check engine YAMAHA WR 250F 2001 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: WR 250F, Model: YAMAHA WR 250F 2001Pages: 686, PDF Size: 62.6 MB

Page 184 of 686

3 - 10

INSP

ADJ

THROTTLE CABLE ADJUSTMENT

THROTTLE CABLE ADJUSTMENT

1. Check:

lThrottle grip free play a

Out of specification ® Adjust.

Throttle grip free play a:

3 ~ 5 mm (0.12 ~ 0.20 in)

2. Adjust:

lThrottle grip free play

Throttle grip free play adjustment steps:

lRemove the throttle cable cap 1 and

throttle cable cover 2.

NOTE:

lBefore adjusting the throttle cable free

play, the engine idle speed should be

adjusted.

lWhen the motorcycle is accelerating,

throttle cable #1 3 is pulled and throttle

cable #2 4 is pushed.

1st step:

lLoosen the locknuts 5 on throttle cable

#2.

lAdjust the free play by changing their

tightening position.

2nd step:

lLoosen the locknuts 6 on throttle cable

#1.

lAdjust the free play by changing their

tightening position.

lTighten the locknuts.

WARNING

After adjusting, turn the handlebar to

right and left and make sure that the

engine idling does not run faster.

lInstall the throttle cable cover and throttle

cable cap.

T R..

Throttle cable cover:

4 Nm (0.4 m • kg, 2.9 ft • lb)

2

1

Page 198 of 686

3 - 17

INSP

ADJ

ENGINE OIL REPLACEMENT

7. If the oil filter is to be replaced during this

oil change, remove the following parts

and reinstall them.

8. Install:

lCopper washer 1

lOil strainer (frame) 2

lOil hose 3

lBolt (oil hose) 4

lOil hose clamp 5

lLower engine bracket

9. Install:

lCopper washer

lOil filter element drain bolt

lCrankcase oil drain bolt

lFrame oil drain bolt

10. Fill:

lEngine oil

11. Check:

lOil leakage

12. Install:

lOil tank cap

13. Check:

lEngine oil level Replacement steps:

lRemove the oil filter element cover 1 and

oil filter element 2.

lCheck the O-rings 3, if cracked or dam-

aged, replace them with a new one.

lInstall the oil filter element and oil filter ele-

ment cover.

T R..

Oil filter element cover:

10 Nm (1.0 m • kg, 7.2 ft • lb)

Oil quantity:

Total amount:

1.7 L (1.50 Imp qt, 1.80 US qt)

Periodic oil change:

1.5 L (1.32 Imp qt, 1.59 US qt)

With oil filter replacement:

1.6 L (1.41 Imp qt, 1.69 US qt)

T R..90 Nm (9.0 m · kg, 65 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..2 Nm (0.2 m · kg, 1.4 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..20 Nm (2.0 m · kg, 14 ft · lb)

T R..23 Nm (2.3 m · kg, 17 ft · lb)

