lock YAMAHA WOLVERINE 2018 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2018, Model line: WOLVERINE, Model: YAMAHA WOLVERINE 2018Pages: 188, PDF Size: 5.4 MB

Page 149 of 188

8-36

8

11. Thoroughly apply Yamaha foam air filteroil or other quality liquid foam air filter oil

(not spray type) to the sponge material.

The sponge material should be wet but

not dripping.

12. Pull the sponge material over its frame.

13. Install the air filt er element holder.

14. Install the air filter element.

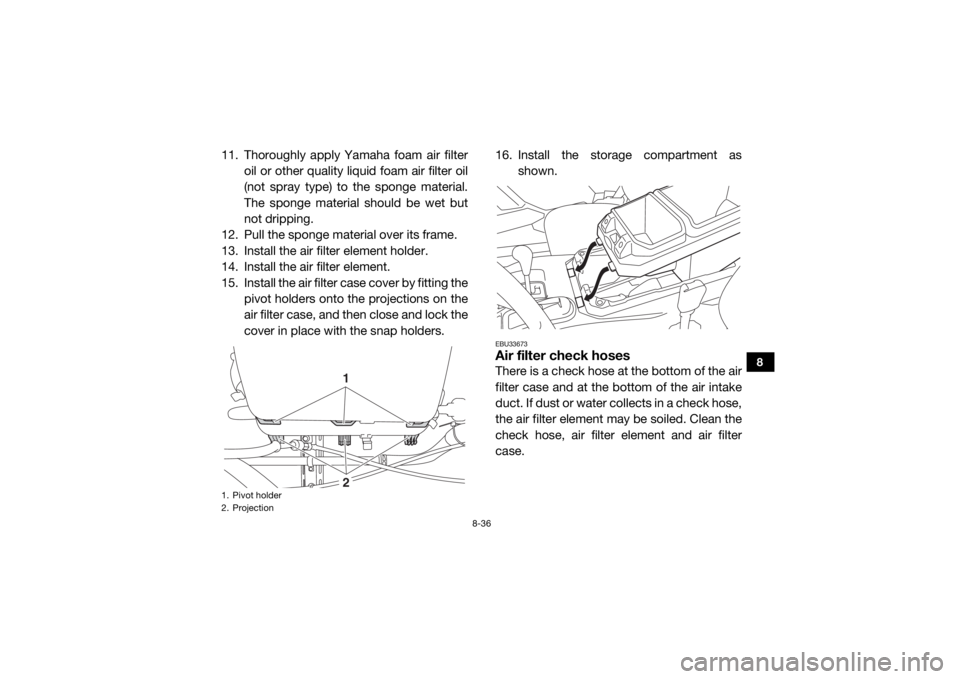

15. Install the air filter case cover by fitting the

pivot holders onto the projections on the

air filter case, and th en close and lock the

cover in place with the snap holders. 16. Install the storage compartment as

shown.

EBU33673Air filter check hosesThere is a check hose at the bottom of the air

filter case and at the bottom of the air intake

duct. If dust or water collects in a check hose,

the air filter element may be soiled. Clean the

check hose, air filter element and air filter

case.

1. Pivot holder

2. Projection

1

2

UB3D7AE0.book Page 36 Tuesday, November 7, 2017 9:38 AM

Page 154 of 188

8-41

8

Clean the filler cap before removing. Use

only DOT 4 brake fluid from a sealed

container.

Use only the specified brake fluid; other-

wise, the rubber seals may deteriorate,

causing leakage.

Refill with the same type of brake fluid.

Adding a brake fluid other than DOT 4

may result in a harmful chemical reac-

tion.

Be careful that water does not enter the

brake fluid reservoir when refilling. Wa-

ter will significantly lower the boiling

point of the fluid and may result in vapor

lock. NOTICEECB01161Brake fluid may damage painted surfaces

or plastic parts. Always clean up spilled

fluid immediately.

As the brake pads wear, it is normal for the

brake fluid level to gradually go down. A low

brake fluid level may indicate worn brake

pads and/or brake system leakage; therefore,

be sure to check the brake pads for wear and

the brake system for leakage. If the brake fluid

level goes down suddenly, have a Yamaha

dealer check and repair the vehicle before

any further operation.EBU32520Brake fluid replacementComplete fluid replacement should be done

only by trained Yamaha service personnel.

Have a Yamaha dealer replace the following

components during periodic maintenance or

when they are damaged or leaking.

Replace the oil seals every two years.

