wheel YAMAHA WR 250F 2001 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: WR 250F, Model: YAMAHA WR 250F 2001Pages: 686, PDF Size: 62.6 MB

Page 254 of 686

3 - 44

INSP

ADJ

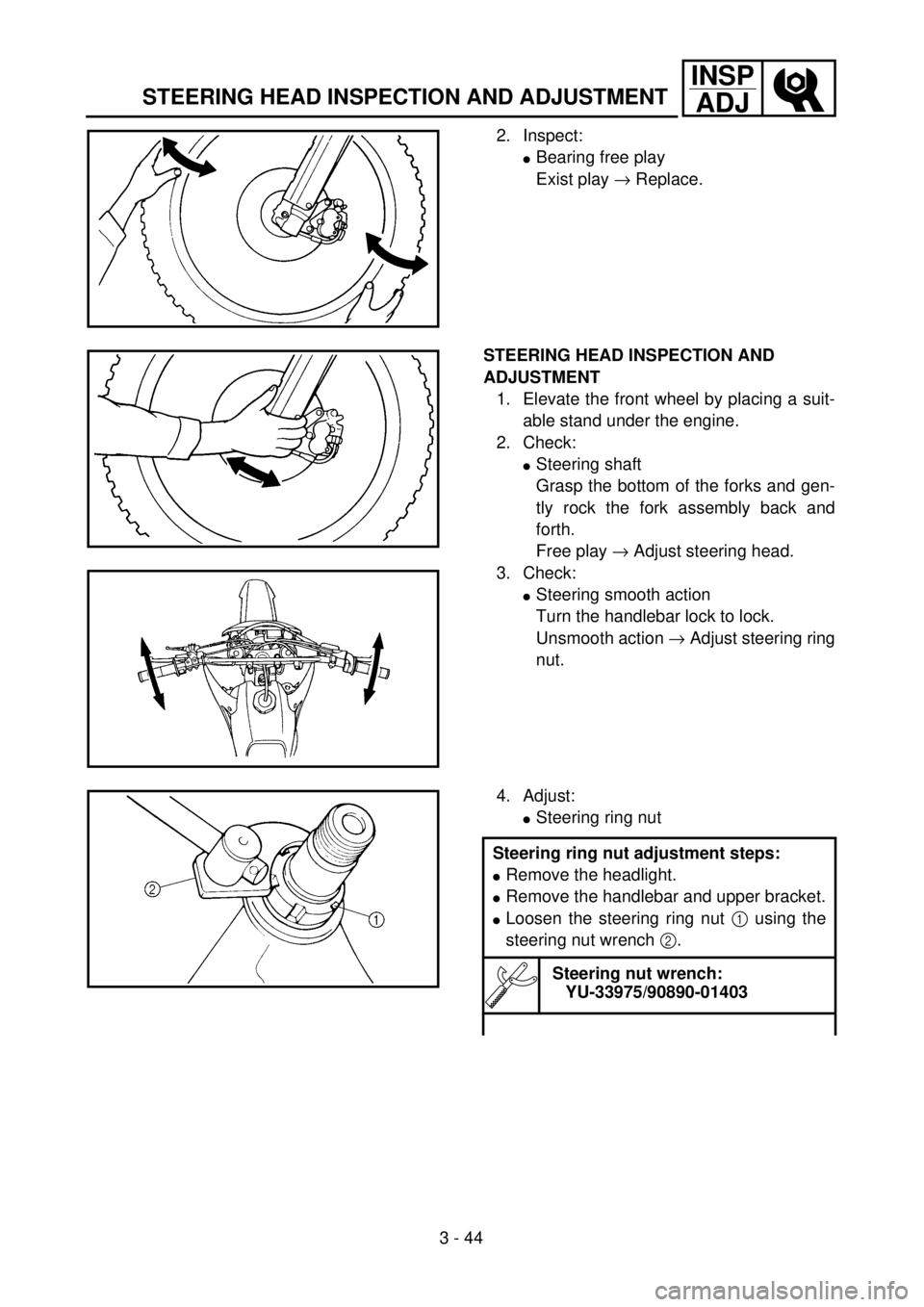

STEERING HEAD INSPECTION AND ADJUSTMENT

2. Inspect:

lBearing free play

Exist play ® Replace.

STEERING HEAD INSPECTION AND

ADJUSTMENT

1. Elevate the front wheel by placing a suit-

able stand under the engine.

2. Check:

lSteering shaft

Grasp the bottom of the forks and gen-

tly rock the fork assembly back and

forth.

Free play ® Adjust steering head.

3. Check:

lSteering smooth action

Turn the handlebar lock to lock.

Unsmooth action ® Adjust steering ring

nut.

4. Adjust:

lSteering ring nut

Steering ring nut adjustment steps:

lRemove the headlight.

lRemove the handlebar and upper bracket.

lLoosen the steering ring nut 1 using the

steering nut wrench 2.

Steering nut wrench:

