONS

7. Install:

Big end bearings

Connecting rod assembly 1

(into the cylinder and onto the

crankshaft pin)

Connecting rod cap

(onto the crankshaft pin)

NOTE:

Align the projections on the big end bearings

with the notches in the connecting rods and

connecting rod caps.

Be sure to reinstall each big end bearing in

its original place.

While compressing the piston rings with pis-

ton ring compressor 2

, install the connecting

rod assembly into the cylinder with the other

hand.

Make sure the “Y” marks a

on the connect-

ing rods face towards the front side of the

crankshaft.

Make sure the characters b

on both the con-

necting rod and connecting rod cap are

aligned.

8. Align:

Bolt heads

(with the connecting rod)

Piston ring compressor:

YM-08037/90890-05158

ProCarManuals.com

Page 312 of 347

8-19

E

HULL

HOOD

SERVICE POINTS

Cooling water pilot outlet installation

1. Install:

Cooling water pilot outlet 1

Seal 2

Nut 3

NOTE:

When installing the cooling water pilot outlet,

face the discharge hole toward the stern and

downward at a 30° angle from the horizontal

line as shown in the illustration.

Tighten the nut while holding the cooling

water pilot outlet in place.

30˚

FWD3

12

Grommet installation

1. Install:

Ventilation hose 1

Grommet 2

NOTE:

Install the grommet on the ventilation hose,

making sure that the end of the hose protrudes

the specified length a from the groove around

the outside of the grommet as shown in the

illustration.

Specified length a:

30–40 mm (1.18–1.57 in)

1

2

a

Ventilation hose assembly installation

1. Install:

Ventilation hose assembly

NOTE:

When installing the ventilation hose assembly,

make sure that the grommet is properly seated

in the hole in the inner hull as shown in the

illustration.

HOSES

ProCarManuals.com