oil level YAMAHA WOLVERINE 2017 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: WOLVERINE, Model: YAMAHA WOLVERINE 2017Pages: 186, PDF Size: 4.22 MB

Page 134 of 186

8-22

8

6. Check the oil filler bolt gasket for dam-age, and replace it if necessary.

7. Install the oil filler bolt and its gasket, and then tighten the bolt to the specified

torque.

8. Check for oil leakage. If oil leakage is found, check for the cause.EBU36060Differential gear oilCheck the oil level and change the differential

gear oil at the intervals specified in the gener-

al maintenance and lubrication chart.

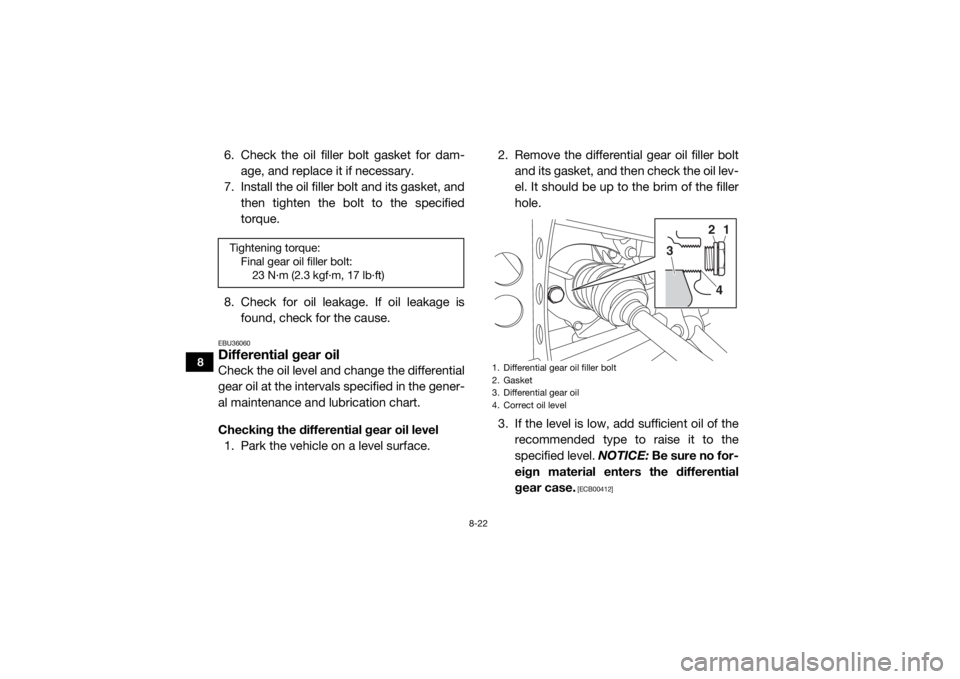

Checking the differential gear oil level

1. Park the vehicle on a level surface. 2. Remove the differential gear oil filler bolt

and its gasket, and then check the oil lev-

el. It should be up to the brim of the filler

hole.

3. If the level is low, add sufficient oil of the recommended type to raise it to the

specified level. NOTICE: Be sure no for-

eign material enters the differential

gear case.

[ECB00412]

Tightening torque: Final gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)

1. Differential gear oil filler bolt

2. Gasket

3. Differential gear oil

4. Correct oil level

1

2

3

4

U2MB7BE0.book Page 22 Thursday, March 3, 2016 11:46 AM

Page 135 of 186

8-23

8

4. Check the gasket for damage, and re-place it if necessary.

5. Install the differential gear oil filler bolt and its gasket, and then tighten the bolt

to the specified torque.

