recommended oil YAMAHA WHY 50 2006 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: WHY 50, Model: YAMAHA WHY 50 2006Pages: 80, PDF Size: 1.18 MB

Page 23 of 80

INSTRUMENT AND CONTROL FUNCTIONS

3

2-stroke engine oil tank cap

To remove the 2-stroke engine oil tank

cap, pull it off.

To install the 2-stroke engine oil tank

cap, push it into the oil tank opening.

EW000025

Make sure that the fuel and 2-stroke

engine oil tank caps are properly

installed before riding the scooter.

ZAUM0204

1

2

ZAUM0020

1. Filler tube

2. Fuel level

EAU03753

Fuel

Make sure that there is sufficient fuel

in the tank. Fill the fuel tank to the

bottom of the filler tube as shown.

EW000130

•Do not overfill the fuel tank,

otherwise it may overflow when

the fuel warms up and expands.

•Avoid spilling fuel on the hot

engine.

EAU00185

EC000008

Immediately wipe off spilled fuel with

a clean, dry, soft cloth, since fuel may

deteriorate painted surfaces or plas-

tic parts.

EAU04206

Recommended fuel:

REGULAR UNLEADED

GASOLINE ONLY

Fuel tank capacity:

Total amount:

7.2 L

Your Yamaha engine has been

designed to use regular unleaded

gasoline with a research octane

number of 91 or higher. If knocking (or

pinging) occurs, use a gasoline of a

different brand or premium unleaded

fuel. Use of unleaded fuel will extend

spark plug life and reduce maintenance

costs.

3-6

Page 24 of 80

3

INSTRUMENT AND CONTROL FUNCTIONS

EAU03098

Catalytic converter

This scooter is equipped with a catalytic

converter in the muffler.

EW000128

The exhaust system is hot after

operation. Make sure that the

exhaust system has cooled down

before doing any maintenance work.

EC000114

The following precautions must be

observed to prevent a fire hazard or

other damages.

•Use only unleaded gasoline.

The use of leaded gasoline will

cause unrepairable damage to

the catalytic converter.

•Never park the scooter near

possible fire hazards such as

grass or other materials that

easily burn.

•Do not allow the engine to idle

too long.

EAU03750

2-stroke engine oil

Make sure that there is sufficient oil in

the 2-stroke engine oil tank. Add the

recommended 2-stroke engine oil if

necessary.

NOTE :

Make sure that the 2-stroke engine oil

tank cap is properly installed.

Recommended oil:

Yamalube 2 or equivalent

2-stroke engine oil

(JASO grade "FC",

or ISO grades "EG-C" or "EG-D")

Oil quantity:

1.3 L

EAUS0015

Kickstarter

To start the engine, push the kickstarter

down lightly with your foot until the

gears engage, and then push it down

smoothly but forcefully.

1

ZAUM0362

1. Kickstarter

3-7

Page 28 of 80

PRE-OPERATION CHECKS

4

•Check fuel level in fuel tank.

Fuel•Refuel if necessary. 3-5 — 3-6

•Check fuel line for leakage.

•Check oil level in oil tank.

2-stroke engine oil•If necessary, add recommended oil to specified level. 3-5 — 3-7

•Check vehicle for oil leakage.

Final transmission oil•Check vehicle for oil leakage. 6-6

•Check operation.

•If soft or spongy, have Yamaha dealer bleed hydraulic system.

Front brake•Check fluid level in reservoir. 3-5, 6-13 — 6-15

•If necessary, add recommended brake fluid to specified level.

•Check hydraulic system for leakage.

•Check operation.

Rear brake•Check pedal free play. 3-5, 6-13 — 6-15

•Adjust if necessary.

•Make sure that operation is smooth.

Throttle grip•Check cable free play.

6-9, 6-15

•If necessary, have Yamaha dealer adjust cable free play

and lubricate cable and grip housing.

The condition of a vehicle is the owner’s responsibility. Vital components can start to deteriorate quickly and unexpectedly,

even if the vehicle remains unused (for example, as a result of exposure to the elements). Any damage, fluid leakage or

loss of tire air pressure could have serious consequences. Therefore, it is very important, in addition to a thorough visual

inspection, to check the following points before each ride.

