torque YAMAHA WHY 50 2003 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2003, Model line: WHY 50, Model: YAMAHA WHY 50 2003Pages: 80, PDF Size: 1.18 MB

Page 43 of 80

PERIODIC MAINTENANCE AND MINOR REPAIR

6 If the spark plug shows signs of

electrode erosion and excessive

carbon or other deposits, it should be

replaced.

Specified spark plug:

BR8HS (NGK)

Before installing a spark plug, the spark

plug gap should be measured with a

wire thickness gauge and, if necessary,

adjusted to specification.

Spark plug gap:

0.6 — 0.7 mmClean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

Tightening torque:

Spark plug:

23 Nm (2.3 m

•kg)

NOTE :

If a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4 — 1/2 turn

past finger tight. However, the spark

plug should be tightened to the

specified torque as soon as possible.

a

ZAUM0037

a Spark plug gap

EAU04228

Final transmission oil

The final transmission case must be

checked for oil leakage before each

ride. If any leakage is found, have a

Yamaha dealer check and repair the

scooter. In addition, the final transmis-

sion oil must be changed as follows at

the intervals specified in the periodic

maintenance and lubrication chart.

1. Start the engine, warm it up by

riding the scooter for several mi-

nutes, and then stop the engine.

2. Place the scooter on the

centerstand.

3. Place an oil pan under the final

transmission case to collect the

used oil.

6-6

Page 44 of 80

PERIODIC MAINTENANCE AND MINOR REPAIR

64. Remove the oil filler cap and drain

bolt to drain the oil from the final

transmission case.

5. Install the final transmission oil

drain bolt, and then tighten it to

the specified torque.

Tightening torque:

Final transmission oil drain bolt:

17 Nm (1.7 m

•kg)

6. Add the specified amount of the

recommended final transmission

oil, and then install and tighten the

oil filler cap.Recommended final transmission oil:

See page 8-1.

Oil quantity:

0.11 L

EWA00062

•Make sure that no foreign

material enters the final trans-

mission case.

•Make sure that no oil gets on

the tire or wheel.

7. Check the final transmission case

for oil leakage. If oil is leaking,

check for the cause.

1

2

ZAUM0371

1. Oil filler cap

2. Oil drain bolt

EAUM0071

Cleaning the air filter element

The air filter element should be cleaned

at the intervals specified in the periodic

maintenance and lubrication chart.

Clean the air filter element more

frequently if you are riding in unusually

wet or dusty areas.

1. Remove the air filter case cover

by removing the screws.

1

ZAUM0372

1. Screws

6-7

Page 71 of 80

SPECIFICATIONS

8

EAU04513

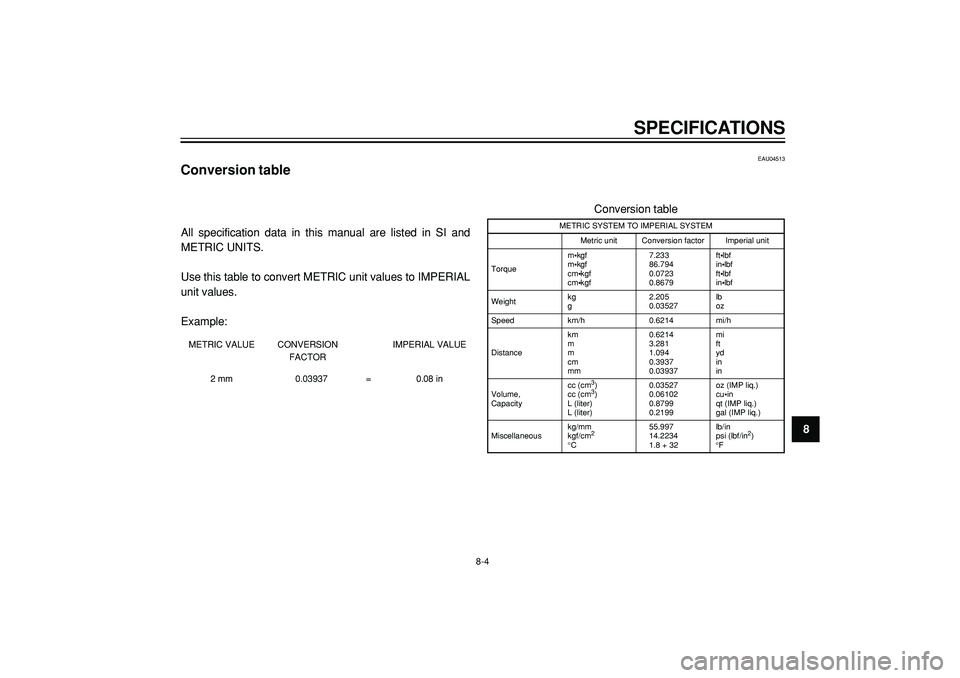

Conversion table

All specification data in this manual are listed in SI and

METRIC UNITS.

Use this table to convert METRIC unit values to IMPERIAL

unit values.

Example:

METRIC VALUE CONVERSION

FACTORIMPERIAL VALUE

2 mm 0.03937 = 0.08 in

Conversion table

METRIC SYSTEM TO IMPERIAL SYSTEM

Metric unit Conversion factor Imperial unit

Torquem•kgf

m•kgf

cm•kgf

cm•kgf

7.233 86.794 0.0723 0.8679ft•lbf

in•lbf

ft•lbf

in•lbf

Weightkg

g

2.205 0.03527lb

oz

Speed km/h

0.6214 mi/h

Distancekm

m

m

cm

mm

0.6214 3.281 1.094 0.3937 0.03937mi

ft

yd

in

in

Volume,

Capacitycc (cm3)

cc (cm3)

L (liter)

L (liter) 0.03527 0.06102 0.8799 0.2199oz (IMP liq.)

cu•in

qt (IMP liq.)

gal (IMP liq.)

Miscellaneouskg/mm

kgf/cm

2

°C

55.997 14.2234 1.8 + 32 lb/in

psi (lbf/in

2)

°F

8-4