coolant YAMAHA WR 250F 2001 Betriebsanleitungen (in German)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: WR 250F, Model: YAMAHA WR 250F 2001Pages: 686, PDF-Größe: 62.6 MB

Page 26 of 686

GEN

INFO

1 - 1

DESCRIPTION

EC100000

GENERAL INFORMATION

EC110000

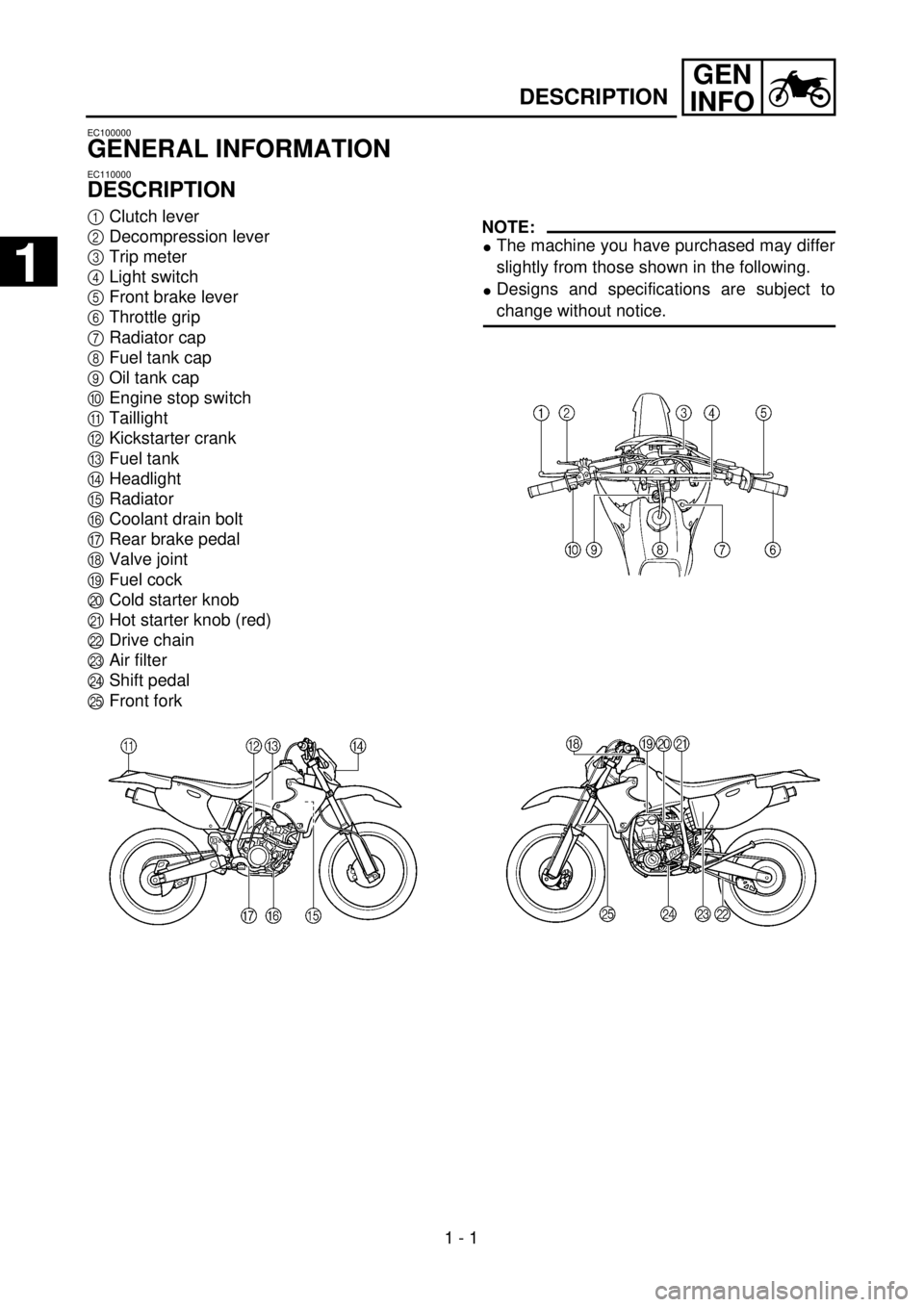

DESCRIPTION

1

Clutch lever

2

Decompression lever

3

Trip meter

4

Light switch

5

Front brake lever

6

Throttle grip

7

Radiator cap

8

Fuel tank cap

9

Oil tank cap

0

Engine stop switch

A

Taillight

B

Kickstarter crank

C

Fuel tank

D

Headlight

E

Radiator

F

Coolant drain bolt

G

Rear brake pedal

H

Valve joint

I

Fuel cock

J

Cold starter knob

K

Hot starter knob (red)

L

Drive chain

M

Air filter

N

Shift pedal

O

Front fork

NOTE:

l

The machine you have purchased may differ

slightly from those shown in the following.

l

Designs and specifications are subject to

change without notice.

