torque YAMAHA WOLVERINE 2015 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2015, Model line: WOLVERINE, Model: YAMAHA WOLVERINE 2015Pages: 186, PDF Size: 4.22 MB

Page 135 of 186

8-23

8

Changing the differential gear oil1. Park the vehicle on a level surface.

2. Place an oil pan under the differential

gear case to collect the used oil.

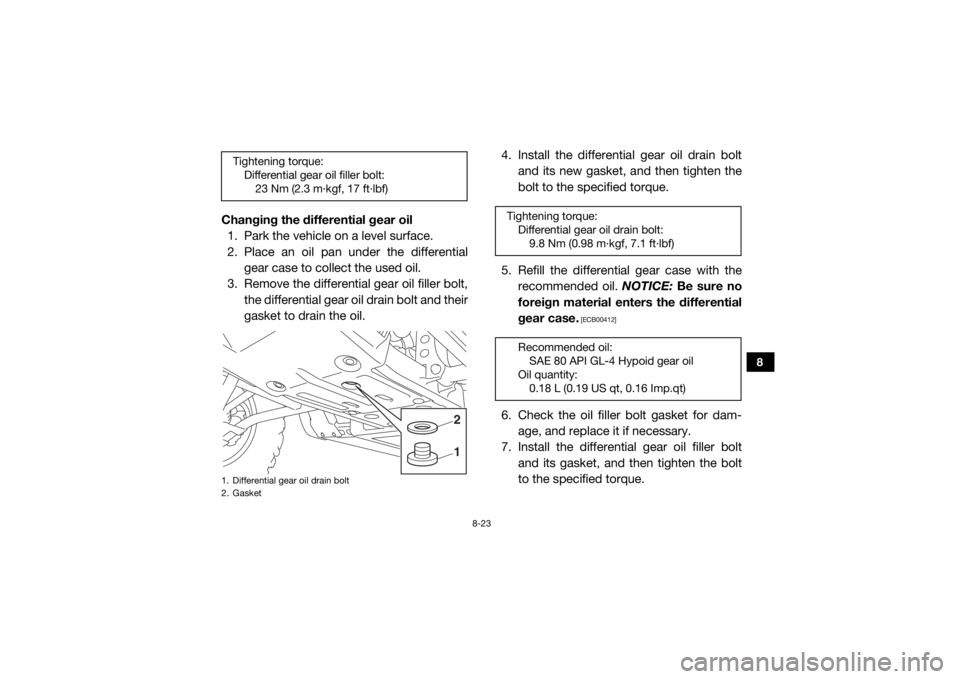

3. Remove the differential gear oil filler bolt,

the differential gear oil drain bolt and their

gasket to drain the oil. 4. Install the differential gear oil drain bolt

and its new gasket, and then tighten the

bolt to the specified torque.

5. Refill the differential gear case with the recommended oil. NOTICE: Be sure no

foreign material enters the differential

gear case.

[ECB00412]

6. Check the oil filler bolt gasket for dam- age, and replace it if necessary.

7. Install the differential gear oil filler bolt and its gasket, and then tighten the bolt

to the specified torque.

Tightening torque:Differential gear oil filler bolt:23 Nm (2.3 m·kgf, 17 ft·lbf)1. Differential gear oil drain bolt

2. Gasket

12

Tightening torque: Differential gear oil drain bolt:9.8 Nm (0.98 m·kgf, 7.1 ft·lbf)

Recommended oil: SAE 80 API GL-4 Hypoid gear oil

Oil quantity: 0.18 L (0.19 US qt, 0.16 Imp.qt)

U2MB7AE0.book Page 23 Thursday, January 29, 2015 3:42 PM

Page 136 of 186

8-24

8

8. Check for oil leakage. If oil leakage isfound, check for the cause.EBU33660CoolantThe coolant level should be checked before

each ride. In addition, the coolant must be

changed at the intervals specified in the peri-

odic maintenance and lubrication chart.