Page 200 of 686

3 - 18

INSP

ADJ

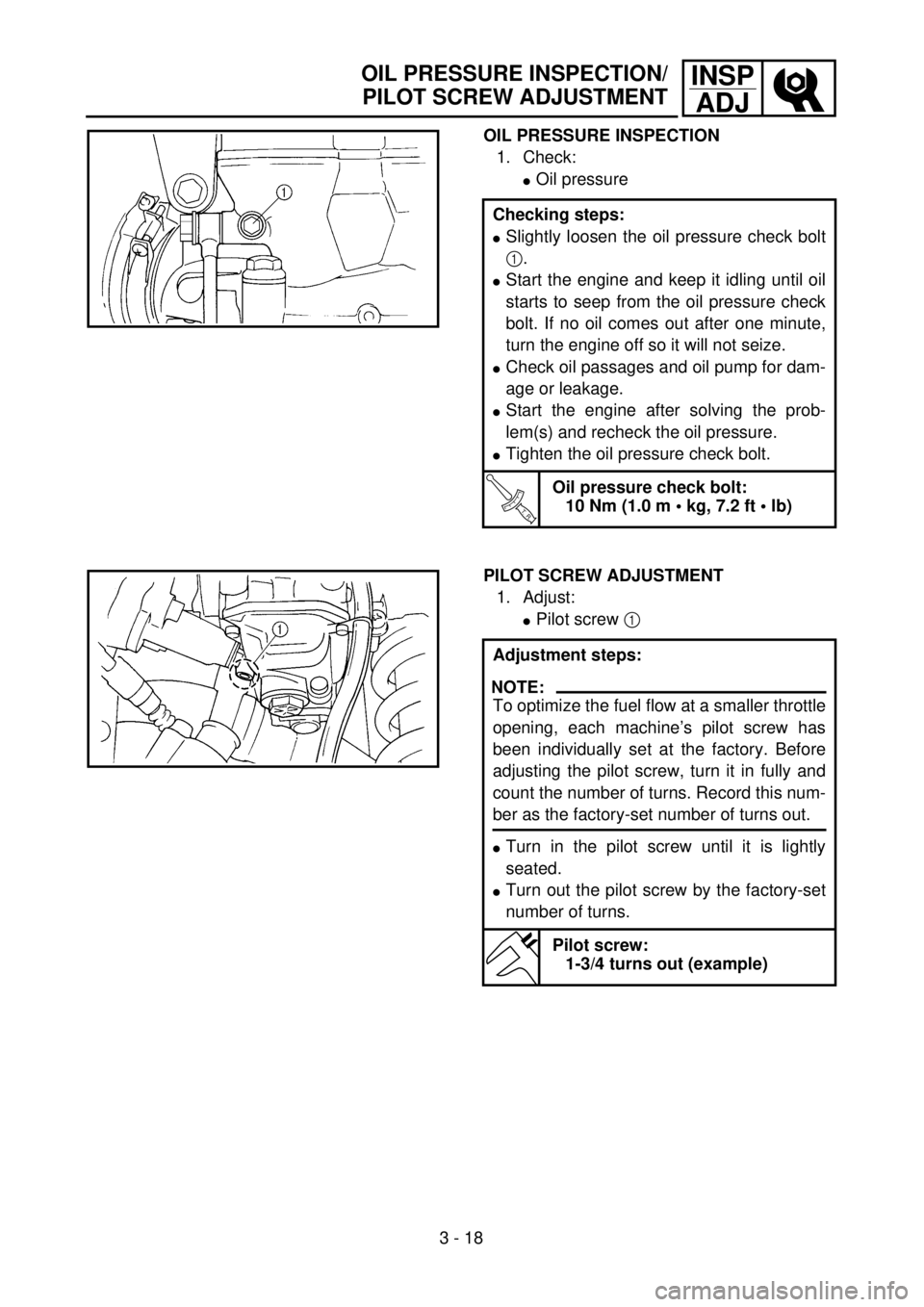

OIL PRESSURE INSPECTION

1. Check:

lOil pressure

Checking steps:

lSlightly loosen the oil pressure check bolt

1.

lStart the engine and keep it idling until oil

starts to seep from the oil pressure check

bolt. If no oil comes out after one minute,

turn the engine off so it will not seize.

lCheck oil passages and oil pump for dam-

age or leakage.

lStart the engine after solving the prob-

lem(s) and recheck the oil pressure.

lTighten the oil pressure check bolt.

T R..

Oil pressure check bolt:

10 Nm (1.0 m • kg, 7.2 ft • lb)

PILOT SCREW ADJUSTMENT

1. Adjust:

lPilot screw 1

Adjustment steps:

NOTE:

To optimize the fuel flow at a smaller throttle

opening, each machine’s pilot screw has

been individually set at the factory. Before

adjusting the pilot screw, turn it in fully and

count the number of turns. Record this num-

ber as the factory-set number of turns out.

lTurn in the pilot screw until it is lightly

seated.

lTurn out the pilot screw by the factory-set

number of turns.

Pilot screw:

1-3/4 turns out (example)

