maintenance YAMAHA WOLVERINE 2018 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2018, Model line: WOLVERINE, Model: YAMAHA WOLVERINE 2018Pages: 188, PDF Size: 5.4 MB

Page 133 of 188

8-20

8

TIPBe sure to wipe off spilled oil on any parts af-

ter the engine and exhaust system have

cooled down. 14. Start the engine, and then let it idle forseveral minutes while checking it for oil

leakage. If oil is leaking, immediately turn

the engine off and check for the cause.

15. Turn the engine off, wait at least 10 minu-

tes, and then check the oil level and cor-

rect it if necessary.

16. Install the rubber cover.

17. Install the passenger seat cushion.EBU36051Final gear oilCheck the oil level and change the final gear

oil at the intervals specified in the general

maintenance and lubrication chart.

NOTICEECB03590When checking or changing the final gear

oil, make sure that no foreign material en-

ters the final gear case. If necessary, clean

the final gear oil filler bolt and surrounding

area. Checking the final gear oil level 1. Park the vehicle on a level surface.

2. Remove the final gear oil filler bolt and its

gasket, and then check the oil level in the

final gear case. The oil level should be at

the brim of the filler hole.

Recommended oil:SAE 80 API GL-4 Hypoid gear oil

Oil quantity: 0.64 L (0.68 US qt, 0.56 Imp.qt)

UB3D7AE0.book Page 20 Tuesday, November 7, 2017 9:38 AM

Page 135 of 188

8-22

8

4. Install the drain bolt and its new gasket,and then tighten the bolt to the specified

torque.

5. Refill with the recommended final gear oil up to the brim of the filler hole.TIPGL-4 is a quality and additive rating; GL-5

rated hypoid gear oils may also be used.

If desired, an SAE 80W-90 hypoid gear oil

may be used instead. 6. Check the oil filler bolt gasket for dam-

age, and replace it if necessary.

7. Install the oil filler bolt and its gasket, and then tighten the bolt to the specified

torque. 8. Check for oil leakage. If oil leakage is

found, check for the cause.

EBU36061Differential gear oilCheck the oil level and change the differential

gear oil at the intervals specified in the gener-

al maintenance and lubrication chart.NOTICEECB03600When checking or changing the differen-

tial gear oil, make sure that no foreign ma-

terial enters the differential gear case. If

necessary, clean the differential gear oil

filler bolt and surrounding area.

Tightening torque:Final gear oil drain bolt:22 N·m (2.2 kgf·m, 16 lb·ft)

Tightening torque: Final gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)

Recommended oil: SAE 80 API GL-4 Hypoid gear oil

Oil quantity: 0.18 L (0.19 US qt, 0.16 Imp.qt)

UB3D7AE0.book Page 22 Tuesday, November 7, 2017 9:38 AM

Page 145 of 188

8-32

8

Installation1. Clean the surface of the spark plug gas-

ket and its mating surface, and then wipe

off any grime from the spark plug

threads.

2. Install the spark plug and tighten it to the specified torque. If a torque wrench is not

available when you are installing the

spark plug, a good estimate of the cor-

rect torque is one-quarter to one-half turn

past finger tight. Have the spark plug

tightened to the specified torque as soon

as possible.

3. Install the spark plug cap.

EBU33581Cleaning the air filter elementThe air filter element should be cleaned every

20–40 hours. It should be cleaned and lubri-

cated more often if the vehicle is operated in

extremely dusty areas. Each time air filter ele-

ment maintenance is performed, check the air

inlet to the air filter case for obstructions.

Check the air filter elem ent rubber joint to the

throttle body and manifold fittings for an air-

tight seal. Tighten all fittings securely to avoid

the possibility of unfiltered air entering the en-

gine.NOTICEECB02270Never operate the engine with the air filter

element removed. Doing so would allow

unfiltered air to enter, causing rapid en-

gine wear and possible engine damage.

Additionally, the fuel injection system

would be affected, re sulting in poor engine

performance and possible overheating.

