check oil YAMAHA VXR 2014 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: VXR, Model: YAMAHA VXR 2014Pages: 98, PDF Size: 3.98 MB

Page 5 of 98

Table of contents

General and important labels ........... 1Identification numbers .................... 1

Primary Identification (PRI-ID)

number............................................ 1

Craft Identification Number (CIN) ....... 1

Engine serial number.......................... 1

Manufactured date label .................... 2

Model information ........................... 2

Builder’s plate .................................... 2

Important labels .............................. 4

Warning labels.................................... 5

Other labels ........................................ 8

Safety information ........................... 10 Limitations on who may operate the watercraft ............................. 10

Cruising limitations ........................ 11

Operation requirements ................ 12

Recommended equipment ........... 14

Hazard information........................ 15

Watercraft characteristics ............. 15

Water-skiing .................................. 17

Safe boating rules ......................... 18

Enjoy your watercraft responsibly ................................. 19

Description....................................... 20 Watercraft glossary ....................... 20

Location of main components ...... 21

Control function operation ............. 25 Watercraft control functions ......... 25

Remote control transmitter .............. 25

Yamaha Security System ................. 26

Engine stop switch .......................... 27

Engine shut-off switch .................... 27

Start switch ..................................... 27

Throttle lever .................................... 28

Steering system ............................... 28

Cooling water pilot outlet ................. 29

Water separator................................ 29

Watercraft operation ...................... 30Watercraft operation functions ..... 30

Reverse system ................................ 30

Watercraft operation modes ......... 31

Low RPM Mode ............................... 31

Instrument operation ...................... 33Multifunction information center ... 33

Information display ........................... 33

Equipment operation ...................... 38Equipment..................................... 38

Seat .................................................. 38

Handgrip........................................... 39

Reboarding step (VXR) ..................... 39

Bow eye............................................ 40

Stern eyes ........................................ 40

Cleat ................................................. 40

Storage compartments .................... 40

Fire extinguisher holder and cover ... 42

Operation and handling

requirements ................................... 44Fuel requirements ......................... 44

Fuel................................................... 44

Engine oil requirements ................ 45

Engine oil .......................................... 45

Draining the bilge water ................ 47

Draining the bilge water on land....... 47

Draining the bilge water on water .... 47

Transporting on a trailer................ 48

First-time operation ........................ 49 Engine break-in............................. 49

Pre-operation checks ..................... 50

Pre-operation checklist .................... 50

Pre-operation check points .......... 52

Pre-launch checks ........................... 52

Post-launch checks.......................... 58

UF2M73E0.book Page 1 Friday, August 2, 2013 11:28 AM

Page 39 of 98

Instrument operation

33

EJU41851

Multifunction information center

The multifunction information center displays

various watercraft information.

Multifunction information center initial op-

eration

When the multifunction information center is

activated, all of the display segments and the

“SECURITY” indicator light come on. After 2

seconds, the warning indicators in the infor-

mation display go off, and then the center

starts to operate normally.

TIP:

The “SECURITY” indicator light will go off

when the engine is started.

Multifunction information center standby

state

If the multifunction information center does

not receive any operation input within 25 sec-

onds after the engine stops, the center will

turn off and enter a standby state. When the

engine is started again, the displays return to

their state before the center turned off, and

then the center starts to operate normally.

EJU35025Information display

The information display shows watercraft op-

erating conditions.

EJU31504Speedometer

The speedometer shows the watercraft

speed against water.

By switching the display units, the speed can

be shown in kilometers per hour “km/h” or

miles per hour “mph”.

TIP:

“mph” is selected as the display unit at the

Yamaha factory.

1 “SECURITY” indicator light

2 Select button

3 Information display

4 “L-MODE” indicator light

5 “WARNING” indicator light

21345

1Tachometer

2 Speedometer

3 Hour meter/voltmeter

4 Fuel level meter

5 Check engine warning indicator

6 Engine overheat warning indicator

7 Oil pressure warning indicator

8 Fuel level warning indicator

1 Speedometer

1234

8765

1

UF2M73E0.book Page 33 Friday, August 2, 2013 11:28 AM

Page 42 of 98

Instrument operation

36

TIP:

Push the select button on the multifunction

information center to stop the buzzer.