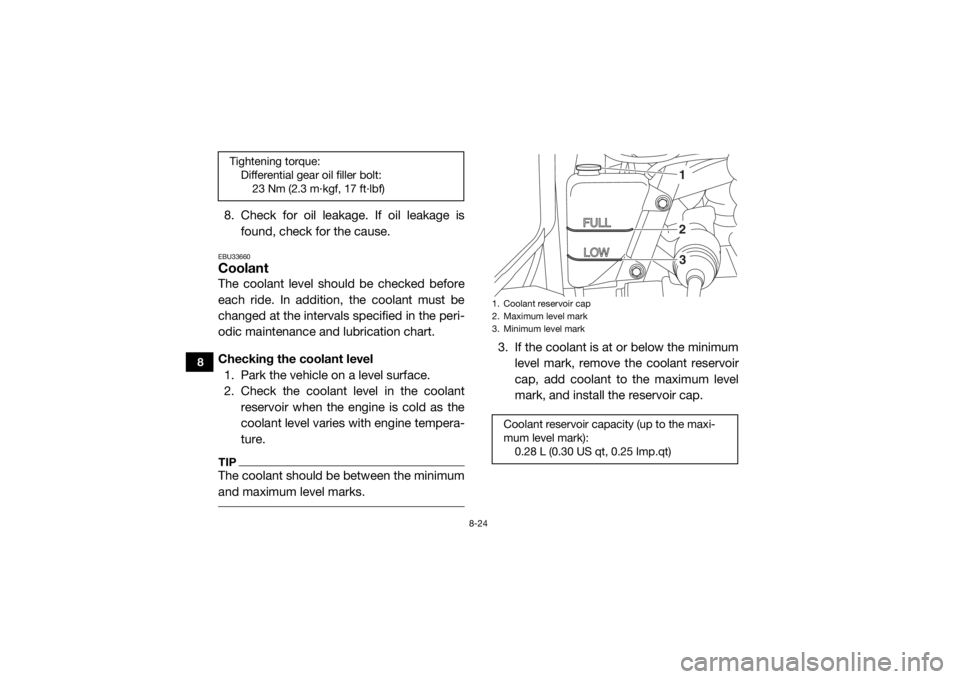

Checking the coolant level1. Park the vehicle on a level surface.

2. Check the coolant level in the coolant reservoir when the engine is cold as the

coolant level varies with engine tempera-

ture.TIPThe coolant should be between the minimum

and maximum level marks.

3. If the coolant is at or below the minimum

level mark, remove the coolant reservoir

cap, add coolant to the maximum level

mark, and install the reservoir cap.

Tightening torque:Differential gear oil filler bolt:23 Nm (2.3 m·kgf, 17 ft·lbf)

1. Coolant reservoir cap

2. Maximum level mark

3. Minimum level markCoolant reservoir capacity (up to the maxi-

mum level mark):0.28 L (0.30 US qt, 0.25 Imp.qt)