Spark plug gap: 0.8–0.9 mm (0.031–0.035 in)

Tightening torque: Spark plug:11 N·m (1.1 kgf·m, 8.1 lb·ft)

UB3D7AE0.book Page 32 Tuesday, November 7, 2017 9:38 AM

Page 153 of 188

8-40

8

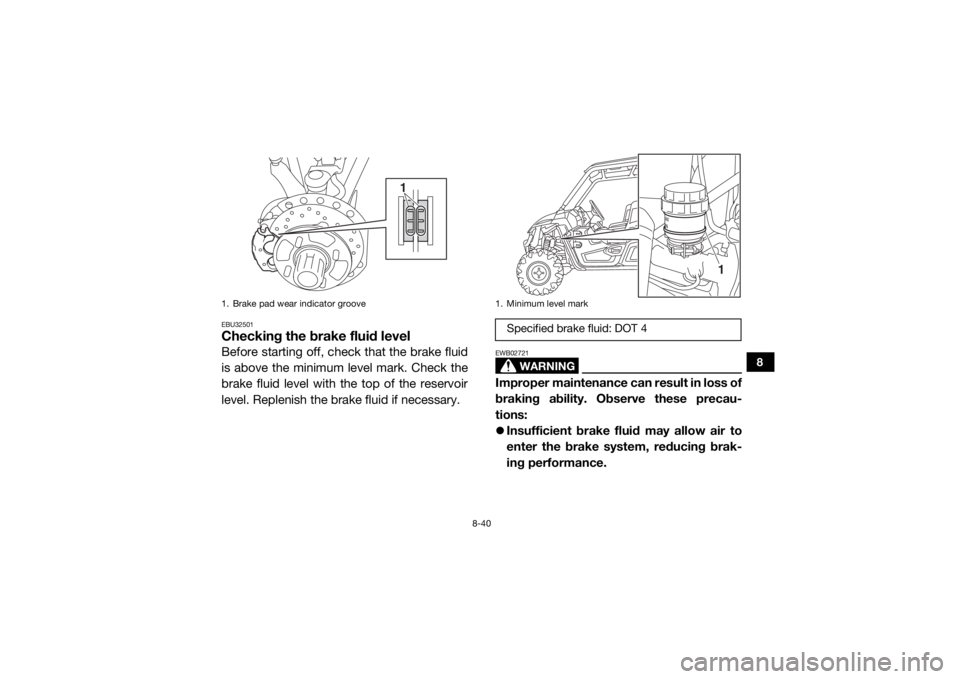

EBU32501Checking the brake fluid levelBefore starting off, check that the brake fluid

is above the minimum level mark. Check the

brake fluid level with the top of the reservoir

level. Replenish the brake fluid if necessary.

WARNING

EWB02721Improper maintenance can result in loss of

braking ability. Observe these precau-

tions:

Insufficient brake fluid may allow air to

enter the brake system, reducing brak-

ing performance.

1. Brake pad wear indicator groove

1

1. Minimum level markSpecified brake fluid: DOT 4

1

UB3D7AE0.book Page 40 Tuesday, November 7, 2017 9:38 AM

Page 154 of 188

8-41

8

Clean the filler cap before removing. Use

only DOT 4 brake fluid from a sealed

container.

Use only the specified brake fluid; other-

wise, the rubber seals may deteriorate,

causing leakage.

Refill with the same type of brake fluid.

Adding a brake fluid other than DOT 4

may result in a harmful chemical reac-

tion.

Be careful that water does not enter the

brake fluid reservoir when refilling. Wa-

ter will significantly lower the boiling

point of the fluid and may result in vapor

lock. NOTICEECB01161Brake fluid may damage painted surfaces

or plastic parts. Always clean up spilled

fluid immediately.

As the brake pads wear, it is normal for the

brake fluid level to gradually go down. A low

brake fluid level may indicate worn brake

pads and/or brake system leakage; therefore,

be sure to check the brake pads for wear and

the brake system for leakage. If the brake fluid

level goes down suddenly, have a Yamaha

dealer check and repair the vehicle before

any further operation.EBU32520Brake fluid replacementComplete fluid replacement should be done

only by trained Yamaha service personnel.

