radiator cap YAMAHA WR 250F 2001 Manuale duso (in Italian)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: WR 250F, Model: YAMAHA WR 250F 2001Pages: 686, PDF Dimensioni: 62.6 MB

Page 23 of 686

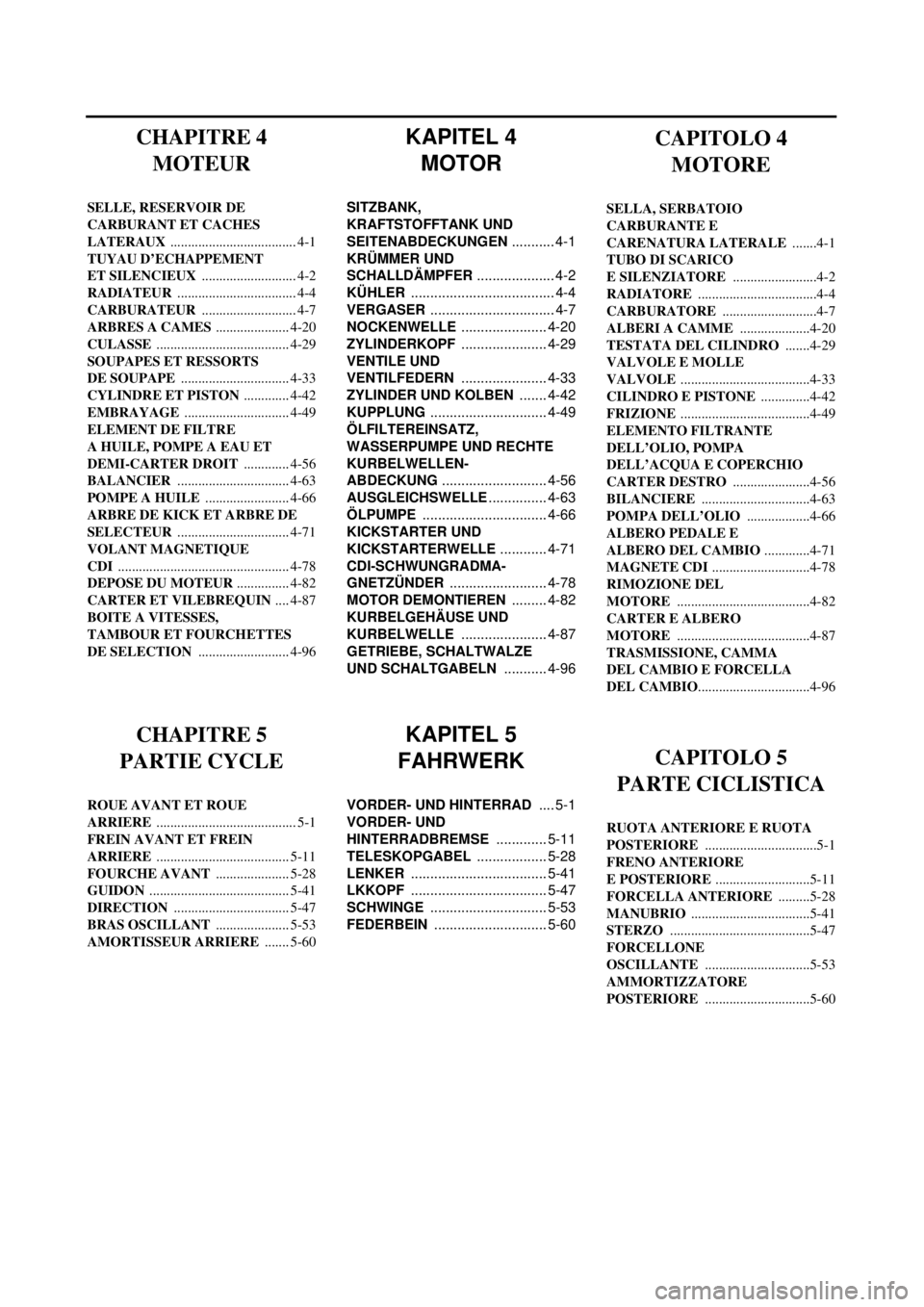

KAPITEL 4

MOTOR

SITZBANK,

KRAFTSTOFFTANK UND

SEITENABDECKUNGEN

........... 4-1

KRÜMMER UND

SCHALLDÄMPFER

.................... 4-2

KÜHLER

..................................... 4-4

VERGASER

................................ 4-7

NOCKENWELLE

...................... 4-20

ZYLINDERKOPF

...................... 4-29

VENTILE UND

VENTILFEDERN

...................... 4-33

ZYLINDER UND KOLBEN

....... 4-42

KUPPLUNG

.............................. 4-49

ÖLFILTEREINSATZ,

WASSERPUMPE UND RECHTE

KURBELWELLEN-

ABDECKUNG

........................... 4-56

AUSGLEICHSWELLE

............... 4-63

ÖLPUMPE

................................ 4-66

KICKSTARTER UND

KICKSTARTERWELLE

............ 4-71

CDI-SCHWUNGRADMA-

GNETZÜNDER

......................... 4-78

MOTOR DEMONTIEREN

......... 4-82

KURBELGEHÄUSE UND

KURBELWELLE

...................... 4-87

GETRIEBE, SCHALTWALZE

UND SCHALTGABELN

........... 4-96

KAPITEL 5

FAHRWERK

VORDER- UND HINTERRAD

.... 5-1

VORDER- UND

HINTERRADBREMSE

............. 5-11

TELESKOPGABEL

.................. 5-28

LENKER

................................... 5-41

LKKOPF

................................... 5-47

SCHWINGE

.............................. 5-53

FEDERBEIN

............................. 5-60

CHAPITRE 4

MOTEUR

SELLE, RESERVOIR DE

CARBURANT ET CACHES

LATERAUX

.................................... 4-1

TUYAU D’ECHAPPEMENT

ET SILENCIEUX

........................... 4-2

RADIATEUR

.................................. 4-4

CARBURATEUR

........................... 4-7

ARBRES A CAMES

..................... 4-20

CULASSE

...................................... 4-29

SOUPAPES ET RESSORTS

DE SOUPAPE

............................... 4-33

CYLINDRE ET PISTON

............. 4-42

EMBRAYAGE

.............................. 4-49

ELEMENT DE FILTRE

A HUILE, POMPE A EAU ET

DEMI-CARTER DROIT

............. 4-56

BALANCIER

................................ 4-63

POMPE A HUILE

........................ 4-66

ARBRE DE KICK ET ARBRE DE

SELECTEUR

................................ 4-71

VOLANT MAGNETIQUE

CDI

................................................. 4-78

DEPOSE DU MOTEUR

............... 4-82

CARTER ET VILEBREQUIN

.... 4-87

BOITE A VITESSES,

TAMBOUR ET FOURCHETTES

DE SELECTION

.......................... 4-96

CHAPITRE 5

PARTIE CYCLE

ROUE AVANT ET ROUE

ARRIERE

........................................ 5-1

FREIN AVANT ET FREIN

ARRIERE

...................................... 5-11

FOURCHE AVANT

..................... 5-28

GUIDON ........................................ 5-41

