brake YAMAHA WR 250F 2004 Betriebsanleitungen (in German)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2004, Model line: WR 250F, Model: YAMAHA WR 250F 2004Pages: 864, PDF-Größe: 22.07 MB

Page 180 of 864

SPEC

2 - 101

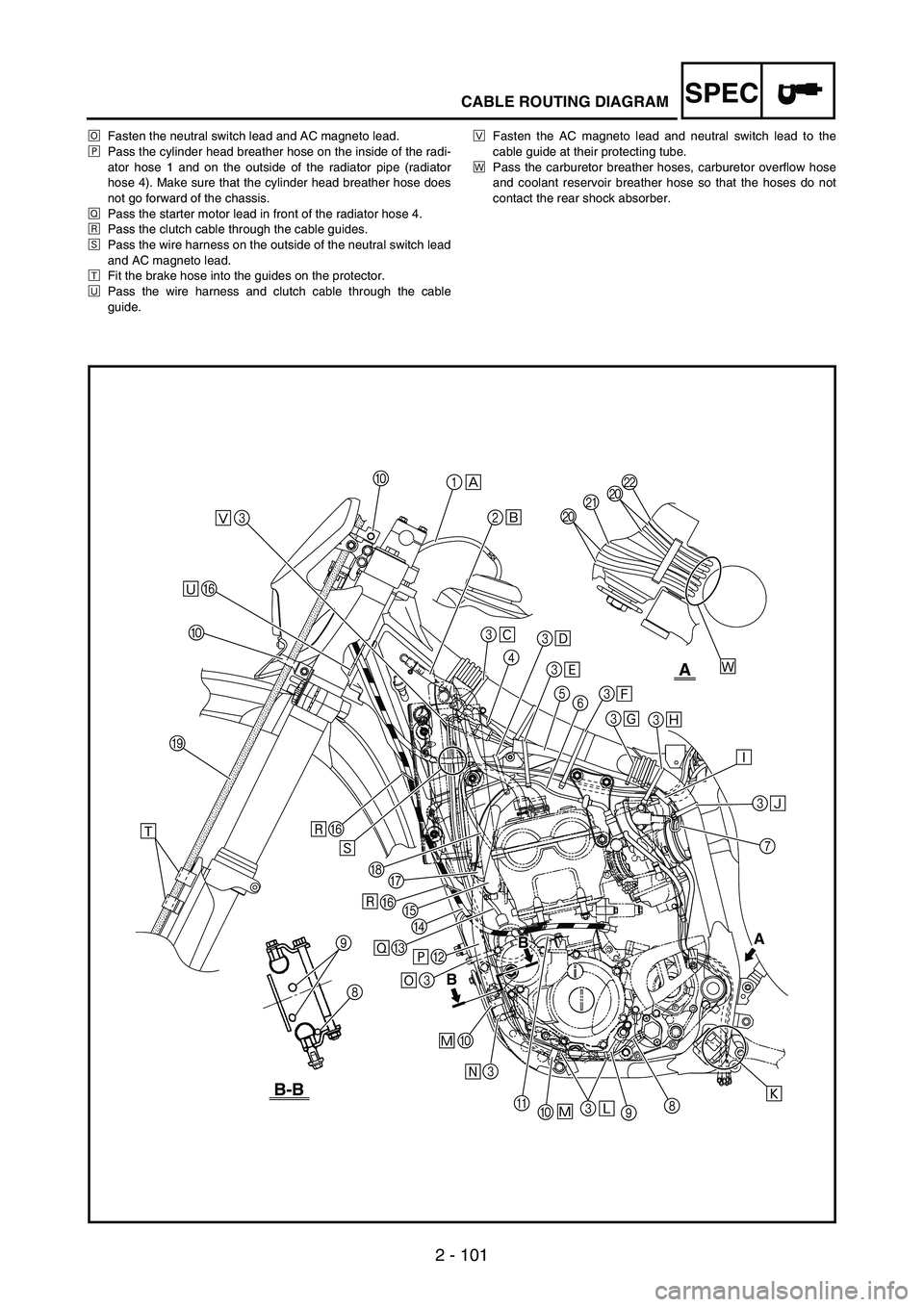

CABLE ROUTING DIAGRAM

ÖFasten the neutral switch lead and AC magneto lead.