Have a Yamaha dealer replace the following

components during periodic maintenance or

when they are damaged or leaking.

Replace the oil seals every two years.

Replace the brake hoses every four years.

UB3D7AE0.book Page 41 Tuesday, November 7, 2017 9:38 AM

Page 155 of 188

8-42

8

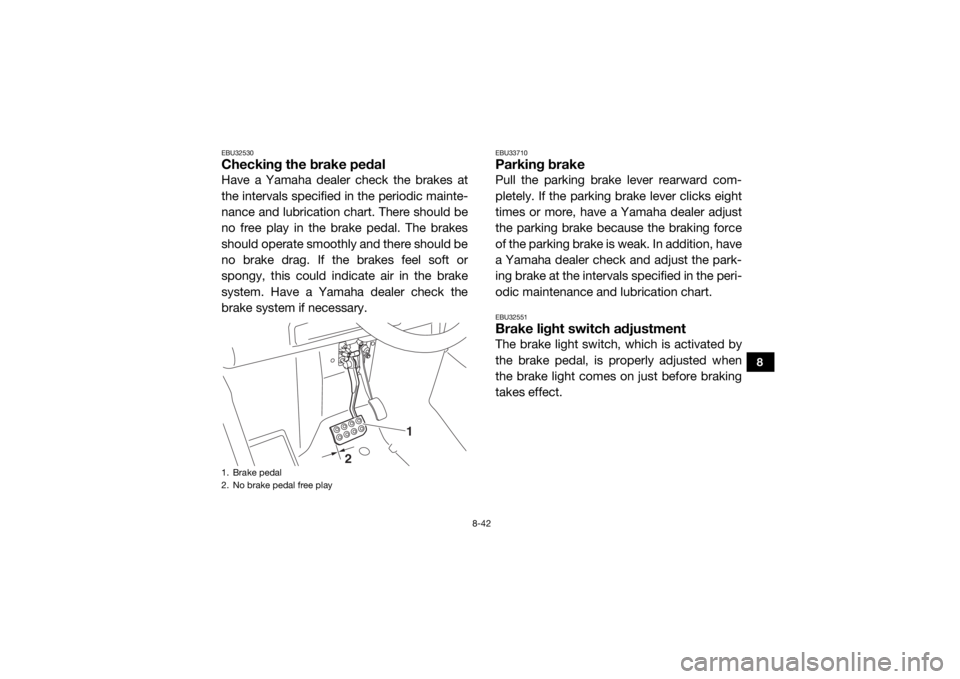

EBU32530Checking the brake pedalHave a Yamaha dealer check the brakes at

the intervals specified in the periodic mainte-

nance and lubrication chart. There should be

no free play in the brake pedal. The brakes

should operate smoothly and there should be

no brake drag. If the brakes feel soft or

spongy, this could indicate air in the brake

system. Have a Yamaha dealer check the

brake system if necessary.

EBU33710Parking brakePull the parking brake lever rearward com-

pletely. If the parking brake lever clicks eight

times or more, have a Yamaha dealer adjust

the parking brake because the braking force

of the parking brake is weak. In addition, have

a Yamaha dealer check and adjust the park-

ing brake at the intervals specified in the peri-

odic maintenance and lubrication chart.EBU32551Brake light switch adjustmentThe brake light switch, which is activated by

the brake pedal, is properly adjusted when

the brake light comes on just before braking

takes effect.