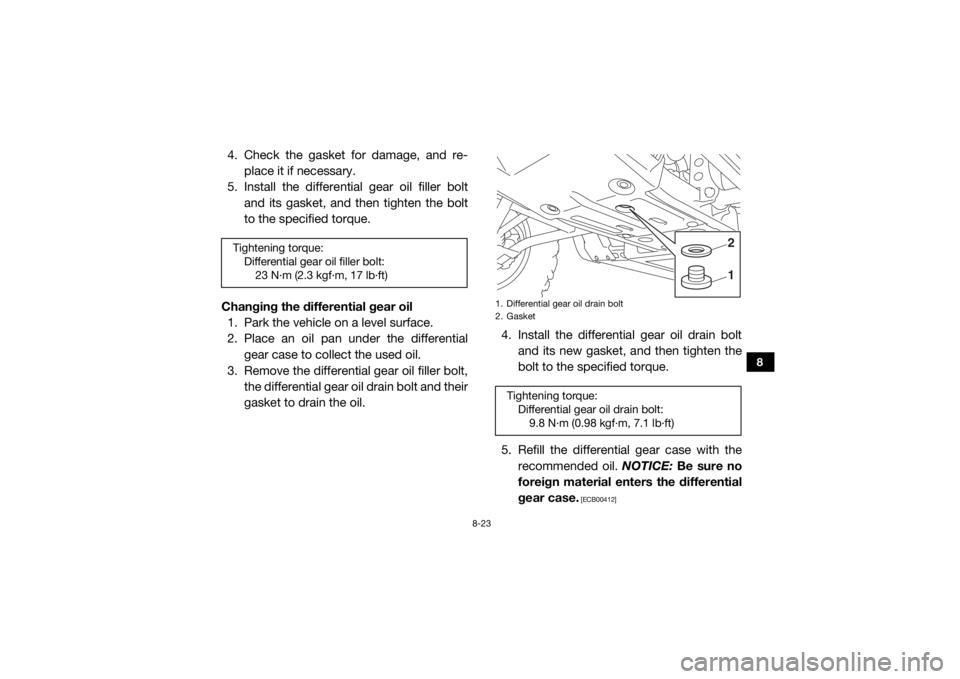

Changing the differential gear oil 1. Park the vehicle on a level surface.

2. Place an oil pan under the differential gear case to collect the used oil.

3. Remove the differential gear oil filler bolt, the differential gear oil drain bolt and their

gasket to drain the oil. 4. Install the differential gear oil drain bolt

and its new gasket, and then tighten the

bolt to the specified torque.

5. Refill the differential gear case with the recommended oil. NOTICE: Be sure no

foreign material enters the differential

gear case.

[ECB00412]

Tightening torque: Differential gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)

1. Differential gear oil drain bolt

2. GasketTightening torque: Differential gear oil drain bolt:9.8 N·m (0.98 kgf·m, 7.1 lb·ft)

12

U2MB7BE0.book Page 23 Thursday, March 3, 2016 11:46 AM

Page 136 of 186

8-24

8

TIPGL-4 is a quality and additive rating; GL-5

rated hypoid gear oils may also be used.

If desired, an SAE 80W -90 hypoid gear oil

may be used instead. 6. Check the oil filler bolt gasket for dam-

age, and replace it if necessary.

7. Install the differential gear oil filler bolt

and its gasket, and then tighten the bolt

to the specified torque.

8. Check for oil leakage. If oil leakage is found, check for the cause.

EBU33660CoolantThe coolant level should be checked before

each ride. In addition, the coolant must be

changed at the intervals specified in the peri-

odic maintenance and lubrication chart.

Checking the coolant level1. Park the vehicle on a level surface.

2. Check the coolant level in the coolant reservoir when the engine is cold as the

coolant level varies with engine tempera-

ture.TIPThe coolant should be between the minimum

and maximum level marks.

Recommended oil:SAE 80 API GL-4 Hypoid gear oil

Oil quantity: 0.18 L (0.19 US qt, 0.16 Imp.qt)

Tightening torque: Differential gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)

U2MB7BE0.book Page 24 Thursday, March 3, 2016 11:46 AM

Page 152 of 186

8-40

8

WARNING

EWB02721Improper maintenance can result in loss of

braking ability. Observe these precau-

tions:

Insufficient brake fluid may allow air to

enter the brake system, reducing brak-

ing performance.

Clean the filler cap before removing. Use

only DOT 4 brake fluid from a sealed

container.

Use only the specified brake fluid; other-

wise, the rubber seals may deteriorate,

causing leakage.

Refill with the same type of brake fluid.