YU-33975/90890-01403

Page 408 of 686

4 - 71

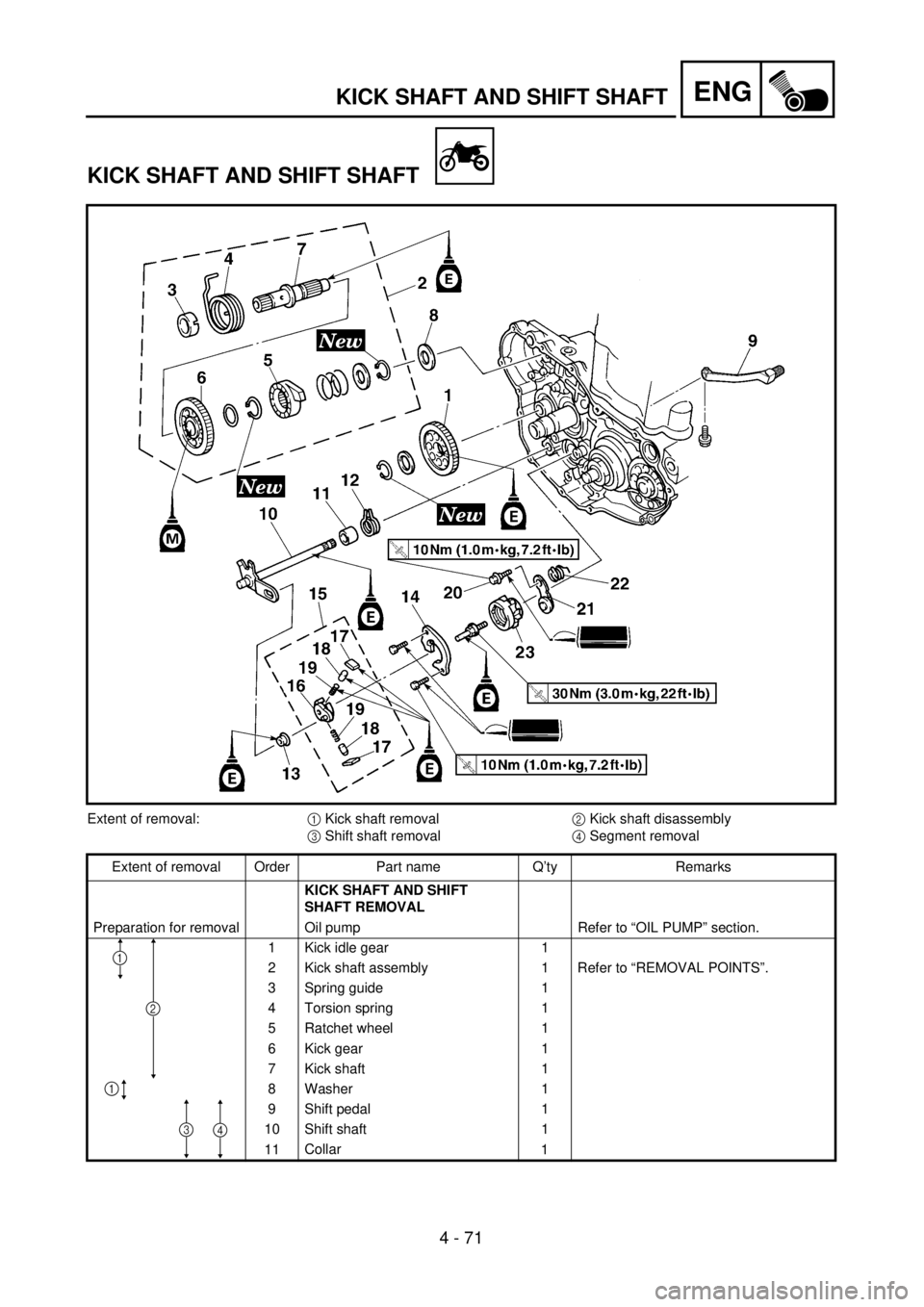

ENGKICK SHAFT AND SHIFT SHAFT

KICK SHAFT AND SHIFT SHAFT

Extent of removal:1 Kick shaft removal2 Kick shaft disassembly

3 Shift shaft removal4 Segment removal

Extent of removal Order Part name Q’ty Remarks

KICK SHAFT AND SHIFT

SHAFT REMOVAL

Preparation for removal Oil pump Refer to “OIL PUMP” section.

