torque YAMAHA WOLVERINE 2017 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: WOLVERINE, Model: YAMAHA WOLVERINE 2017Pages: 186, PDF Size: 4.22 MB

Page 55 of 186

4-17

4

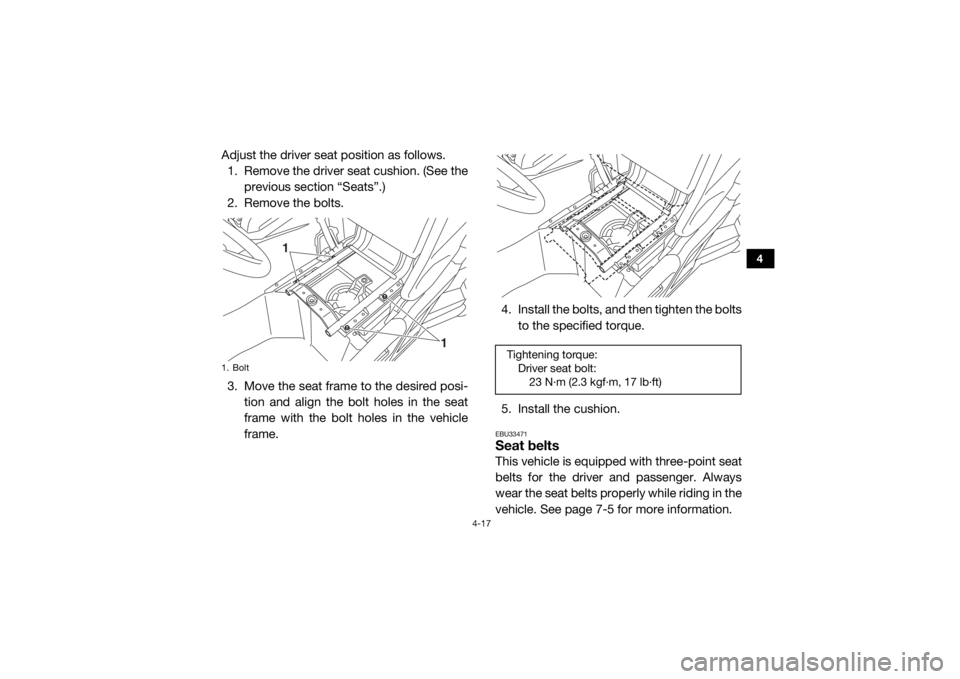

Adjust the driver seat position as follows.1. Remove the driver seat cushion. (See the

previous section “Seats”.)

2. Remove the bolts.

3. Move the seat frame to the desired posi- tion and align the bolt holes in the seat

frame with the bolt holes in the vehicle

frame. 4. Install the bolts, and then tighten the bolts

to the specified torque.

5. Install the cushion.

EBU33471Seat beltsThis vehicle is equipped with three-point seat

belts for the driver and passenger. Always

wear the seat belts properly while riding in the

vehicle. See page 7-5 for more information.

1. Bolt

1

1

Tightening torque: Driver seat bolt:23 N·m (2.3 kgf·m, 17 lb·ft)

U2MB7BE0.book Page 17 Thursday, March 3, 2016 11:46 AM

Page 63 of 186

![YAMAHA WOLVERINE 2017 Owners Manual 4-25

4

3. Tighten the locknut to the specifiedtorque. NOTICE: Always tighten the

locknut against the adjusting nut, and

then tighten it to the specified torque.

[ECB00082]

Rebound damping force

Turn YAMAHA WOLVERINE 2017 Owners Manual 4-25

4

3. Tighten the locknut to the specifiedtorque. NOTICE: Always tighten the

locknut against the adjusting nut, and

then tighten it to the specified torque.

[ECB00082]

Rebound damping force

Turn](/img/51/52235/w960_52235-62.png)

4-25

4

3. Tighten the locknut to the specifiedtorque. NOTICE: Always tighten the

locknut against the adjusting nut, and

then tighten it to the specified torque.