×Pass the cylinder head breather hose on the inside of the radi-

ator hose 1 and on the outside of the radiator pipe (radiator

hose 4). Make sure that the cylinder head breather hose does

not go forward of the chassis.

ØPass the starter motor lead in front of the radiator hose 4.

ÙPass the clutch cable through the cable guides.

ÚPass the wire harness on the outside of the neutral switch lead

and AC magneto lead.

ÛFit the brake hose into the guides on the protector.

ÜPass the wire harness and clutch cable through the cable

guide.ÝFasten the AC magneto lead and neutral switch lead to the

cable guide at their protecting tube.

ÞPass the carburetor breather hoses, carburetor overflow hose

and coolant reservoir breather hose so that the hoses do not

contact the rear shock absorber.

A

A

B-B

B

B

Þ 3

4

3

5

63

3

3

3

7 J

JKL

8

9 3

0 A 3 0 3B CD E FG H F

9

8 I0F30

1

2 È

É

Ê

Ì

Î Í

3

Ë

Ï

Ð

Ñ

Ò

Ó

Ô Õ Ö× Ø Ù

Ú Û

Ô Ù ÜÝ

Page 186 of 864

SPEC

2 - 107

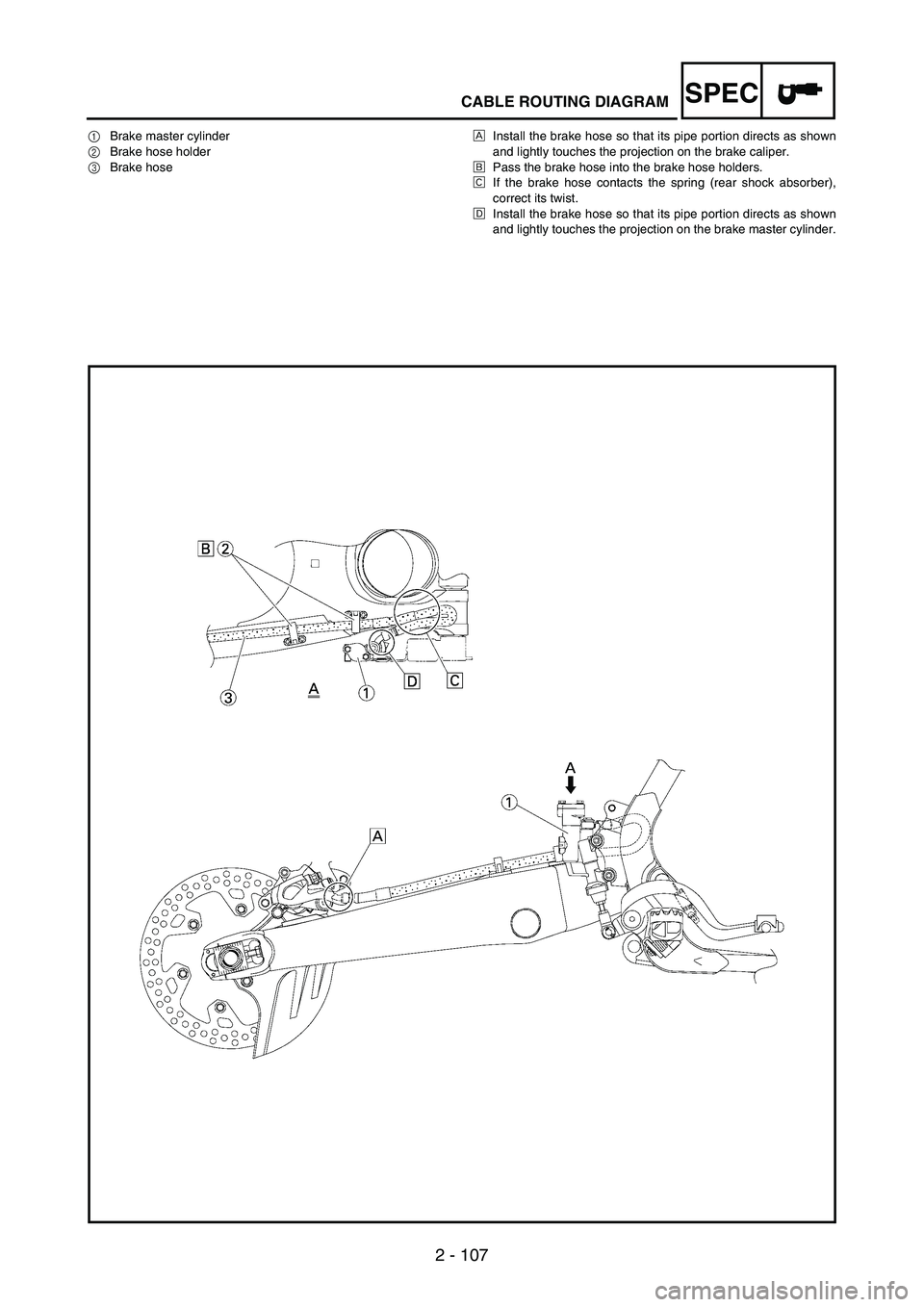

CABLE ROUTING DIAGRAM

1Brake master cylinder

2Brake hose holder

3Brake hoseÈInstall the brake hose so that its pipe portion directs as shown

and lightly touches the projection on the brake caliper.

ÉPass the brake hose into the brake hose holders.

ÊIf the brake hose contacts the spring (rear shock absorber),

correct its twist.

ËInstall the brake hose so that its pipe portion directs as shown

and lightly touches the projection on the brake master cylinder.