Replace the brake hoses every four years.

UB3D7AE0.book Page 41 Tuesday, November 7, 2017 9:38 AM

Page 166 of 188

8-53

8

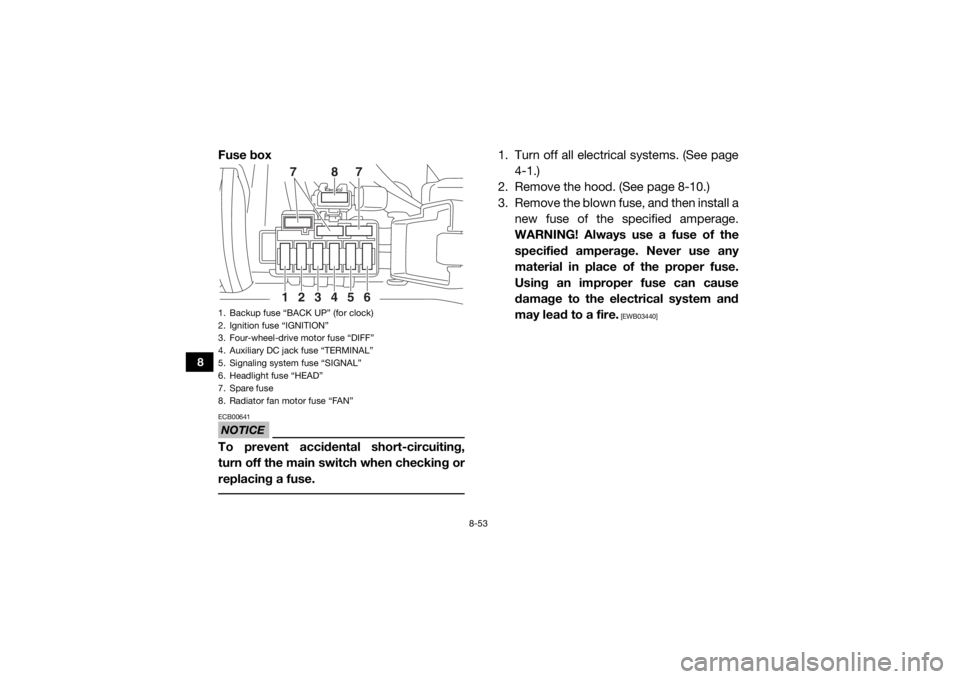

Fuse boxNOTICEECB00641To prevent accidental short-circuiting,

turn off the main switch when checking or

replacing a fuse.

1. Turn off all electrical systems. (See page4-1.)

2. Remove the hood. (See page 8-10.)

3. Remove the blown fuse, and then install a new fuse of the specified amperage.

WARNING! Always use a fuse of the

specified amperage. Never use any

material in place of the proper fuse.

Using an improper fuse can cause

damage to the electrical system and

may lead to a fire.

[EWB03440]