DIRECTION ................................. 5-47

BRAS OSCILLANT ..................... 5-53

AMORTISSEUR ARRIERE ....... 5-60

CAPITOLO 4

MOTORE

SELLA, SERBATOIO

CARBURANTE E

CARENATURA LATERALE .......4-1

TUBO DI SCARICO

E SILENZIATORE ........................4-2

RADIATORE ..................................4-4

CARBURATORE ...........................4-7

ALBERI A CAMME ....................4-20

TESTATA DEL CILINDRO .......4-29

VALVOLE E MOLLE

VALVOLE .....................................4-33

CILINDRO E PISTONE ..............4-42

FRIZIONE .....................................4-49

ELEMENTO FILTRANTE

DELL’OLIO, POMPA

DELL’ACQUA E COPERCHIO

CARTER DESTRO ......................4-56

BILANCIERE ...............................4-63

POMPA DELL’OLIO ..................4-66

ALBERO PEDALE E

ALBERO DEL CAMBIO .............4-71

MAGNETE CDI ............................4-78

RIMOZIONE DEL

MOTORE ......................................4-82

CARTER E ALBERO

MOTORE ......................................4-87

TRASMISSIONE, CAMMA

DEL CAMBIO E FORCELLA

DEL CAMBIO................................4-96

CAPITOLO 5

PARTE CICLISTICA

RUOTA ANTERIORE E RUOTA

POSTERIORE ................................5-1

FRENO ANTERIORE

E POSTERIORE ...........................5-11

FORCELLA ANTERIORE .........5-28

MANUBRIO ..................................5-41

STERZO ........................................5-47

FORCELLONE

OSCILLANTE ..............................5-53

AMMORTIZZATORE

POSTERIORE ..............................5-60

Page 26 of 686

GEN

INFO

1 - 1

DESCRIPTION

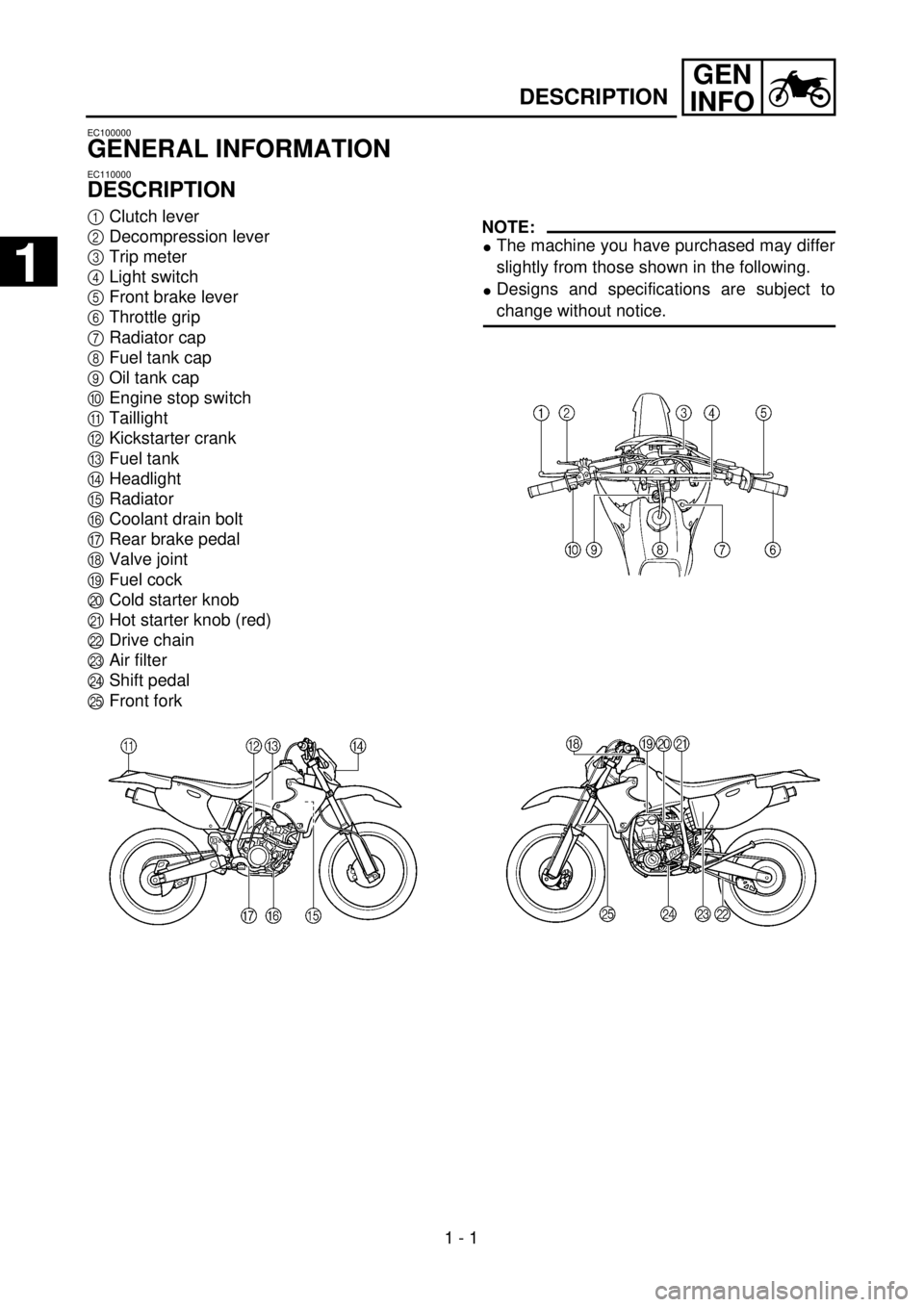

EC100000

GENERAL INFORMATION

EC110000

DESCRIPTION

1

Clutch lever

2

Decompression lever

3

Trip meter

4

Light switch

5

Front brake lever

6

Throttle grip

7

Radiator cap

8

Fuel tank cap

9

Oil tank cap

0

Engine stop switch

A

Taillight

B

Kickstarter crank

C

Fuel tank

D

Headlight

E

Radiator

F

Coolant drain bolt

G

Rear brake pedal

H

Valve joint

I

Fuel cock

J

Cold starter knob

K

Hot starter knob (red)

L

Drive chain

M

Air filter

N

Shift pedal

O

Front fork

NOTE:

l

The machine you have purchased may differ

slightly from those shown in the following.

l

Designs and specifications are subject to

change without notice.

1

Page 38 of 686

GEN

INFO

1 - 7

SPECIAL TOOLS

EC140001

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the

correct special tool will help prevent damage caused by the use of improper tools or improvised

techniques. The shape and part number used for the special tool differ by country, so two types are

provided. Refer to the list provided to avoid errors when placing an order.

NOTE:

lFor U.S.A. and Canada, use part number starting with “YM-” or “YU-”.

lFor others, use part number starting with “90890-”.