Page 190 of 864

SPEC

2 - 111

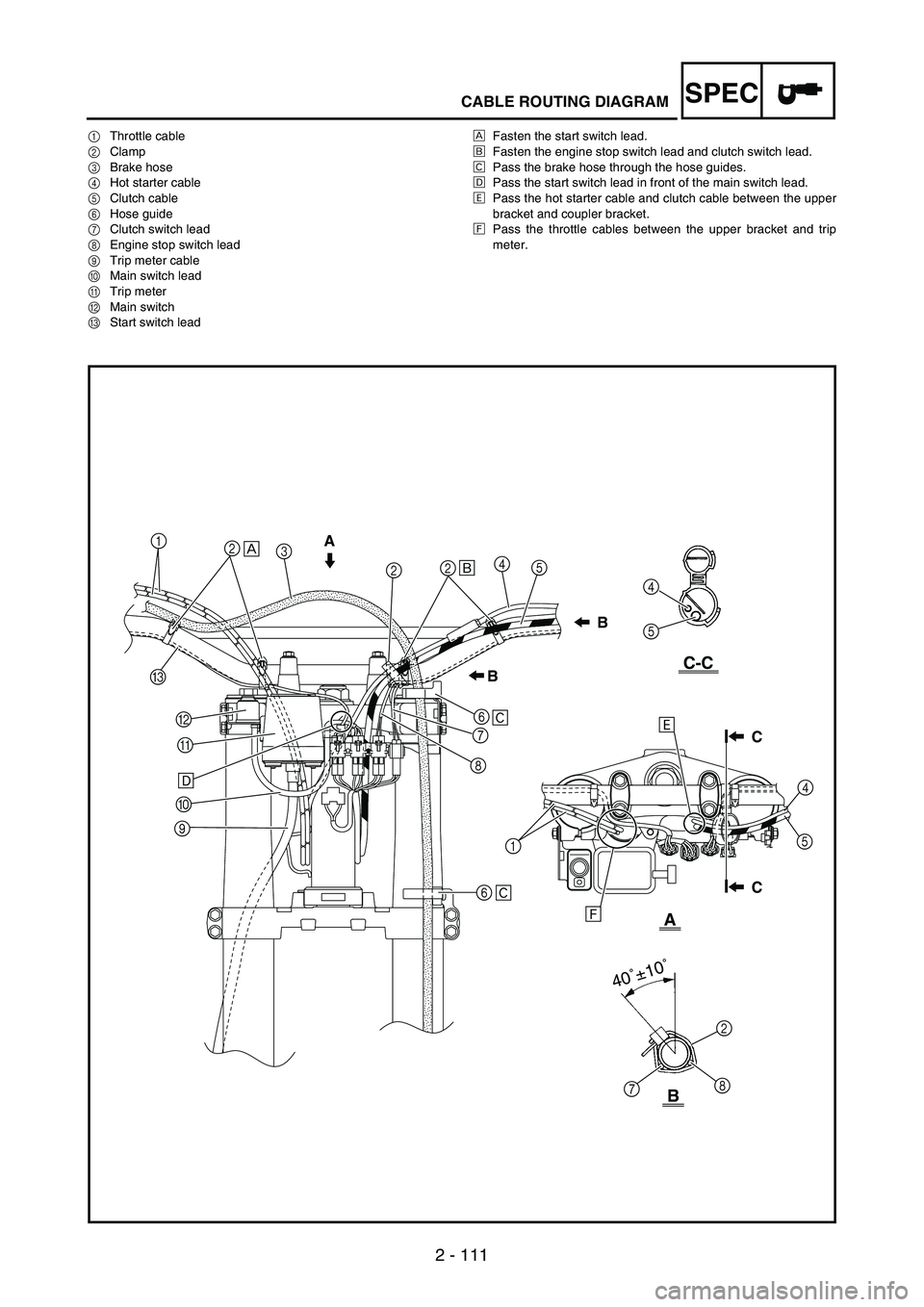

CABLE ROUTING DIAGRAM

1Throttle cable

2Clamp

3Brake hose

4Hot starter cable

5Clutch cable

6Hose guide

7Clutch switch lead

8Engine stop switch lead

9Trip meter cable

0Main switch lead

ATrip meter

BMain switch

CStart switch leadÈFasten the start switch lead.

ÉFasten the engine stop switch lead and clutch switch lead.

ÊPass the brake hose through the hose guides.

ËPass the start switch lead in front of the main switch lead.

ÌPass the hot starter cable and clutch cable between the upper

bracket and coupler bracket.

ÍPass the throttle cables between the upper bracket and trip

meter.