OIL PRESSURE INSPECTION/

PILOT SCREW ADJUSTMENT

Page 202 of 686

3 - 19

INSP

ADJ

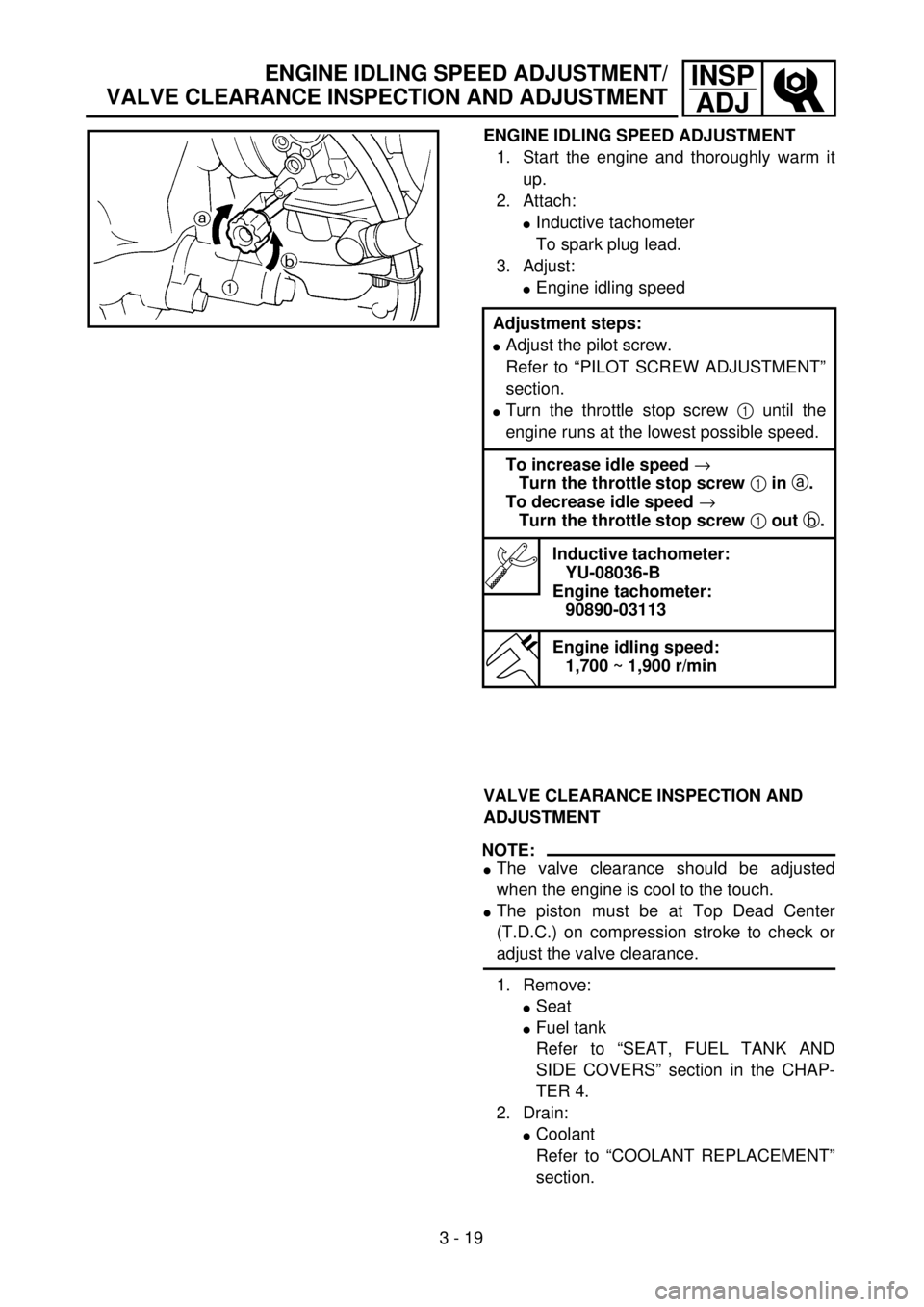

ENGINE IDLING SPEED ADJUSTMENT

1. Start the engine and thoroughly warm it

up.

2. Attach:

lInductive tachometer

To spark plug lead.

3. Adjust:

lEngine idling speed

Adjustment steps:

lAdjust the pilot screw.

Refer to “PILOT SCREW ADJUSTMENT”

section.

lTurn the throttle stop screw 1 until the

engine runs at the lowest possible speed.

To increase idle speed ®

Turn the throttle stop screw 1 in a.

To decrease idle speed ®

Turn the throttle stop screw 1 out b.

Inductive tachometer:

YU-08036-B

Engine tachometer:

90890-03113

Engine idling speed:

1,700 ~ 1,900 r/min

VALVE CLEARANCE INSPECTION AND

ADJUSTMENT

NOTE:

lThe valve clearance should be adjusted

when the engine is cool to the touch.

lThe piston must be at Top Dead Center

(T.D.C.) on compression stroke to check or

adjust the valve clearance.

