warning YAMAHA VX110 2005 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: VX110, Model: YAMAHA VX110 2005Pages: 347, PDF Size: 14.17 MB

Page 4 of 347

E

IMPORTANT INFORMATION

In this Service Manual particularly important information is distinguished in the following ways.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

WARNING

Failure to follow WARNING instructions could result in severe injury or death to the machine

operator, passenger(s), a bystander, or a person inspecting or repairing the watercraft.

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to the water-

craft.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

IMPORTANT:

This part has been subjected to change of specification during production.

ProCarManuals.com

Page 52 of 347

3-3

E

INSP

ADJ

CONTROL SYSTEM

2. Adjust:

Steering cable joint

(steering column end)

NOTE:

Adjust the cable joint at the jet pump end.

Refer to “REMOTE CONTROL CABLES AND

SPEED SENSOR LEAD” in Chapter 8. Adjustment steps:

Set the control grip to the neutral posi-

tion.

Loosen the locknut 1

.

Disconnect the cable joint 2

from the ball

joint 3

.

Turn the cable joint 2

in or out to adjust

the steering cable length c

.

Steering cable length

c:

218.8 mm (8.61 in)

NOTE:

Check that the sum of lengths c

and d

is

581.8 ±

1 mm (22.91 ±

0.04 in).

If the sum of lengths c

and d

is out of

specification, adjust length d

, and then

check the jet thrust nozzle distances

again.

WARNING

The cable joint must be screwed in more

than 8 mm (0.31 in).

Connect the cable joint and tighten the

locknut.

T R..

Locknut:

6.8 N m (0.68 kgf m, 4.9 ft lb)

c

d

ProCarManuals.com

Page 54 of 347

3-5

E

INSP

ADJ

CONTROL SYSTEM

WARNING

After adjusting the free play, turn the han-

dlebar to the right and left and make sure

that the trolling speed does not increase.e. Install the handlebar cover.

T R..

Lower handlebar cover screw:

3.7 N m (0.37 kgf m, 2.7 ft lb)

LOCTITE 242

Upper handlebar cover screw:

1.1 N m (0.11 kgf m, 0.8 ft lb)

Shift cable inspection and adjustment

(Deluxe model only)

1. Check:

Reverse gate stopper lever position

Incorrect →

Adjust.

2. Adjust:

Shift cable joint Checking steps:

Set the shift lever to the reverse position.

Check that the reverse gate 1

contacts

the stopper 2

.

Adjustment steps:

Loosen the locknut 1

.

Disconnect the cable joint 2

from the ball

joint 3

.

Situate the reverse gate to the stopper.

Turn the cable joint in or out to align it

with the ball joint.

Turn in Length is decreased.

Turn out Length is increased.

1

23

ProCarManuals.com

Page 55 of 347

3-6

E

INSP

ADJ

CONTROL SYSTEM

Turn out the cable joint nine times a

to

extend the cable 7 mm (0.28 in) from the

aligned position.

WARNING

The cable joint must be screwed in more

than 8 mm (0.31 in).

Connect the cable joint and tighten the

locknut.

T R..

Locknut:

3.8 N m (0.38 kgf m, 2.7 ft lb)

Trolling speed inspection

1. Inspect:

Trolling speed

Trolling speed:

1,550–1,750 r/min

Checking steps (watercraft in water):

Start the engine and allow it to warm up

for 15 minutes.

Check the engine trolling speed using the

tachometer of the multifunction meter or

using the Yamaha Diagnostic System.

ProCarManuals.com

Page 56 of 347

3-7

E

INSP

ADJ

FUEL SYSTEM

FUEL SYSTEM

WARNING

When removing fuel system parts, wrap

them in a cloth and take care that no fuel

spills into the engine compartment.

Fuel line inspection

1. Inspect:

Fuel pump filter

Clog/contaminants →

Clean.

Refer to “FUEL TANK AND FUEL

PUMP MODULE” in Chapter 4.

Fuel hose

Cracks/damage →

Replace.

O-rings (quick connector)

Cracks/damage →

Replace the quick

connector.

Fuel rail

Cracks/damage →

Replace.

Refer to “FUEL INJECTION SYSTEM”

in Chapter 4.

Fuel filler hose

Fuel filler cap

Cracks/damage →

Replace.