1

Page 58 of 686

1 - 14

GEN

INFO

STARTING AND BREAK-IN

STARTING AND BREAK-IN

WARNING

Never start or run the engine in a closed

area. The exhaust fumes are poisonous;

they can cause loss of consciousness and

death in a very short time. Always operate

the machine in a well-ventilated area.

CAUTION:

lThe carburetor on this motorcycle has a

built-in accelerator pump. Therefore,

when starting the engine, do not operate

the throttle or the spark plug will foul.

lUnlike a two-stroke engine, this engine

cannot be kick started when the throttle is

open because the kick starter may kick

back. Also, if the throttle is open the air/

fuel mixture may be too lean for the

engine to start.

lNever use the decompression lever after

the engine is started. The engine may be

damaged if you use the decompression

lever while it is running.

lBefore starting the machine, perform the

checks in the pre-operation check list.

STARTING A COLD ENGINE

1. Inspect the coolant level.

2. Turn the fuel cock to “ON”.

3. Shift the transmission into neutral.

4. Fully open the cold starter knob.

5. Without pulling in the decompression

lever, slowly depress the kickstarter

crank until the compression stroke is

found. When considerable resistance of

the kickstarter crank is felt, the engine is

on the compression stroke. If the engine

is on the exhaust stroke, resistance will

only be felt when the kickstarter crank is

initially depressed, not through the entire

range of depression (as when the engine

is on the compression stroke); therefore,

depress the kickstarter crank a few more

times.