1. Remove:

lSeat

lFuel tank

Refer to “SEAT, FUEL TANK AND

SIDE COVERS” section in the CHAP-

TER 4.

2. Drain:

lCoolant

Refer to “COOLANT REPLACEMENT”

section.

ENGINE IDLING SPEED ADJUSTMENT/

VALVE CLEARANCE INSPECTION AND ADJUSTMENT

Page 204 of 686

3 - 20

INSP

ADJ

VALVE CLEARANCE INSPECTION AND ADJUSTMENT

3. Remove:

lRight radiator

Refer to “RADIATOR” section in the

CHAPTER 4.

lCarburetor

Refer to “CARBURETOR” section in

the CHAPTER 4.

lSpark plug

lUpper engine bracket

lCylinder head cover

Refer to “CAMSHAFTS” section in the

CHAPTER 4.

4. Remove:

lTiming mark accessing screw 1

lCrankshaft end accessing screw 2

lO-ring

5. Check:

lValve clearance

Out of specification ® Adjust.

Valve clearance (cold):

Intake valve:

0.10 ~ 0.15 mm (0.0039 ~ 0.0059 in)

Exhaust valve:

0.17 ~ 0.22 mm (0.0067 ~ 0.0087 in)

Page 234 of 686

3 - 34

INSP

ADJ

DRIVE CHAIN SLACK ADJUSTMENT

5. Install:

lChain joint 1

lO-ring 2

lDrive chain 3

NOTE:

When installing the drive chain, apply the lith-

ium soap base grease on the chain joint and

O-rings.

6. Install:

lLink plate 4

NOTE:

lPress the link plate onto the chain joint using

a chain rivetter 5.

lRivet the end of the chain joint using a chain

rivetter 6.

lAfter rivetting the chain joint, make sure its

movement is smooth.

7. Lubricate:

lDrive chain

Drive chain lubricant:

SAE 10W-30 motor oil or suit-

able chain lubricants

EC36A060

DRIVE CHAIN SLACK ADJUSTMENT

1. Elevate the rear wheel by placing the

suitable stand under the engine.

2. Check:

lDrive chain slack a

Above the seal guard installation bolt.

Out of specification ® Adjust.

NOTE:

Before checking and/or adjusting, rotate the

rear wheel through several revolutions and

check the slack several times to find the tight-

est point. Check and/or adjust chain slack with

rear wheel in this “tight chain” position.

Drive chain slack:

40 ~ 50 mm (1.6 ~ 2.0 in)