1. Backup fuse “BACK UP” (for clock)

2. Ignition fuse “IGNITION”

3. Four-wheel-drive motor fuse “DIFF”

4. Auxiliary DC jack fuse “TERMINAL”

5. Signaling system fuse “SIGNAL”

6. Headlight fuse “HEAD”

7. Spare fuse

8. Radiator fan motor fuse “FAN”

1

2

3

4

5

6

8

7

7

UB3D7AE0.book Page 53 Tuesday, November 7, 2017 9:38 AM

Page 170 of 188

8-57

8

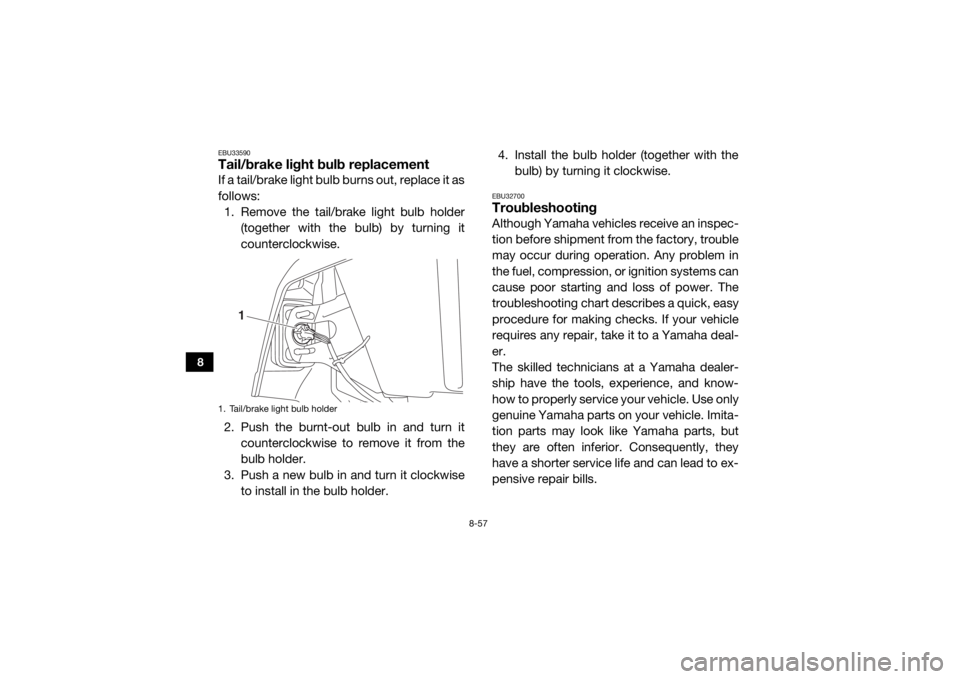

EBU33590Tail/brake light bulb replacementIf a tail/brake light bulb burns out, replace it as

follows:1. Remove the tail/brake light bulb holder

(together with the bulb) by turning it

counterclockwise.

2. Push the burnt-out bulb in and turn it counterclockwise to remove it from the

bulb holder.

3. Push a new bulb in and turn it clockwise to install in the bulb holder. 4. Install the bulb holder (together with the

bulb) by turning it clockwise.

EBU32700TroubleshootingAlthough Yamaha vehicles receive an inspec-

tion before shipment from the factory, trouble

may occur during operation. Any problem in

the fuel, compression, or ignition systems can

cause poor starting and loss of power. The

troubleshooting chart describes a quick, easy

procedure for making checks. If your vehicle

requires any repair, take it to a Yamaha deal-

er.

The skilled technicians at a Yamaha dealer-

ship have the tools, experience, and know-

how to properly service your vehicle. Use only

genuine Yamaha parts on your vehicle. Imita-

tion parts may look like Yamaha parts, but

they are often inferior. Consequently, they

have a shorter service life and can lead to ex-

pensive repair bills.

1. Tail/brake light bulb holder

1

UB3D7AE0.book Page 57 Tuesday, November 7, 2017 9:38 AM

Page 174 of 188

9-1

9

EBU32720

CLEANING AND STORAGE

EBU33681CleaningFrequent, thorough cleaning of your vehicle

will not only enhance its appearance but will

improve its general performance and extend

the useful life of many components.1. Before cleaning the vehicle: a. Block off the end of the exhaust pipe to prevent water entry. A plastic bag

and strong rubber band may be used.

b. Make sure the spark plug and all filler caps are properly installed.

2. If the engine case is excessively greasy, apply degreaser with a paint brush. Do

not apply degreaser to the wheel axles.

3. Rinse the dirt and degreaser off with a garden hose. Use only enough pressure

to do the job. WARNING! Test the

brakes after washing. Apply the

brakes several times at slow speeds to

let friction dry the brakes. Wet brakes may have reduced stopping ability, in-

creasing the chance of an accident.

[EWB03471]

NOTICE: Excessive water pres-

sure may cause water seepage and

deterioration of wheel bearings,

brakes, transmission seals and electri-

cal devices. Many expensive repair

bills have resulted from improper high-

pressure detergent applications such

as those available in coin-operated car

washers.

[ECB00712]

TIPThe tailgate can be removed to make it easier

to clean the cargo bed. To separate the tail-

gate from the cargo bed, unhook the latches,

and then pull up the tailgate. (See page 4-20

for tailgate removal and installation proce-

dures.)

UB3D7AE0.book Page 1 Tuesday, November 7, 2017 9:38 AM

Page 176 of 188

9-3

9

Remove the spark plug wire and ground

it. Operate the electric starter to turn the

engine over several times and coat the

cylinder walls with oil.

3. Lubricate all control cables.

4. Put the frame on stands or blocks to raise

all wheels off the ground.

5. Tie a plastic bag over the exhaust pipe

outlet to prevent moisture from entering.

6. If storing in a humid or salt-air atmo- sphere, coat all exposed metal surfaces

with a light film of oil. Do not apply oil to

any rubber parts or the seat covers.