EJU31627Oil pressure warning

If the oil pressure drops significantly, the oil

pressure warning indicator and the “WARN-

ING” indicator light blink, and the buzzer

sounds intermittently. At the same time, the

maximum engine speed is limited.

If the oil pressure warning is activated, imme-

diately reduce the engine speed, return to

shore, and then check the engine oil level.

(See page 45 for information on checking the

engine oil level.) If the oil level is sufficient,

have a Yamaha dealer check the watercraft.

TIP:

Push the select button on the multifunction

information center to stop the buzzer.

EJU3160AEngine overheat warning

If the engine temperature rises significantly,

the engine overheat warning indicator and

the “WARNING” indicator light blink, and the

buzzer sounds intermittently. Then, the en-

gine overheat warning indicator and the

“WARNING” indicator light stop blinking and

remain on, and the buzzer sounds continu-ously. At the same ti

me, the maximum engine

speed is limited.

If the engine overheat warning is activated,

immediately reduce the engine speed, return

to shore, and then make sure that water is

being discharged from the cooling water pilot

outlet while the engine is running. If there is

no discharge of water, stop the engine, and

then check the jet intake for clogging. (See

page 85 for information on the jet intake.)

NOTICE: If you cannot locate and correct

the cause of the overheating, consult a

Yamaha dealer. Continuing to operate at higher speeds could result in severe en-

gine damage.

[ECJ00042]

TIP:

Push the select button on the multifunction

information center to stop the buzzer.

UF2M73E0.book Page 36 Friday, August 2, 2013 11:28 AM

Page 51 of 98

Operation and handling requirements

45

(6) Stop filling when the fuel level reachesapproximately 50 mm (2 in) from the top

of the fuel tank. Do not overfill the fuel

tank. Because fuel expands when it

heats up, heat from the engine or the sun

can cause fuel to spill out of the fuel tank.

Do not leave the watercraft with a full

tank in direct sunlight.

(7) Wipe up any spilled fuel immediately with a dry cloth.

(8) Securely install the fuel filler cap by tight- ening it until it clicks.

(9) Securely install the seat in its original po- sition.

EJU40291

Engine oil requirementsEJU41871Engine oil

NOTICE

ECJ00282

Use only 4-stroke engine oil. Usage of 2-

stroke engine oil could result in severe en-

gine damage.

Checking the engine oil level

WARNING

EWJ00341

Engine oil is extremely hot immediately af-

ter the engine is turned off. Coming in con-

tact with or getting any engine oil on your

clothes could result in burns.

NOTICE

ECJ01002

Make sure that debris and water do not

enter the oil filler hole. Debris and water in

the engine oil can cause serious engine

damage.

To check the engine oil level:

(1) Place the watercraft in a precisely levelposition on land with the engine

stopped. If the engine was running, allow

the engine oil to settle by waiting 5 minu-

tes or more before checking the oil level.

(2) Remove the seat. (See page 38 for seat removal and installation procedures.)

Fuel tank capacity:

70 L (18.5 US gal, 15.4 Imp.gal)

1Approximately 50 mm (2 in) from top of the

fuel tank

1

Recommended engine oil type:

SAE 10W-30, 10W-40, 20W-40,

20W-50

Recommended engine oil grade: API SE,SF,SG,SH,SJ,SL

UF2M73E0.book Page 45 Friday, August 2, 2013 11:28 AM

Page 52 of 98

Operation and handling requirements

46

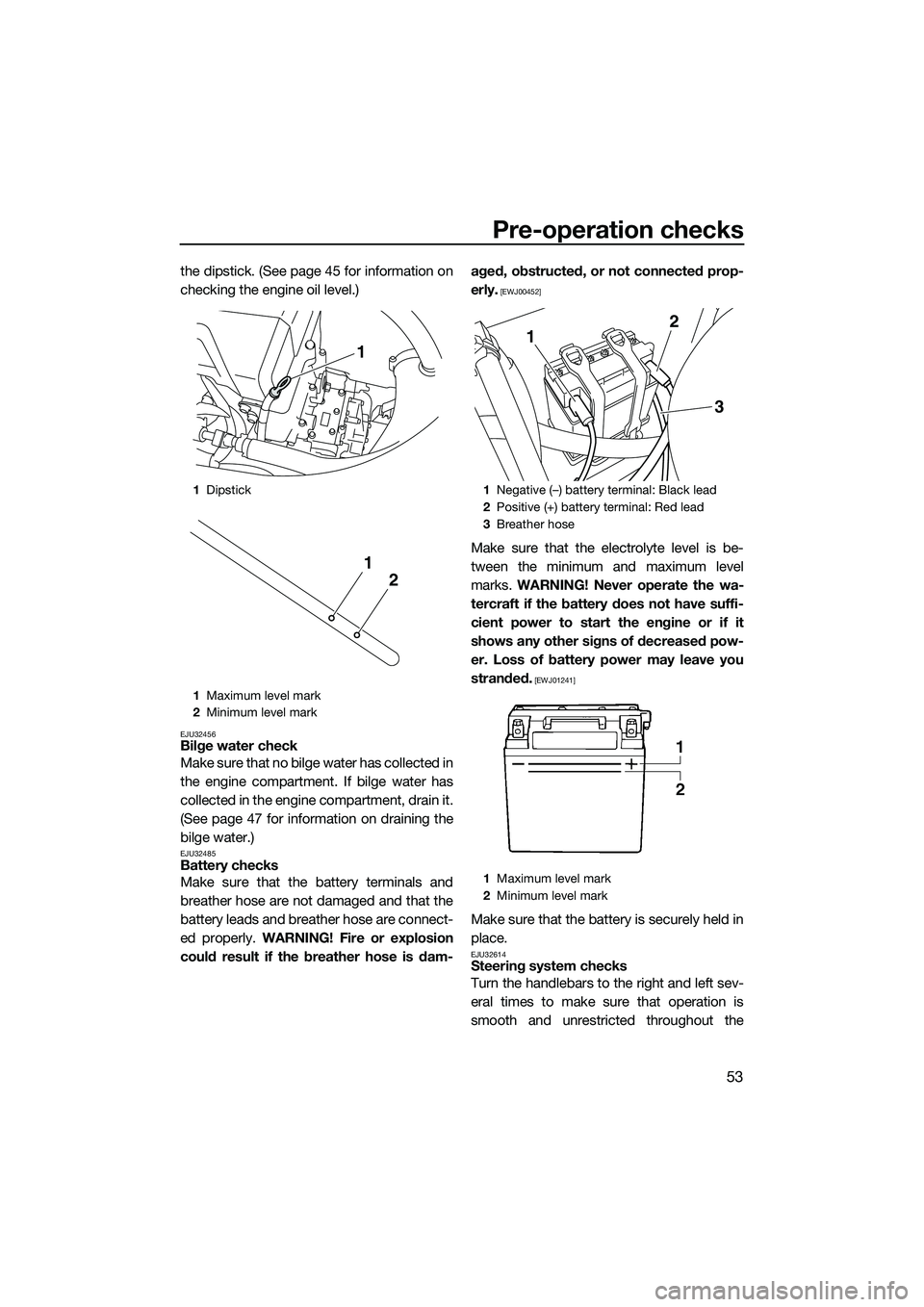

(3) Remove the dipstick and wipe it clean.

(4) Insert the dipstick back into the dipsticktube completely. Remove the dipstick

again and make sure that the engine oil

level is between the minimum and maxi-

mum level marks.

(5) If the engine oil level is significantly above the maximum level mark, consult

a Yamaha dealer. If the engine oil level is

below the minimum level mark, add en-

gine oil. (6) Loosen the engine oil filler cap and re-

move it.

(7) Slowly add engine oil.

TIP:

The difference between the minimum and

maximum level marks on the dipstick is equal

to approximately 1 L (1.06 US qt, 0.88 Imp.qt)

of engine oil.

(8) Wait approximately 5 minutes to allow the engine oil to settle, and then check

the engine oil level again.

(9) Repeat steps 3–8 until the engine oil is at the proper level.

(10) Securely install the engine oil filler cap by tightening it until it stops.

(11) Securely install the seat in its original po- sition.