Page 254 of 686

3 - 44

INSP

ADJ

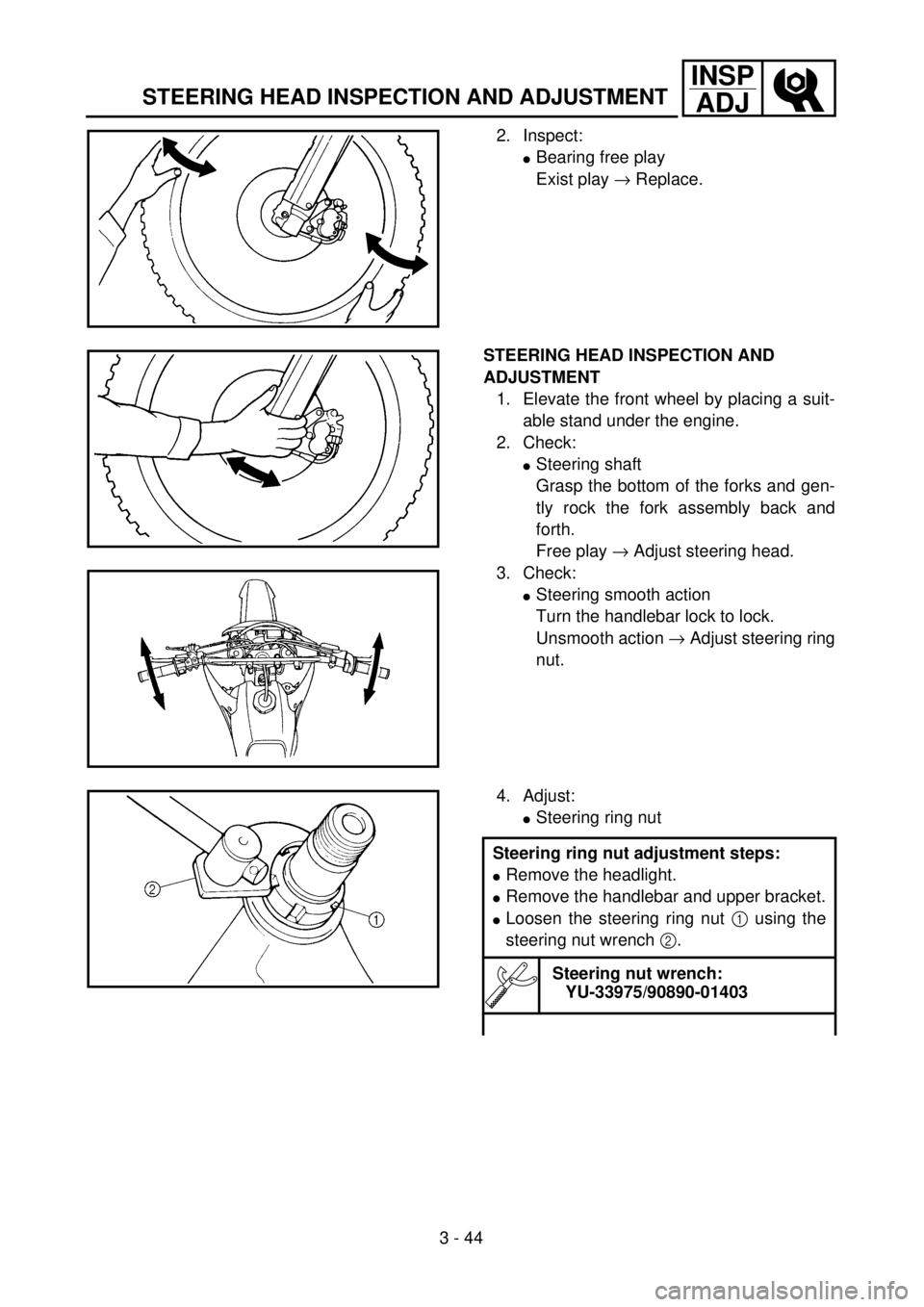

STEERING HEAD INSPECTION AND ADJUSTMENT

2. Inspect:

lBearing free play

Exist play ® Replace.

STEERING HEAD INSPECTION AND

ADJUSTMENT

1. Elevate the front wheel by placing a suit-

able stand under the engine.

2. Check:

lSteering shaft

Grasp the bottom of the forks and gen-

tly rock the fork assembly back and

forth.

Free play ® Adjust steering head.

3. Check:

lSteering smooth action

Turn the handlebar lock to lock.

Unsmooth action ® Adjust steering ring

nut.

4. Adjust:

lSteering ring nut

Steering ring nut adjustment steps:

lRemove the headlight.

lRemove the handlebar and upper bracket.

lLoosen the steering ring nut 1 using the

steering nut wrench 2.

Steering nut wrench:

YU-33975/90890-01403

Page 260 of 686

3 - 47

INSP

ADJ

ELECTRICAL/SPARK PLUG INSPECTION

EC370000

ELECTRICAL

EC371001

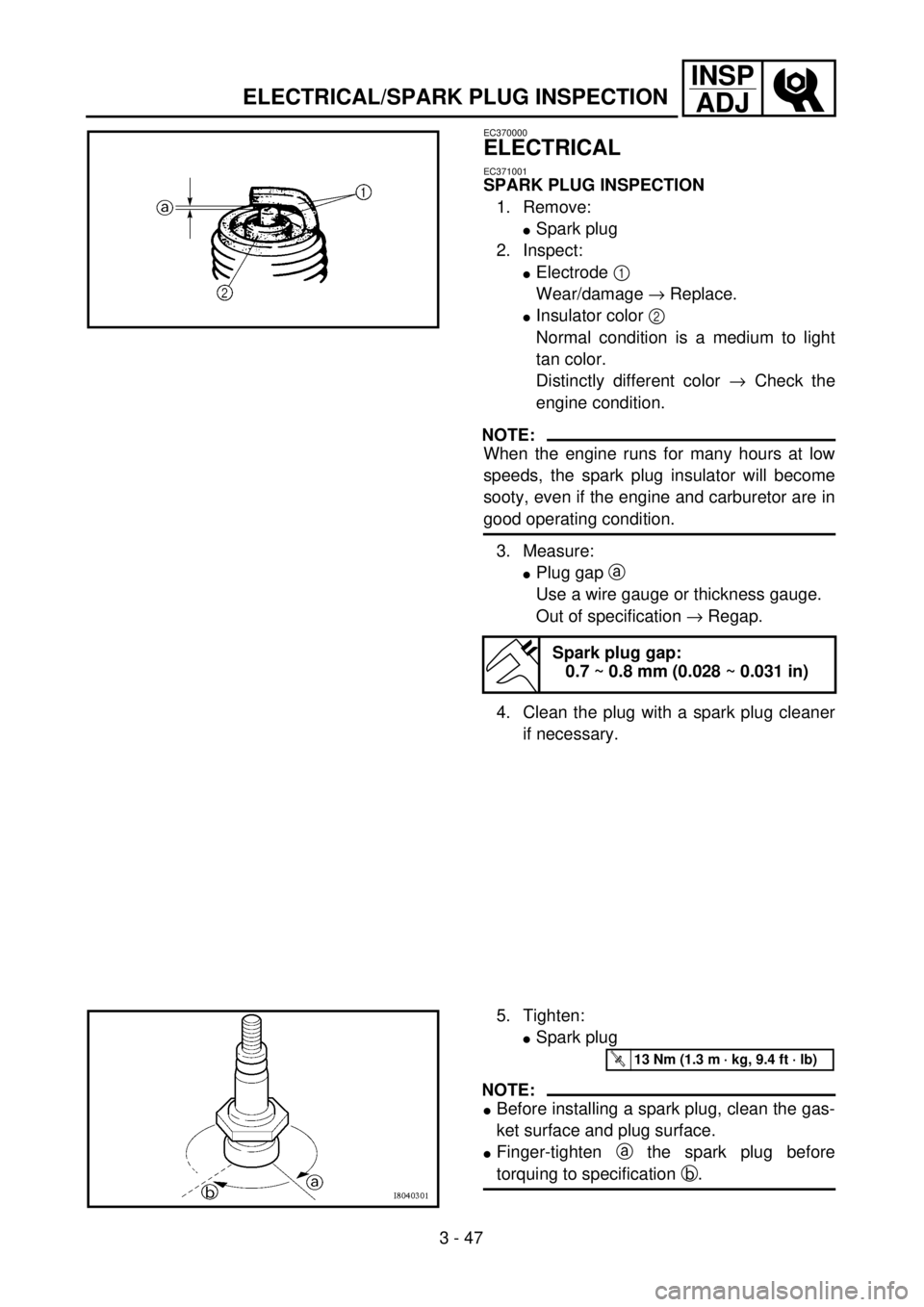

SPARK PLUG INSPECTION

1. Remove:

lSpark plug

2. Inspect:

lElectrode 1

Wear/damage ® Replace.

lInsulator color 2

Normal condition is a medium to light

tan color.

Distinctly different color ® Check the

engine condition.

NOTE:

When the engine runs for many hours at low

speeds, the spark plug insulator will become

sooty, even if the engine and carburetor are in

good operating condition.

3. Measure:

lPlug gap a

Use a wire gauge or thickness gauge.

Out of specification ® Regap.

4. Clean the plug with a spark plug cleaner

if necessary.

Spark plug gap:

0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

5. Tighten:

lSpark plug

NOTE:

lBefore installing a spark plug, clean the gas-

ket surface and plug surface.

lFinger-tighten a the spark plug before

torquing to specification b.

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)