EAU03439

Pre-operation check list

ITEM CHECKS PAGE

4-1

Page 44 of 80

PERIODIC MAINTENANCE AND MINOR REPAIR

64. Remove the oil filler cap and drain

bolt to drain the oil from the final

transmission case.

5. Install the final transmission oil

drain bolt, and then tighten it to

the specified torque.

Tightening torque:

Final transmission oil drain bolt:

17 Nm (1.7 m

•kg)

6. Add the specified amount of the

recommended final transmission

oil, and then install and tighten the

oil filler cap.Recommended final transmission oil:

See page 8-1.

Oil quantity:

0.11 L

EWA00062

•Make sure that no foreign

material enters the final trans-

mission case.

•Make sure that no oil gets on

the tire or wheel.

7. Check the final transmission case

for oil leakage. If oil is leaking,

check for the cause.

1

2

ZAUM0371

1. Oil filler cap

2. Oil drain bolt

EAUM0071

Cleaning the air filter element

The air filter element should be cleaned

at the intervals specified in the periodic

maintenance and lubrication chart.

Clean the air filter element more

frequently if you are riding in unusually

wet or dusty areas.

1. Remove the air filter case cover

by removing the screws.

1

ZAUM0372

1. Screws

6-7

Page 45 of 80

PERIODIC MAINTENANCE AND MINOR REPAIR

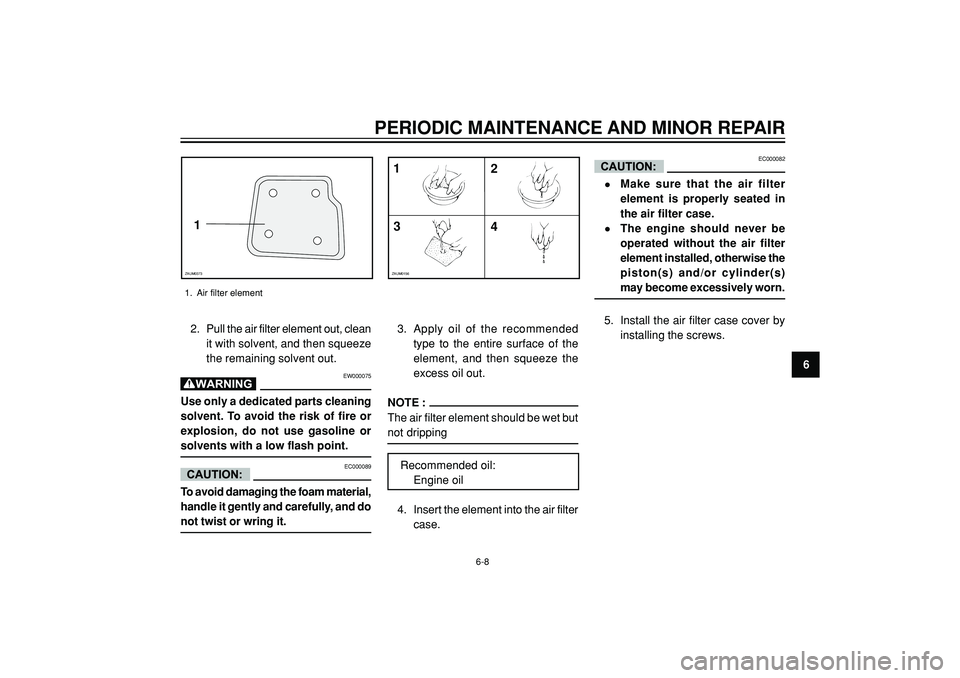

6 2. Pull the air filter element out, clean

it with solvent, and then squeeze

the remaining solvent out.EW000075

Use only a dedicated parts cleaning

solvent. To avoid the risk of fire or

explosion, do not use gasoline or

solvents with a low flash point.

EC000089

To avoid damaging the foam material,

handle it gently and carefully, and do

not twist or wring it.

1

ZAUM0373

1

4 32

ZAUM0156

3. Apply oil of the recommended

type to the entire surface of the

element, and then squeeze the

excess oil out.

NOTE :

The air filter element should be wet but

not dripping

Recommended oil:

Engine oil

4. Insert the element into the air filter

case.