123

U2MB7AE0.book Page 24 Thursday, January 29, 2015 3:42 PM

Page 138 of 186

8-26

8

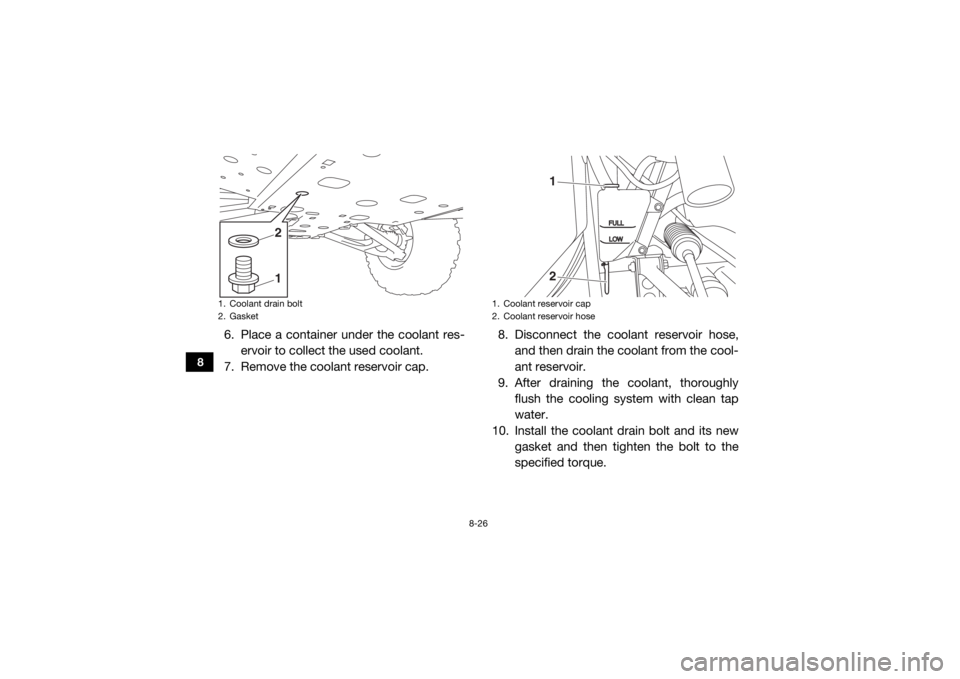

6. Place a container under the coolant res-ervoir to collect the used coolant.

7. Remove the coolant reservoir cap. 8. Disconnect the coolant reservoir hose,

and then drain the coolant from the cool-

ant reservoir.

9. After draining the coolant, thoroughly flush the cooling system with clean tap

water.

10. Install the coolant drain bolt and its new gasket and then tighten the bolt to the

specified torque.1. Coolant drain bolt

2. Gasket

1 2

1. Coolant reservoir cap

2. Coolant reservoir hose

12

U2MB7AE0.book Page 26 Thursday, January 29, 2015 3:42 PM

Page 139 of 186

8-27

8

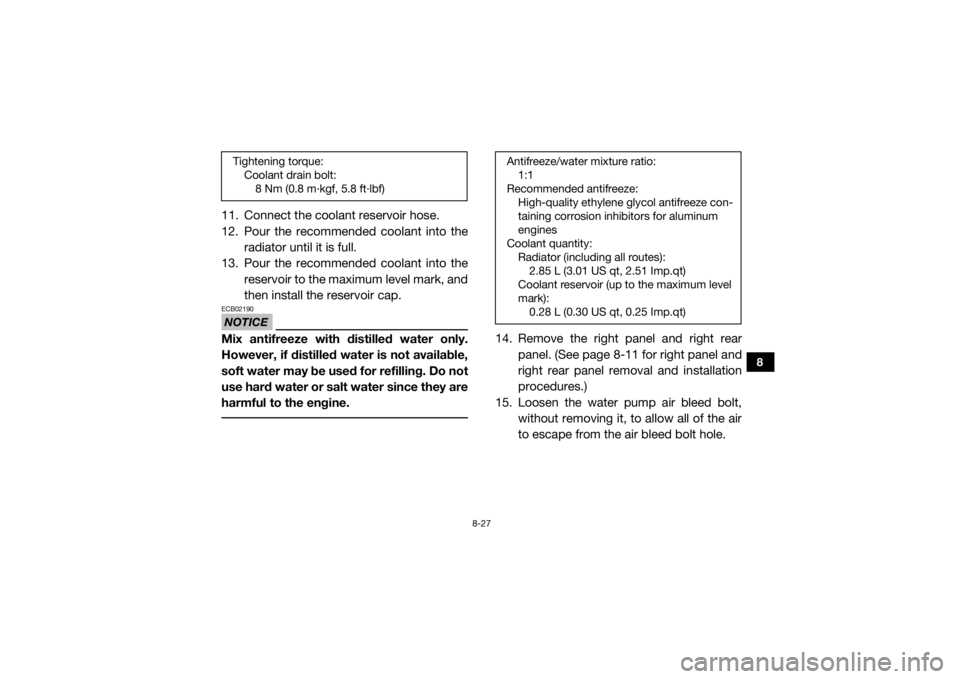

11. Connect the coolant reservoir hose.

12. Pour the recommended coolant into theradiator until it is full.

13. Pour the recommended coolant into the

reservoir to the maximum level mark, and

then install the reservoir cap.NOTICEECB02190Mix antifreeze with distilled water only.

However, if distilled water is not available,

soft water may be used for refilling. Do not

use hard water or salt water since they are

harmful to the engine.

14. Remove the right panel and right rearpanel. (See page 8-11 for right panel and

right rear panel removal and installation

procedures.)

15. Loosen the water pump air bleed bolt, without removing it, to allow all of the air

to escape from the air bleed bolt hole.