Page 75 of 686

SPEC

2 - 2

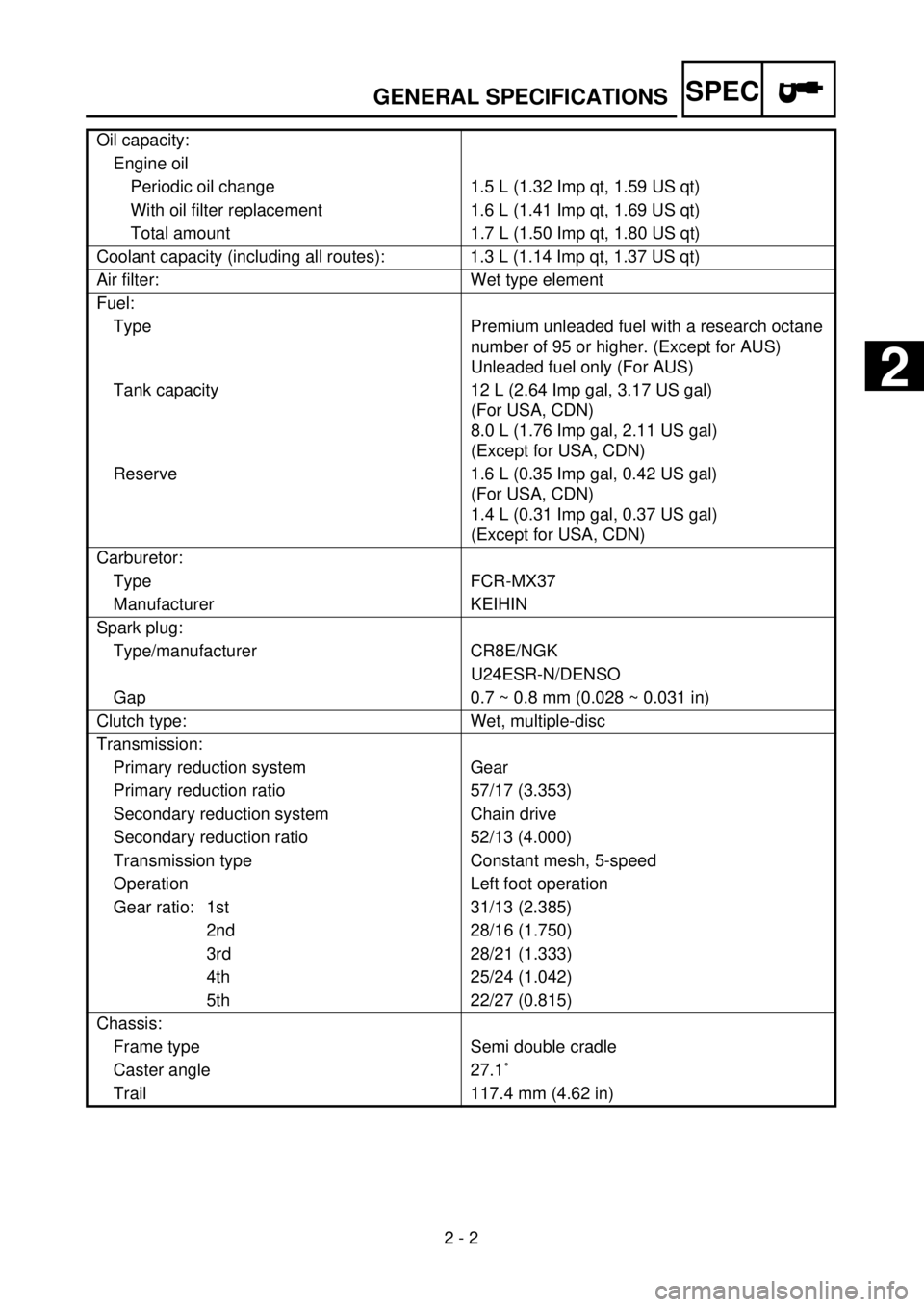

GENERAL SPECIFICATIONS

Oil capacity:

Engine oil

Periodic oil change 1.5 L (1.32 Imp qt, 1.59 US qt)

With oil filter replacement 1.6 L (1.41 Imp qt, 1.69 US qt)

Total amount 1.7 L (1.50 Imp qt, 1.80 US qt)

Coolant capacity (including all routes): 1.3 L (1.14 Imp qt, 1.37 US qt)

Air filter: Wet type element

Fuel:

Type Premium unleaded fuel with a research octane

number of 95 or higher. (Except for AUS)

Unleaded fuel only (For AUS)

Tank capacity 12 L (2.64 Imp gal, 3.17 US gal)

(For USA, CDN)

8.0 L (1.76 Imp gal, 2.11 US gal)

(Except for USA, CDN)

Reserve 1.6 L (0.35 Imp gal, 0.42 US gal)

(For USA, CDN)

1.4 L (0.31 Imp gal, 0.37 US gal)

(Except for USA, CDN)

Carburetor:

Type FCR-MX37

Manufacturer KEIHIN

Spark plug:

Type/manufacturer CR8E/NGK

U24ESR-N/DENSO

Gap 0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

Clutch type: Wet, multiple-disc

Transmission:

Primary reduction system Gear

Primary reduction ratio 57/17 (3.353)

Secondary reduction system Chain drive

Secondary reduction ratio 52/13 (4.000)

Transmission type Constant mesh, 5-speed

Operation Left foot operation

Gear ratio: 1st 31/13 (2.385)

2nd 28/16 (1.750)

3rd 28/21 (1.333)

4th 25/24 (1.042)

5th 22/27 (0.815)

Chassis:

Frame type Semi double cradle

Caster angle 27.1˚

Trail 117.4 mm (4.62 in)