[ECB00082]

Rebound damping force

Turn the rebound damping force adjusting

screw in direction (a) to increase the rebound

damping force and thereby harden the damp-

ing, and in direction (b) to decrease the re-

bound damping force and thereby soften the

damping.

Spring preload setting: Minimum (soft):Distance A = 313.5 mm (12.34 in)

Standard: Distance A = 305.5 mm (12.03 in)

Maximum (hard): Distance A = 298.5 mm (11.75 in)1. Distance A

1

Tightening torque: Locknut:30 N·m (3.0 kgf·m, 22 lb·ft)1. Rebound damping force adjusting screw

1

(a)

(b)

U2MB7BE0.book Page 25 Thursday, March 3, 2016 11:46 AM

Page 68 of 186

![YAMAHA WOLVERINE 2017 Owners Manual 4-30

4

3. Tighten the locknut to the specifiedtorque. NOTICE: Always tighten the

locknut against the adjusting nut, and

then tighten it to the specified torque.

[ECB00082]

Rebound damping force

Turn YAMAHA WOLVERINE 2017 Owners Manual 4-30

4

3. Tighten the locknut to the specifiedtorque. NOTICE: Always tighten the

locknut against the adjusting nut, and

then tighten it to the specified torque.

[ECB00082]

Rebound damping force

Turn](/img/51/52235/w960_52235-67.png)

4-30

4

3. Tighten the locknut to the specifiedtorque. NOTICE: Always tighten the

locknut against the adjusting nut, and

then tighten it to the specified torque.

[ECB00082]

Rebound damping force

Turn the rebound damping force adjusting

screw in direction (a) to increase the rebound

damping force and thereby harden the damp-

ing, and in direction (b) to decrease the re-

bound damping force and thereby soften the

damping.

Spring preload setting: Minimum (soft):Distance A = 386.0 mm (15.20 in)

Standard: Distance A = 378.0 mm (14.88 in)

Maximum (hard): Distance A = 372.0 mm (14.65 in)1. Distance A

1

Tightening torque:Locknut:30 N·m (3.0 kgf·m, 22 lb·ft)1. Rebound damping force adjusting screw

1

(a)

(b)

U2MB7BE0.book Page 30 Thursday, March 3, 2016 11:46 AM

Page 79 of 186

5-7

5

The latch plate should click securely into the

buckle and release when the release button is

pushed firmly. Wash off any dirt or mud that

could affect operation. Have a Yamaha dealer

repair as necessary for proper operation.

A crash can damage the restraint systems in

your vehicle. A damaged restraint system

may not properly protect the person using it,

resulting in serious injury or death in a crash.

To help make sure your restraint systems are

working properly after a crash, have them in-

spected and any necessary replacements

made as soon as possible.EBU31810Passenger handholdCheck that the handhold bar and its supports

are in good condition. Confirm that the lock-

ing pins are securely fastened, and then push

and pull on the handhold to make sure that it

is not loose.

EBU31820SteeringPark on level ground. Turn the steering wheel

right and left. Check for excessive free play,

abnormal noises, or a rough feeling. Have a

Yamaha dealer repair as necessary for proper operation.EBU31831Fittings and fastenersAlways check the tightness of chassis fittings

and fasteners before a drive. Take the vehicle

to a Yamaha dealer or refer to the Service

Manual for correct tightening torque.EBU31840Instruments, lights and switchesCheck that all instrument s, lights and switch-

es are working properly. Correct if necessary.