1Dipstick

1 Maximum level mark

2 Minimum level mark

1

2

1

1Engine oil filler cap

1

UF2M73E0.book Page 46 Friday, August 2, 2013 11:28 AM

Page 55 of 98

First-time operation

49

EJU36666

Engine break-in

NOTICE

ECJ00432

Failure to perform the engine break-in

could result in reduced engine life or even

severe engine damage.

The engine break-in is essential to allow the

various components of the engine to wear

and polish themselves to the correct operat-

ing clearances. This ensures proper perfor-

mance and promotes longer component life.

To perform the engine break-in:

(1) Check the engine oil level. (See page 45for information on checking the engine

oil level.)

(2) Launch the watercraft and start the en- gine. (See page 60 for information on

starting the engine.)

(3) For the first 5 minutes, operate with the engine speed at 2000 r/min.

(4) For the next 30 minutes, operate with the engine speed below 5000 r/min.

(5) For the next 1 hour, operate with the en- gine speed below 6000 r/min.

After the engine break-in is complete, the wa-

tercraft can be operated normally.

UF2M73E0.book Page 49 Friday, August 2, 2013 11:28 AM

Page 56 of 98

Pre-operation checks

50

EJU31982

WARNING

EWJ00412

Failure to inspect or maintain the watercraft properly increases the possibility of an ac-

cident or damage to the watercraft. Do not operate the watercraft if you find any prob-

lem. If a problem cannot be corrected by the procedures provided in this manual, have

the watercraft inspected by a Yamaha dealer.