7. Remove the battery and charge it. Store

it in a dry place and recharge it once a

month. Do not store the battery in an ex-

cessively warm or cold place [less than 0

°C (30 °F) or more than 30 °C (90 °F)].

Use of fuel stabilizer eliminates the need to

drain the fuel system. Consult a Yamaha

dealer if the fuel system needs to be drained.

UB3D7AE0.book Page 3 Tuesday, November 7, 2017 9:38 AM

Page 180 of 188

10-4

10

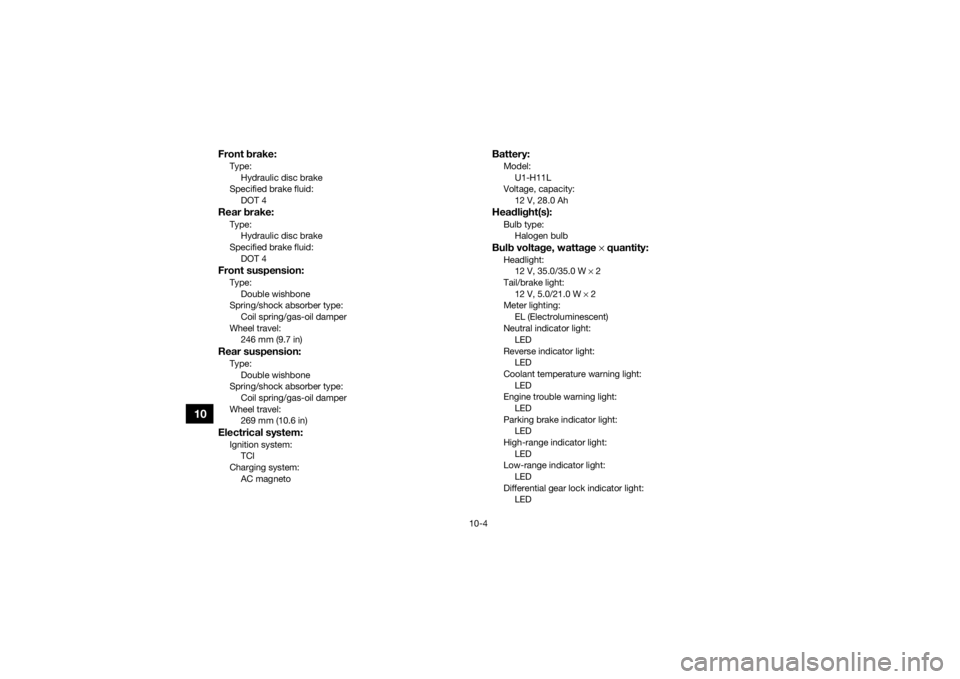

Front brake:Type:Hydraulic disc brake

Specified brake fluid:

DOT 4Rear brake:Type:Hydraulic disc brake

Specified brake fluid:

DOT 4Front suspension:Type:Double wishbone

Spring/shock absorber type:

Coil spring/gas-oil damper

Wheel travel: 246 mm (9.7 in)Rear suspension:Type:

Double wishbone

Spring/shock absorber type: Coil spring/gas-oil damper

Wheel travel: 269 mm (10.6 in)Electrical system:Ignition system:TCI

Charging system: AC magneto

Battery:Model:U1-H11L

Voltage, capacity:

12 V, 28.0 AhHeadlight(s):Bulb type:Halogen bulbBulb voltage, wattage × quantity:Headlight:

12 V, 35.0/35.0 W × 2

Tail/brake light: 12 V, 5.0/21.0 W × 2

Meter lighting:

EL (Electroluminescent)

Neutral indicator light: LED

Reverse indicator light: LED

Coolant temperature warning light:

LED

Engine trouble warning light: LED

Parking brake indicator light: LED

High-range indicator light:

LED

Low-range indicator light: LED

Differential gear lock indicator light: LED

UB3D7AE0.book Page 4 Tuesday, November 7, 2017 9:38 AM

Page 184 of 188

12-1

12

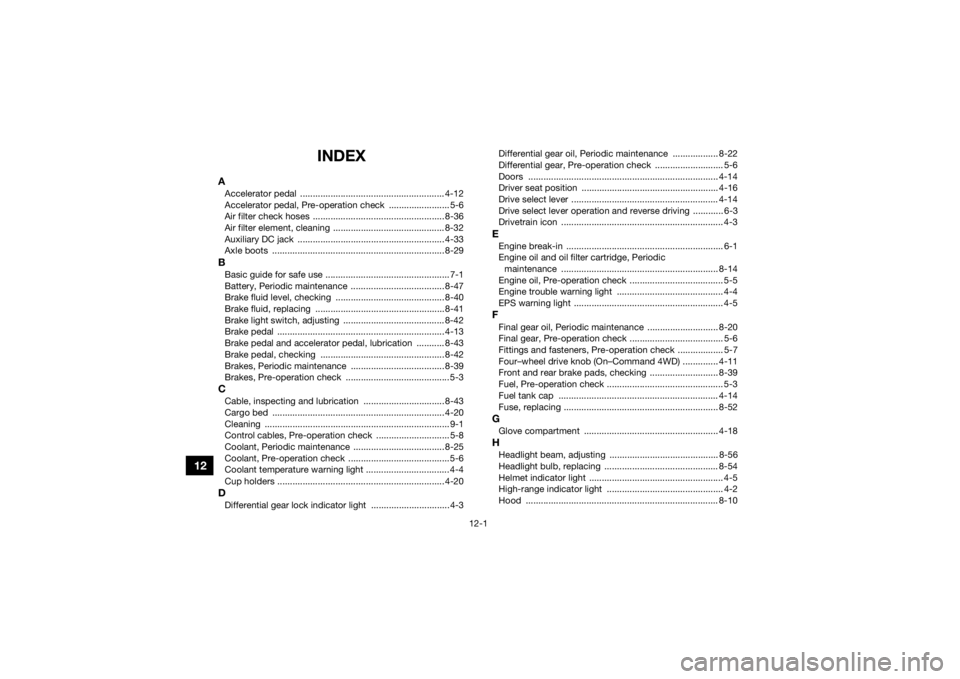

INDEX

AAccelerator pedal ......................................................... 4-12

Accelerator pedal, Pre-operation check ........................ 5-6

Air filter check hoses .................................................... 8-36

Air filter element, cleaning ............................................ 8-32

Auxiliary DC jack .......................................................... 4-33

Axle boots .................................................................... 8-29BBasic guide for safe use ................................................. 7-1

Battery, Periodic maintenance ..................................... 8-47

Brake fluid level, checking ........................................... 8-40

Brake fluid, replacing ...................................................8-41

Brake light switch, adjusting ........................................ 8-42

Brake pedal .................................................................. 4-13

Brake pedal and accelerator pedal, lubrication ........... 8-43

Brake pedal, checking ................................................. 8-42

Brakes, Periodic maintenance ..................................... 8-39

Brakes, Pre-operation check ......................................... 5-3CCable, inspecting and lubrication ................................ 8-43

Cargo bed .................................................................... 4-20

Cleaning ......................................................................... 9-1

Control cables, Pre-operation check ............................. 5-8

Coolant, Periodic maintenance .................................... 8-25

Coolant, Pre-operation check ........................................ 5-6

Coolant temperature warning light ................................. 4-4

Cup holders .................................................................. 4-20DDifferential gear lock indicator light ............................... 4-3Differential gear oil, Periodic maintenance .................. 8-22

Differential gear, Pre-operation check ........................... 5-6

Doors ........................................................................... 4-14

Driver seat position ...................................................... 4-16

Drive select lever .......................................................... 4-14

Drive select lever operation and reverse driving ............ 6-3

Drivetrain icon ................................................................ 4-3

EEngine break-in .............................................................. 6-1

Engine oil and oil filter cartridge, Periodic

maintenance .............................................................. 8-14

Engine oil, Pre-operation check ..................................... 5-5

Engine trouble warning light .......................................... 4-4

EPS warning light ........................................................... 4-5FFinal gear oil, Periodic maintenance ............................ 8-20

Final gear, Pre-operation check ..................................... 5-6

Fittings and fasteners, Pre-operation check .................. 5-7

Four–wheel drive knob (On–Command 4WD) .............. 4-11

Front and rear brake pads, checking ........................... 8-39

Fuel, Pre-operation check .............................................. 5-3

Fuel tank cap ............................................................... 4-14

Fuse, replacing ............................................................. 8-52GGlove compartment ..................................................... 4-18HHeadlight beam, adjusting ........................................... 8-56

Headlight bulb, replacing ............................................. 8-54

Helmet indicator light ..................................................... 4-5

High-range indicator light .............................................. 4-2

Hood ............................................................................ 8-10

UB3D7AE0.book Page 1 Tuesday, November 7, 2017 9:38 AM