Tightening torque:Coolant drain bolt:8 Nm (0.8 m·kgf, 5.8 ft·lbf)

Antifreeze/water mixture ratio: 1:1

Recommended antifreeze: High-quality ethylene glycol antifreeze con-

taining corrosion inhibitors for aluminum

engines

Coolant quantity: Radiator (including all routes):2.85 L (3.01 US qt, 2.51 Imp.qt)

Coolant reservoir (up to the maximum level

mark): 0.28 L (0.30 US qt, 0.25 Imp.qt)

U2MB7AE0.book Page 27 Thursday, January 29, 2015 3:42 PM

Page 140 of 186

8-28

8

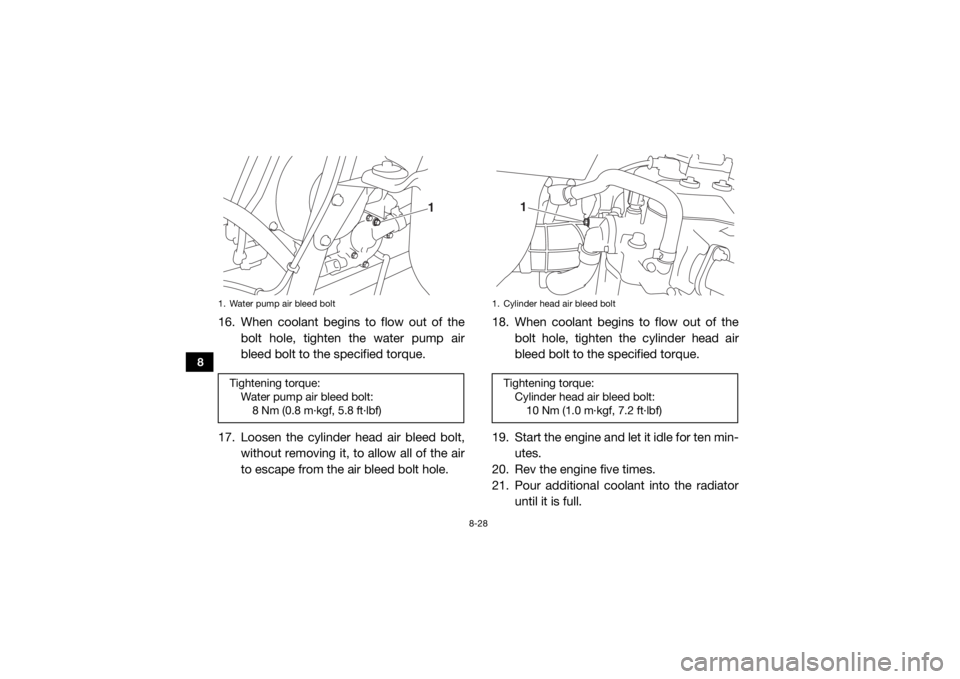

16. When coolant begins to flow out of thebolt hole, tighten the water pump air

bleed bolt to the specified torque.

17. Loosen the cylinder head air bleed bolt, without removing it, to allow all of the air

to escape from the air bleed bolt hole. 18. When coolant begins to flow out of the

bolt hole, tighten the cylinder head air

bleed bolt to the specified torque.

19. Start the engine and let it idle for ten min- utes.

20. Rev the engine five times.

21. Pour additional coolant into the radiator until it is full.1. Water pump air bleed boltTightening torque:Water pump air bleed bolt:8 Nm (0.8 m·kgf, 5.8 ft·lbf)

1

1. Cylinder head air bleed boltTightening torque:Cylinder head air bleed bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