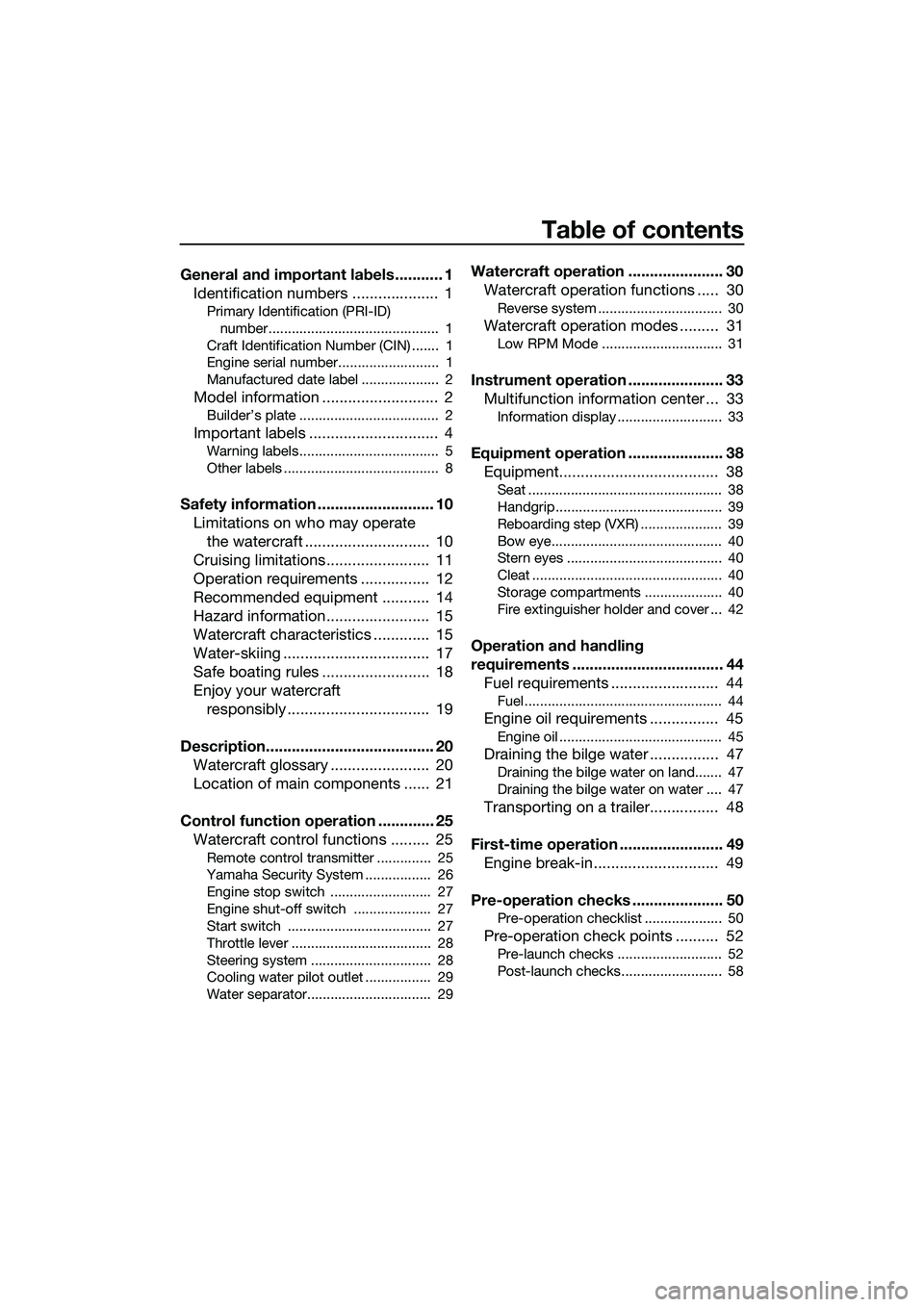

EJU41233Pre-operation checklist

Before using this watercraft, be sure to perform the checks in the following checklist.

ITEMROUTINEPAGE

PRE-LAUNCH CHECKS

Engine compartment Ventilate the engine compartment.

Check inside the engine compartment for damage.

52

Fuel system Check the fuel system for leakage.

Check the fuel level in the fuel tank.

52

Water separator Check the water separator for water. 52

Engine unit Check the exterior of the engine unit for damage. 52

Engine oil level Check the engine oil level. 52

Bilge water Check the engine compartment for bilge water. 53

Battery Check the battery connections and electrolyte level. 53

Steering system Check the steering system for proper operation. 53

Reverse system Check the reverse system for proper operation. 54

Throttle lever Check the throttle lever for proper operation.

Check the throttle lever free play.

55

Remote control transmitter Check the remote control transmitter for proper op-

eration.

55

Engine shut-off cord (lan-

yard) Check the engine shut-off cord (lanyard) for dam-

age.

55

Switches Check the start switch, engine stop switch, and en-

gine shut-off switch for proper operation.

56

Storage compartments Check the storage compartments for damage and

water.

56

Fire extinguisher holder,

cover, and band Check the fire extinguisher holder, cover, and band

for damage.

56

Fire extinguisher Check the condition of the fire extinguisher. 57

Safety equipment Check that safety equipment meeting the applica-

ble regulations is on board.

57

Hull and deck Check the hull and deck for damage. 57

Jet intake Check the jet intake for damage and clogging. 57

Stern drain plugs Check the stern drain plugs for damage and foreign

material and check that they are securely installed.

57

Hood Check that the hood is securely closed. 58

UF2M73E0.book Page 50 Friday, August 2, 2013 11:28 AM

Page 58 of 98

Pre-operation checks

52

EJU32282

Pre-operation check pointsEJU40546Pre-launch checks

Perform the pre-launch checks in the pre-op-

eration checklist while the watercraft is on

land.

To perform the pre-launch checks:

(1) Remove the seat. (See page 38 for seatremoval and installation procedures.)

(2) Perform the checks and make sure that there are no malfunctioning items or oth-

er problems.

(3) After completing these checks, securely install the seat in its original position.

EJU32334Engine compartment check

WARNING

EWJ00462

Failure to ventilate the engine compart-

ment could result in a fire or explosion. Do

not start the engine if there is a fuel leak.

Ventilate the engine compartment. Leave the

engine compartment open for a few minutes

to allow any fuel vapors to escape.

Make sure that there is no damage inside the

engine compartment.

EJU34215Fuel system checks

WARNING

EWJ00382

Leaking fuel can result in fire or explosion.

Check for fuel leakage regularly.

If any fuel leakage is found, the fuel sys-

tem must be repaired by a qualified me-

chanic. Improper repairs can make the

watercraft unsafe to operate.

Make sure that there is no damage, leakage,

or other problem in the fuel system.