U2MB7BE0.book Page 7 Thursday, March 3, 2016 11:46 AM

Page 114 of 186

8-2

8

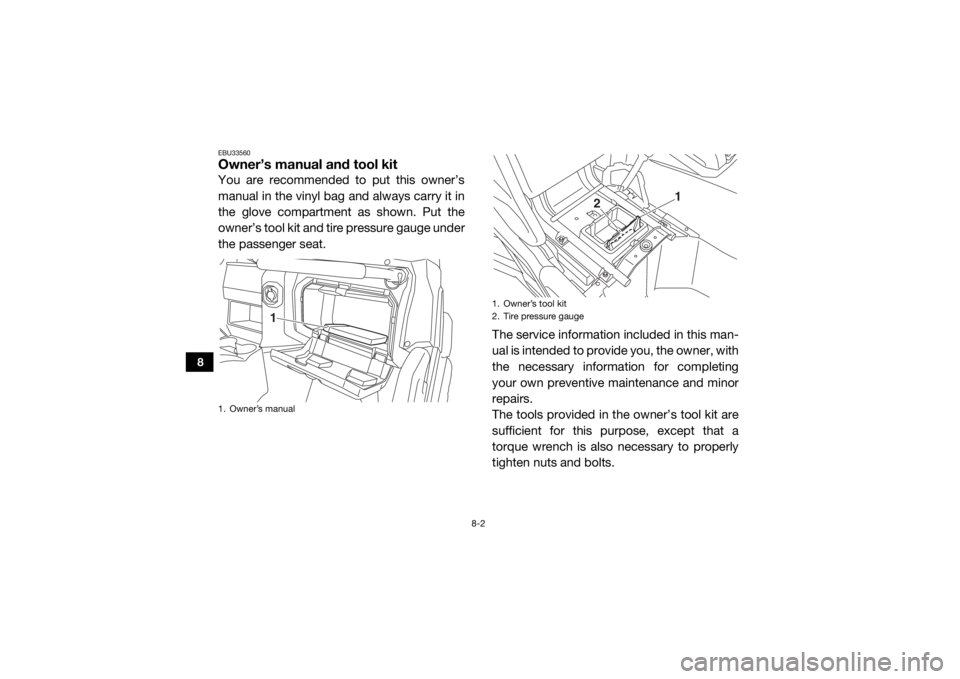

EBU33560Owner’s manual and tool kitYou are recommended to put this owner’s

manual in the vinyl bag and always carry it in

the glove compartment as shown. Put the

owner’s tool kit and tire pressure gauge under

the passenger seat.The service information included in this man-

ual is intended to provide you, the owner, with

the necessary information for completing

your own preventive maintenance and minor

repairs.