1 Kick idle gear 1

2 Kick shaft assembly 1 Refer to “REMOVAL POINTS”.

3 Spring guide 1

4 Torsion spring 1

5 Ratchet wheel 1

6 Kick gear 1

7 Kick shaft 1

8 Washer 1

9 Shift pedal 1

10 Shift shaft 1

11Collar

1

3

2

1

4

1

Page 412 of 686

4 - 73

ENGKICK SHAFT AND SHIFT SHAFT

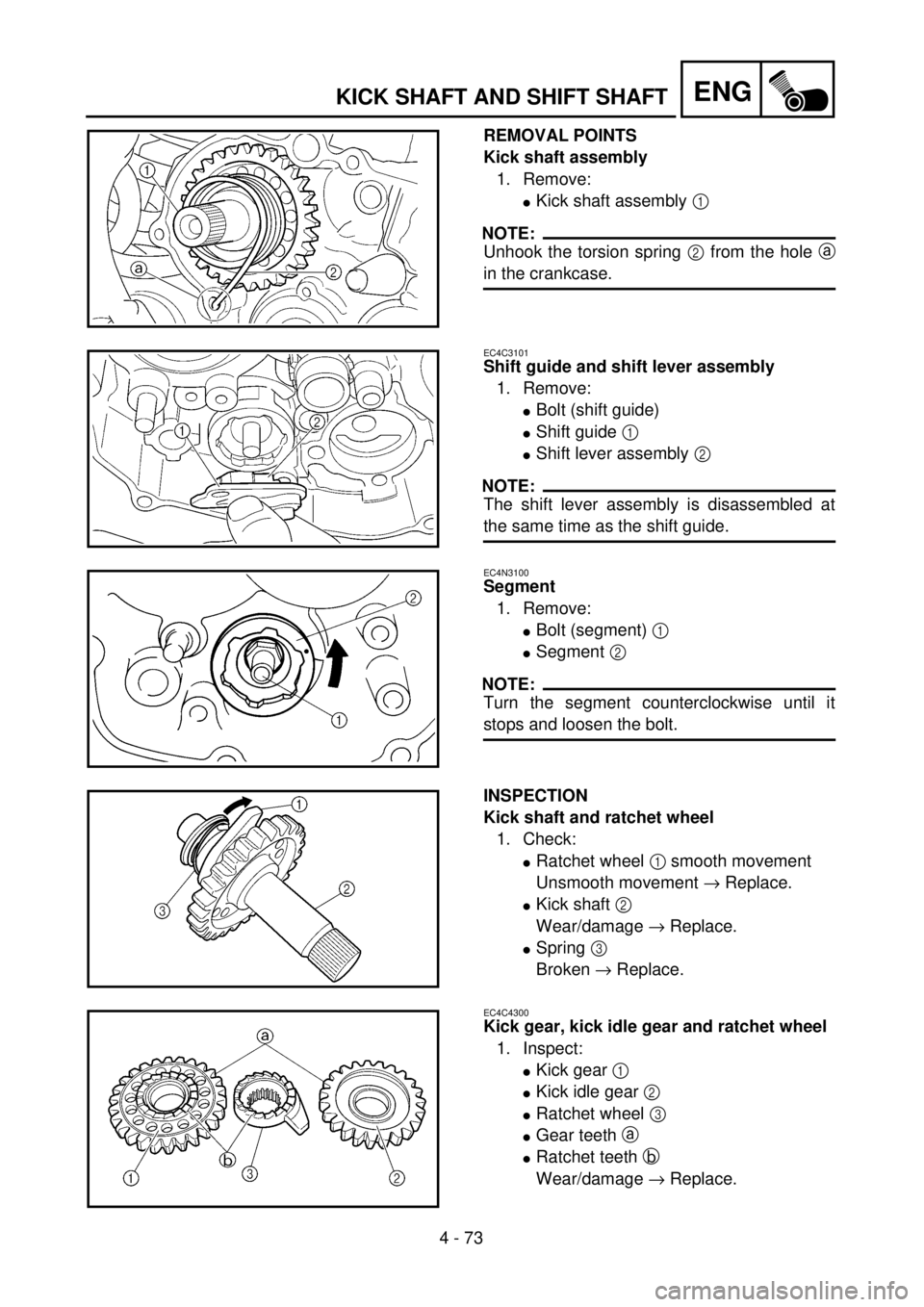

REMOVAL POINTS

Kick shaft assembly

1. Remove:

lKick shaft assembly 1

NOTE:

Unhook the torsion spring 2 from the hole a

in the crankcase.

EC4C3101

Shift guide and shift lever assembly

1. Remove:

lBolt (shift guide)

lShift guide 1

lShift lever assembly 2

NOTE:

The shift lever assembly is disassembled at

the same time as the shift guide.

EC4N3100

Segment

1. Remove:

lBolt (segment) 1

lSegment 2

NOTE:

Turn the segment counterclockwise until it

stops and loosen the bolt.

INSPECTION

Kick shaft and ratchet wheel

1. Check:

lRatchet wheel 1 smooth movement

Unsmooth movement ® Replace.

lKick shaft 2

Wear/damage ® Replace.

lSpring 3

Broken ® Replace.

EC4C4300

Kick gear, kick idle gear and ratchet wheel

1. Inspect:

lKick gear 1

lKick idle gear 2

lRatchet wheel 3

lGear teeth a

lRatchet teeth b

Wear/damage ® Replace.

Page 418 of 686

4 - 76

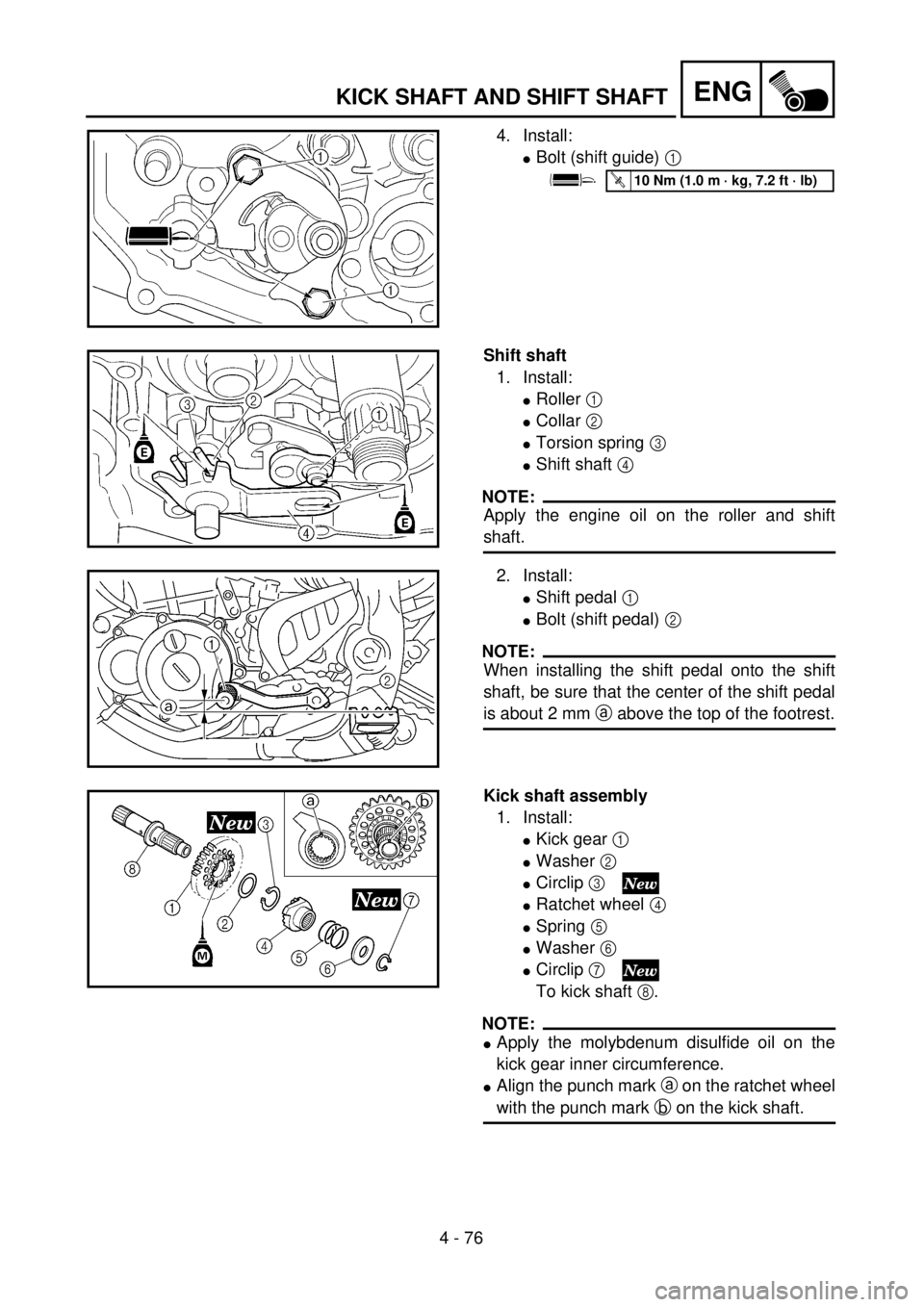

ENGKICK SHAFT AND SHIFT SHAFT

4. Install:

lBolt (shift guide) 1

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Shift shaft

1. Install:

lRoller 1

lCollar 2

lTorsion spring 3

lShift shaft 4

NOTE:

Apply the engine oil on the roller and shift

shaft.

2. Install:

lShift pedal 1

lBolt (shift pedal) 2

NOTE:

When installing the shift pedal onto the shift

shaft, be sure that the center of the shift pedal

is about 2 mm a above the top of the footrest.

Kick shaft assembly

1. Install:

lKick gear 1

lWasher 2

lCirclip 3

lRatchet wheel 4

lSpring 5

lWasher 6

lCirclip 7

To kick shaft 8.

NOTE:

lApply the molybdenum disulfide oil on the

kick gear inner circumference.

lAlign the punch mark a on the ratchet wheel

with the punch mark b on the kick shaft.

Page 424 of 686

4 - 79

ENGCDI MAGNETO

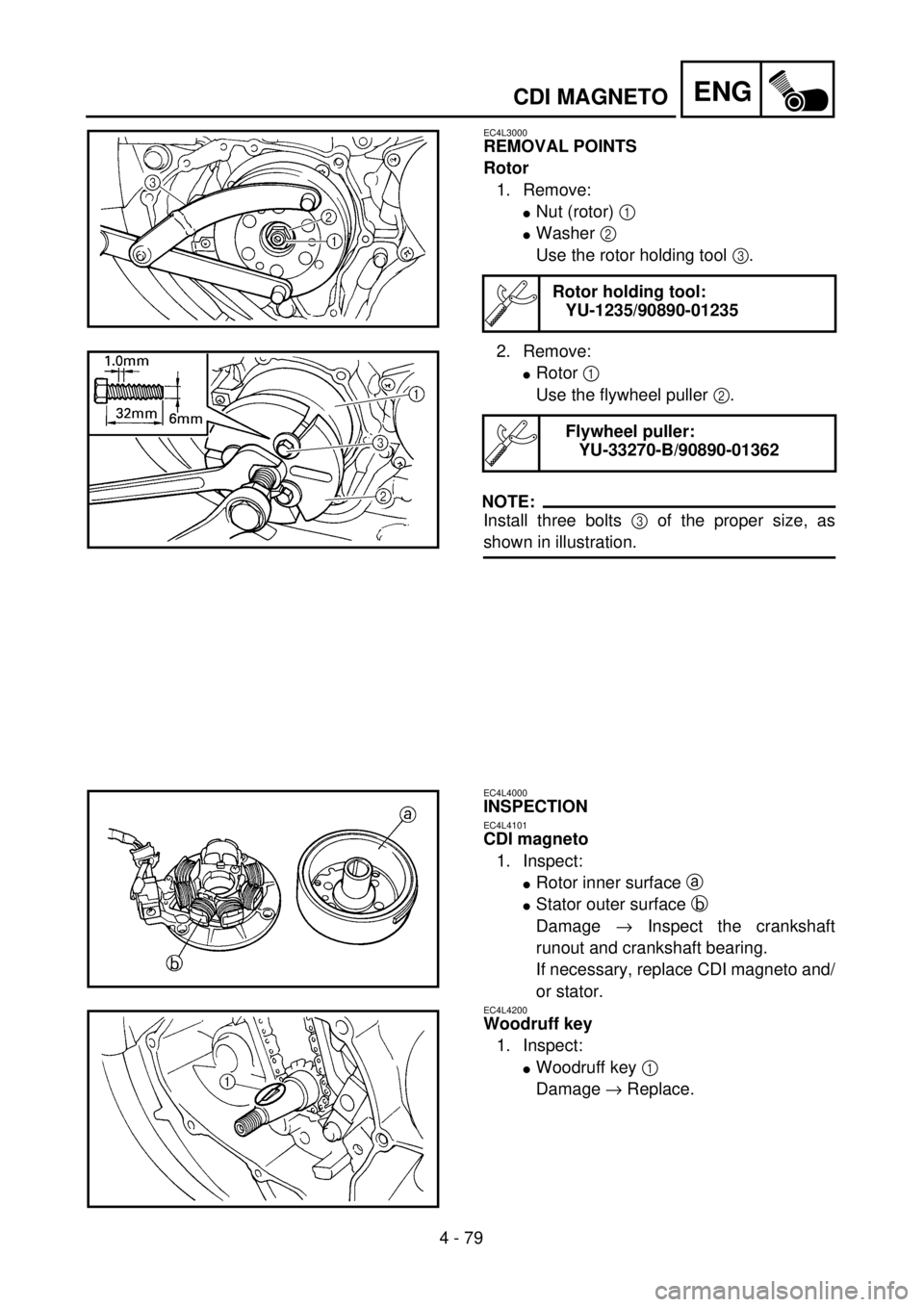

EC4L3000

REMOVAL POINTS

Rotor

1. Remove:

lNut (rotor) 1

lWasher 2

Use the rotor holding tool 3.

2. Remove:

lRotor 1

Use the flywheel puller 2.

NOTE:

Install three bolts 3 of the proper size, as

shown in illustration.

Rotor holding tool:

YU-1235/90890-01235

Flywheel puller:

YU-33270-B/90890-01362

EC4L4000

INSPECTION

EC4L4101

CDI magneto

1. Inspect:

lRotor inner surface a

lStator outer surface b

Damage ® Inspect the crankshaft

runout and crankshaft bearing.