Check:

Fuel filler cap and seal for damage

Fuel tank for damage and leakage

Fuel hoses and joints for damage and leak-

age

Fuel tank breather hose for damage and

leakage

EJU36875Fuel level check

Check the fuel level in the fuel tank.

Add fuel if necessary. (See page 44 for infor-

mation on filling the fuel tank.)

EJU32424Water separator check

Make sure that no water has collected in the

water separator. If water has collected in the

water separator, drain it. (See page 29 for in-

formation on draining the water separator.)

EJU40182Engine unit check

Check the exterior of the engine unit for dam-

age or other problem.

EJU36886Engine oil level check

Make sure that the engine oil level is between

the minimum and maxi mum level marks on

1Water separator

1

UF2M73E0.book Page 52 Friday, August 2, 2013 11:28 AM

Page 59 of 98

Pre-operation checks

53

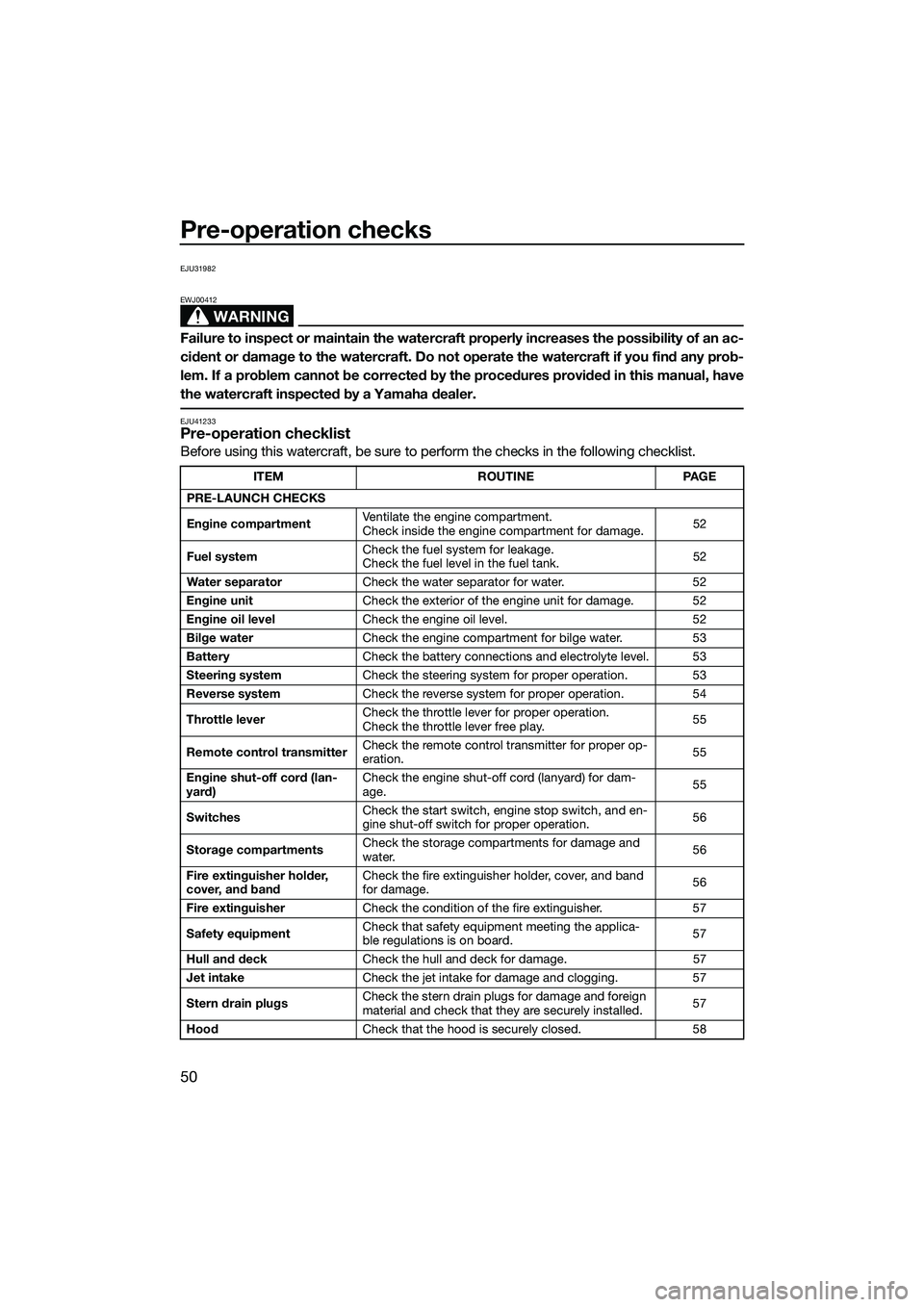

the dipstick. (See page 45 for information on

checking the engine oil level.)

EJU32456Bilge water check

Make sure that no bilge water has collected in

the engine compartment. If bilge water has

collected in the engine compartment, drain it.

(See page 47 for information on draining the

bilge water.)

EJU32485Battery checks

Make sure that the battery terminals and

breather hose are not damaged and that the

battery leads and breather hose are connect-

ed properly. WARNING! Fire or explosion

could result if the breather hose is dam- aged, obstructed, or not connected prop-

erly.

[EWJ00452]

Make sure that the electrolyte level is be-

tween the minimum and maximum level

marks.

WARNING! Never operate the wa-

tercraft if the battery does not have suffi-

cient power to start the engine or if it

shows any other signs of decreased pow-

er. Loss of battery power may leave you

stranded.

[EWJ01241]

Make sure that the battery is securely held in

place.

