maintenance YAMAHA WR 250F 2003 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2003, Model line: WR 250F, Model: YAMAHA WR 250F 2003Pages: 860, PDF Size: 35.16 MB

Page 192 of 860

3 - 1

INSP

ADJ

MAINTENANCE INTERVALS

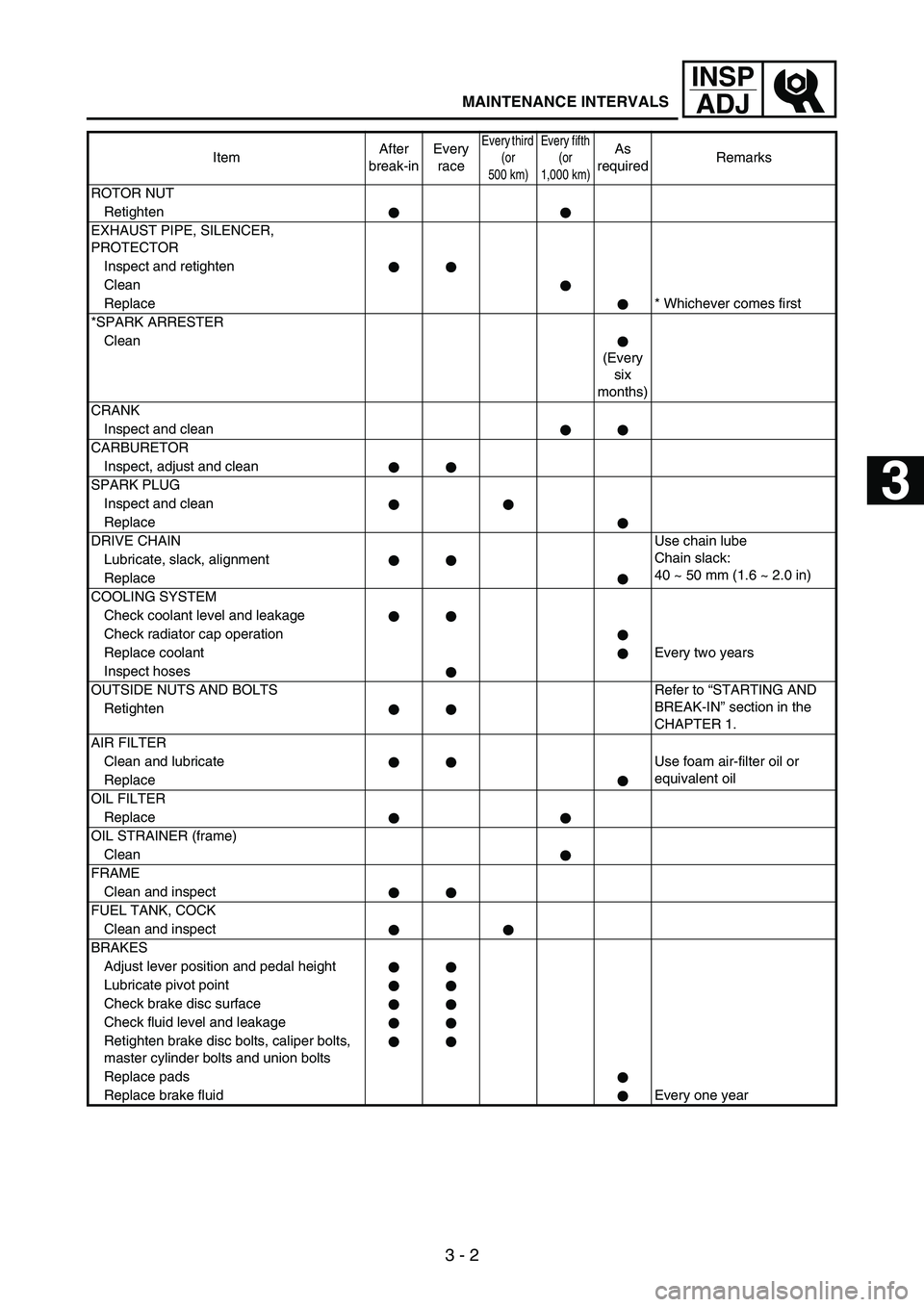

EC300000

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as

weather, terrain, geographical location, and individual usage will alter the required maintenance and lubrication intervals. If

you are a doubt as to what intervals to follow in maintaining and lubricating your machine, consult your Yamaha dealer.

