brake YAMAHA WOLVERINE 2017 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: WOLVERINE, Model: YAMAHA WOLVERINE 2017Pages: 186, PDF Size: 4.22 MB

Page 154 of 186

8-42

8

EBU33710Parking brakePull the parking brake lever rearward com-

pletely. If the parking brake lever clicks eight

times or more, have a Yamaha dealer adjust

the parking brake because the braking force

of the parking brake is weak. In addition, have

a Yamaha dealer check and adjust the park-

ing brake at the intervals specified in the peri-

odic maintenance and lubrication chart.EBU32550Brake light switch adjustmentThe brake light switch, which is activated by

the brake pedal, is properly adjusted when

the brake light comes on just before braking

takes effect. If necessary, adjust the brake

light switch as follows.

Turn the adjusting nut while holding the brake

light switch in place. To make the brake light

come on earlier, turn the adjusting nut in di-

rection (a). To make the brake light come on

later, turn the adjusting nut in direction (b).

EBU35930Cable inspection and lubrication

WARNING

EWB03380Damaged cables could restrict operation,

which may cause an accident or injury. In-

spect control cables frequently and re-

place damaged cables. Corrosion can

result when the outer covering of control

cables becomes damaged. Cables can

also become frayed or kinked. 1. Brake light switch

2. Adjusting nut

(a)

(b)

1

2

U2MB7BE0.book Page 42 Thursday, March 3, 2016 11:46 AM

Page 155 of 186

8-43

8

Lubricate the cable ends. If the cables do not

operate smoothly, ask a Yamaha dealer to re-

place them.EBU32570Brake pedal and accelerator pedal lu-

bricationLubricate the pivoting parts.

EBU32582Checking the stabilizer bushesThe stabilizer bushes must be checked for

cracks or damage at the intervals specified in

the periodic maintenance and lubrication

chart.

Have a Yamaha dealer replace the stabilizer

bushes if necessary.

Recommended lubricant: Yamalube LubezAll (synthetic lubricant

spray with PTFE)

Recommended lubricant: Lithium-soap-based grease

U2MB7BE0.book Page 43 Thursday, March 3, 2016 11:46 AM

Page 169 of 186

8-57

8

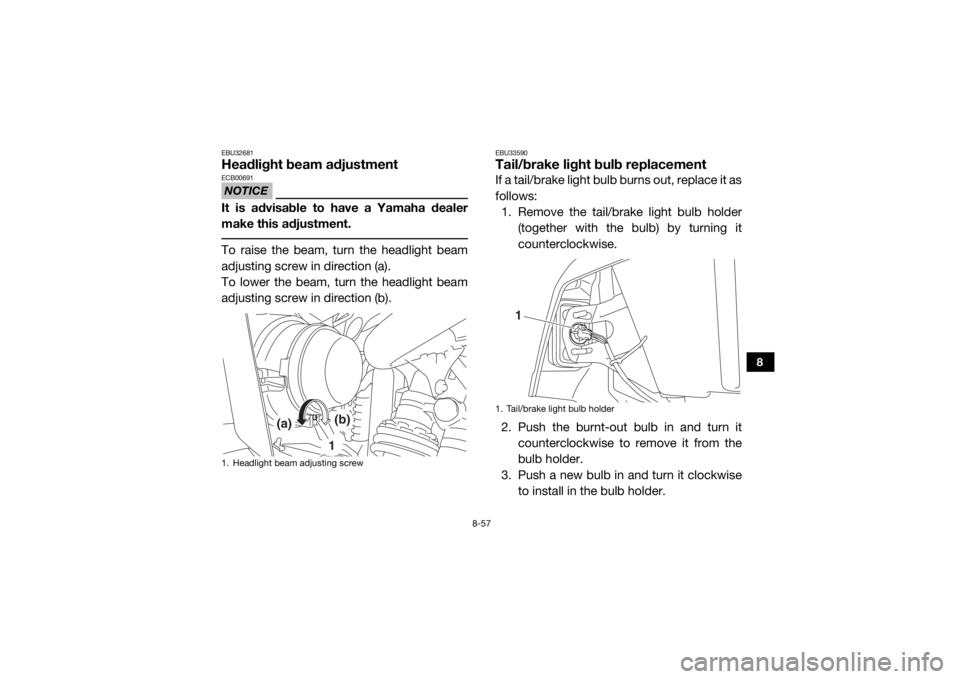

EBU32681Headlight beam adjustmentNOTICEECB00691It is advisable to have a Yamaha dealer

make this adjustment. To raise the beam, turn the headlight beam

adjusting screw in direction (a).

To lower the beam, turn the headlight beam

adjusting screw in direction (b).

EBU33590Tail/brake light bulb replacementIf a tail/brake light bulb burns out, replace it as

follows: 1. Remove the tail/brake light bulb holder

(together with the bulb) by turning it

counterclockwise.