The tools provided in the owner’s tool kit are

sufficient for this purpose, except that a

torque wrench is also necessary to properly

tighten nuts and bolts.1. Owner’s manual

1

1. Owner’s tool kit

2. Tire pressure gauge

1

2

U2MB7BE0.book Page 2 Thursday, March 3, 2016 11:46 AM

Page 115 of 186

8-3

8

If you do not have a torque wrench available

during a service operation requiring one, take

your vehicle to a Yamaha dealer to check the

torque settings and adjust them as neces-

sary.U2MB7BE0.book Page 3 Thursday, March 3, 2016 11:46 AM

Page 130 of 186

8-18

8

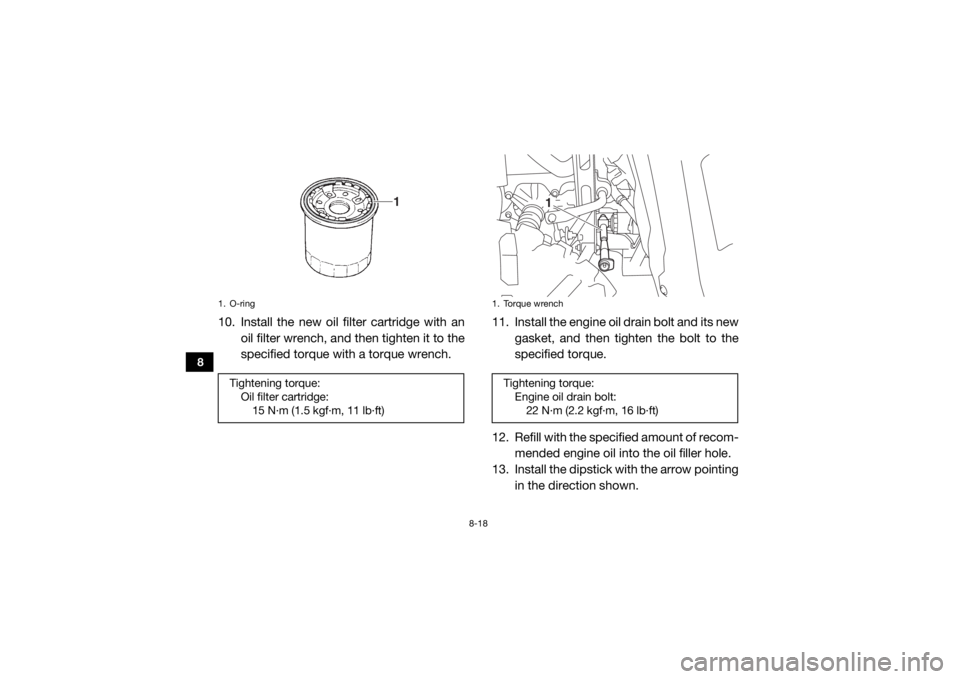

10. Install the new oil filter cartridge with anoil filter wrench, and then tighten it to the

specified torque with a torque wrench. 11. Install the engine oil drain bolt and its new

gasket, and then tighten the bolt to the

specified torque.

12. Refill with the specified amount of recom- mended engine oil into the oil filler hole.

13. Install the dipstick with the arrow pointing in the direction shown.1. O-ringTightening torque:Oil filter cartridge:15 N·m (1.5 kgf·m, 11 lb·ft)

1

1. Torque wrenchTightening torque:Engine oil drain bolt:22 N·m (2.2 kgf·m, 16 lb·ft)

1

U2MB7BE0.book Page 18 Thursday, March 3, 2016 11:46 AM

Page 132 of 186

8-20

8

15. Turn the engine off, wait at least 10 minu-tes, and then check the oil level and cor-

rect it if necessary.

16. Install the rubber cover.

17. Install the passenger seat cushion.EBU36050Final gear oilCheck the oil level and change the final gear

oil at the intervals specified in the general

maintenance and lubrication chart.

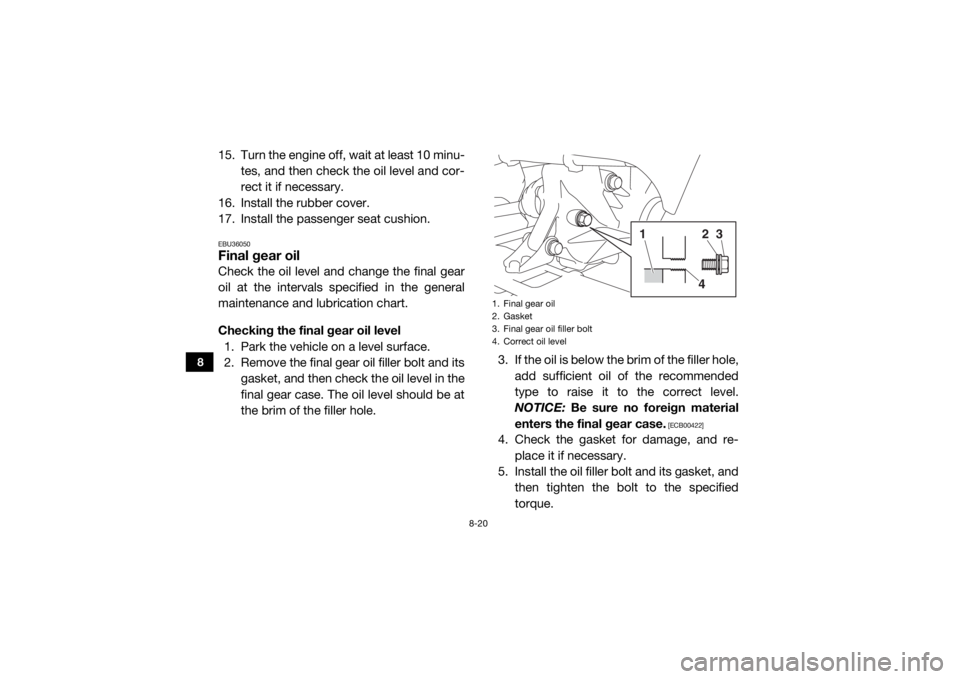

Checking the final gear oil level 1. Park the vehicle on a level surface.