A

A

B

C-CB

B

C

C

1

2

3

224

5

C

B

A

0

96

7

8

64

5

4

15

2

8

7

40˚±10˚

ËÈ

É

Ê

Ê

ÍÌ

Page 193 of 864

3 - 2

INSP

ADJ

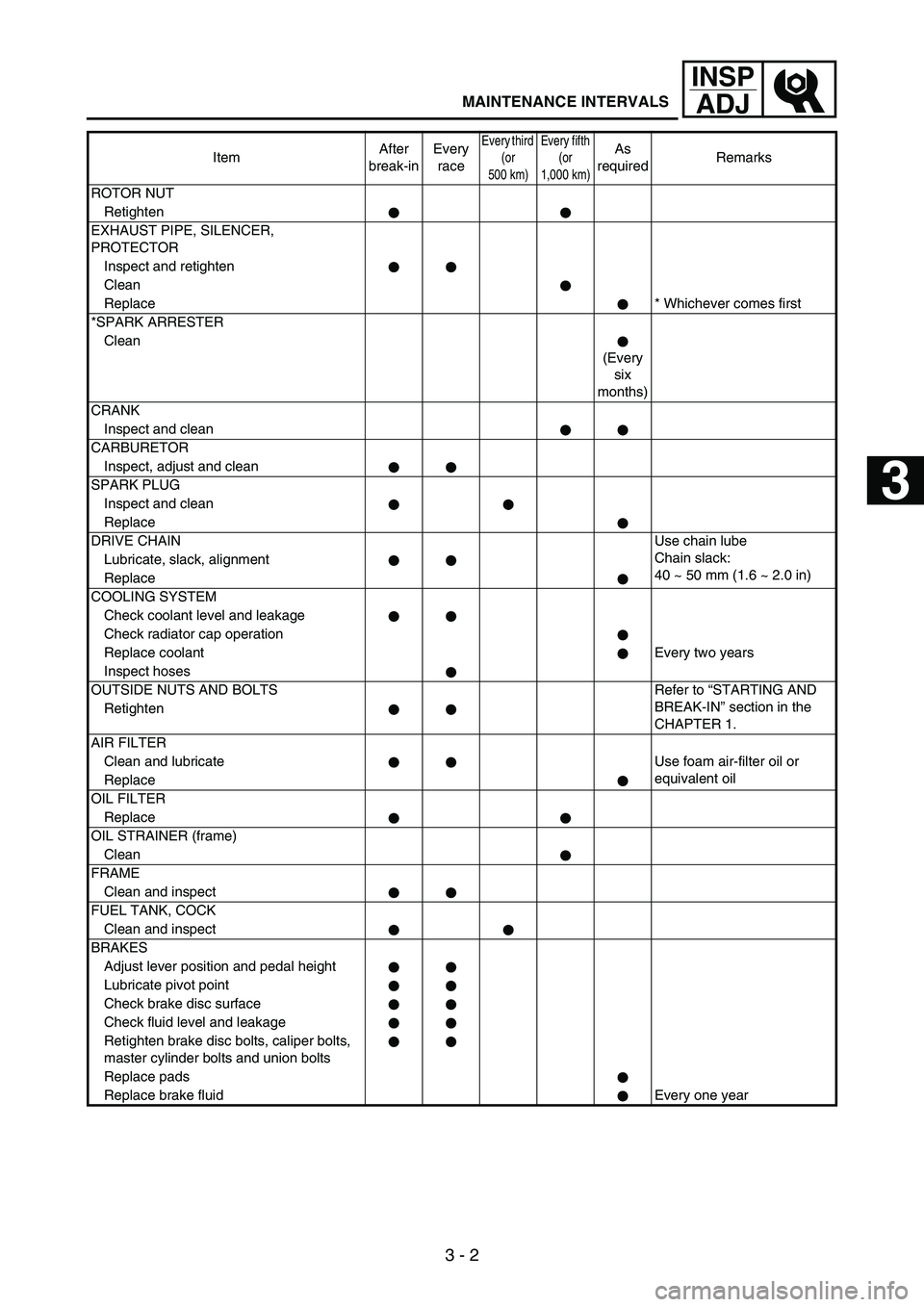

MAINTENANCE INTERVALS

ROTOR NUT

Retighten

EXHAUST PIPE, SILENCER,

PROTECTOR

Inspect and retighten

Clean

Replace* Whichever comes first

*SPARK ARRESTER

Clean

(Every

six

months)

CRANK

Inspect and clean

CARBURETOR

Inspect, adjust and clean

SPARK PLUG

Inspect and clean

Replace

DRIVE CHAINUse chain lube

Chain slack:

40 ~ 50 mm (1.6 ~ 2.0 in) Lubricate, slack, alignment

Replace

COOLING SYSTEM

Check coolant level and leakage

Check radiator cap operation

Replace coolantEvery two years

Inspect hoses

OUTSIDE NUTS AND BOLTS Refer to “STARTING AND

BREAK-IN” section in the

CHAPTER 1. Retighten

AIR FILTER

Clean and lubricate Use foam air-filter oil or

equivalent oil

Replace

OIL FILTER

Replace

OIL STRAINER (frame)