If necessary, replace CDI magneto and/

or stator.

EC4L4200

Woodruff key

1. Inspect:

lWoodruff key 1

Damage ® Replace.

Page 464 of 686

4 - 99

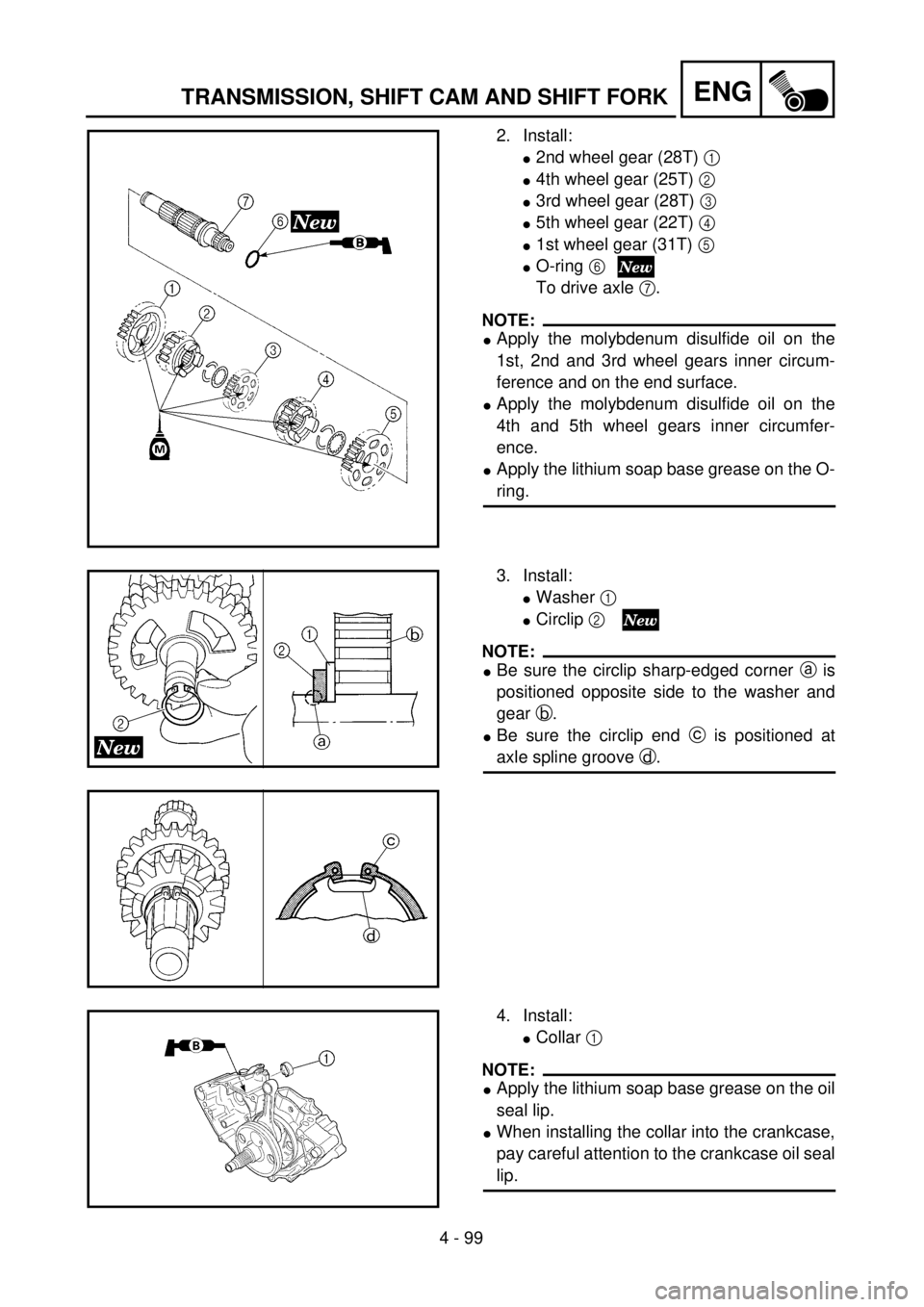

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

2. Install:

l2nd wheel gear (28T) 1

l4th wheel gear (25T) 2

l3rd wheel gear (28T) 3

l5th wheel gear (22T) 4

l1st wheel gear (31T) 5

lO-ring 6

To drive axle 7.

NOTE:

lApply the molybdenum disulfide oil on the

1st, 2nd and 3rd wheel gears inner circum-

ference and on the end surface.

lApply the molybdenum disulfide oil on the

4th and 5th wheel gears inner circumfer-

ence.

lApply the lithium soap base grease on the O-

ring.

3. Install:

lWasher 1

lCirclip 2

NOTE:

lBe sure the circlip sharp-edged corner a is

positioned opposite side to the washer and

gear b.

lBe sure the circlip end c is positioned at

axle spline groove d.

4. Install:

lCollar 1

NOTE:

lApply the lithium soap base grease on the oil

seal lip.

lWhen installing the collar into the crankcase,

pay careful attention to the crankcase oil seal

lip.