ItemAfter

break-inEvery

race

Every third

(or

500 km)Every fifth

(or

1,000 km)As

requiredRemarks

ENGINE OIL

Replace

Inspect

VALVES

Check the valve clearances The engine must be cold.

Check the valve seats and

valve stems for wear. Inspect

Replace

VALVE SPRINGS

InspectCheck the free length and

the tilt.

Replace

VALVE LIFTERS

InspectCheck for scratches and

wear.

Replace

CAMSHAFTSInspect the camshaft

surface.

Inspect the decompression

system. Inspect

Replace

TIMING CHAIN SPROCKETS, TIMING

CHAIN

InspectCheck for wear on the teeth

and for damage.

Replace

PISTON

InspectInspect crack

Inspect carbon deposits and

eliminate them. Clean

Replace

PISTON RING

InspectCheck ring end gap

Replace

PISTON PIN

Inspect

Replace

CYLINDER HEADInspect carbon deposits and

eliminate them.

Change gasket Inspect and clean

CYLINDER

Inspect and clean Inspect score marks

Inspect wear

Replace

CLUTCH

Inspect and adjust Inspect housing, friction

plate, clutch plate and spring

Replace

TRANSMISSION

Inspect

Replace bearing

SHIFT FORK, SHIFT CAM, GUIDE BAR

InspectInspect wear

Page 193 of 860

3 - 2

INSP

ADJ

MAINTENANCE INTERVALS

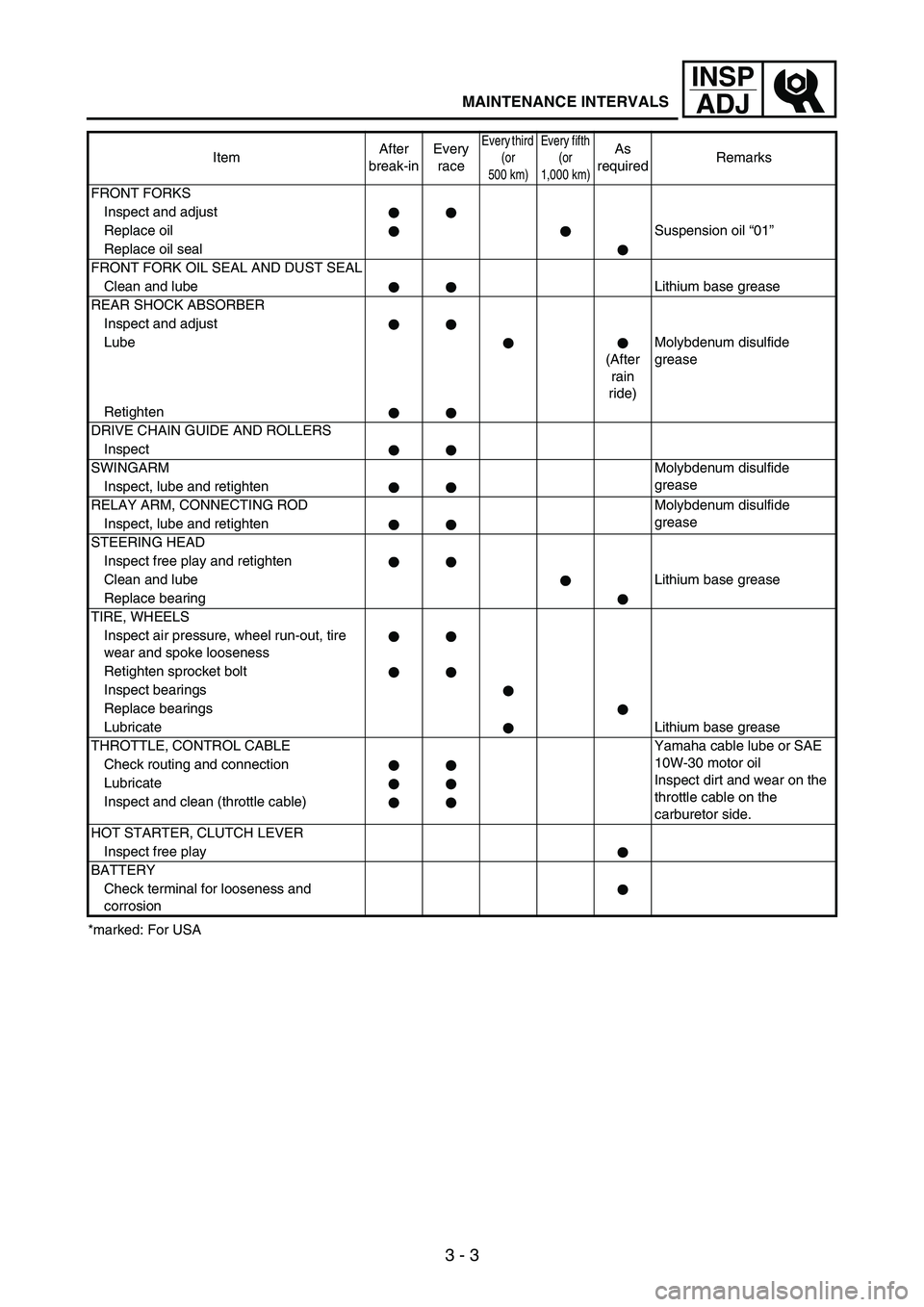

ROTOR NUT

Retighten

EXHAUST PIPE, SILENCER,

PROTECTOR

Inspect and retighten

Clean

Replace* Whichever comes first

*SPARK ARRESTER

Clean

(Every

six

months)

CRANK

Inspect and clean

CARBURETOR

Inspect, adjust and clean

SPARK PLUG

Inspect and clean

Replace

DRIVE CHAINUse chain lube

Chain slack:

40 ~ 50 mm (1.6 ~ 2.0 in) Lubricate, slack, alignment

Replace

COOLING SYSTEM

Check coolant level and leakage