2. Push the burnt-out bulb in and turn it counterclockwise to remove it from the

bulb holder.

3. Push a new bulb in and turn it clockwise to install in the bulb holder.

1. Headlight beam adjusting screw

1

(a)

(b)

1. Tail/brake light bulb holder

1

U2MB7BE0.book Page 57 Thursday, March 3, 2016 11:46 AM

Page 173 of 186

9-1

9

EBU32720

CLEANING AND STORAGE

EBU33681CleaningFrequent, thorough cleaning of your vehicle

will not only enhance its appearance but will

improve its general performance and extend

the useful life of many components.1. Before cleaning the vehicle: a. Block off the end of the exhaust pipeto prevent water entry. A plastic bag

and strong rubber band may be used.

b. Make sure the spark plug and all filler caps are properly installed.

2. If the engine case is excessively greasy, apply degreaser with a paint brush. Do

not apply degreaser to the wheel axles.

3. Rinse the dirt and degreaser off with a garden hose. Use only enough pressure

to do the job. WARNING! Test the

brakes after washing. Apply the

brakes several times at slow speeds to

let friction dry the brakes. Wet brakes may have reduced stopping ability, in-

creasing the chance of an accident.

[EWB03471]

NOTICE: Excessive water pres-

sure may cause water seepage and

deterioration of wheel bearings,

brakes, transmission seals and electri-

cal devices. Many expensive repair

bills have resulted from improper high-

pressure detergent applications such

as those available in coin-operated car

washers.

[ECB00712]

TIPThe tailgate can be removed to make it easier

to clean the cargo bed. To separate the tail-

gate from the cargo bed, unhook the latches,

and then pull up the tailgate. (See page 4-21

for tailgate removal and installation proce-

dures.)

U2MB7BE0.book Page 1 Thursday, March 3, 2016 11:46 AM

Page 179 of 186

10-4

10

Rear wheel:Wheel type:Cast wheel (YXE70WPAH)

Panel wheel (YXE70WPHH, YXE70WPXH)

Rim size: 12 x 7.5ATFront brake:Type:Hydraulic disc brake

Operation: Unified brake

Specified brake fluid:

DOT 4Rear brake:Type:Hydraulic disc brake

Operation:

Unified brake

Specified brake fluid: DOT 4Front suspension:Type:

Double wishbone

Spring/shock absorber type: Coil spring/gas-oil damper

Wheel travel: 246 mm (9.7 in)Rear suspension:Type:Double wishbone Spring/shock absorber type:

Coil spring/gas-oil damper

Wheel travel: 269 mm (10.6 in)

Electrical system:Ignition system:TCI

Charging system: AC magnetoBattery:Model:U1-H11L

Voltage, capacity: 12 V, 28.0 AhHeadlight(s):Bulb type:Halogen bulbBulb voltage, wattage × quantity:Headlight:

12 V, 35.0/35.0 W × 2

Tail/brake light: 12 V, 5.0/21.0 W × 2

Neutral indicator light: LED

Reverse indicator light:

LED

Coolant temperature warning light: LED

Engine trouble warning light: LED

U2MB7BE0.book Page 4 Thursday, March 3, 2016 11:46 AM

Page 180 of 186

10-5

10

Parking brake indicator light:LED

On-Command four-wheel-drive/differential gear lock

indicator: LCD

High-range indicator light: LED

Low-range indicator light:

LED

Differential gear lock indicator light: LED

EPS warning light: LED

Helmet/Seat belt indicator light:

14 V, 0.85 W × 2Fuses:Main fuse:

40.0 A

Fuel injection system fuse:

10.0 A

EPS fuse: 40.0 A

Headlight fuse: 15.0 A

Signaling system fuse:

10.0 A

Ignition fuse: 10.0 A

Auxiliary DC jack fuse: 10.0 A

Backup fuse:

10.0 A Four-wheel-drive motor fuse:

10.0 A

Radiator fan motor fuse: 25.0 A

EBU33221For Europe only

The figures quoted are emission levels and

are not necessarily safe working levels. Whilst

there is a correlation between the emission

and exposure levels, this cannot be used reli-

ably to determine whether or not further pre-

cautions are required. Factors that influence

the actual level of exposure of work-force in-

clude the characteristics of the work room,

the other sources of noise, etc. i.e. the num-

ber of machines and other adjacent process-

es, and the length of time for which an

operator is exposed to the noise. Also the

permissible exposure level can vary from

country. This information, however, will en-

able the user of the machine to make a better

evaluation of the hazard and risk.