Page 466 of 686

4 - 100

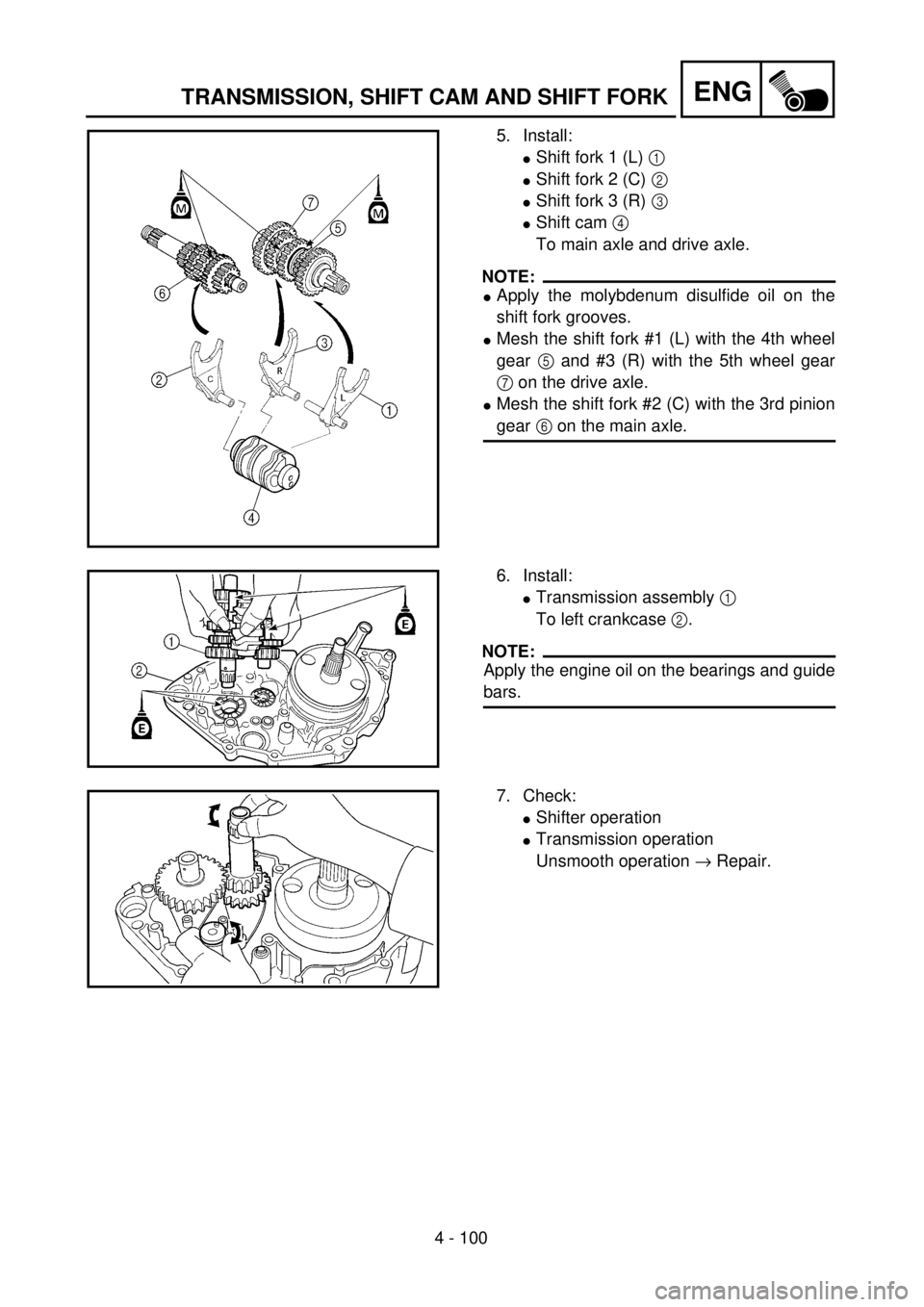

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

5. Install:

lShift fork 1 (L) 1

lShift fork 2 (C) 2

lShift fork 3 (R) 3

lShift cam 4

To main axle and drive axle.

NOTE:

lApply the molybdenum disulfide oil on the

shift fork grooves.

lMesh the shift fork #1 (L) with the 4th wheel

gear 5 and #3 (R) with the 5th wheel gear

7 on the drive axle.

lMesh the shift fork #2 (C) with the 3rd pinion

gear 6 on the main axle.

6. Install:

lTransmission assembly 1

To left crankcase 2.

NOTE:

Apply the engine oil on the bearings and guide

bars.

7. Check:

lShifter operation

lTransmission operation

Unsmooth operation ® Repair.