Part number Tool name/How to use Illustration

YU-1135-A, 90890-01135 Crankcase separating tool

These tool is used to remove the crankshaft from

either case.YU-1135-A 90890-01135

YU-1235, 90890-01235 Rotor holding tool

This tool is used when loosening or tightening the fly-

wheel magneto securing nut.YU-1235 90890-01235

YU-3097, 90890-01252

YU-1256Dial gauge and stand

Stand

These tools are used to check each part for runout or

bent.YU-3097

YU-125690890-01252

YU-90050, 90890-01274

YU-90050, 90890-01275

YU-91044, 90890-04081

YM-1277, 90890-01277Crankshaft installing tool

Crankshaft installing pot

Crankshaft installing bolt

Spacer (crankshaft installer)

Adapter (M10)

These tools are used to install the crankshaft.YU-90050

YM-1277

YU-9104490890-01274

90890-01275

90890-01277

90890-04081

YU-1304, 90890-01304 Piston pin puller set

This tool is used to remove the piston pin.YU-1304 90890-01304

YU-24460-01, 90890-01325

YU-33984, 90890-01352Radiator cap tester

Radiator cap tester adapter

These tools are used for checking the cooling sys-

tem.YU-24460-01

YU-3398490890-01325

90890-01352

YU-33270-B, 90890-01362Flywheel puller

This tool is used to remove the flywheel magneto.YM-33270-B 90890-01362

Page 82 of 686

SPEC

2 - 9

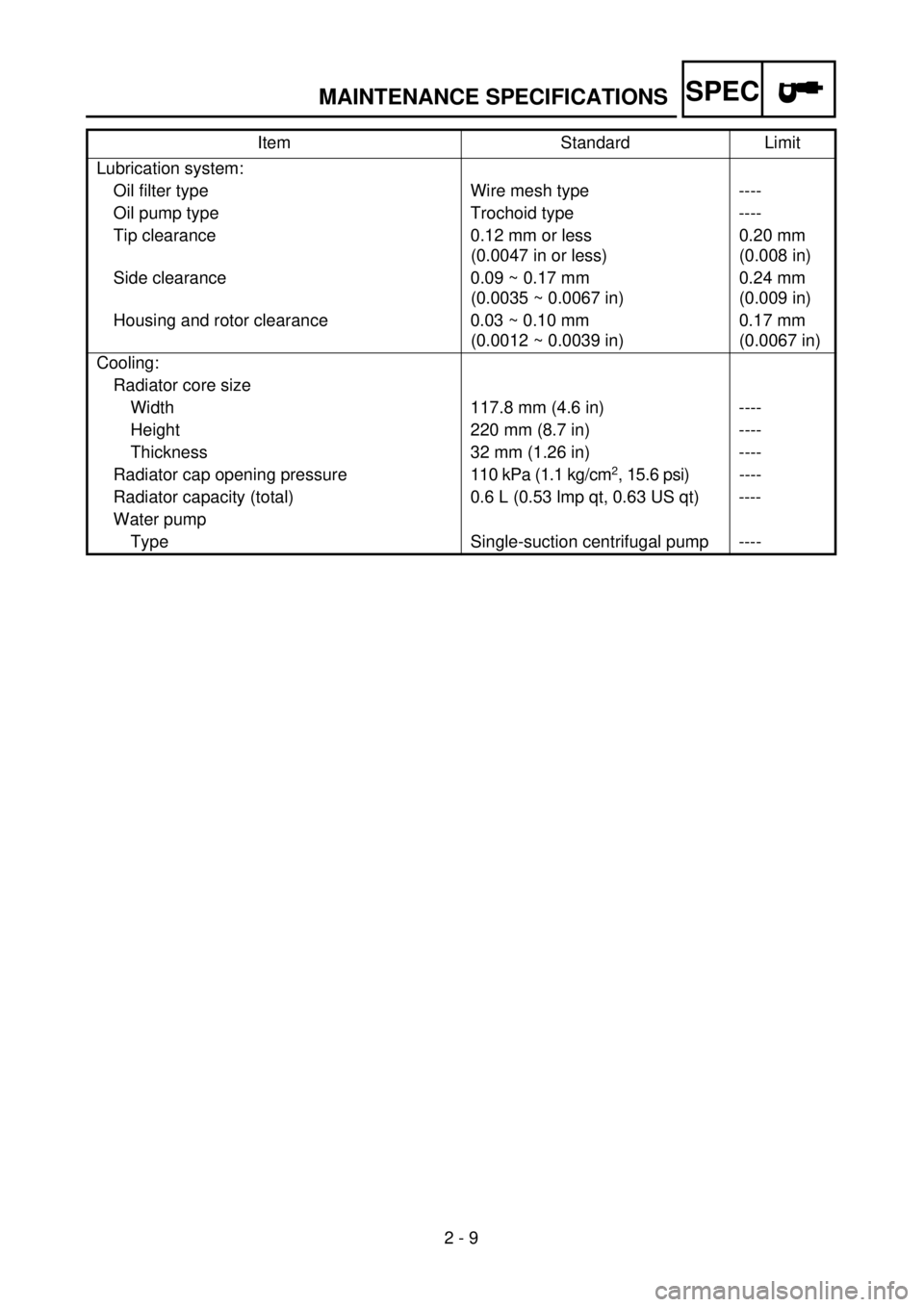

MAINTENANCE SPECIFICATIONS

Lubrication system:

Oil filter type Wire mesh type ----

Oil pump type Trochoid type ----

Tip clearance 0.12 mm or less

(0.0047 in or less)0.20 mm

(0.008 in)

Side clearance 0.09 ~ 0.17 mm

(0.0035 ~ 0.0067 in)0.24 mm

(0.009 in)

Housing and rotor clearance 0.03 ~ 0.10 mm

(0.0012 ~ 0.0039 in)0.17 mm

(0.0067 in)

Cooling:

Radiator core size

Width 117.8 mm (4.6 in) ----

Height 220 mm (8.7 in) ----

Thickness 32 mm (1.26 in) ----

Radiator cap opening pressure110 kPa (1.1 kg/cm

2

, 15.6 psi)----

Radiator capacity (total) 0.6 L (0.53 lmp qt, 0.63 US qt) ----

Water pump

Type Single-suction centrifugal pump ----Item Standard Limit

Page 83 of 686

SPEC

2 - 10

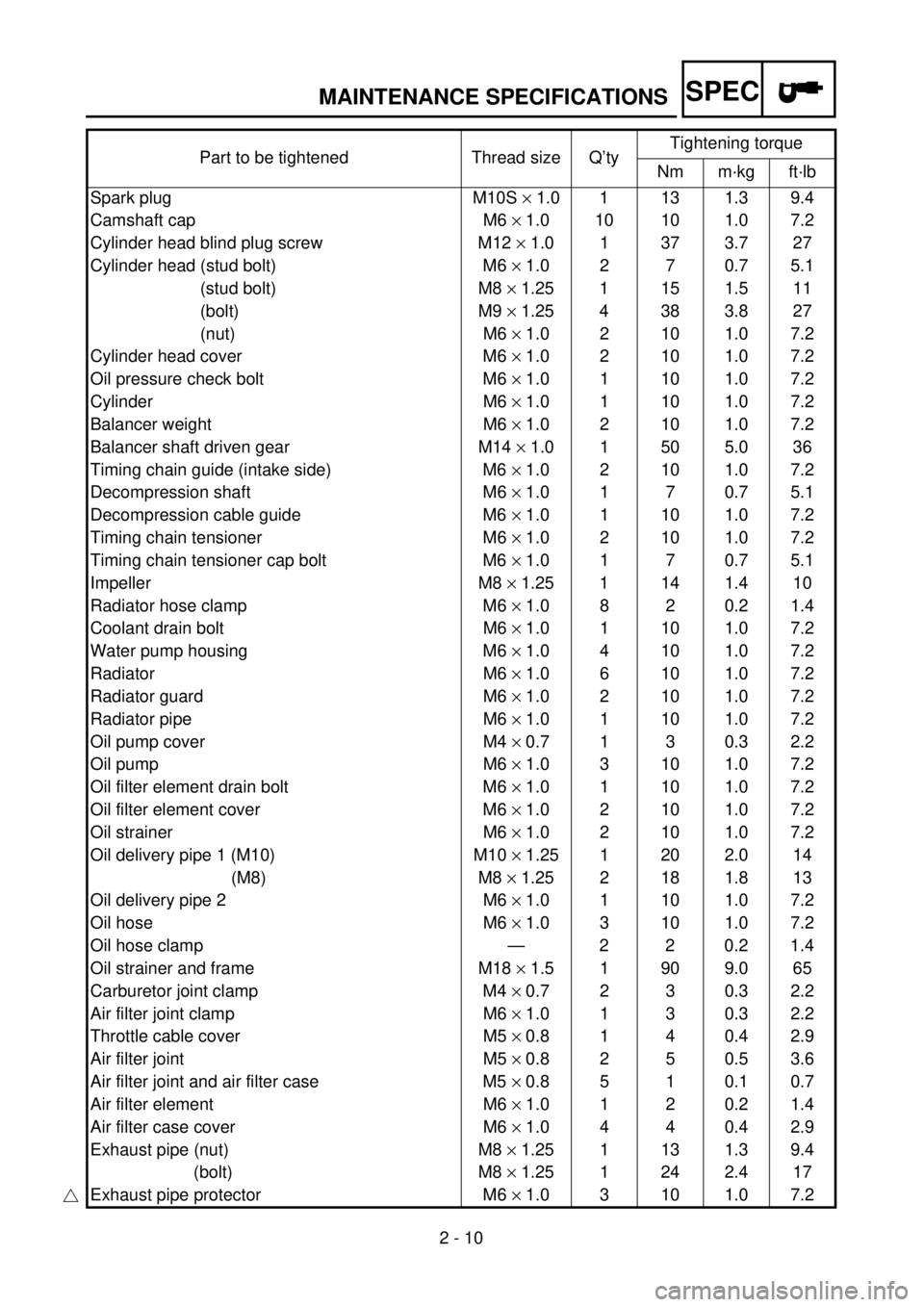

MAINTENANCE SPECIFICATIONS

Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Spark plug M10S

´

1.0 1 13 1.3 9.4

Camshaft cap M6

´

1.0 10 10 1.0 7.2

Cylinder head blind plug screw M12

´

1.0 1 37 3.7 27

Cylinder head (stud bolt) M6

´

1.0 2 7 0.7 5.1

(stud bolt) M8

´

1.25 1 15 1.5 11

(bolt) M9

´

1.25 4 38 3.8 27

(nut) M6

´

1.0 2 10 1.0 7.2

Cylinder head cover M6

´

1.0 2 10 1.0 7.2

Oil pressure check bolt M6

´

1.0 1 10 1.0 7.2

Cylinder M6

´

1.0 1 10 1.0 7.2

Balancer weight M6

´

1.0 2 10 1.0 7.2

Balancer shaft driven gear M14

´

1.0 1 50 5.0 36

Timing chain guide (intake side) M6

´

1.0 2 10 1.0 7.2

Decompression shaft M6

´

1.0 1 7 0.7 5.1

Decompression cable guide M6

´

1.0 1 10 1.0 7.2

Timing chain tensioner M6

´

1.0 2 10 1.0 7.2

Timing chain tensioner cap bolt M6

´

1.0 1 7 0.7 5.1

Impeller M8

´

1.25 1 14 1.4 10

Radiator hose clamp M6

´

1.0 8 2 0.2 1.4

Coolant drain bolt M6

´

1.0 1 10 1.0 7.2

Water pump housing M6

´

1.0 4 10 1.0 7.2

Radiator M6

´

1.0 6 10 1.0 7.2

Radiator guard M6

´

1.0 2 10 1.0 7.2

Radiator pipe M6

´

1.0 1 10 1.0 7.2

Oil pump cover M4

´

0.7 1 3 0.3 2.2

Oil pump M6

´

1.0 3 10 1.0 7.2

Oil filter element drain bolt M6

´

1.0 1 10 1.0 7.2

Oil filter element cover M6

´

1.0 2 10 1.0 7.2

Oil strainer M6

´

1.0 2 10 1.0 7.2

Oil delivery pipe 1 (M10) M10 ´ 1.25 1 20 2.0 14

(M8) M8 ´ 1.25 2 18 1.8 13

Oil delivery pipe 2 M6 ´ 1.0 1 10 1.0 7.2

Oil hose M6 ´ 1.0 3 10 1.0 7.2

Oil hose clamp — 2 2 0.2 1.4

Oil strainer and frame M18 ´ 1.5 1 90 9.0 65

Carburetor joint clamp M4 ´ 0.7 2 3 0.3 2.2

Air filter joint clamp M6 ´ 1.0 1 3 0.3 2.2

Throttle cable cover M5 ´ 0.8 1 4 0.4 2.9

Air filter joint M5 ´ 0.8 2 5 0.5 3.6

Air filter joint and air filter case M5 ´ 0.8 5 1 0.1 0.7