2

Page 83 of 686

SPEC

2 - 10

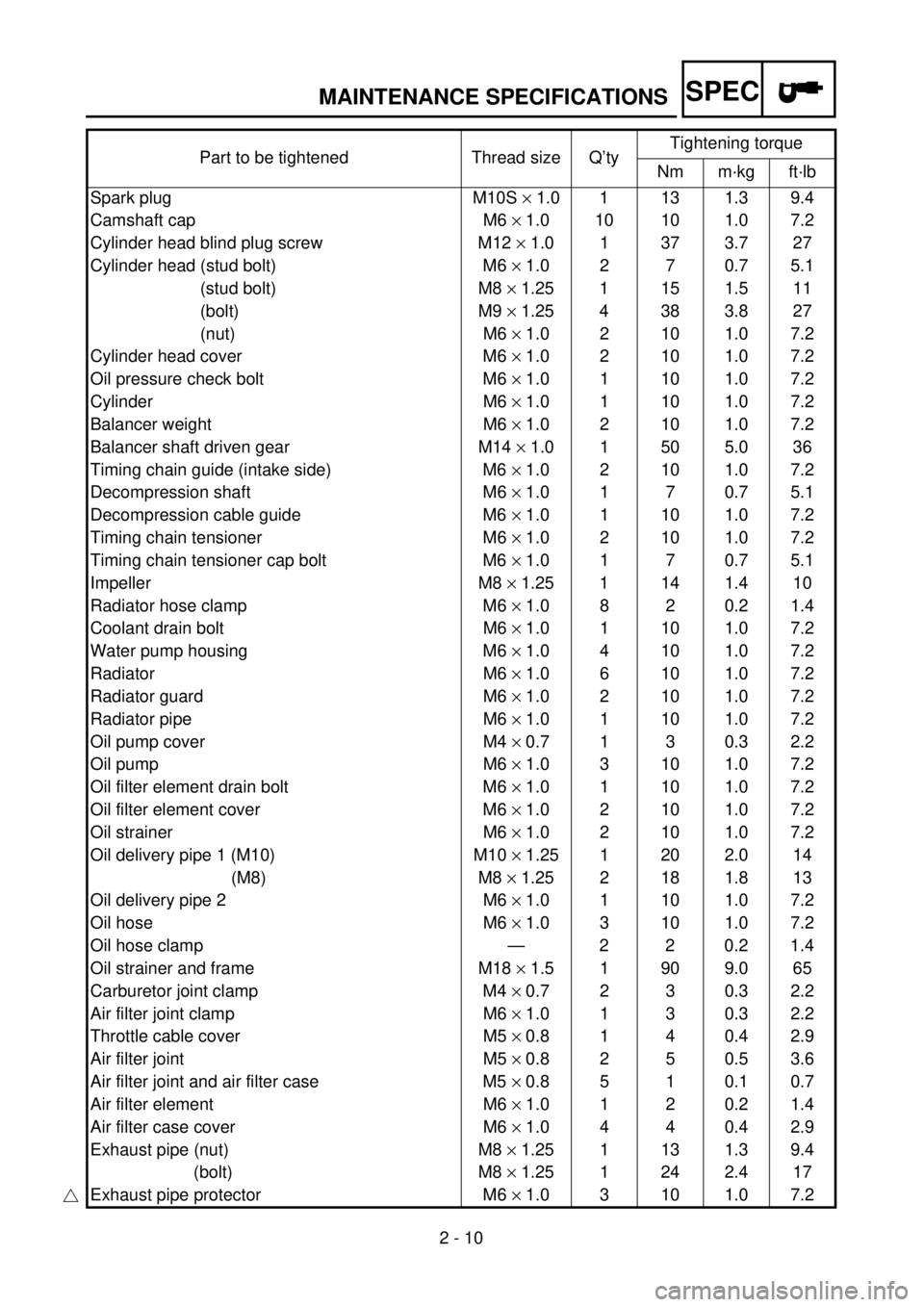

MAINTENANCE SPECIFICATIONS

Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Spark plug M10S

´

1.0 1 13 1.3 9.4

Camshaft cap M6

´

1.0 10 10 1.0 7.2

Cylinder head blind plug screw M12

´

1.0 1 37 3.7 27

Cylinder head (stud bolt) M6

´

1.0 2 7 0.7 5.1

(stud bolt) M8

´

1.25 1 15 1.5 11

(bolt) M9

´

1.25 4 38 3.8 27

(nut) M6

´

1.0 2 10 1.0 7.2

Cylinder head cover M6

´

1.0 2 10 1.0 7.2

Oil pressure check bolt M6

´

1.0 1 10 1.0 7.2

Cylinder M6

´

1.0 1 10 1.0 7.2

Balancer weight M6

´

1.0 2 10 1.0 7.2

Balancer shaft driven gear M14

´

1.0 1 50 5.0 36

Timing chain guide (intake side) M6

´

1.0 2 10 1.0 7.2

Decompression shaft M6

´

1.0 1 7 0.7 5.1

Decompression cable guide M6

´

1.0 1 10 1.0 7.2

Timing chain tensioner M6

´

1.0 2 10 1.0 7.2

Timing chain tensioner cap bolt M6

´

1.0 1 7 0.7 5.1

Impeller M8

´

1.25 1 14 1.4 10

Radiator hose clamp M6

´

1.0 8 2 0.2 1.4

Coolant drain bolt M6

´

1.0 1 10 1.0 7.2

Water pump housing M6

´

1.0 4 10 1.0 7.2

Radiator M6