2. Remove the final gear oil filler bolt and its gasket, and then check the oil level in the

final gear case. The oil level should be at

the brim of the filler hole. 3. If the oil is below the brim of the filler hole,

add sufficient oil of the recommended

type to raise it to the correct level.

NOTICE: Be sure no foreign material

enters the final gear case.

[ECB00422]

4. Check the gasket for damage, and re- place it if necessary.

5. Install the oil filler bolt and its gasket, and then tighten the bolt to the specified

torque.1. Final gear oil

2. Gasket

3. Final gear oil filler bolt

4. Correct oil level

24

3

1

U2MB7BE0.book Page 20 Thursday, March 3, 2016 11:46 AM

Page 133 of 186

8-21

8

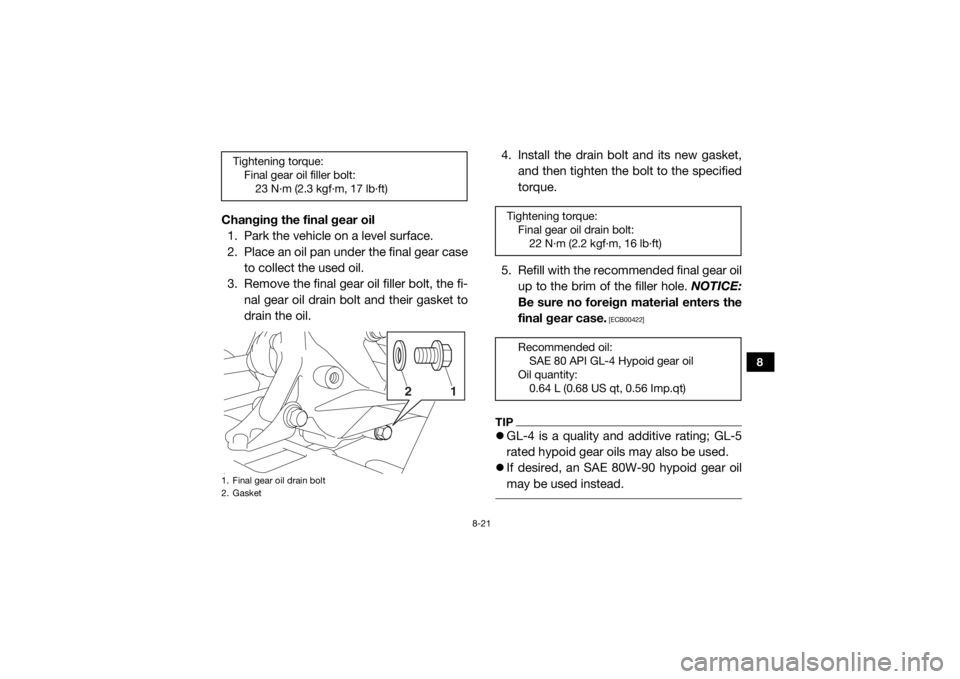

Changing the final gear oil1. Park the vehicle on a level surface.

2. Place an oil pan under the final gear case

to collect the used oil.

3. Remove the final gear oil filler bolt, the fi-

nal gear oil drain bolt and their gasket to

drain the oil. 4. Install the drain bolt and its new gasket,

and then tighten the bolt to the specified

torque.

5. Refill with the recommended final gear oil up to the brim of the filler hole. NOTICE:

Be sure no foreign material enters the

final gear case.