1. Brake pedal

2. No brake pedal free play

1

2

UB3D7AE0.book Page 42 Tuesday, November 7, 2017 9:38 AM

Page 157 of 188

8-44

8

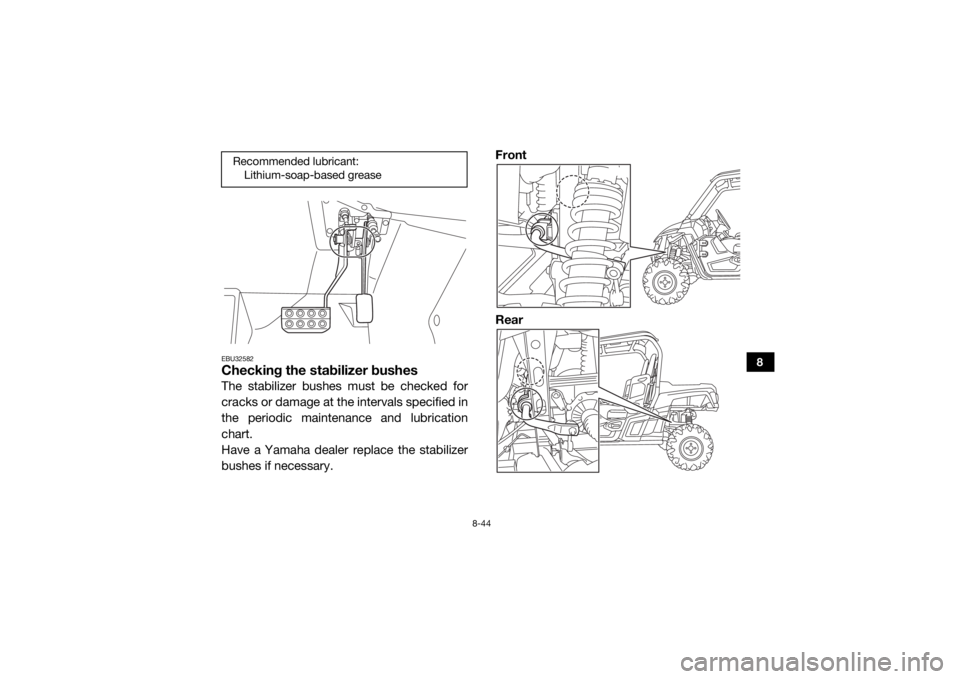

EBU32582Checking the stabilizer bushesThe stabilizer bushes must be checked for

cracks or damage at the intervals specified in

the periodic maintenance and lubrication

chart.

Have a Yamaha dealer replace the stabilizer

bushes if necessary.Front

RearRecommended lubricant:

Lithium-soap-based grease

UB3D7AE0.book Page 44 Tuesday, November 7, 2017 9:38 AM

Page 184 of 188

12-1

12

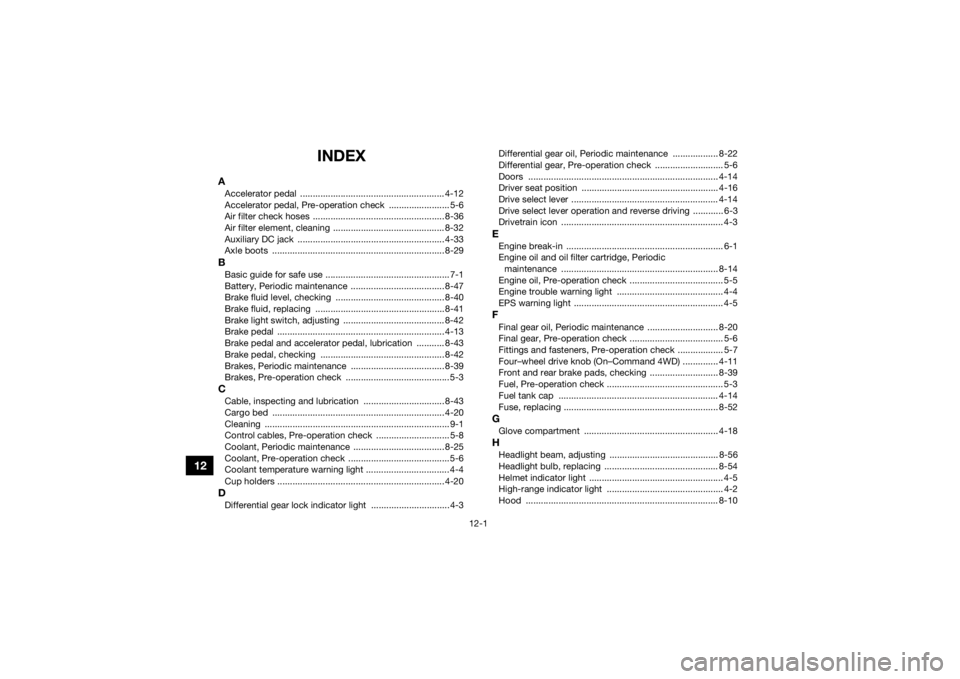

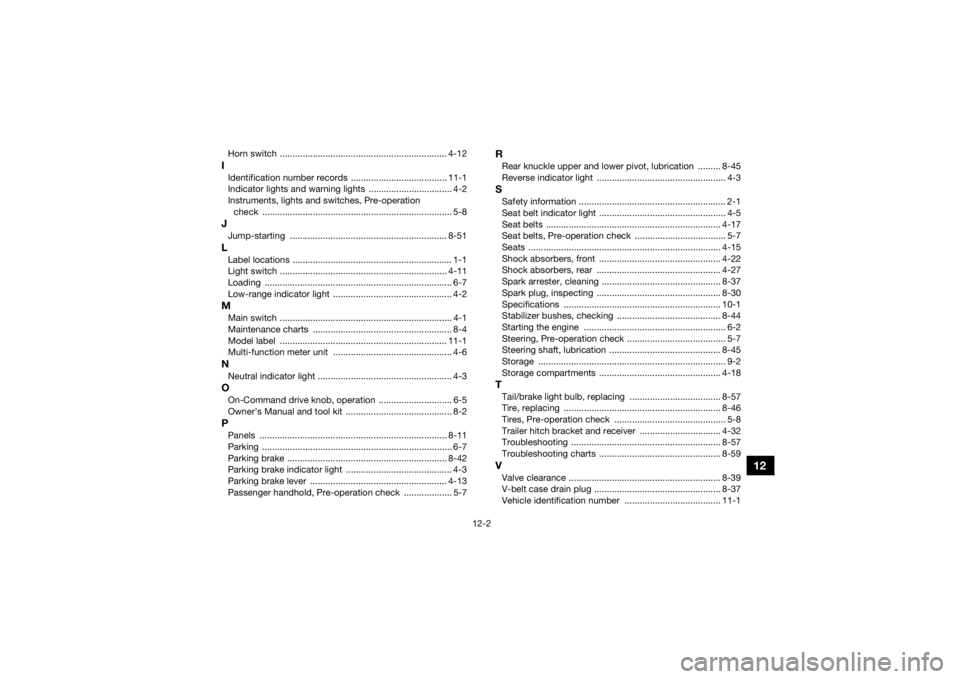

INDEX

AAccelerator pedal ......................................................... 4-12

Accelerator pedal, Pre-operation check ........................ 5-6

Air filter check hoses .................................................... 8-36

Air filter element, cleaning ............................................ 8-32

Auxiliary DC jack .......................................................... 4-33

Axle boots .................................................................... 8-29BBasic guide for safe use ................................................. 7-1

Battery, Periodic maintenance ..................................... 8-47

Brake fluid level, checking ........................................... 8-40

Brake fluid, replacing ...................................................8-41

Brake light switch, adjusting ........................................ 8-42

Brake pedal .................................................................. 4-13

Brake pedal and accelerator pedal, lubrication ........... 8-43

Brake pedal, checking ................................................. 8-42

Brakes, Periodic maintenance ..................................... 8-39

Brakes, Pre-operation check ......................................... 5-3CCable, inspecting and lubrication ................................ 8-43

Cargo bed .................................................................... 4-20

Cleaning ......................................................................... 9-1

Control cables, Pre-operation check ............................. 5-8

Coolant, Periodic maintenance .................................... 8-25

Coolant, Pre-operation check ........................................ 5-6

Coolant temperature warning light ................................. 4-4

Cup holders .................................................................. 4-20DDifferential gear lock indicator light ............................... 4-3Differential gear oil, Periodic maintenance .................. 8-22