´

1.0 6 10 1.0 7.2

Radiator guard M6

´

1.0 2 10 1.0 7.2

Radiator pipe M6

´

1.0 1 10 1.0 7.2

Oil pump cover M4

´

0.7 1 3 0.3 2.2

Oil pump M6

´

1.0 3 10 1.0 7.2

Oil filter element drain bolt M6

´

1.0 1 10 1.0 7.2

Oil filter element cover M6

´

1.0 2 10 1.0 7.2

Oil strainer M6

´

1.0 2 10 1.0 7.2

Oil delivery pipe 1 (M10) M10 ´ 1.25 1 20 2.0 14

(M8) M8 ´ 1.25 2 18 1.8 13

Oil delivery pipe 2 M6 ´ 1.0 1 10 1.0 7.2

Oil hose M6 ´ 1.0 3 10 1.0 7.2

Oil hose clamp — 2 2 0.2 1.4

Oil strainer and frame M18 ´ 1.5 1 90 9.0 65

Carburetor joint clamp M4 ´ 0.7 2 3 0.3 2.2

Air filter joint clamp M6 ´ 1.0 1 3 0.3 2.2

Throttle cable cover M5 ´ 0.8 1 4 0.4 2.9

Air filter joint M5 ´ 0.8 2 5 0.5 3.6

Air filter joint and air filter case M5 ´ 0.8 5 1 0.1 0.7

Air filter element M6 ´ 1.0 1 2 0.2 1.4

Air filter case cover M6 ´ 1.0 4 4 0.4 2.9

Exhaust pipe (nut) M8 ´ 1.25 1 13 1.3 9.4

(bolt) M8 ´ 1.25 1 24 2.4 17

Exhaust pipe protector M6 ´ 1.0 3 10 1.0 7.2

Page 89 of 686

SPEC

2 - 16

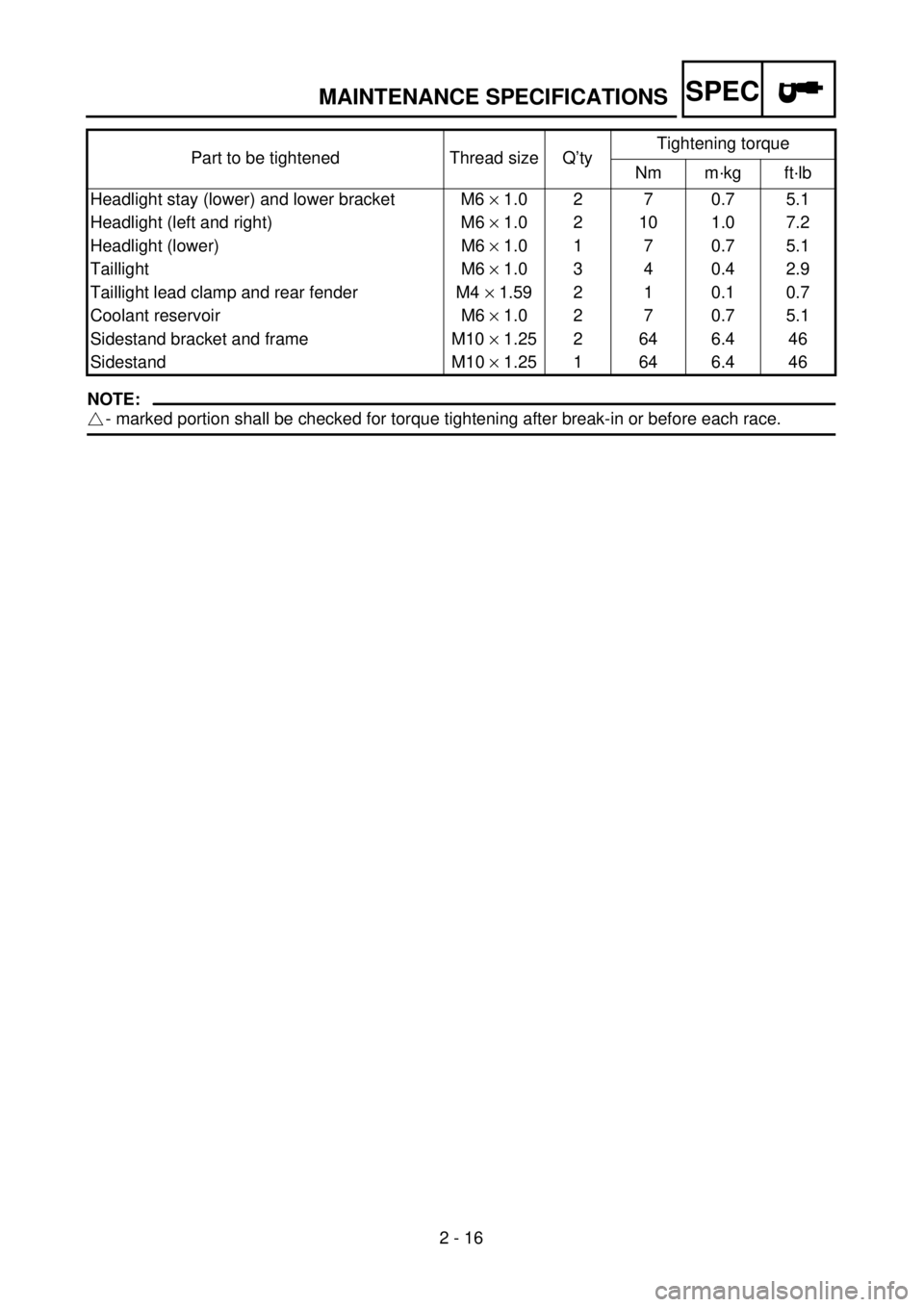

MAINTENANCE SPECIFICATIONS

NOTE:

- marked portion shall be checked for torque tightening after break-in or before each race. Headlight stay (lower) and lower bracket M6 ´ 1.0 2 7 0.7 5.1

Headlight (left and right) M6 ´ 1.0 2 10 1.0 7.2

Headlight (lower) M6 ´ 1.0 1 7 0.7 5.1

Taillight M6 ´ 1.0 3 4 0.4 2.9

Taillight lead clamp and rear fender M4 ´ 1.59 2 1 0.1 0.7

Coolant reservoir M6 ´ 1.0 2 7 0.7 5.1

Sidestand bracket and frame M10 ´ 1.25 2 64 6.4 46

Sidestand M10 ´ 1.25 1 64 6.4 46 Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Page 146 of 686

2 - 19

SPEC

CABLE ROUTING DIAGRAM

EC240000

CABLE ROUTING DIAGRAM

1

Hose guide

2

Brake hose

3

Voltage regulator

4

Light switch lead

5

Fuel tank breather hose

6

Clamp

7

Oil tank breather hose

8

Engine stop switch lead

9

Sub-wire harness

0

Taillight lead

A

Throttle position sensor lead

B

Neutral switch lead

C

Oil hose

D

Cylinder head breather hose

E

CDI magneto lead

F

Clutch cable

G

Cable guide

H

Carburetor breather hose

I

Carburetor overflow hose

J

Coolant reservoir breather hose

K

Decompression cable

L

CDI unit lead

M

Ignition coil lead

N

Voltage regulator lead

Pass the fuel tank breather hose

behind handlebar, then insert it

into the steering stem hole.

õ

Pass the decompression cable,

engine stop switch lead and light

switch lead under where the oil

hose is attached.

‚

Pass the voltage regulator lead,

engine stop switch lead and light

switch lead over the radiator

hose.

ë

Fasten the engine stop switch

lead and ignition coil lead of the

sub-wire harness.

ä

Fasten the sub-wire harness

and engine stop switch lead.

ì

Pass the cylinder head breather

hose along the right side of the

oil tank breather hose.

í

Fasten the sub-wire harness

and engine stop switch lead in

front of the upper engine brack-

ets.

î

Fasten the sub-wire harness.

é

Pass the sub-wire harness

between the upper engine

brackets.

ï

Fasten the sub-wire harness.

ð

Fasten the throttle position sen-

sor lead.

Page 150 of 686

2 - 21

SPEC

1

Coolant reservoir breather hose

2

Radiator breather hose

3

Ignition coil

4

CDI unit

5CDI unit band

6Throttle cable (return)

7Throttle cable (pull)

8Cable guide

9CDI unit lead

0Spark plug lead

ACDI unit stayFasten the coolant reservoir breather hose and

carburetor breather hose together.

õPass the throttle cables along inner side of the

spark plug lead.

‚Pass the CDI unit lead between the radiator hose

and radiator mounting boss.

ëPass the throttle cables through the cable guide.

äInsert the CDI unit band over the CDI unit stay

(frame) as far as possible.

CABLE ROUTING DIAGRAM

Page 152 of 686

2 - 22

SPEC

1Coolant reservoir hose

2Coolant reservoir breather hose

3Clamp

4Taillight lead

5Hose guideFasten the coolant reservoir hose and coolant

reservoir breather hose.

õDo not allow the taillight lead to slacken.

‚Pass the coolant reservoir hose and coolant res-

ervoir breather hose through the hose guide.