Adding a brake fluid other than DOT 4

may result in a harmful chemical reac-

tion.

Be careful that water does not enter the

brake fluid reservoir when refilling. Wa-

ter will significantly lower the boiling

point of the fluid and may result in vapor

lock.

NOTICEECB01161Brake fluid may damage painted surfaces

or plastic parts. Always clean up spilled

fluid immediately.

1. Minimum level markSpecified brake fluid: DOT 4

1

U2MB7BE0.book Page 40 Thursday, March 3, 2016 11:46 AM

Page 153 of 186

8-41

8

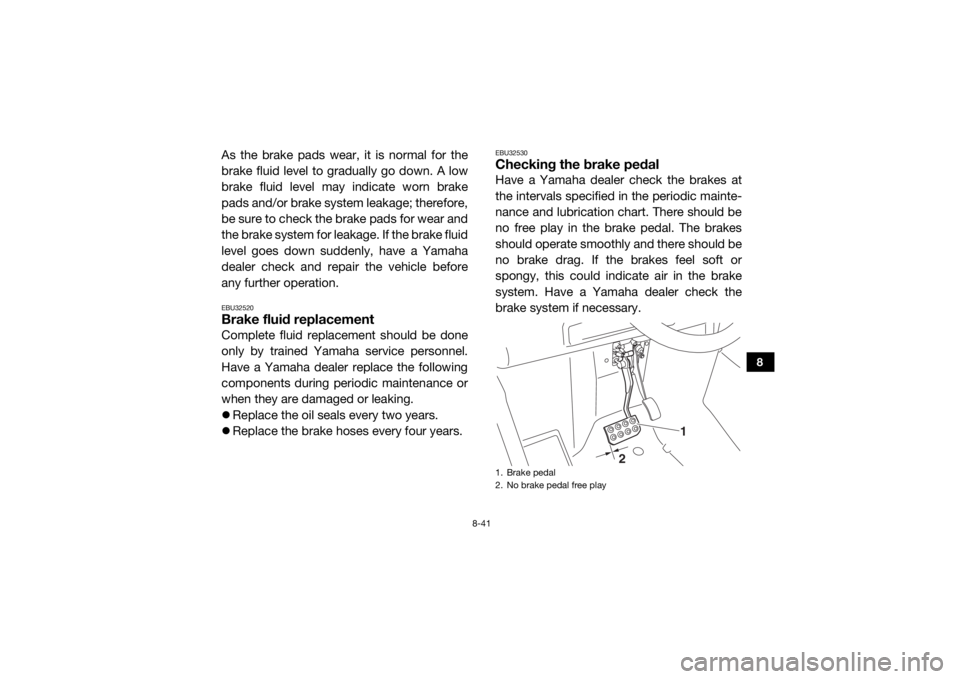

As the brake pads wear, it is normal for the

brake fluid level to gradually go down. A low

brake fluid level may indicate worn brake

pads and/or brake system leakage; therefore,

be sure to check the brake pads for wear and

the brake system for leakage. If the brake fluid

level goes down suddenly, have a Yamaha

dealer check and repair the vehicle before

any further operation.EBU32520Brake fluid replacementComplete fluid replacement should be done

only by trained Yamaha service personnel.

Have a Yamaha dealer replace the following

components during pe riodic maintenance or

when they are damaged or leaking.

Replace the oil seals every two years.

Replace the brake hoses every four years.

EBU32530Checking the brake pedalHave a Yamaha dealer check the brakes at

the intervals specified in the periodic mainte-

nance and lubrication chart. There should be

no free play in the brake pedal. The brakes

should operate smoothly and there should be

no brake drag. If the brakes feel soft or

spongy, this could indicate air in the brake

system. Have a Yamaha dealer check the

brake system if necessary.1. Brake pedal

2. No brake pedal free play

1

2

U2MB7BE0.book Page 41 Thursday, March 3, 2016 11:46 AM

Page 176 of 186

10-1

10

EBU32750

SPECIFICATIONS

Dimensions:Overall length:2970 mm (116.9 in)

Overall width: 1540 mm (60.6 in)