Check radiator cap operation

Replace coolantEvery two years

Inspect hoses

OUTSIDE NUTS AND BOLTS Refer to “STARTING AND

BREAK-IN” section in the

CHAPTER 1. Retighten

AIR FILTER

Clean and lubricate Use foam air-filter oil or

equivalent oil

Replace

OIL FILTER

Replace

OIL STRAINER (frame)

Clean

FRAME

Clean and inspect

FUEL TANK, COCK

Clean and inspect

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper bolts,

master cylinder bolts and union bolts

Replace pads

Replace brake fluid Every one yearItemAfter

break-inEvery

race

Every third

(or

500 km)Every fifth

(or

1,000 km)As

requiredRemarks

1

2

3

4

5

6

7

Page 194 of 860

3 - 3

INSP

ADJ

MAINTENANCE INTERVALS

*marked: For USAFRONT FORKS

Inspect and adjust

Replace oilSuspension oil “01”

Replace oil seal

FRONT FORK OIL SEAL AND DUST SEAL

Clean and lubeLithium base grease

REAR SHOCK ABSORBER

Inspect and adjust

Lube

(After

rain

ride)Molybdenum disulfide

grease

Retighten

DRIVE CHAIN GUIDE AND ROLLERS

Inspect

SWINGARMMolybdenum disulfide

grease

Inspect, lube and retighten

RELAY ARM, CONNECTING ROD Molybdenum disulfide

grease

Inspect, lube and retighten

STEERING HEAD

Inspect free play and retighten

Clean and lubeLithium base grease

Replace bearing

TIRE, WHEELS

Inspect air pressure, wheel run-out, tire

wear and spoke looseness

Retighten sprocket bolt

Inspect bearings

Replace bearings

LubricateLithium base grease

THROTTLE, CONTROL CABLE Yamaha cable lube or SAE

10W-30 motor oil

Inspect dirt and wear on the

throttle cable on the

carburetor side. Check routing and connection

Lubricate

Inspect and clean (throttle cable)