U2MB7BE0.book Page 5 Thursday, March 3, 2016 11:46 AM

Page 183 of 186

12-1

12

INDEX

AAccelerator pedal ......................................................... 4-13

Accelerator pedal, Pre-operation check ........................ 5-6

Air filter case/air duct check hose, cleaning ................ 8-36

Air filter element, cleaning ........................................... 8-32

Auxiliary DC jack .......................................................... 4-33

Axle boots .................................................................... 8-29BBasic guide for safe use ................................................ 7-1

Battery, Periodic maintenance .................................... 8-47

Brake fluid level, checking ........................................... 8-39

Brake fluid, replacing ................................................... 8-41

Brake light switch, adjusting ........................................ 8-42

Brake pedal .................................................................. 4-13

Brake pedal and accelerator pedal, lubrication ........... 8-43

Brake pedal, checking ................................................. 8-41

Brakes, Periodic maintenance ..................................... 8-38

Brakes, Pre-operation check ......................................... 5-3CCable, inspecting and lubrication ................................ 8-42

Cargo bed .................................................................... 4-21

Cleaning ......................................................................... 9-1

Control cables, Pre-operation check ............................. 5-8

Coolant, Periodic maintenance ................................... 8-24

Coolant, Pre-operation check ........................................ 5-6

Coolant temperature warning light ................................ 4-4

Cup holders ................................................................. 4-20DDifferential gear oil, Periodic maintenance .................. 8-22 Differential gear, Pre-operation check ........................... 5-6

Doors ........................................................................... 4-15

Driver seat position ...................................................... 4-16

Drive select lever ......................................................... 4-14

Drive select lever operation and reverse driving ............ 6-3

EEngine break-in .............................................................. 6-1

Engine oil and oil filter cartridge, Periodic

maintenance .............................................................. 8-14

Engine oil, Pre-operation check .................................... 5-5

Engine trouble warning light .......................................... 4-4

EPS warning light .......................................................... 4-5FFinal gear oil, Periodic maintenance ............................ 8-20

Final gear, Pre-operation check .................................... 5-6

Fittings and fasteners, Pre-operation check ................. 5-7

Front and rear brake pads, checking .......................... 8-39

Fuel, Pre-operation check ............................................. 5-3

Fuel tank cap ............................................................... 4-15

Fuse, replacing ............................................................ 8-52GGlove compartment ..................................................... 4-18HHeadlight beam, adjusting ........................................... 8-57

Headlight bulb, replacing ............................................. 8-54

Helmet indicator light ..................................................... 4-5

High-range indicator light .............................................. 4-2

Hood ............................................................................ 8-10

Horn switch .................................................................. 4-12IIdentification number records ...................................... 11-1

U2MB7BE0.book Page 1 Thursday, March 3, 2016 11:46 AM

Page 184 of 186

12-2

12

Indicator lights and warning lights ................................. 4-2

Instruments, lights and switches, Pre-operation check ........................................................................... 5-7JJump-starting ............................................................... 8-50LLabel locations ............................................................... 1-1

Light switch .................................................................. 4-11

Loading ..........................................................................6-7

Low-range indicator light ............................................... 4-2MMain switch .................................................................... 4-1

Maintenance and lubrication chart ................................8-6

Maintenance chart, emission control system ................ 8-4

Model label ................................................................... 11-1

Multi-function meter unit ................................................ 4-6NNeutral indicator light .....................................................4-3OOn-Command drive knob ............................................ 4-12

On-Command drive knob, operation ............................. 6-5

On-Command four-wheel-drive /differential gear lock

indicator ....................................................................... 4-3

Owner’s manual and tool kit .......................................... 8-2PPanels .......................................................................... 8-11

Parking ........................................................................... 6-7

Parking brake ............................................................... 8-42

Parking brake indicator light .......................................... 4-3

Parking brake lever ...................................................... 4-13

Passenger handhold, Pre-operation check ................... 5-7

RRear knuckle upper and lower pivot, lubrication ......... 8-44

Reverse indicator light ................................................... 4-3SSafety information .......................................................... 2-1

Seat belt indicator light .................................................. 4-5

Seat belts ..................................................................... 4-17

Seat belts, Pre-operation check .................................... 5-6

Seats ............................................................................ 4-15

Shock absorber assemblies, adjusting the front ......... 4-23

Shock absorber assemblies, adjusting the rear ........... 4-28

Spark arrester, cleaning ............................................... 8-37

Spark plug, inspecting ................................................. 8-30

Specifications .............................................................. 10-1

Stabilizer bushes, checking ......................................... 8-43

Starting the engine ......................................................... 6-2

Steering, Pre-operation check ....................................... 5-7

Steering shaft, lubrication ............................................ 8-44

Storage .......................................................................... 9-2

Storage compartments ................................................ 4-19TTail/brake light bulb, replacing ..................................... 8-57

Tire, replacing .............................................................. 8-45

Tires, Pre-operation check ............................................. 5-8

Trailer hitch bracket and receiver ................................ 4-33

Troubleshooting ........................................................... 8-58

Troubleshooting charts ................................................ 8-59VValve clearance ............................................................ 8-38

V-belt case drain plug .................................................. 8-36

Vehicle identification number ....................................... 11-1

U2MB7BE0.book Page 2 Thursday, March 3, 2016 11:46 AM