Air filter element M6 ´ 1.0 1 2 0.2 1.4

Air filter case cover M6 ´ 1.0 4 4 0.4 2.9

Exhaust pipe (nut) M8 ´ 1.25 1 13 1.3 9.4

(bolt) M8 ´ 1.25 1 24 2.4 17

Exhaust pipe protector M6 ´ 1.0 3 10 1.0 7.2

Page 88 of 686

SPEC

2 - 15

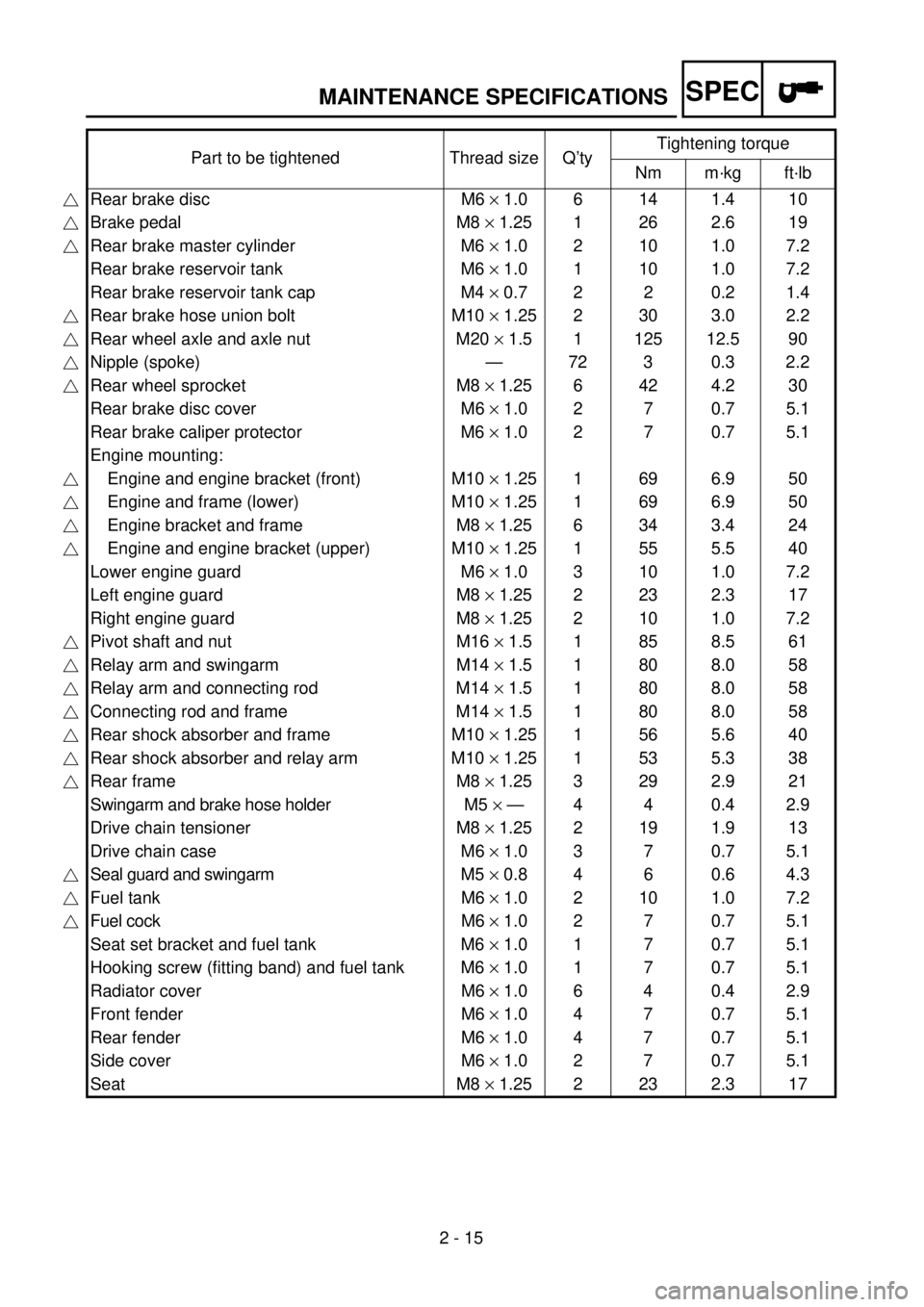

MAINTENANCE SPECIFICATIONS

Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Rear brake disc M6 ´ 1.0 6 14 1.4 10

Brake pedal M8 ´ 1.25 1 26 2.6 19

Rear brake master cylinder M6 ´ 1.0 2 10 1.0 7.2

Rear brake reservoir tank M6 ´ 1.0 1 10 1.0 7.2

Rear brake reservoir tank cap M4 ´ 0.7 2 2 0.2 1.4

Rear brake hose union bolt M10 ´ 1.25 2 30 3.0 2.2

Rear wheel axle and axle nut M20 ´ 1.5 1 125 12.5 90

Nipple (spoke) — 72 3 0.3 2.2

Rear wheel sprocket M8 ´ 1.25 6 42 4.2 30

Rear brake disc cover M6 ´ 1.0 2 7 0.7 5.1

Rear brake caliper protector M6 ´ 1.0 2 7 0.7 5.1

Engine mounting:

Engine and engine bracket (front) M10 ´ 1.25 1 69 6.9 50

Engine and frame (lower) M10 ´ 1.25 1 69 6.9 50

Engine bracket and frame M8 ´ 1.25 6 34 3.4 24

Engine and engine bracket (upper) M10 ´ 1.25 1 55 5.5 40

Lower engine guard M6 ´ 1.0 3 10 1.0 7.2

Left engine guard M8 ´ 1.25 2 23 2.3 17

Right engine guard M8 ´ 1.25 2 10 1.0 7.2

Pivot shaft and nut M16 ´ 1.5 1 85 8.5 61

Relay arm and swingarm M14 ´ 1.5 1 80 8.0 58

Relay arm and connecting rod M14 ´ 1.5 1 80 8.0 58

Connecting rod and frame M14 ´ 1.5 1 80 8.0 58

Rear shock absorber and frame M10 ´ 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 ´ 1.25 1 53 5.3 38

Rear frame M8 ´ 1.25 3 29 2.9 21

Swingarm and brake hose holder M5 ´ — 4 4 0.4 2.9

Drive chain tensioner M8 ´ 1.25 2 19 1.9 13

Drive chain case M6 ´ 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 ´ 0.8 4 6 0.6 4.3

Fuel tank M6 ´ 1.0 2 10 1.0 7.2

Fuel cock M6 ´ 1.0 2 7 0.7 5.1

Seat set bracket and fuel tank M6 ´ 1.0 1 7 0.7 5.1

Hooking screw (fitting band) and fuel tank M6 ´ 1.0 1 7 0.7 5.1

Radiator cover M6 ´ 1.0 6 4 0.4 2.9

Front fender M6 ´ 1.0 4 7 0.7 5.1

Rear fender M6 ´ 1.0 4 7 0.7 5.1

Side cover M6 ´ 1.0 2 7 0.7 5.1

Seat M8 ´ 1.25 2 23 2.3 17

Page 136 of 686

SPEC

2 - 9

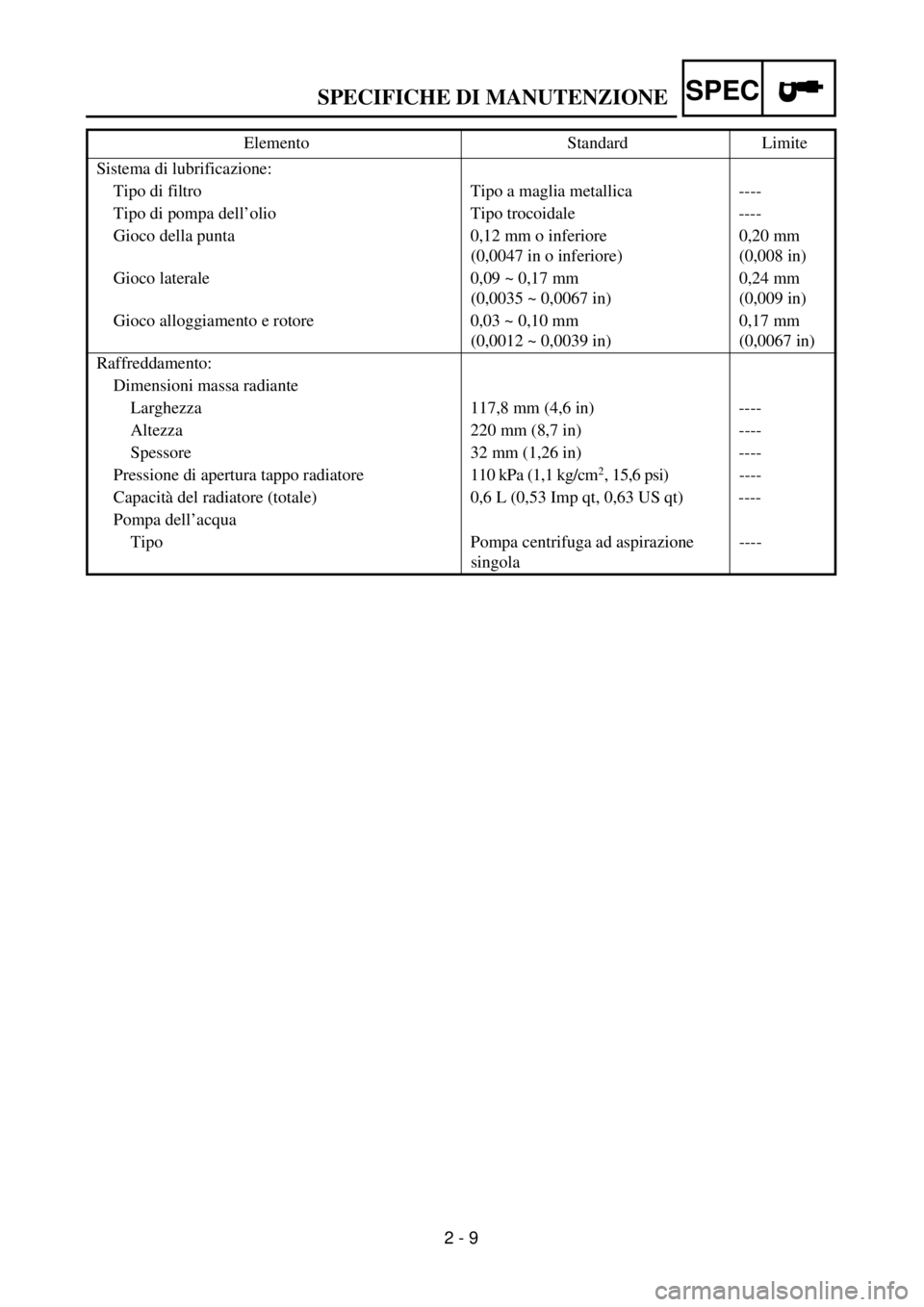

SPECIFICHE DI MANUTENZIONE

Sistema di lubrificazione:

Tipo di filtro Tipo a maglia metallica ----

Tipo di pompa dell’olio Tipo trocoidale ----

Gioco della punta 0,12 mm o inferiore

(0,0047 in o inferiore)0,20 mm

(0,008 in)

Gioco laterale 0,09 ~ 0,17 mm

(0,0035 ~ 0,0067 in)0,24 mm

(0,009 in)

Gioco alloggiamento e rotore 0,03 ~ 0,10 mm

(0,0012 ~ 0,0039 in)0,17 mm

(0,0067 in)

Raffreddamento:

Dimensioni massa radiante

Larghezza 117,8 mm (4,6 in) ----

Altezza 220 mm (8,7 in) ----

Spessore 32 mm (1,26 in) ----

Pressione di apertura tappo radiatore110 kPa (1,1 kg/cm

2

, 15,6 psi)----

Capacità del radiatore (totale) 0,6 L (0,53 Imp qt, 0,63 US qt) ----

Pompa dell’acqua

Tipo Pompa centrifuga ad aspirazione

singola---- Elemento Standard Limite

Page 137 of 686

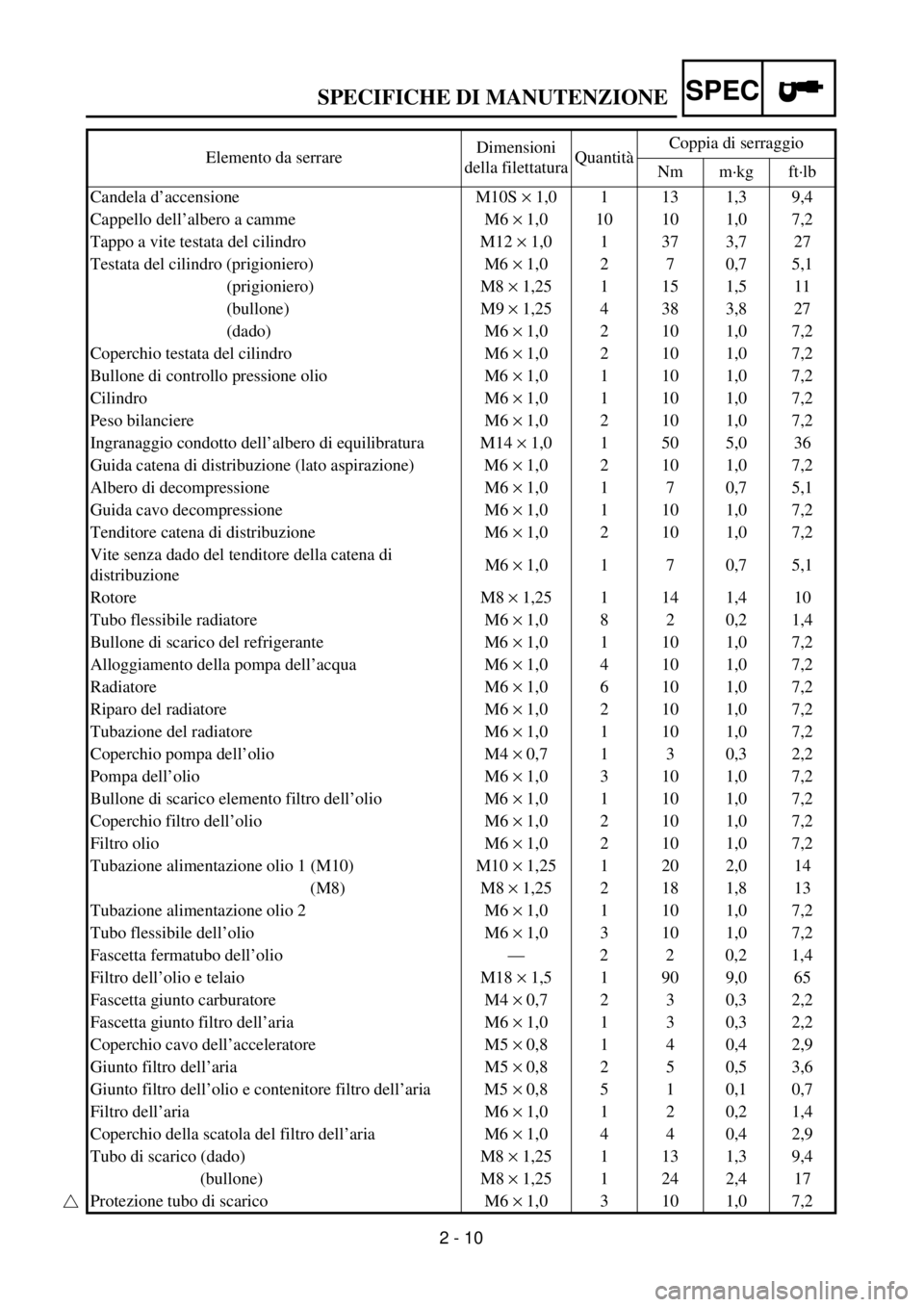

SPEC

2 - 10

SPECIFICHE DI MANUTENZIONE

Elemento da serrareDimensioni

della filettaturaQuantitàCoppia di serraggio

Nm m·kg ft·lb

Candela d’accensione M10S

´

1,0 1 13 1,3 9,4

Cappello dell’albero a camme M6

´

1,0 10 10 1,0 7,2

Tappo a vite testata del cilindro M12

´

1,0 1 37 3,7 27

Testata del cilindro (prigioniero) M6

´

1,0 2 7 0,7 5,1

(prigioniero) M8

´

1,25 1 15 1,5 11

(bullone) M9

´

1,25 4 38 3,8 27

(dado) M6

´

1,0 2 10 1,0 7,2

Coperchio testata del cilindro M6

´

1,0 2 10 1,0 7,2

Bullone di controllo pressione olio M6

´

1,0 1 10 1,0 7,2

Cilindro M6

´

1,0 1 10 1,0 7,2

Peso bilanciere M6

´

1,0 2 10 1,0 7,2

Ingranaggio condotto dell’albero di equilibratura M14

´

1,0 1 50 5,0 36

Guida catena di distribuzione (lato aspirazione) M6

´

1,0 2 10 1,0 7,2

Albero di decompressione M6

´

1,0 1 7 0,7 5,1

Guida cavo decompressione M6

´

1,0 1 10 1,0 7,2

Tenditore catena di distribuzione M6

´

1,0 2 10 1,0 7,2

Vite senza dado del tenditore della catena di

distribuzioneM6

´

1,0 1 7 0,7 5,1

Rotore M8

´

1,25 1 14 1,4 10

Tubo flessibile radiatore M6

´

1,0 8 2 0,2 1,4

Bullone di scarico del refrigerante M6

´

1,0 1 10 1,0 7,2

Alloggiamento della pompa dell’acqua M6

´

1,0 4 10 1,0 7,2

Radiatore M6

´

1,0 6 10 1,0 7,2

Riparo del radiatore M6

´

1,0 2 10 1,0 7,2

Tubazione del radiatore M6

´

1,0 1 10 1,0 7,2

Coperchio pompa dell’olio M4

´

0,7 1 3 0,3 2,2

Pompa dell’olio M6

´

1,0 3 10 1,0 7,2

Bullone di scarico elemento filtro dell’olio M6

´

1,0 1 10 1,0 7,2

Coperchio filtro dell’olio M6

´

1,0 2 10 1,0 7,2

Filtro olio M6

´

1,0 2 10 1,0 7,2

Tubazione alimentazione olio 1 (M10) M10

´

1,25 1 20 2,0 14

(M8) M8

´

1,25 2 18 1,8 13

Tubazione alimentazione olio 2 M6

´

1,0 1 10 1,0 7,2

Tubo flessibile dell’olio M6

´

1,0 3 10 1,0 7,2

Fascetta fermatubo dell’olio — 2 2 0,2 1,4

Filtro dell’olio e telaio M18

´

1,5 1 90 9,0 65

Fascetta giunto carburatore M4

´

0,7 2 3 0,3 2,2

Fascetta giunto filtro dell’aria M6

´

1,0 1 3 0,3 2,2

Coperchio cavo dell’acceleratore M5

´

0,8 1 4 0,4 2,9

Giunto filtro dell’aria M5

´

0,8 2 5 0,5 3,6

Giunto filtro dell’olio e contenitore filtro dell’aria M5

´

0,8 5 1 0,1 0,7

Filtro dell’aria M6

´

1,0 1 2 0,2 1,4

Coperchio della scatola del filtro dell’aria M6

´

1,0 4 4 0,4 2,9

Tubo di scarico (dado) M8

´ 1,25 1 13 1,3 9,4

(bullone) M8 ´ 1,25 1 24 2,4 17

Protezione tubo di scarico M6 ´ 1,0 3 10 1,0 7,2

Page 147 of 686

SPEC

2 - 19

CHEMINEMENT DES CABLES

KABELFÜHRUNG

SCHEMA DEL PERCORSO DEI CAVI

KABELFÜHRUNG

1

Schlauchführung

2

Bremsschlauch

3

Spannungsregulator

4

Lichtschalterleitung