HOT STARTER, CLUTCH LEVER

Inspect free play

BATTERY

Check terminal for looseness and

corrosionItemAfter

break-inEvery

race

Every third

(or

500 km)Every fifth

(or

1,000 km)As

requiredRemarks

Page 207 of 860

3 - 16

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

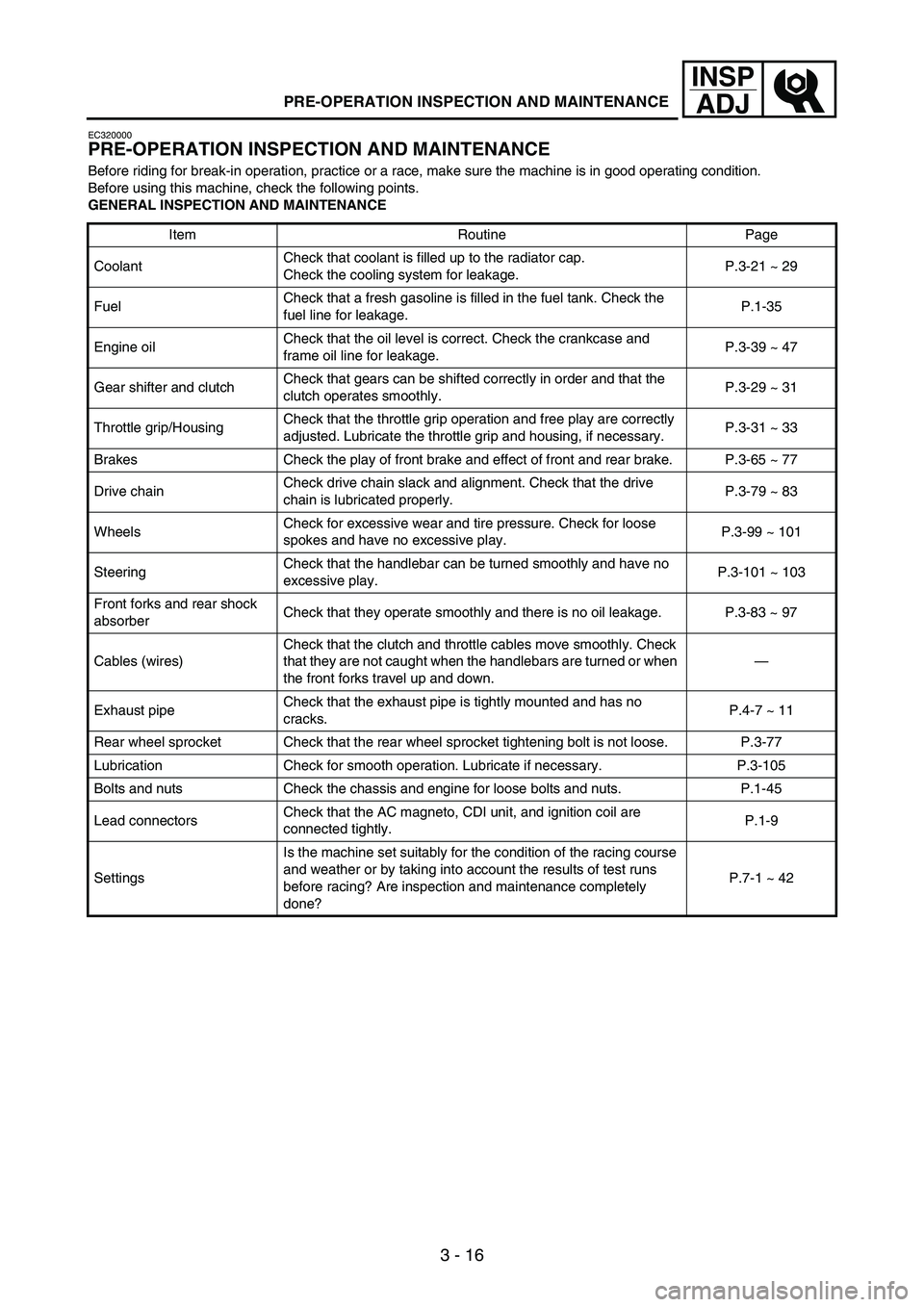

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.P.3-21 ~ 29

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-35

Engine oilCheck that the oil level is correct. Check the crankcase and

frame oil line for leakage.P.3-39 ~ 47

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-29 ~ 31

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-31 ~ 33

Brakes Check the play of front brake and effect of front and rear brake. P.3-65 ~ 77

Drive chainCheck drive chain slack and alignment. Check that the drive

chain is lubricated properly.P.3-79 ~ 83

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-99 ~ 101

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-101 ~ 103

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-83 ~ 97

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and has no

cracks.P.4-7 ~ 11

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-77

Lubrication Check for smooth operation. Lubricate if necessary. P.3-105

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-45

Lead connectorsCheck that the AC magneto, CDI unit, and ignition coil are

connected tightly.P.1-9

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 42

Page 226 of 860

3 - 35

INSP

ADJ

AIR FILTER CLEANING

NOTE:Proper air filter maintenance is the

biggest key to preventing premature

engine wear and damage.

CAUTION:

Never run the engine without the

air filter element in place; this

would allow dirt and dust to enter

the engine and cause rapid wear

and possible engine damage.

1. Remove:

Air filter case cover

1

NOTE:Loosen the quick screw

2 and draw

the air filter case cover to remove it

because its claws

a are inserted in

the side cover as shown.

2. Unhook:

Binder

1

3. Remove:

Air filter element

1

Filter guide

2

4. Clean:

Air filter element

Clean them with solvent.

NOTE:After cleaning, remove the remaining

solvent by squeezing the element.

CAUTION:

Do not twist the element when

squeezing the element.

Leaving too much of solvent in

the element may result in poor

starting.

NETTOYAGE DU FILTRE A AIR

N.B.:

Un entretien convenable du filtre à air

est la clé pour éviter l’usure prématurée

et l’endommagement du moteur.

ATTENTION:

Ne jamais faire tourner le moteur

lorsque l’élément du filtre à air n’est

pas en place; ceci permettrait la péné-

tration de poussière dans le moteur et

causerait son usure rapide et son

endommagement.

1. Déposer:

Le couvercle du boîtier du filtre à

air 1

N.B.:

Desserrer la vis rapide 2 et tirer le cou-

vercle du boîtier de filtre à air pour

l’enlever comme indiqué car les griffes

a sont insérées dans le capot latéral.

2. Décrocher:

Ressort 1

3. Déposer:

Elément du filtre à air 1

Guide de filtre 2

4. Nettoyer:

Elément du filtre à air

Les nettoyer avec du dissolvant.

N.B.:

Une fois l’entretien terminé, éliminer ce

qui reste de solvant en serrant l’élément.

ATTENTION:

Ne pas tordre l’élément en l’esso-

rant.

Un excès de dissolvant sur l’élément

risque de rendre la mise en marche

du moteur plus difficile.