1. Air filter element

EC000082

•Make sure that the air filter

element is properly seated in

the air filter case.

•The engine should never be

operated without the air filter

element installed, otherwise the

piston(s) and/or cylinder(s)

may become excessively worn.

5. Install the air filter case cover by

installing the screws.

6-8

Page 51 of 80

PERIODIC MAINTENANCE AND MINOR REPAIR

6

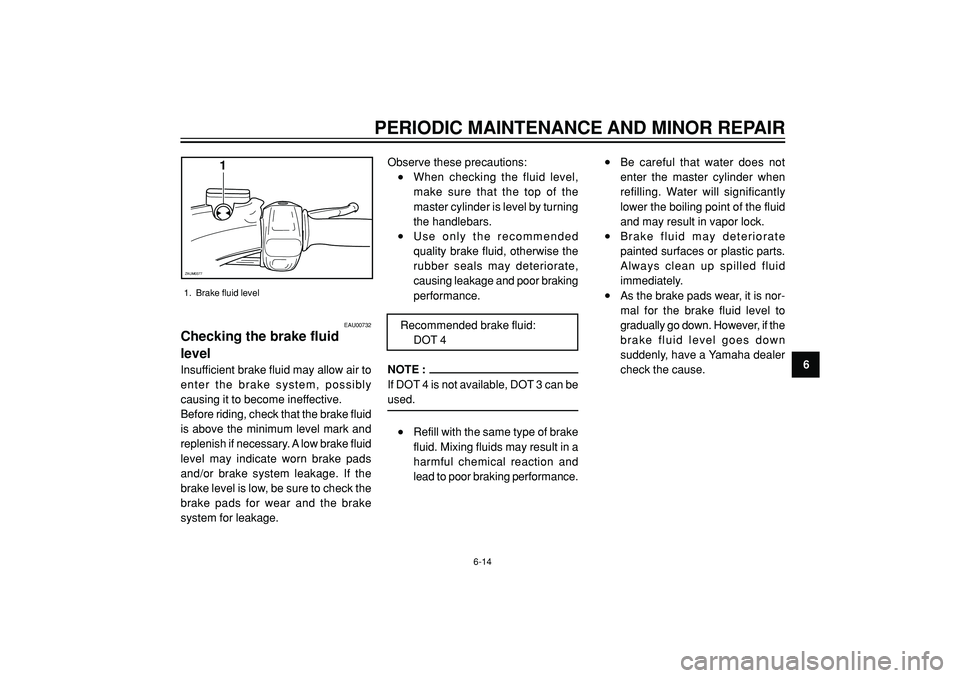

EAU00732

Checking the brake fluid

level

Insufficient brake fluid may allow air to

enter the brake system, possibly

causing it to become ineffective.

Before riding, check that the brake fluid

is above the minimum level mark and

replenish if necessary. A low brake fluid

level may indicate worn brake pads

and/or brake system leakage. If the

brake level is low, be sure to check the

brake pads for wear and the brake

system for leakage.Observe these precautions:

•When checking the fluid level,

make sure that the top of the

master cylinder is level by turning

the handlebars.

•Use only the recommended

quality brake fluid, otherwise the

rubber seals may deteriorate,

causing leakage and poor braking

performance.

Recommended brake fluid:

DOT 4

NOTE :

If DOT 4 is not available, DOT 3 can be

used.

•Refill with the same type of brake

fluid. Mixing fluids may result in a

harmful chemical reaction and

lead to poor braking performance.

•Be careful that water does not

enter the master cylinder when

refilling. Water will significantly

lower the boiling point of the fluid

and may result in vapor lock.

•Brake fluid may deteriorate

painted surfaces or plastic parts.

Always clean up spilled fluid

immediately.

•As the brake pads wear, it is nor-

mal for the brake fluid level to

gradually go down. However, if the

brake fluid level goes down

suddenly, have a Yamaha dealer

check the cause.

1

ZAUM0377

1. Brake fluid level

6-14

Page 53 of 80

PERIODIC MAINTENANCE AND MINOR REPAIR

6 To check the operation

1. Place the scooter on a level sur-

face and hold it in an upright po-

sition.

2. While applying the front brake,

push down hard on the

handlebars several times to check

if the front fork compresses and

rebounds smoothly.