EJU32614Steering system checks

Turn the handlebars to the right and left sev-

eral times to make sure that operation is

smooth and unrestricted throughout the

1 Dipstick

1 Maximum level mark

2 Minimum level mark

1

2

1

1Negative (–) battery terminal: Black lead

2 Positive (+) battery terminal: Red lead

3 Breather hose

1 Maximum level mark

2 Minimum level mark

1 2

3

UF2M73E0.book Page 53 Friday, August 2, 2013 11:28 AM

Page 78 of 98

Care and storage

72

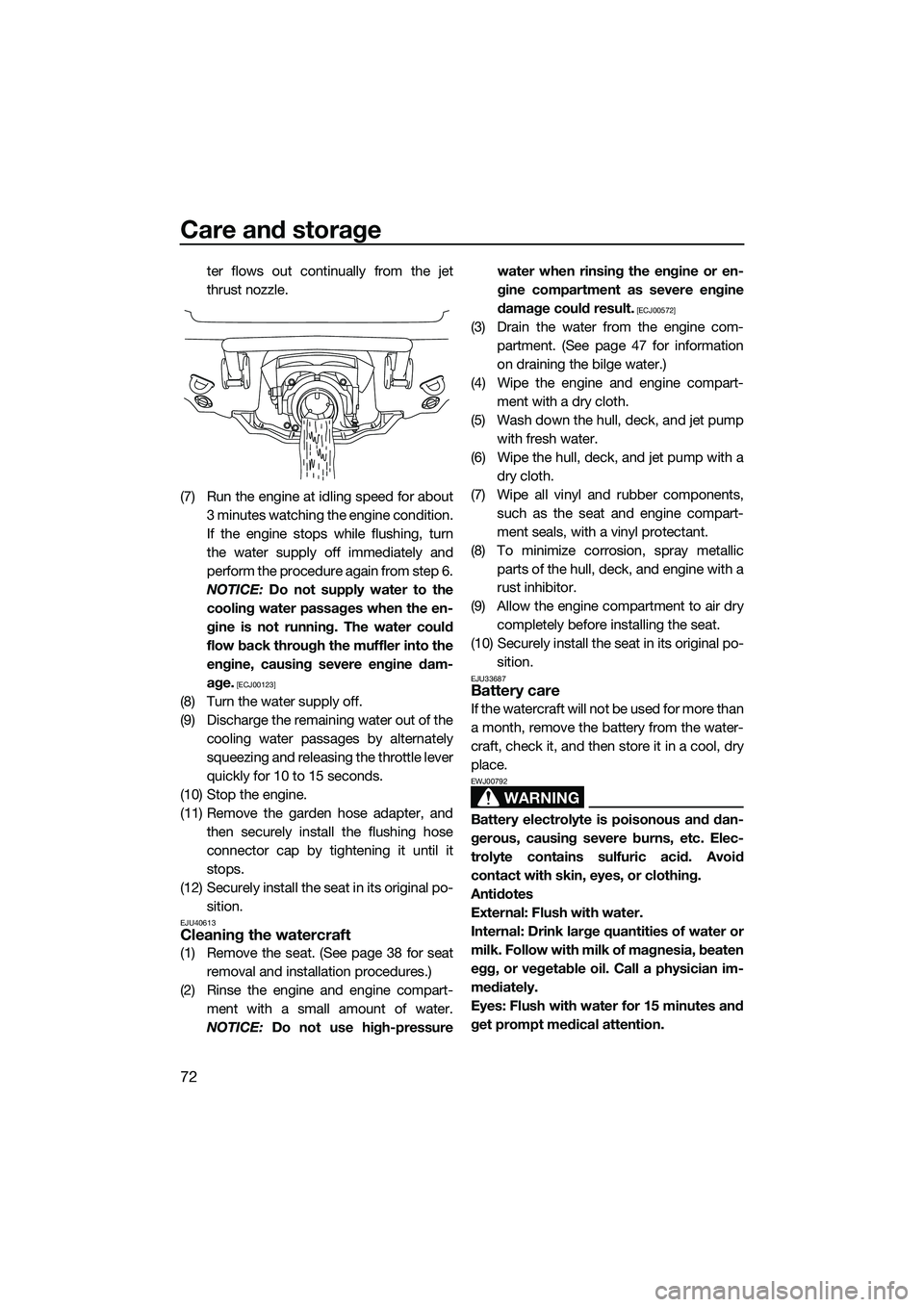

ter flows out continually from the jet

thrust nozzle.

(7) Run the engine at idling speed for about 3 minutes watching the engine condition.

If the engine stops while flushing, turn

the water supply off immediately and

perform the procedure again from step 6.

NOTICE: Do not supply water to the

cooling water passages when the en-

gine is not running. The water could

flow back through the muffler into the

engine, causing severe engine dam-

age.

[ECJ00123]

(8) Turn the water supply off.

(9) Discharge the remaining water out of the cooling water passages by alternately

squeezing and releasing the throttle lever

quickly for 10 to 15 seconds.

(10) Stop the engine.

(11) Remove the garden hose adapter, and then securely install the flushing hose

connector cap by tightening it until it

stops.

(12) Securely install the seat in its original po- sition.

EJU40613Cleaning the watercraft

(1) Remove the seat. (See page 38 for seatremoval and installation procedures.)