Page 262 of 686

3 - 48

INSP

ADJ

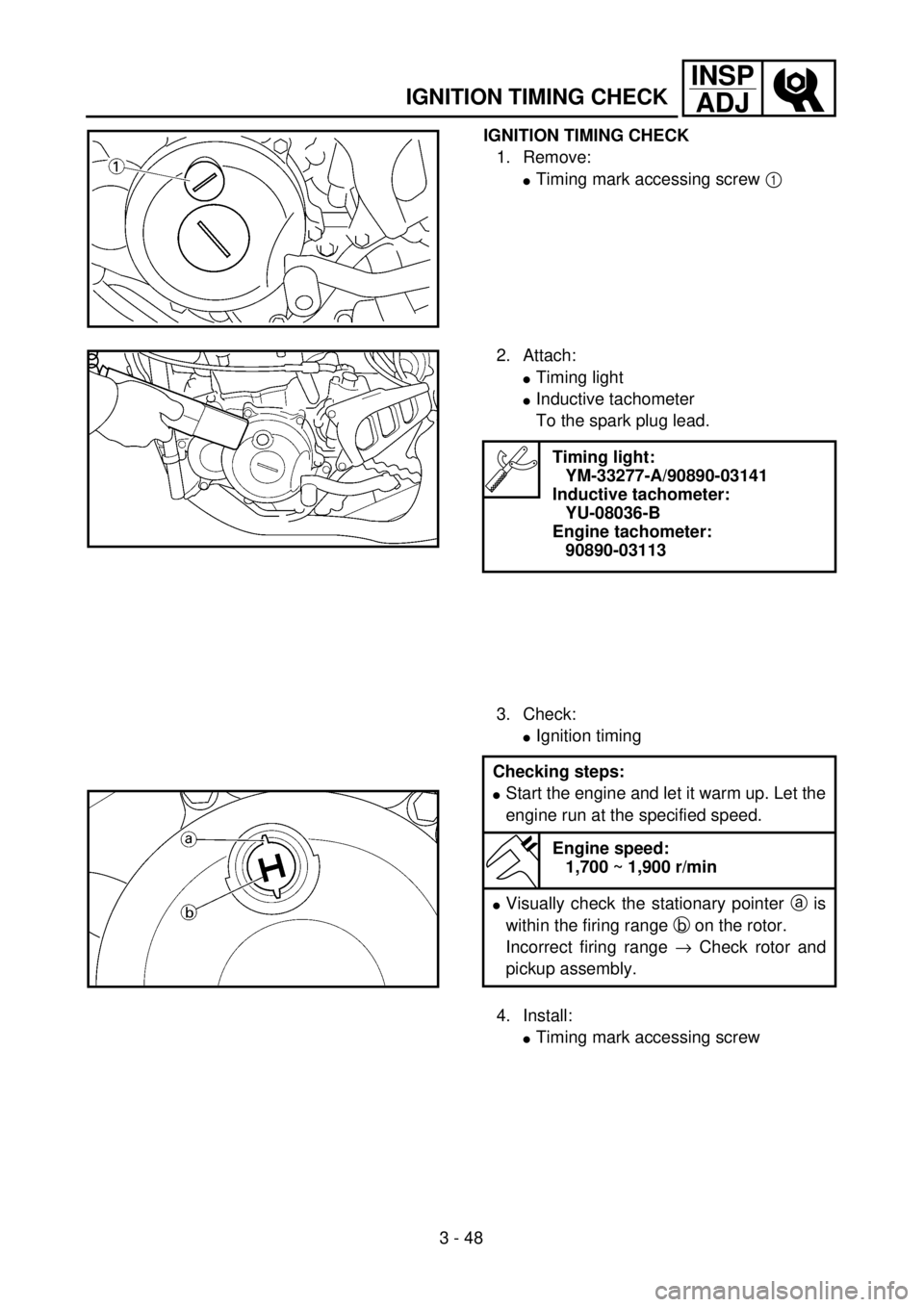

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

lTiming mark accessing screw 1

2. Attach:

lTiming light

lInductive tachometer

To the spark plug lead.

3. Check:

lIgnition timing

Timing light:

YM-33277-A/90890-03141

Inductive tachometer:

YU-08036-B

Engine tachometer:

90890-03113

Checking steps:

lStart the engine and let it warm up. Let the

engine run at the specified speed.

Engine speed:

1,700 ~ 1,900 r/min

lVisually check the stationary pointer a is

within the firing range b on the rotor.

Incorrect firing range ® Check rotor and

pickup assembly.