Page 468 of 686

5 - 1

CHAS

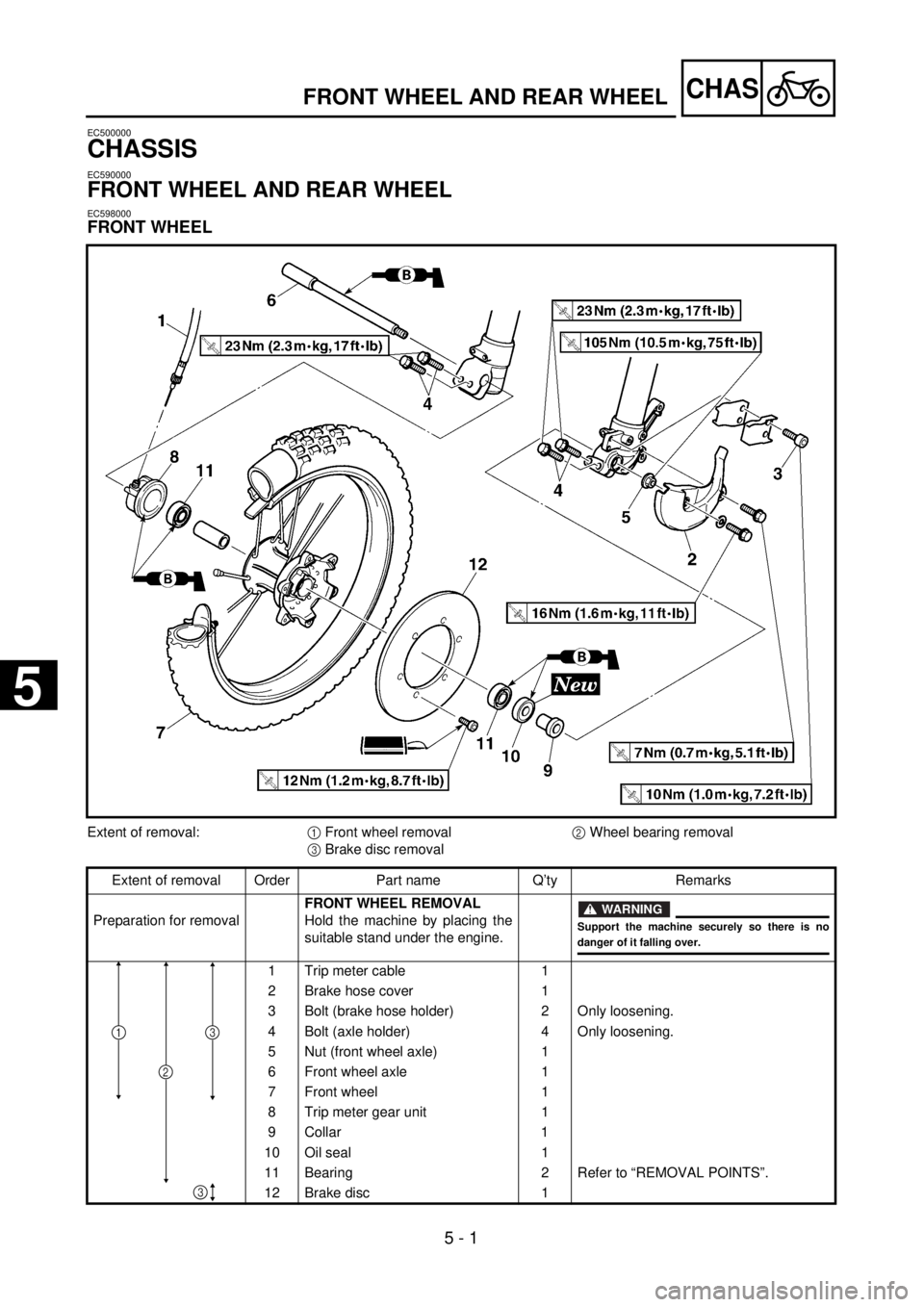

EC500000

CHASSIS

EC590000

FRONT WHEEL AND REAR WHEEL

EC598000

FRONT WHEEL

FRONT WHEEL AND REAR WHEEL

Extent of removal:

1

Front wheel removal

2

Wheel bearing removal

3

Brake disc removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removal

FRONT WHEEL REMOVAL

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is no

danger of it falling over.

1 Trip meter cable 1

2 Brake hose cover 1

3 Bolt (brake hose holder) 2 Only loosening.

4 Bolt (axle holder) 4 Only loosening.

5 Nut (front wheel axle) 1

6 Front wheel axle 1

7 Front wheel 1

8 Trip meter gear unit 1

9 Collar 1

10 Oil seal 1

11 Bearing 2 Refer to “REMOVAL POINTS”.

12 Brake disc 1

2

31

3

5

Page 470 of 686

5 - 2

CHAS

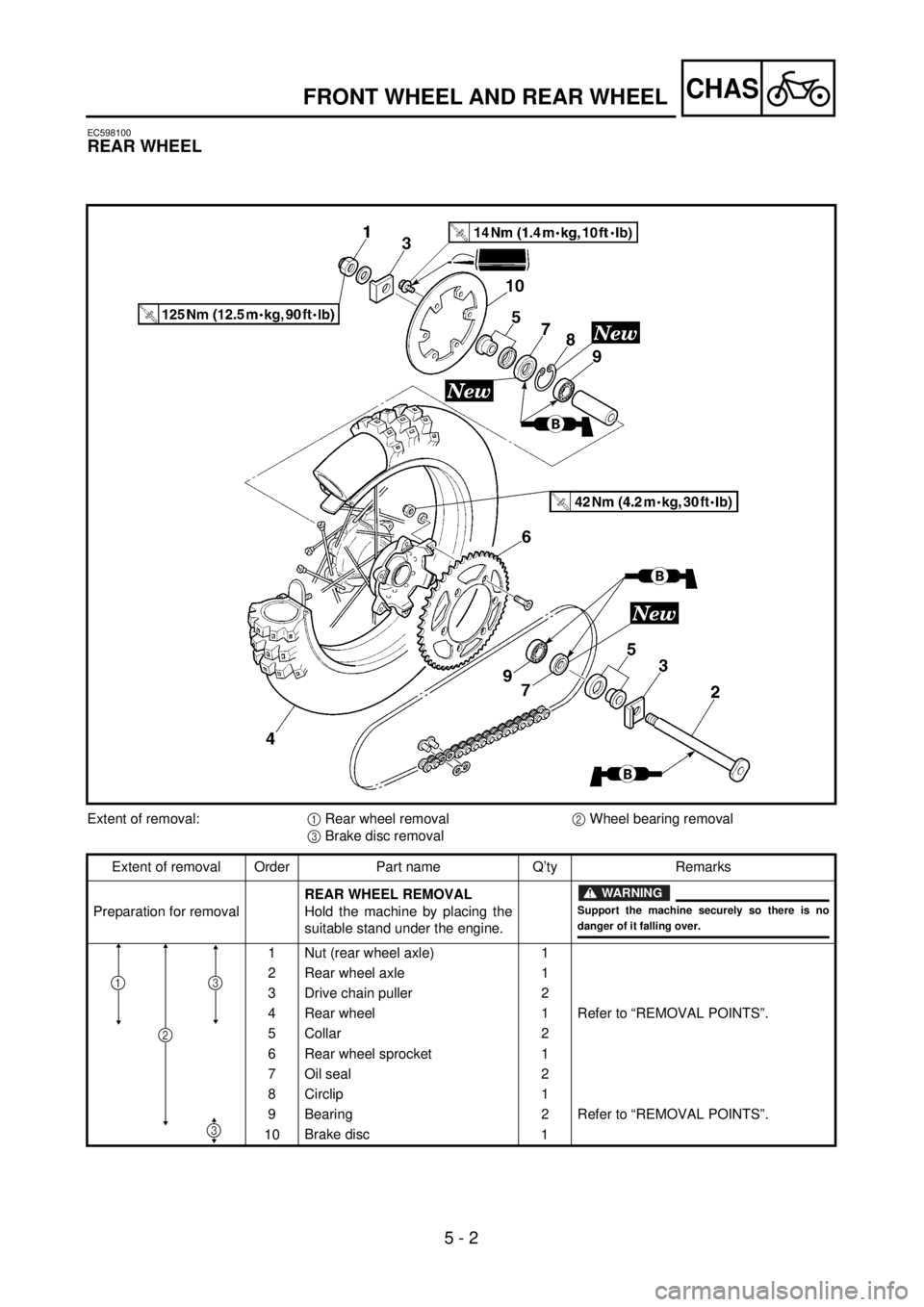

EC598100

REAR WHEEL

Extent of removal:

1

Rear wheel removal

2

Wheel bearing removal

3

Brake disc removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removal

REAR WHEEL REMOVAL

Hold the machine by placing the

suitable stand under the engine.