(2) Rinse the engine and engine compart- ment with a small amount of water.

NOTICE: Do not use high-pressure water when rinsing the engine or en-

gine compartment as severe engine

damage could result.

[ECJ00572]

(3) Drain the water from the engine com-

partment. (See page 47 for information

on draining the bilge water.)

(4) Wipe the engine and engine compart- ment with a dry cloth.

(5) Wash down the hull, deck, and jet pump with fresh water.

(6) Wipe the hull, deck, and jet pump with a dry cloth.

(7) Wipe all vinyl and rubber components, such as the seat and engine compart-

ment seals, with a vinyl protectant.

(8) To minimize corrosion, spray metallic parts of the hull, deck, and engine with a

rust inhibitor.

(9) Allow the engine compartment to air dry completely before installing the seat.

(10) Securely install the seat in its original po- sition.

EJU33687Battery care

If the watercraft will not be used for more than

a month, remove the battery from the water-

craft, check it, and then store it in a cool, dry

place.

WARNING

EWJ00792

Battery electrolyte is poisonous and dan-

gerous, causing severe burns, etc. Elec-

trolyte contains sulfuric acid. Avoid

contact with skin, eyes, or clothing.

Antidotes

External: Flush with water.

Internal: Drink large quantities of water or

milk. Follow with milk of magnesia, beaten

egg, or vegetable oil. Call a physician im-

mediately.

Eyes: Flush with water for 15 minutes and

get prompt medical attention.

UF2M73E0.book Page 72 Friday, August 2, 2013 11:28 AM