1

U2MB7AE0.book Page 28 Thursday, January 29, 2015 3:42 PM

Page 143 of 186

8-31

8

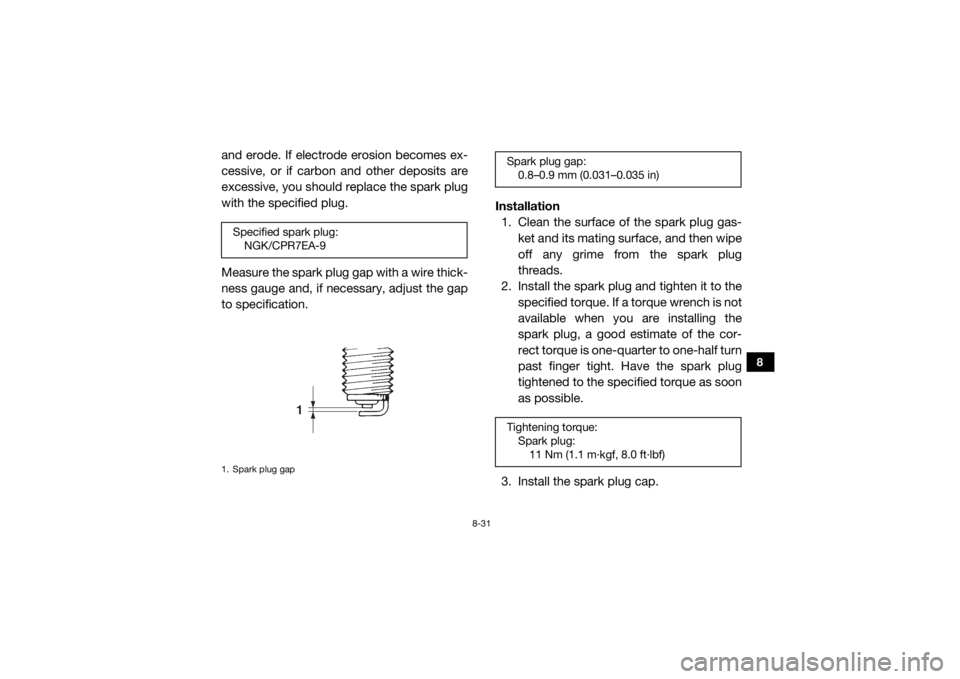

and erode. If electrode erosion becomes ex-

cessive, or if carbon and other deposits are

excessive, you should replace the spark plug

with the specified plug.

Measure the spark plug gap with a wire thick-

ness gauge and, if necessary, adjust the gap

to specification.Installation

1. Clean the surface of the spark plug gas-

ket and its mating surface, and then wipe

off any grime from the spark plug

threads.

2. Install the spark plug and tighten it to the specified torque. If a torque wrench is not

available when you are installing the

spark plug, a good estimate of the cor-

rect torque is one-quarter to one-half turn

past finger tight. Have the spark plug

tightened to the specified torque as soon

as possible.

3. Install the spark plug cap.Specified spark plug: NGK/CPR7EA-91. Spark plug gap

1

Spark plug gap:0.8–0.9 mm (0.031–0.035 in)

Tightening torque: Spark plug:11 Nm (1.1 m·kgf, 8.0 ft·lbf)

U2MB7AE0.book Page 31 Thursday, January 29, 2015 3:42 PM

Page 149 of 186

8-37

8

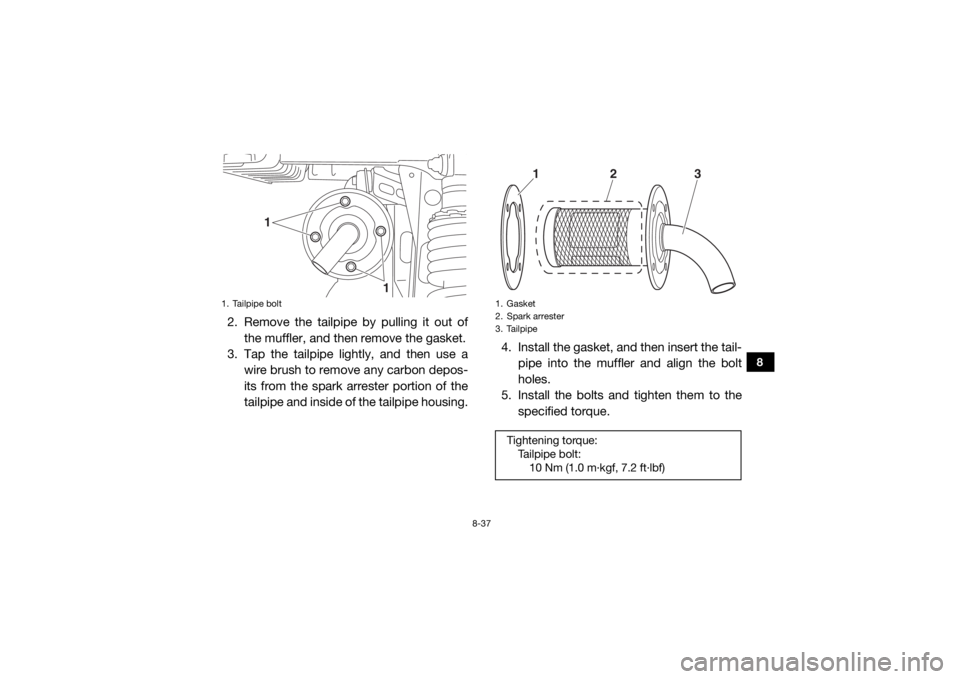

2. Remove the tailpipe by pulling it out ofthe muffler, and then remove the gasket.

3. Tap the tailpipe lightly, and then use a

wire brush to remove any carbon depos-

its from the spark arrester portion of the

tailpipe and inside of the tailpipe housing. 4. Install the gasket, and then insert the tail-

pipe into the muffler and align the bolt

holes.