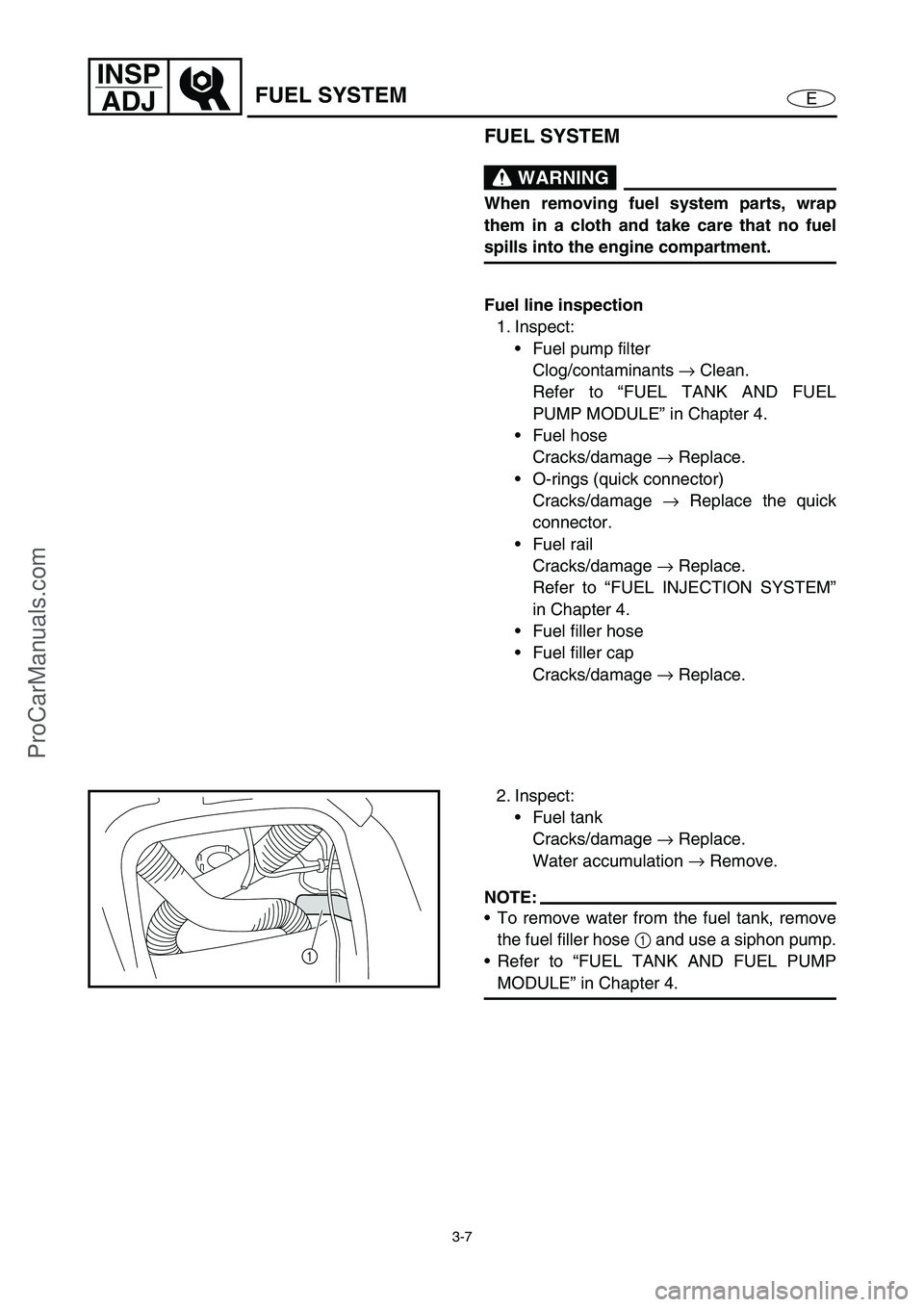

2. Inspect:

Fuel tank

Cracks/damage →

Replace.

Water accumulation →

Remove.

NOTE:

To remove water from the fuel tank, remove

the fuel filler hose 1

and use a siphon pump.

Refer to “FUEL TANK AND FUEL PUMP

MODULE” in Chapter 4.

1

ProCarManuals.com

Page 65 of 347

3-16

E

INSP

ADJ

POWER UNIT

Remove the oil tank filler cap again and

check that the oil level is between the

minimum level mark a

and maximum

level mark b

on the dipstick.

If the engine oil is below the minimum

level mark b

, add sufficient oil of the rec-

ommended type to raise it to the correct

level.

If the engine oil is above the maximum

level mark a

, extract sufficient oil using

an oil changer to lower it to the correct

level.

NOTE:

If the oil temperature is low, the reading on

the dipstick will be low, and if the tempera-

ture is high, the reading on the dipstick will

be high.