WARNING

Support the machine securely so there is no

danger of it falling over.

1 Nut (rear wheel axle) 1

2 Rear wheel axle 1

3 Drive chain puller 2

4 Rear wheel 1 Refer to “REMOVAL POINTS”.

5 Collar 2

6 Rear wheel sprocket 1

7 Oil seal 2

8 Circlip 1

9 Bearing 2 Refer to “REMOVAL POINTS”.

10Brake disc

1

2

31

3

FRONT WHEEL AND REAR WHEEL

Page 472 of 686

5 - 3

CHAS

FRONT WHEEL AND REAR WHEEL

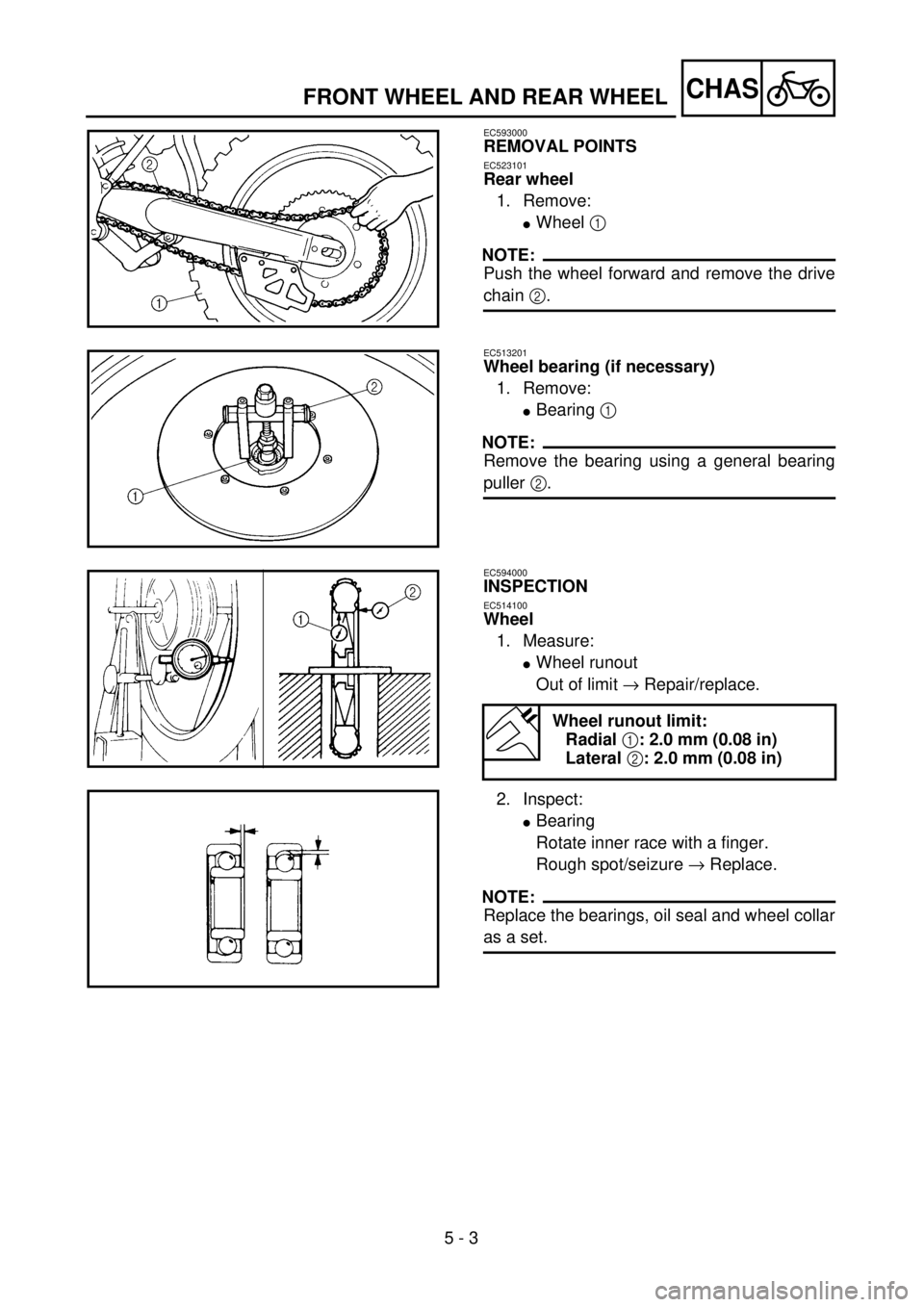

EC593000

REMOVAL POINTS

EC523101

Rear wheel

1. Remove:

l

Wheel

1

NOTE:

Push the wheel forward and remove the drive

chain

2

.

EC513201

Wheel bearing (if necessary)

1. Remove:

l

Bearing

1

NOTE:

Remove the bearing using a general bearing

puller

2

.

EC594000

INSPECTION

EC514100

Wheel

1. Measure:

l

Wheel runout

Out of limit

®

Repair/replace.

2. Inspect:

l

Bearing

Rotate inner race with a finger.

Rough spot/seizure

®

Replace.

NOTE:

Replace the bearings, oil seal and wheel collar

as a set.

Wheel runout limit:

Radial

1

: 2.0 mm (0.08 in)

Lateral

2

: 2.0 mm (0.08 in)