5

Kraftstofftank-Lüftungsschlauch

6

Klammer

7

Öltank-Lüftungsschlauch

8

Motorstoppschalterleitung

9

Nebenkabelbaum

0

Heckleuchte

A

Drosselpositionssensor-Leitung

B

Leerlaufschalterleitung

C

Ölschlauch

D

Zylinderkopf-Lüftungsschlauch

E

CDI-Magnetzünderleitung

F

Kupplungsseilzug

G

Seilzugführung

H

Vergaserlüftungsschlauch

I

Vergaserüberlaufschlauch

J

Kühlmittelausgleichstank-Lüftungs-

schlauch

K

Dekompressionsseilzug

L

CDI-Einheit-Leitung

M

Zündspulenleitung

N

Spannungsregulatorleitung

Den Kraftstofftank-Lüftungsschlauch

hinter dem Lenker entlang führen,

und dann in das Loch des Lenk-

schafts einführen.

õ

Den Dekompressionsseilzug, die Mo-

torstoppschalterleitung und die Licht-

schalterleitung unter der Stelle ent-

langführen, wo der Ölschlauch

verläuft.

‚

Die Spannungsregulatorleitung, Mo-

torstoppschalterleitung und Licht-

schalterleitung über den Kühler-

schlauch verlegen.

ë

Die Motorstoppschalterleitung und die

Zündspulenleitung des Nebenkabel-

baums befestigen.

ä

Den Nebenkabelbaum und die Motor-

stoppschalterleitung befestigen.

ì

Den Zylinderkopf-Lüftungsschlauch

an der rechten Seite des Öltank-Lüf-

tungsschlauchs entlang verlegen.

í

Den Nebenkabelbaum und Motor-

stoppschalter vor den oberen Motor-

bügeln verlegen.

î

Den Nebenkabelbaum befestigen.

é

Den Nebenkabelbaum zwischen den

oberen Motorbügeln verlegen.

ï

Den Nebenkabelbaum befestigen.

ð

Den Drosselpositionssensor befesti-

gen.

CHEMINEMENT DES

CABLES

1

Guide de durit

2

Durit de frein

3

Régulateur de tension

4

Fil de contacteur d’éclairage

5

Durit de mise à l’air du réservoir de car-

burant

6

Bride

7

Durit de mise à l’air du réservoir d’huile

8

Fil de bouton d’arrêt du moteur

9

Faisceau de fils secondaire

0

Fil de feu arrière

A

Fil de capteur de position du papillon des

gaz

B

Fil de contacteur de point mort

C

Durit d’huile

D

Durit de mise à l’air de culasse

E

Fil de magnéto CDI

F

Câble d’embrayage

G

Guide de câble

H

Durit de mise à l’air du carburateur

I

Durit de trop-plein du carburateur

J

Durit de mise à l’air du vase d’expansion

K

Câble de décompression

L

Fil de CDI

M

Fil de bobine d’allumage

N

Fil de régulateur de tension

Faire passer la durit de mise à l’air du

réservoir de carburant derrière le guidon,

puis l’insérer dans le trou de l’axe de la

colonne de direction.

õ

Faire passer le câble de décompression, le

fil du coupe-circuit du moteur et le fil de

contacteur d’éclairage à l’endroit où la

durit d’huile est attachée.

‚

Faire passer le fil du régulateur de ten-

sion, le fil du coupe-circuit du moteur et

le fil du contacteur d’éclairage par-dessus

la durit de radiateur.

ëAttacher le fil du coupe-circuit de moteur

et le fil de bobine d’allumage du faisceau

de fils secondaire.

äAttacher le faisceau de fils secondaire et

le fil du coupe-circuit du moteur.

ìFaire passer la durit de mise à l’air de la

culasse le long du côté droit de la durit de

mise à l’air du réservoir à huile.

íAttacher le faisceau de fils secondaire et

le fil de coupe-circuit du moteur à l’avant

des supports de moteur supérieurs.

îAttacher le faisceau de fils secondaire.

éFaire passer le faisceau de fils secondaire

entre les supports de moteur supérieurs.

ïAttacher le faisceau de fils secondaire.

ðAttacher le fil de capteur de position du

papillon des gaz.