Engine oil change — using oil changer

WARNING

Avoid changing the engine oil immediately

after turning the engine off. The oil is hot

and should be handled with care to avoid

burns.

CAUTION:

Do not run the engine with too much or

not enough oil in the oil tank. Oil could

spray out or the engine could be dam-

aged.

Do not run the engine for more than 15

seconds without supplying water, when

checking the oil level on land.

The engine could overheat.

Be sure to change the engine oil after the

first 10 hours of operation, and every 100

hours thereafter or at the start of a new

season, otherwise the engine will wear

quickly.

1. Warm the engine up, and then put the

watercraft in a horizontal position.

ProCarManuals.com

Page 71 of 347

3-22

E

INSP

ADJ

ELECTRICAL

ELECTRICAL

Battery inspection

WARNING

Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Electro-

lyte contains sulfuric acid. Avoid contact

with skin, eyes or clothing.

Antidotes

External: Flush with water.

Internal: Drink large quantities of water or

milk. Follow with milk of magnesia, beaten

egg or vegetable oil. Call physician immedi-

ately.

Eyes: Flush with water for 15 minutes and

get prompt medical attention.

Batteries produce explosive gases. Keep

sparks, flame, cigarettes, etc., well away. If

using or charging the battery in an

enclosed space, make sure that it is well

ventilated. Always shield your eyes when

working near batteries.

KEEP OUT OF THE REACH OF CHILDREN.

CAUTION:

Be careful not to place the battery on its

side.

Make sure to remove the battery from the

battery compartment when adding battery

electrolyte or charging the battery.

When checking the battery, make sure the

breather hose is connected to the battery

and not obstructed.

ProCarManuals.com

Page 72 of 347

3-23

E

INSP

ADJ

ELECTRICAL

1. Remove:

Bands

Battery negative lead 1

Battery positive lead 2

Battery

Battery breather hose 3

WARNING

When removing the battery, disconnect

the negative lead first.

Remove the battery to prevent acid loss

during turning the watercraft on its side

for the impeller, etc.

2. Inspect:

Electrolyte level

Low →

Add distilled water.

The electrolyte level should be between

the maximum a

and minimum b

level

marks.

CAUTION:

Use only distilled water. Other types of

water contain minerals which are harmful

to batteries.Filling steps:

Remove each filler cap.

Add distilled water to the maximum level

mark.

When the electrolyte level reaches the

maximum level mark, allow the cell to

stand for 20 minutes. If the electrolyte

level drops, add more distilled water so

the level reaches the maximum level

mark.

ProCarManuals.com

Page 89 of 347

4-12

EFUEL

THROTTLE BODY ASSEMBLY AND INTAKE

MANIFOLD

SERVICE POINTS

Fuel hose clamps removal

1. Remove:

Fuel hose clamps

CAUTION:

If the fuel hose clamps are removed with-

out cutting the joint first, the fuel hose will

be damaged.

Hose clamps installation

1. Install:

Fuel hose clamps

WARNING

Do not reuse the fuel hose clamps, always

replace them with new ones.

NOTE:

Crimp the fuel hose clamps properly to

securely fasten them.

Fuel hose disconnection

WARNING

Before disconnecting the hose, remove the

fuel tank filler cap to reduce any pressure

inside the fuel tank, and then disconnect

the battery negative lead to cut off the elec-

tric current to the electrical systems.

1. Wrap the quick connector with a cloth, and

then rotate the quick connector tab 1

to

the stopper position a

.

WARNING

If the quick connector is removed sud-

denly, pressurized fuel could spray out. To

gradually release the fuel pressure, be sure

to remove the quick connector slowly.

1

a

ProCarManuals.com

Page 90 of 347

4-13

EFUEL

CAUTION:

Do not rotate the quick connector tab

1

past the stopper position, otherwise it

could be damaged.

When the fuel hoses are disconnected,

quickly remove the retainer

2 from the

quick connector, otherwise the retainer

could be lost.

2. Disconnect the fuel hose 1

from the fuel

pipe 2

directly.

WARNING

Always reduce the fuel pressure in the fuel

line before servicing the line or the fuel

pipe. If the fuel pressure is not released,

pressurized fuel could spray out.

21

1

2

3. Cover the quick connector and fuel pipe

with a plastic bag 3 to prevent damage

and to protect them from dirt.

3

Fuel line inspection

1. Inspect:

Fuel hose

Damage/cracks → Replace.

O-rings (quick connector)

Damage/cracks → Replace the quick

connector.

Fuel pipe

Damage/cracks → Replace the fuel

pump.

THROTTLE BODY ASSEMBLY AND INTAKE

MANIFOLD

ProCarManuals.com