Overall height:

1885 mm (74.2 in)

Wheelbase: 2065 mm (81.3 in)

Ground clearance: 290 mm (11.4 in)

Minimum turning radius:

4600 mm (181 in)Weight:Curb weight:595.0 kg (1312 lb)Noise and vibration level:Noise level (77/311/EEC):80.0 dB(A) at 3125 r/min (YXE70WPAH, YXE70WPXH)

Uncertainty of measurement: 3.0 dB(A) (YXE70WPAH, YXE70WPXH)

Vibration on seat (EN1032, ISO5008):

Will not exceed 0.5 m/s² (YXE70WPAH, YXE70WPXH)

Uncertainty of measurement: 0.0 m/s² (YXE70WPAH, YXE70WPXH)

Vibration on handle (EN1032, ISO5008): Will not exceed 2.5 m/s² (YXE70WPAH, YXE70WPXH) Uncertainty of measurement:

0.5 m/s² (YXE70WPAH, YXE70WPXH)

Engine:Engine type:Liquid cooled 4-stroke, DOHC

Cylinder arrangement:

Single cylinder

Displacement: 708 cm³

Bore × stroke:

103.0 × 85.0 mm (4.06 × 3.35 in)

Compression ratio:

10.1 : 1

Starting system: Electric starter

Lubrication system: Wet sumpEngine oil:Recommended brand:YAMALUBE

U2MB7BE0.book Page 1 Thursday, March 3, 2016 11:46 AM

Page 177 of 186

10-2

10

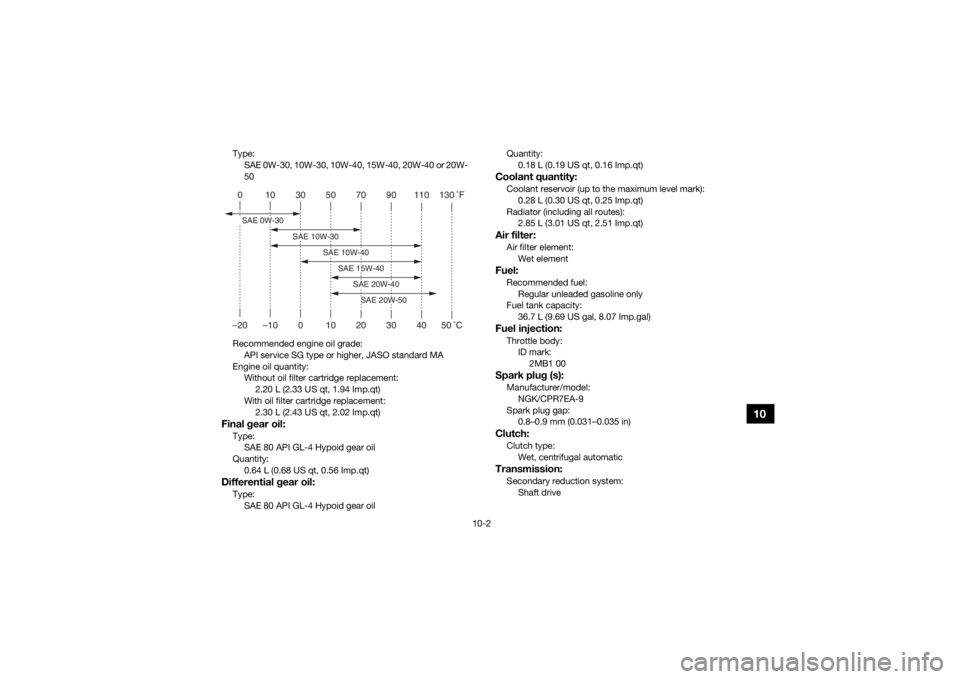

Type:SAE 0W-30, 10W-30, 10W-40, 15W-40, 20W-40 or 20W-

50

Recommended engine oil grade: API service SG type or higher, JASO standard MA

Engine oil quantity: Without oil filter cartridge replacement:2.20 L (2.33 US qt, 1.94 Imp.qt)

With oil filter cartridge replacement: 2.30 L (2.43 US qt, 2.02 Imp.qt)Final gear oil:Type:SAE 80 API GL-4 Hypoid gear oil