[ECB00422]

TIP GL-4 is a quality and additive rating; GL-5

rated hypoid gear oils may also be used.

If desired, an SAE 80W-90 hypoid gear oil

may be used instead.

Tightening torque:

Final gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)1. Final gear oil drain bolt

2. Gasket

21

Tightening torque: Final gear oil drain bolt:22 N·m (2.2 kgf·m, 16 lb·ft)

Recommended oil: SAE 80 API GL-4 Hypoid gear oil

Oil quantity: 0.64 L (0.68 US qt, 0.56 Imp.qt)

U2MB7BE0.book Page 21 Thursday, March 3, 2016 11:46 AM

Page 134 of 186

8-22

8

6. Check the oil filler bolt gasket for dam-age, and replace it if necessary.

7. Install the oil filler bolt and its gasket, and then tighten the bolt to the specified

torque.

8. Check for oil leakage. If oil leakage is found, check for the cause.EBU36060Differential gear oilCheck the oil level and change the differential

gear oil at the intervals specified in the gener-

al maintenance and lubrication chart.

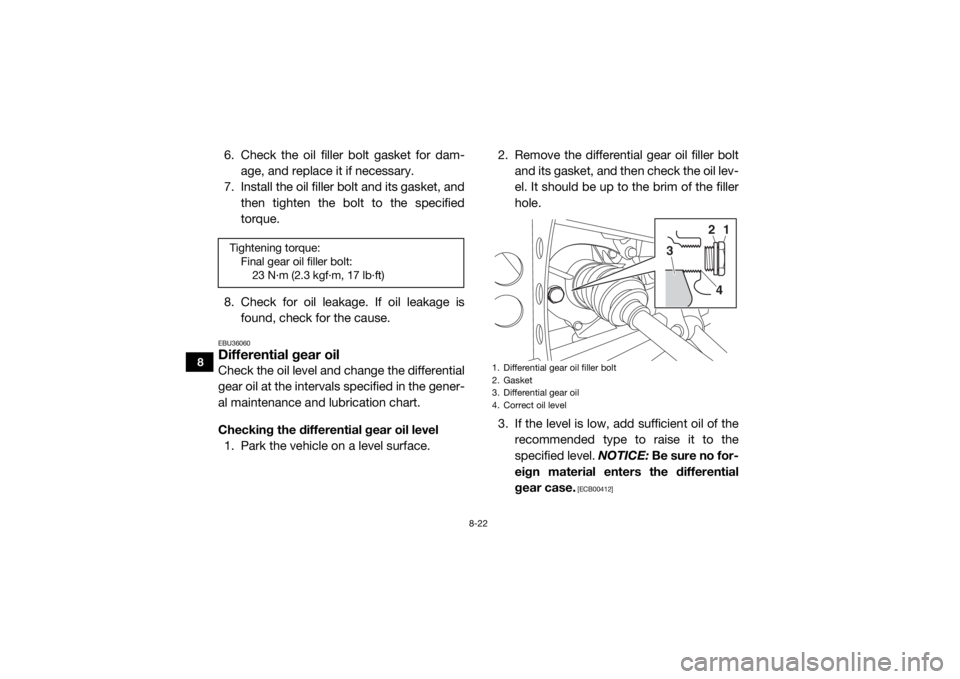

Checking the differential gear oil level

1. Park the vehicle on a level surface. 2. Remove the differential gear oil filler bolt

and its gasket, and then check the oil lev-

el. It should be up to the brim of the filler

hole.

3. If the level is low, add sufficient oil of the recommended type to raise it to the

specified level. NOTICE: Be sure no for-

eign material enters the differential

gear case.

[ECB00412]

Tightening torque: Final gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)

1. Differential gear oil filler bolt

2. Gasket

3. Differential gear oil

4. Correct oil level

1

2

3

4

U2MB7BE0.book Page 22 Thursday, March 3, 2016 11:46 AM