4. Install:

lTiming mark accessing screw

Page 446 of 686

4 - 90

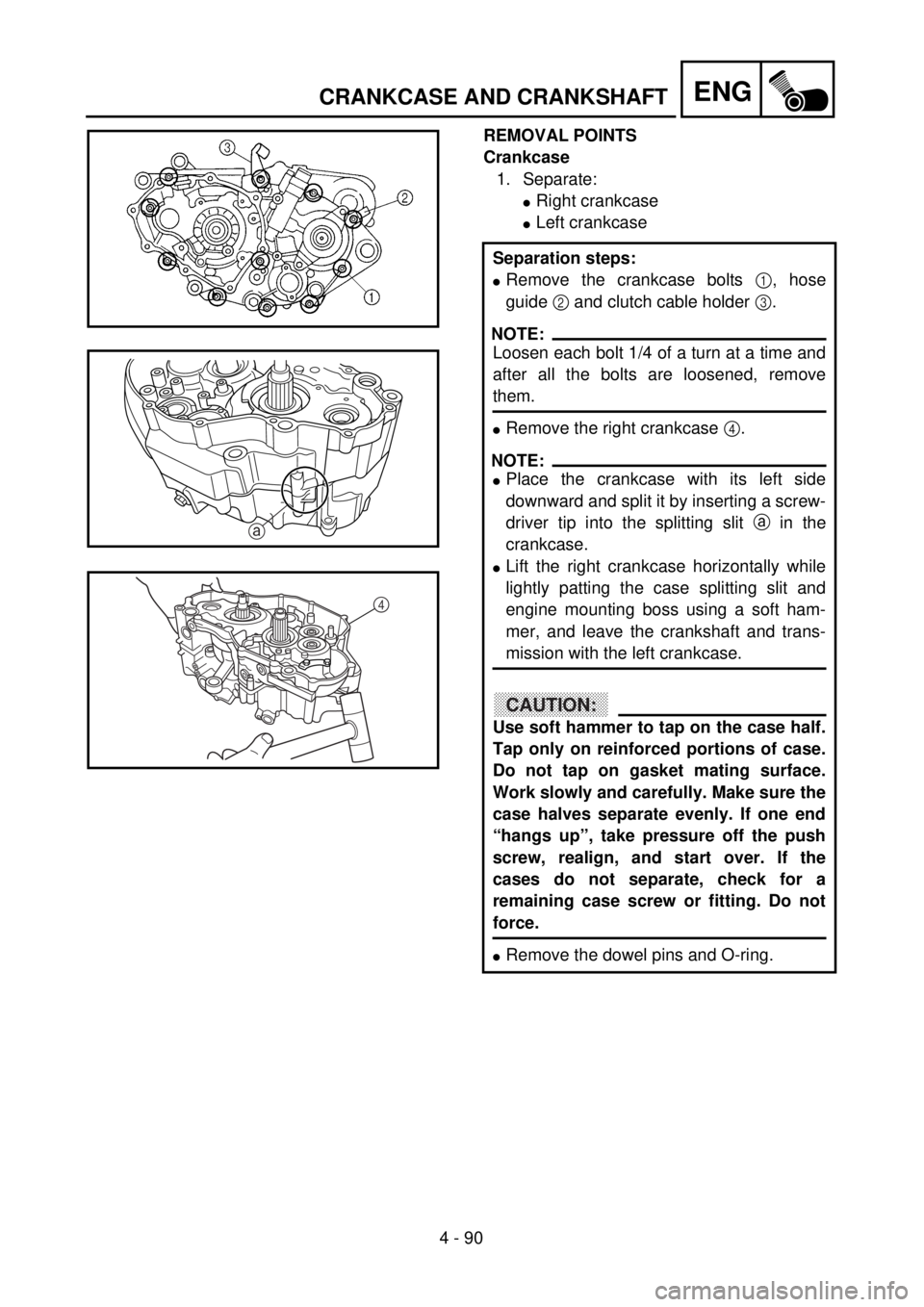

ENGCRANKCASE AND CRANKSHAFT

REMOVAL POINTS

Crankcase

1. Separate:

lRight crankcase

lLeft crankcase

Separation steps:

lRemove the crankcase bolts 1, hose

guide 2 and clutch cable holder 3.

NOTE:

Loosen each bolt 1/4 of a turn at a time and

after all the bolts are loosened, remove

them.

lRemove the right crankcase 4.

NOTE:

lPlace the crankcase with its left side

downward and split it by inserting a screw-

driver tip into the splitting slit a in the

crankcase.

lLift the right crankcase horizontally while

lightly patting the case splitting slit and

engine mounting boss using a soft ham-

mer, and leave the crankshaft and trans-

mission with the left crankcase.

CAUTION:

Use soft hammer to tap on the case half.

Tap only on reinforced portions of case.

Do not tap on gasket mating surface.

Work slowly and carefully. Make sure the

case halves separate evenly. If one end

“hangs up”, take pressure off the push

screw, realign, and start over. If the

cases do not separate, check for a

remaining case screw or fitting. Do not

force.

lRemove the dowel pins and O-ring.

a

4