ENGINE

MOTEUR

Page 704 of 860

5 - 127

CHASSWINGARM

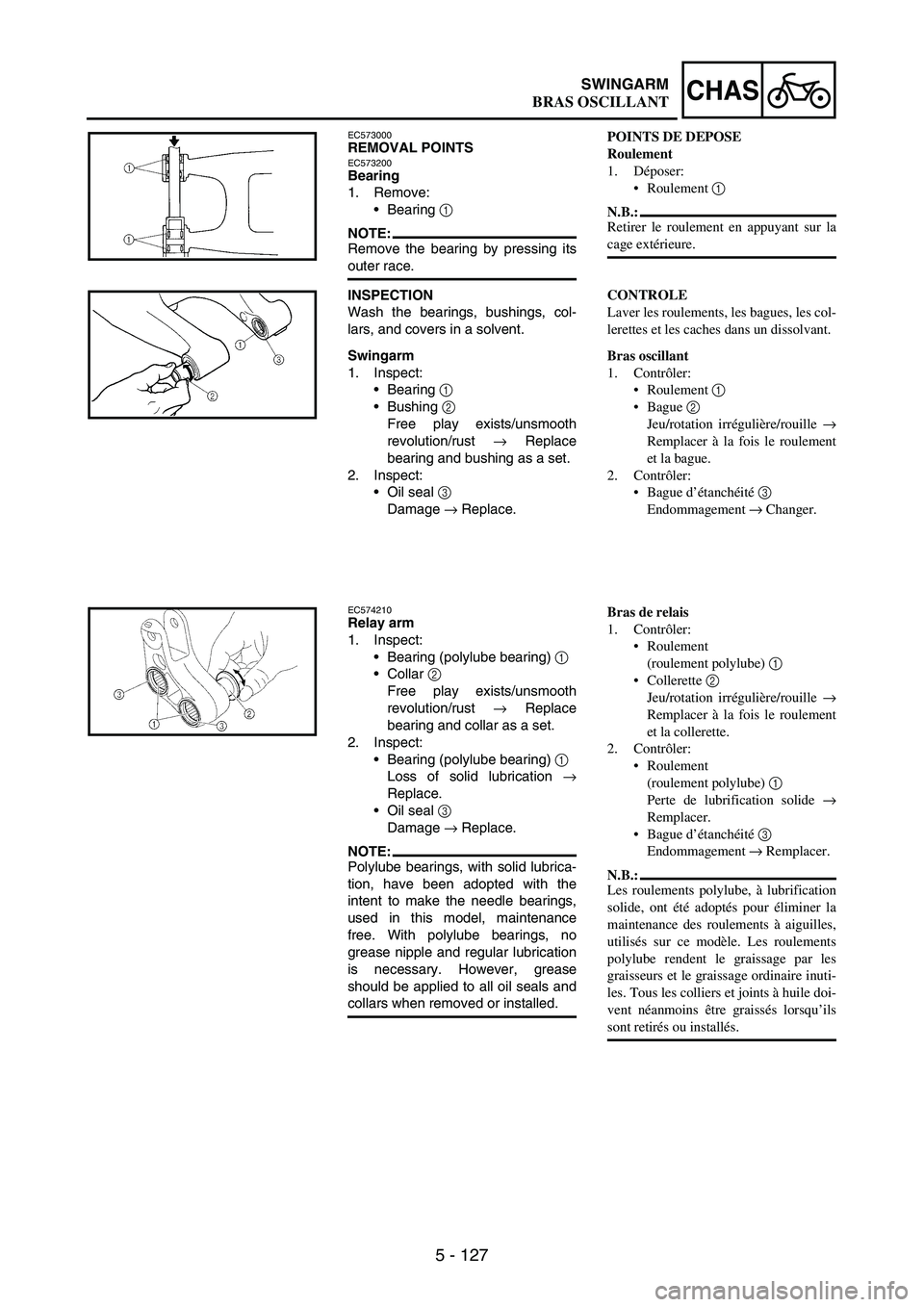

EC573000REMOVAL POINTSEC573200Bearing

1. Remove:

Bearing

1

NOTE:Remove the bearing by pressing its

outer race.

INSPECTION

Wash the bearings, bushings, col-

lars, and covers in a solvent.

Swingarm

1. Inspect:

Bearing

1

Bushing

2

Free play exists/unsmooth

revolution/rust

→ Replace

bearing and bushing as a set.

2. Inspect:

Oil seal

3

Damage

→ Replace.

EC574210Relay arm

1. Inspect:

Bearing (polylube bearing)

1

Collar

2

Free play exists/unsmooth

revolution/rust

→ Replace

bearing and collar as a set.

2. Inspect:

Bearing (polylube bearing)

1

Loss of solid lubrication

→

Replace.

Oil seal

3

Damage

→ Replace.