SCHEMA DEL PER-

CORSO DEI CAVI

1Guida del tubo flessibile

2Tubo flessibile del freno

3Regolatore di tensione

4Cavo dell’interruttore luci

5Tubetto di sfiato del serbatoio del carbu-

rante

6Morsetto

7Tubetto di sfiato del serbatoio dell’olio

8Cavo interruttore di arresto motore

9Sub-cablaggio premontato

0Cavo del fanalino posteriore

ACavo del sensore posizione farfalla

BCavo interruttore di folle

CTubo flessibile dell’olio

DTubetto di sfiato della testa del cilindro

ECavo alternatore CDI

FCavo della frizione

GGuidacavo

HTubetto di sfiato del carburatore

ITubo flessibile di troppopieno del carbu-

ratore

JTubetto di sfiato del serbatoio del liquido

di raffreddamento

KCavo di decompressione

LCavo della centralina CDI

MCavo della bobina di accensione

NCavo del regolatore di tensione

Far passare il tubetto di sfiato del serba-

toio del carburante dietro al manubrio, poi

inserirlo nel forno del cannotto dello

sterzo.

õFar passare il cavo di decompressione, il

cavo dell’interruttore di arresto del

motore ed il cavo dell’interruttore luci

sotto dove è collegato il tubo flessibile

dell’olio.

‚Fare passare il cavo del regolatore di ten-

sione, il cavo dell’interruttore di arresto

motore ed il cavo dell’interruttore luci

sopra il tubo flessibile del radiatore.

ëFissare il cavo dell’interruttore di arresto

del motore ed il cavo della bobina di

accensione del sub-cablaggio premontato.

äFissare il sub-cablaggio premontato e il

cavo dell’interruttore di arresto del

motore.

ìFar passare il tubetto di sfiato della testa

del cilindro lungo il lato destro del tubetto

di sfiato del serbatoio dell’olio.

íFissare il sub-cablaggio premontato ed il

cavo dell’interruttore di arresto del

motore di fronte alle staffe superiori di

supporto del motore.

îFissare il sub-cablaggio premontato.

éFar passare il sub-cablaggio premontato

tra le staffe superiori di supporto del

motore.

ïFissare il sub-cablaggio premontato.

ðFissare il cavo del sensore della posizione

della farfalla.

Page 159 of 686

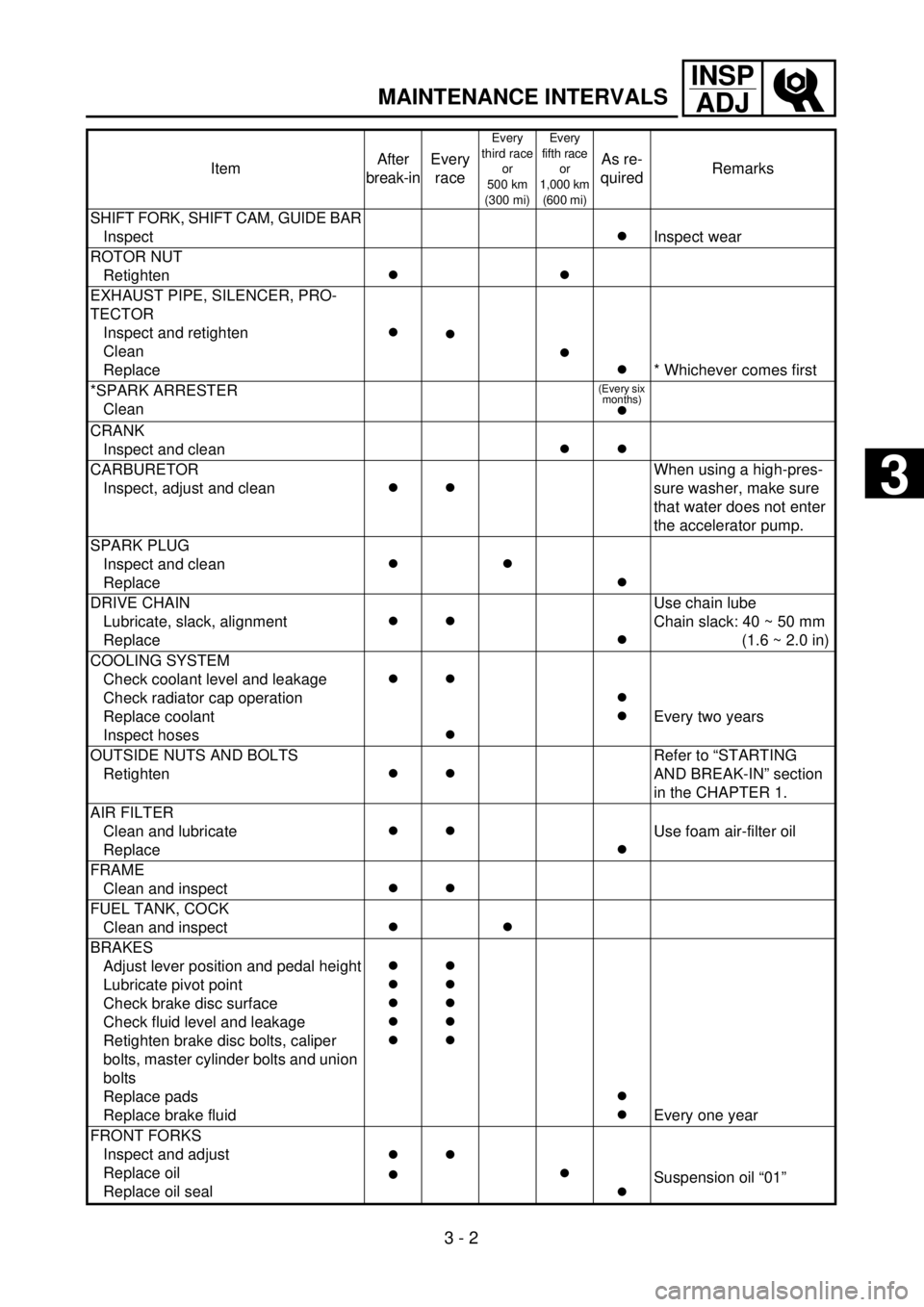

3 - 2

INSP

ADJ

MAINTENANCE INTERVALS

SHIFT FORK, SHIFT CAM, GUIDE BAR

Inspect

c

Inspect wear

ROTOR NUT

Retighten

c

c

EXHAUST PIPE, SILENCER, PRO-

TECTOR

Inspect and retighten

Clean

Replace

c

c

c

c

* Whichever comes first

*SPARK ARRESTER

Clean

(Every six

months)

c

CRANK

Inspect and clean

c

c

CARBURETOR

Inspect, adjust and clean

c

c

When using a high-pres-

sure washer, make sure

that water does not enter

the accelerator pump.

SPARK PLUG

Inspect and clean

Replace

c

c

c

DRIVE CHAIN

Lubricate, slack, alignment

Replace

c

c

c

Use chain lube

Chain slack: 40 ~ 50 mm

(1.6 ~ 2.0 in)

COOLING SYSTEM

Check coolant level and leakage

Check radiator cap operation

Replace coolant

Inspect hoses

c

c

c

c

c

Every two years

OUTSIDE NUTS AND BOLTS

Retighten

c

c

Refer to “STARTING

AND BREAK-IN” section

in the CHAPTER 1.

AIR FILTER

Clean and lubricate

Replace

c

c

c

Use foam air-filter oil

FRAME

Clean and inspect

c

c

FUEL TANK, COCK

Clean and inspect

c

c

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper

bolts, master cylinder bolts and union

bolts

Replace pads

Replace brake fluid

c

c

c

c

c

c

c

c

c

c

c

c

Every one year

FRONT FORKS

Inspect and adjust

Replace oil

Replace oil seal

c

c

c

c

c

Suspension oil “01” ItemAfter

break-inEvery

race

Every

third race

or

500 km

(300 mi)Every

fifth race

or

1,000 km

(600 mi)

As re-

quiredRemarks

3