Differential gear, Pre-operation check ........................... 5-6

Doors ........................................................................... 4-14

Driver seat position ...................................................... 4-16

Drive select lever .......................................................... 4-14

Drive select lever operation and reverse driving ............ 6-3

Drivetrain icon ................................................................ 4-3

EEngine break-in .............................................................. 6-1

Engine oil and oil filter cartridge, Periodic

maintenance .............................................................. 8-14

Engine oil, Pre-operation check ..................................... 5-5

Engine trouble warning light .......................................... 4-4

EPS warning light ........................................................... 4-5FFinal gear oil, Periodic maintenance ............................ 8-20

Final gear, Pre-operation check ..................................... 5-6

Fittings and fasteners, Pre-operation check .................. 5-7

Four–wheel drive knob (On–Command 4WD) .............. 4-11

Front and rear brake pads, checking ........................... 8-39

Fuel, Pre-operation check .............................................. 5-3

Fuel tank cap ............................................................... 4-14

Fuse, replacing ............................................................. 8-52GGlove compartment ..................................................... 4-18HHeadlight beam, adjusting ........................................... 8-56

Headlight bulb, replacing ............................................. 8-54

Helmet indicator light ..................................................... 4-5

High-range indicator light .............................................. 4-2

Hood ............................................................................ 8-10

UB3D7AE0.book Page 1 Tuesday, November 7, 2017 9:38 AM

Page 185 of 188

12-2

12

Horn switch .................................................................. 4-12IIdentification number records ...................................... 11-1

Indicator lights and warning lights ................................. 4-2

Instruments, lights and switches, Pre-operation check ........................................................................... 5-8JJump-starting .............................................................. 8-51LLabel locations ............................................................... 1-1

Light switch .................................................................. 4-11

Loading .......................................................................... 6-7

Low-range indicator light ............................................... 4-2MMain switch .................................................................... 4-1

Maintenance charts ....................................................... 8-4

Model label .................................................................. 11-1

Multi-function meter unit ............................................... 4-6NNeutral indicator light ..................................................... 4-3OOn-Command drive knob, operation ............................. 6-5

Owner’s Manual and tool kit .......................................... 8-2PPanels .......................................................................... 8-11

Parking ........................................................................... 6-7

Parking brake ............................................................... 8-42

Parking brake indicator light .......................................... 4-3

Parking brake lever ...................................................... 4-13

Passenger handhold, Pre-operation check ................... 5-7

RRear knuckle upper and lower pivot, lubrication ......... 8-45

Reverse indicator light ................................................... 4-3SSafety information .......................................................... 2-1

Seat belt indicator light .................................................. 4-5

Seat belts ..................................................................... 4-17

Seat belts, Pre-operation check .................................... 5-7

Seats ............................................................................ 4-15

Shock absorbers, front ................................................ 4-22

Shock absorbers, rear ................................................. 4-27

Spark arrester, cleaning ............................................... 8-37

Spark plug, inspecting ................................................. 8-30

Specifications .............................................................. 10-1

Stabilizer bushes, checking .......... ............................... 8-44

Starting the engine ........................................................ 6-2

Steering, Pre-operation check ....................................... 5-7

Steering shaft, lubrication ............................................ 8-45

Storage .......................................................................... 9-2

Storage compartments ................................................ 4-18TTail/brake light bulb, replacing .................................... 8-57

Tire, replacing .............................................................. 8-46

Tires, Pre-operation check ............................................ 5-8

Trailer hitch bracket and receiver ................................ 4-32

Troubleshooting ........................................................... 8-57

Troubleshooting charts ................................................ 8-59VValve clearance ............................................................ 8-39

V-belt case drain plug .................................................. 8-37

Vehicle identification number ...................................... 11-1

UB3D7AE0.book Page 2 Tuesday, November 7, 2017 9:38 AM