5. Install the bolts and tighten them to the

specified torque.1. Tailpipe bolt

1

1

1. Gasket

2. Spark arrester

3. TailpipeTightening torque:Tailpipe bolt:10 Nm (1.0 m·kgf, 7.2 ft·lbf)

3

2

1

U2MB7AE0.book Page 37 Thursday, January 29, 2015 3:42 PM

Page 158 of 186

8-46

8

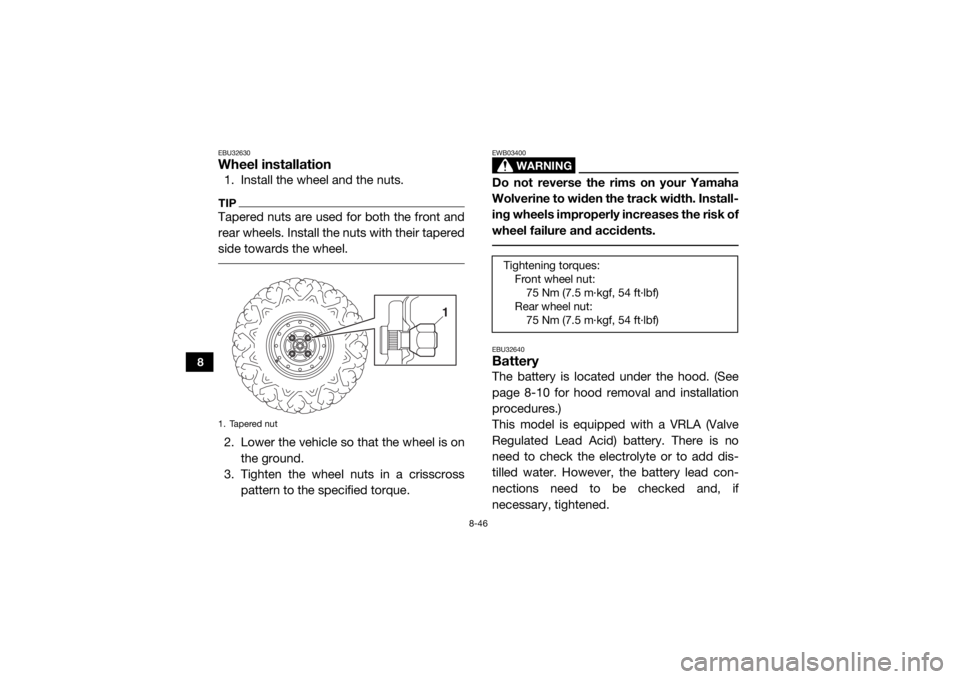

EBU32630Wheel installation1. Install the wheel and the nuts.TIPTapered nuts are used for both the front and

rear wheels. Install the nuts with their tapered

side towards the wheel. 2. Lower the vehicle so that the wheel is onthe ground.

3. Tighten the wheel nuts in a crisscross

pattern to the specified torque.

WARNING

EWB03400Do not reverse the rims on your Yamaha

Wolverine to widen the track width. Install-

ing wheels improperly increases the risk of

wheel failure and accidents. EBU32640BatteryThe battery is located under the hood. (See

page 8-10 for hood removal and installation

procedures.)

This model is equipped with a VRLA (Valve

Regulated Lead Acid) battery. There is no

need to check the electrolyte or to add dis-

tilled water. However, the battery lead con-

nections need to be checked and, if

necessary, tightened.

1. Tapered nut

1

Tightening torques: Front wheel nut:75 Nm (7.5 m·kgf, 54 ft·lbf)

Rear wheel nut: 75 Nm (7.5 m·kgf, 54 ft·lbf)

U2MB7AE0.book Page 46 Thursday, January 29, 2015 3:42 PM