NOTE:Polylube bearings, with solid lubrica-

tion, have been adopted with the

intent to make the needle bearings,

used in this model, maintenance

free. With polylube bearings, no

grease nipple and regular lubrication

is necessary. However, grease

should be applied to all oil seals and

collars when removed or installed.

POINTS DE DEPOSE

Roulement

1. Déposer:

Roulement 1

N.B.:

Retirer le roulement en appuyant sur la

cage extérieure.

CONTROLE

Laver les roulements, les bagues, les col-

lerettes et les caches dans un dissolvant.

Bras oscillant

1. Contrôler:

Roulement 1

Bague 2

Jeu/rotation irrégulière/rouille →

Remplacer à la fois le roulement

et la bague.

2. Contrôler:

Bague d’étanchéité 3

Endommagement → Changer.

Bras de relais

1. Contrôler:

Roulement

(roulement polylube) 1

Collerette 2

Jeu/rotation irrégulière/rouille →

Remplacer à la fois le roulement

et la collerette.

2. Contrôler:

Roulement

(roulement polylube) 1

Perte de lubrification solide →

Remplacer.

Bague d’étanchéité 3

Endommagement → Remplacer.

N.B.:

Les roulements polylube, à lubrification

solide, ont été adoptés pour éliminer la

maintenance des roulements à aiguilles,

utilisés sur ce modèle. Les roulements

polylube rendent le graissage par les

graisseurs et le graissage ordinaire inuti-

les. Tous les colliers et joints à huile doi-

vent néanmoins être graissés lorsqu’ils

sont retirés ou installés.