Quantity: 0.64 L (0.68 US qt, 0.56 Imp.qt)Differential gear oil:Type:SAE 80 API GL-4 Hypoid gear oil Quantity:

0.18 L (0.19 US qt, 0.16 Imp.qt)

Coolant quantity:Coolant reservoir (up to the maximum level mark):

0.28 L (0.30 US qt, 0.25 Imp.qt)

Radiator (including all routes): 2.85 L (3.01 US qt, 2.51 Imp.qt)Air filter:Air filter element:

Wet elementFuel:Recommended fuel:Regular unleaded gasoline only

Fuel tank capacity:

36.7 L (9.69 US gal, 8.07 Imp.gal)Fuel injection:Throttle body:ID mark:2MB1 00Spark plug (s):Manufacturer/model:

NGK/CPR7EA-9

Spark plug gap: 0.8–0.9 mm (0.031–0.035 in)Clutch:Clutch type:

Wet, centrifugal automaticTransmission:Secondary reduction system:Shaft drive

0 10 30 50 70 90 110 130 �F

–20 –10 0 10 20 30 40 50 �CSAE 0W-30

SAE 10W-30

SAE 10W-40

SAE 15W-40

SAE 20W-40SAE 20W-50

U2MB7BE0.book Page 2 Thursday, March 3, 2016 11:46 AM

Page 183 of 186

12-1

12

INDEX

AAccelerator pedal ......................................................... 4-13

Accelerator pedal, Pre-operation check ........................ 5-6

Air filter case/air duct check hose, cleaning ................ 8-36

Air filter element, cleaning ........................................... 8-32

Auxiliary DC jack .......................................................... 4-33

Axle boots .................................................................... 8-29BBasic guide for safe use ................................................ 7-1

Battery, Periodic maintenance .................................... 8-47

Brake fluid level, checking ........................................... 8-39

Brake fluid, replacing ................................................... 8-41

Brake light switch, adjusting ........................................ 8-42

Brake pedal .................................................................. 4-13

Brake pedal and accelerator pedal, lubrication ........... 8-43

Brake pedal, checking ................................................. 8-41

Brakes, Periodic maintenance ..................................... 8-38

Brakes, Pre-operation check ......................................... 5-3CCable, inspecting and lubrication ................................ 8-42

Cargo bed .................................................................... 4-21

Cleaning ......................................................................... 9-1

Control cables, Pre-operation check ............................. 5-8

Coolant, Periodic maintenance ................................... 8-24

Coolant, Pre-operation check ........................................ 5-6

Coolant temperature warning light ................................ 4-4

Cup holders ................................................................. 4-20DDifferential gear oil, Periodic maintenance .................. 8-22 Differential gear, Pre-operation check ........................... 5-6

Doors ........................................................................... 4-15

Driver seat position ...................................................... 4-16

Drive select lever ......................................................... 4-14

Drive select lever operation and reverse driving ............ 6-3

EEngine break-in .............................................................. 6-1

Engine oil and oil filter cartridge, Periodic

maintenance .............................................................. 8-14

Engine oil, Pre-operation check .................................... 5-5

Engine trouble warning light .......................................... 4-4

EPS warning light .......................................................... 4-5FFinal gear oil, Periodic maintenance ............................ 8-20

Final gear, Pre-operation check .................................... 5-6

Fittings and fasteners, Pre-operation check ................. 5-7

Front and rear brake pads, checking .......................... 8-39

Fuel, Pre-operation check ............................................. 5-3

Fuel tank cap ............................................................... 4-15

Fuse, replacing ............................................................ 8-52GGlove compartment ..................................................... 4-18HHeadlight beam, adjusting ........................................... 8-57

Headlight bulb, replacing ............................................. 8-54

Helmet indicator light ..................................................... 4-5

High-range indicator light .............................................. 4-2

Hood ............................................................................ 8-10

Horn switch .................................................................. 4-12IIdentification number records ...................................... 11-1

U2MB7BE0.book Page 1 Thursday, March 3, 2016 11:46 AM