CABLE ROUTING DIAGRAM

Page 159 of 686

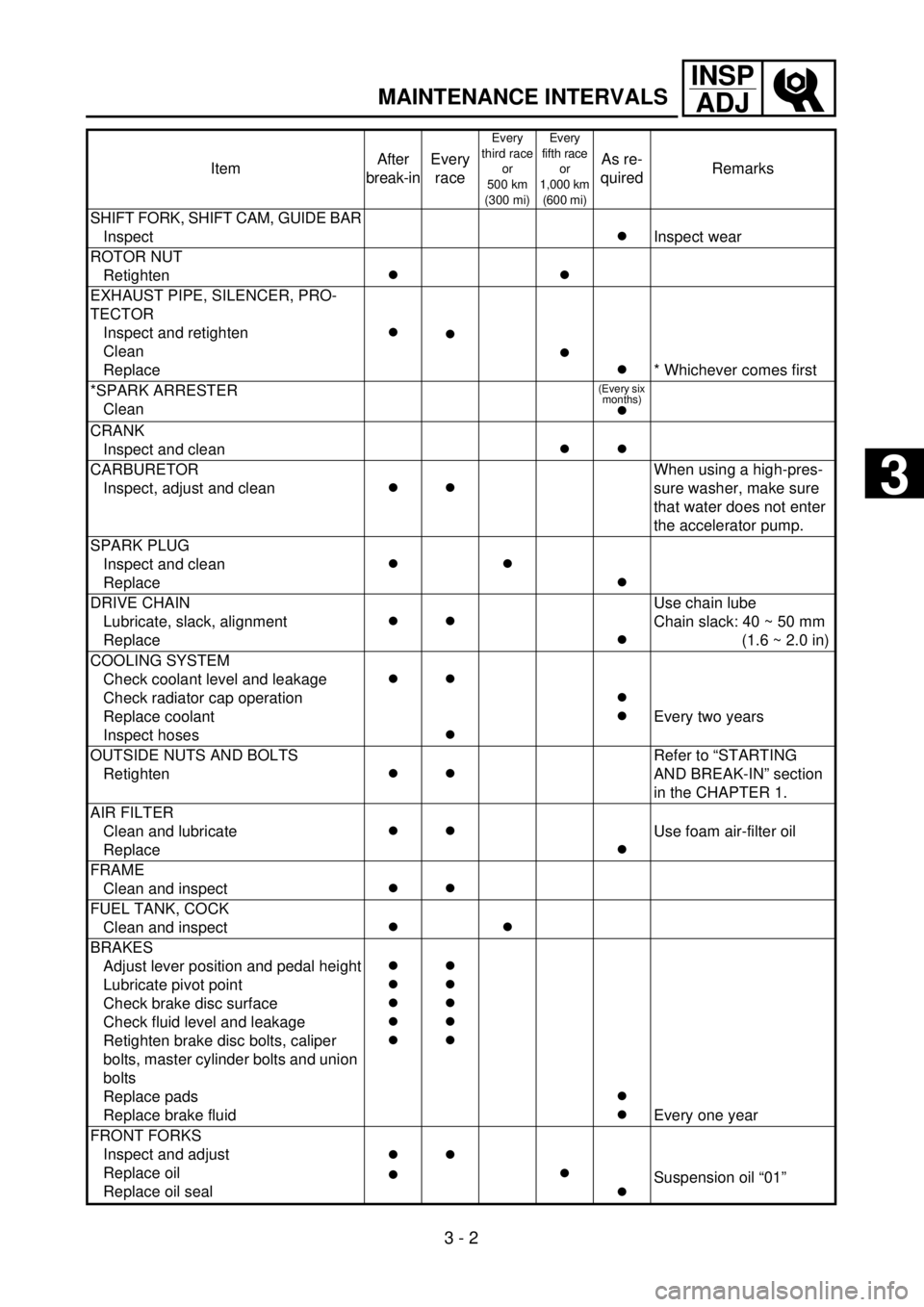

3 - 2

INSP

ADJ

MAINTENANCE INTERVALS

SHIFT FORK, SHIFT CAM, GUIDE BAR

Inspect

c

Inspect wear

ROTOR NUT

Retighten

c

c

EXHAUST PIPE, SILENCER, PRO-

TECTOR

Inspect and retighten

Clean

Replace

c

c

c

c

* Whichever comes first

*SPARK ARRESTER

Clean

(Every six

months)

c

CRANK

Inspect and clean

c

c

CARBURETOR

Inspect, adjust and clean

c

c

When using a high-pres-

sure washer, make sure

that water does not enter

the accelerator pump.

SPARK PLUG

Inspect and clean

Replace

c

c

c

DRIVE CHAIN

Lubricate, slack, alignment

Replace

c

c

c

Use chain lube

Chain slack: 40 ~ 50 mm

(1.6 ~ 2.0 in)

COOLING SYSTEM

Check coolant level and leakage

Check radiator cap operation

Replace coolant

Inspect hoses

c

c

c

c

c

Every two years

OUTSIDE NUTS AND BOLTS

Retighten

c

c

Refer to “STARTING

AND BREAK-IN” section

in the CHAPTER 1.