BRAS OSCILLANT

Page 706 of 860

5 - 129

CHASSWINGARM

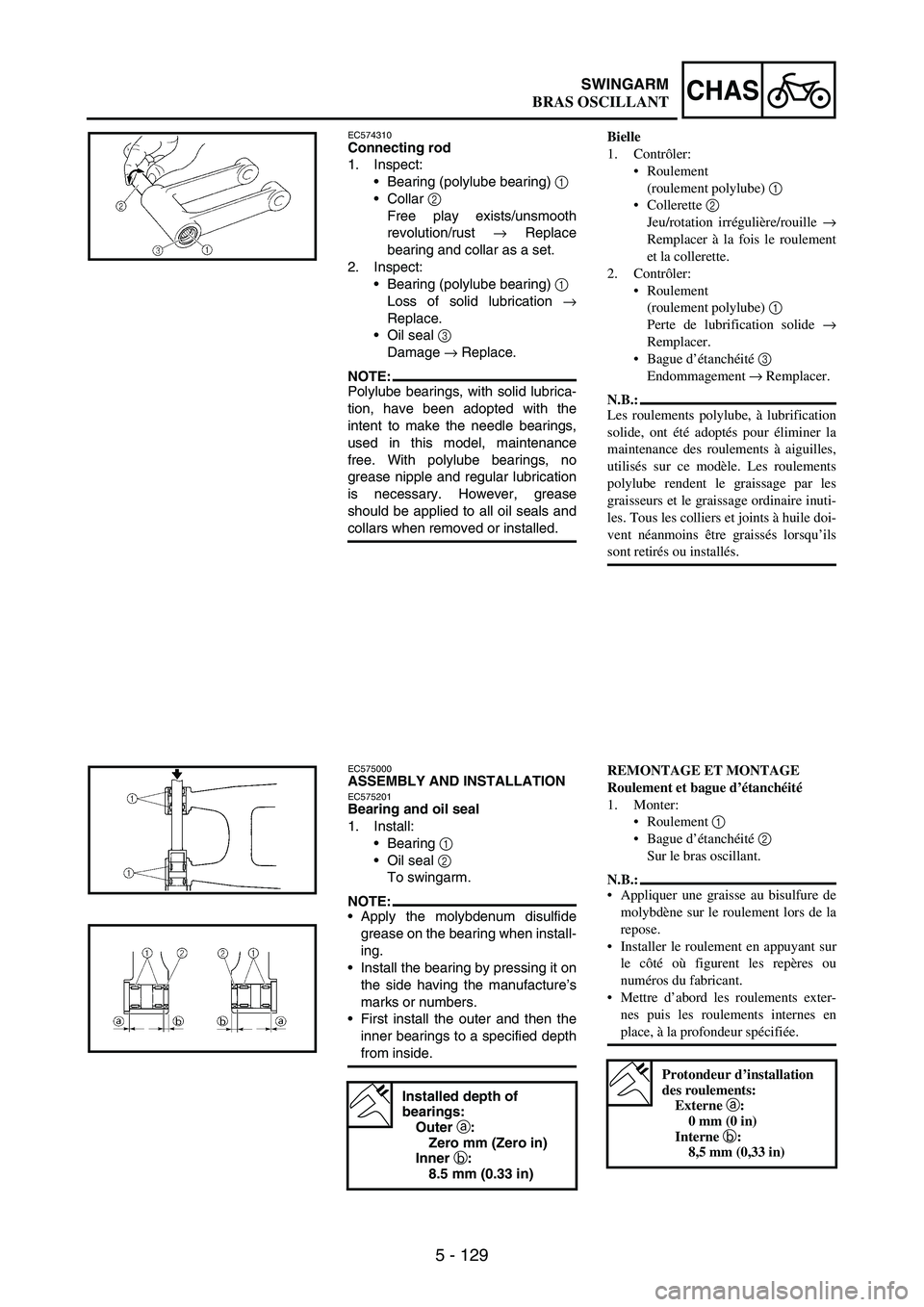

EC574310Connecting rod

1. Inspect:

Bearing (polylube bearing)

1

Collar

2

Free play exists/unsmooth

revolution/rust

→ Replace

bearing and collar as a set.

2. Inspect:

Bearing (polylube bearing)

1

Loss of solid lubrication

→

Replace.

Oil seal

3

Damage

→ Replace.

NOTE:Polylube bearings, with solid lubrica-

tion, have been adopted with the

intent to make the needle bearings,

used in this model, maintenance

free. With polylube bearings, no

grease nipple and regular lubrication

is necessary. However, grease

should be applied to all oil seals and

collars when removed or installed.

EC575000ASSEMBLY AND INSTALLATIONEC575201Bearing and oil seal

1. Install:

Bearing

1

Oil seal

2

To swingarm.

NOTE:Apply the molybdenum disulfide

grease on the bearing when install-

ing.

Install the bearing by pressing it on

the side having the manufacture’s

marks or numbers.

First install the outer and then the

inner bearings to a specified depth

from inside.

Installed depth of

bearings:

Outer a

:

Zero mm (Zero in)

Inner b

:

8.5 mm (0.33 in)

Bielle

1. Contrôler:

Roulement

(roulement polylube) 1

Collerette 2

Jeu/rotation irrégulière/rouille →

Remplacer à la fois le roulement

et la collerette.

2. Contrôler:

Roulement

(roulement polylube) 1

Perte de lubrification solide →

Remplacer.

Bague d’étanchéité 3

Endommagement → Remplacer.

N.B.:

Les roulements polylube, à lubrification

solide, ont été adoptés pour éliminer la

maintenance des roulements à aiguilles,

utilisés sur ce modèle. Les roulements

polylube rendent le graissage par les

graisseurs et le graissage ordinaire inuti-

les. Tous les colliers et joints à huile doi-

vent néanmoins être graissés lorsqu’ils

sont retirés ou installés.

REMONTAGE ET MONTAGE

Roulement et bague d’étanchéité

1. Monter:

Roulement 1

Bague d’étanchéité 2

Sur le bras oscillant.

N.B.:

Appliquer une graisse au bisulfure de

molybdène sur le roulement lors de la

repose.

Installer le roulement en appuyant sur

le côté où figurent les repères ou

numéros du fabricant.

Mettre d’abord les roulements exter-

nes puis les roulements internes en

place, à la profondeur spécifiée.

Protondeur d’installation

des roulements:

Externe a:

0 mm (0 in)

Interne b:

8,5 mm (0,33 in)

BRAS OSCILLANT