EC000098

If any damage is found or the front

fork does not operate smoothly, have

a Yamaha dealer check or repair it.

6-16

EAU02939

Checking the front fork

The condition and operation of the front

fork must be checked as follows at the

intervals specified in the periodic main-

tenance and lubrication chart.

To check the condition

EW000115

Securely support the scooter so that

there is no danger of it falling over.

Check the inner tubes for scratches,

damage and excessive oil leakage.

ZAUM0378

EAU04123

Checking and lubricating the

centerstand

The operation of the centerstand should

be checked before each ride, and the

pivots and metal-to-metal contact sur-

faces should be lubricated if necessary.

EWA00055

If the centerstand does not move up

and down smoothly, have a Yamaha

dealer check or repair it.

Recommended lubricant:

Lithium-soap-based grease

(all-purpose grease)

ZAUM0062

Page 63 of 80

SCOOTER CARE AND STORAGE

7

•For scooters equipped with a

windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or

scratching. Some cleaning

compounds for plastic may

leave scratches on the

windshield. Test the product on

a small hidden part of the

windshield to make sure that it

does not leave any marks. If the

windshield is scratched, use a

quality plastic polishing

compound after washing.

After normal use

Remove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottlebrush

for hard-to-reach areas. Stubborn dirt

and insects will come off more easily if

the area is covered with a wet cloth for

a few minutes before cleaning.

After riding in the rain, near the sea

or on salt-sprayed roads

Since sea salt or salt sprayed on the

roads during winter are extremely cor-

rosive in combination with water, carry

out the following steps after each ride

in the rain, near the sea or on salt-

sprayed roads.

NOTE :

Salt sprayed on roads in the winter may

remain well into spring.

1. Clean the scooter with cold water

and a mild detergent after the

engine has cooled down.

ECA00012

Do not use warm water since it

increases the corrosive action of the

salt.

2. Apply a corrosion protection spray

on all metal, including chrome-

and nickel-plated, surfaces to

prevent corrosion.After cleaning

1. Dry the scooter with a chamois or

an absorbing cloth.

2. Use a chrome polish to shine

chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally

induced discoloring of stainless-

steel exhaust systems can be

removed through polishing.)

3. To prevent corrosion, it is

recommended to apply a corro-

sion protection spray on all metal,

including chrome- and nickel-

plated, surfaces.

4. Use spray oil as a universal

cleaner to remove any remaining

dirt.

5. Touch up minor paint damage

caused by stones, etc.

6. Wax all painted surfaces.

7. Let the scooter dry completely

before storing or covering it.

7-2

Page 68 of 80

SPECIFICATIONS

8

Model YH50

Dimensions:

Overall length 1.940 mm

Overall width 685 mm

Overall height 1.105 mm

Seat height 765 mm

Wheelbase 1.294 mm

Minimum ground clearance 125 mm

Minimum turning radius 1.800 mm

Weight:

Wet (with oil and a full fuel tank) 78 kg

Engine:

Engine type Air cooled, 2 strokes

Cylinder arrangement Single cylinder, horizontal

Displacement 49.2 cm3

Bore x stroke 40.0 x 39.2

Compression ratio 7.25:1

Starting system type Electric and kick starter

Lubrication system Separate lubrication

(Autolube)

Engine oil:

Type Yamalube 2

or 2 strokes engine oil

Classification Jaso FC ou ISO EG-C, EG-D

Capacity 1.3 LTransmission oil:

Type SAE 10W30 type SE

Capacity

Périodic oil change 0.11L

Total amount 0.13L

Air filter type:Wet type element

Fuel:

Recommended fuel Regular unleaded gasoline

(RON 91 mini)

Fuel tank capacity 7L

Carburetor:

Type / quantity PY-12

Manufacturer GURTNER

Spark plug:

Type / Manufacturer BR8HS / NGK

Spark plug gap 0.6—0.7 mm

Clutch type:Dry, centrifugal automatic

Transmission:

Primary reduction system Helical gear

Primary reduction ratio 52/13 (4.000)

Secondary reduction system Spur gear

Secondary reduction ratio 45/12 (3.750)

Transmission type V-belt automatic

Operation Centrifugal automatic type

8-1

Specifications