AIR FILTER

Clean and lubricate

Replace

c

c

c

Use foam air-filter oil

FRAME

Clean and inspect

c

c

FUEL TANK, COCK

Clean and inspect

c

c

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper

bolts, master cylinder bolts and union

bolts

Replace pads

Replace brake fluid

c

c

c

c

c

c

c

c

c

c

c

c

Every one year

FRONT FORKS

Inspect and adjust

Replace oil

Replace oil seal

c

c

c

c

c

Suspension oil “01” ItemAfter

break-inEvery

race

Every

third race

or

500 km

(300 mi)Every

fifth race

or

1,000 km

(600 mi)

As re-

quiredRemarks

3

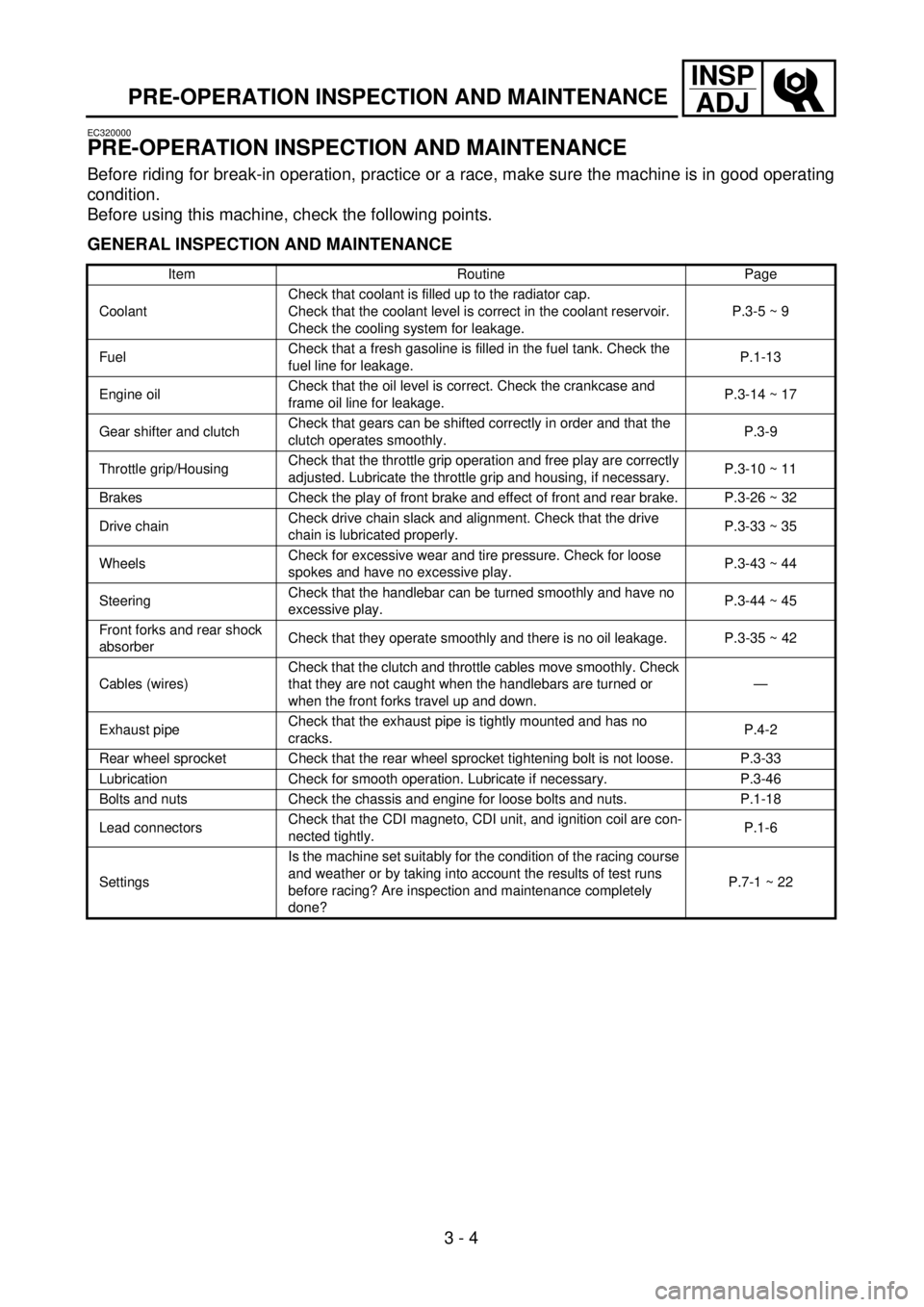

Page 170 of 686

3 - 4

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap.

Check that the coolant level is correct in the coolant reservoir.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-13

Engine oilCheck that the oil level is correct. Check the crankcase and

frame oil line for leakage.P.3-14 ~ 17

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-9

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10 ~ 11

Brakes Check the play of front brake and effect of front and rear brake. P.3-26 ~ 32

Drive chainCheck drive chain slack and alignment. Check that the drive

chain is lubricated properly.P.3-33 ~ 35

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-43 ~ 44

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-44 ~ 45

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-35 ~ 42

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or

when the front forks travel up and down.—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and has no

cracks.P.4-2

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-33

Lubrication Check for smooth operation. Lubricate if necessary. P.3-46

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-18

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-6

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 22