Clean

FRAME

Clean and inspect

FUEL TANK, COCK

Clean and inspect

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper bolts,

master cylinder bolts and union bolts

Replace pads

Replace brake fluid Every one yearItemAfter

break-inEvery

race

Every third

(or

500 km)Every fifth

(or

1,000 km)As

requiredRemarks

1

2

3

4

5

6

7

Page 207 of 864

3 - 16

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

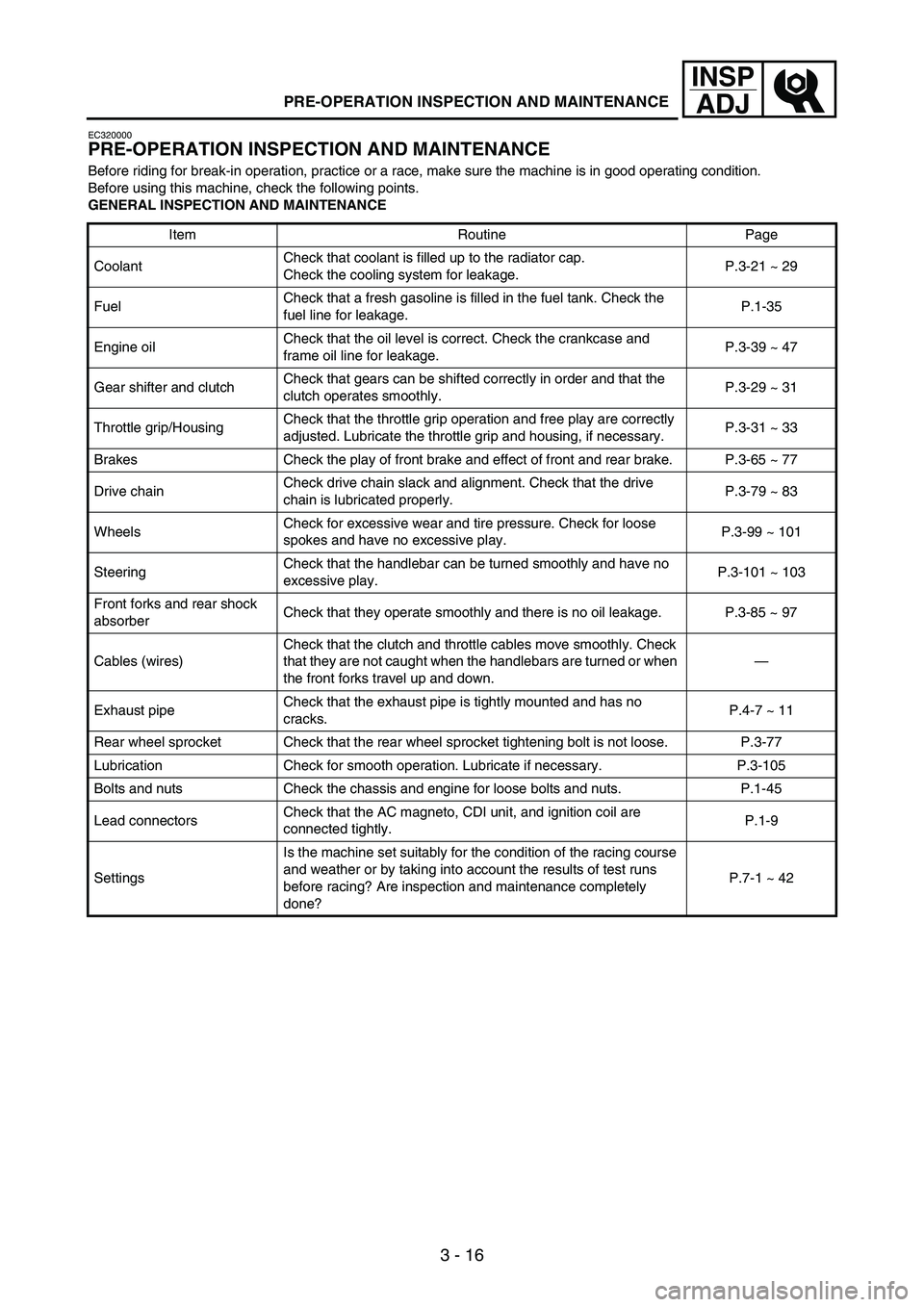

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.P.3-21 ~ 29

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-35

Engine oilCheck that the oil level is correct. Check the crankcase and

frame oil line for leakage.P.3-39 ~ 47

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-29 ~ 31

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-31 ~ 33

Brakes Check the play of front brake and effect of front and rear brake. P.3-65 ~ 77

Drive chainCheck drive chain slack and alignment. Check that the drive

chain is lubricated properly.P.3-79 ~ 83

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-99 ~ 101

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-101 ~ 103

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-85 ~ 97

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and has no

cracks.P.4-7 ~ 11

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-77

Lubrication Check for smooth operation. Lubricate if necessary. P.3-105

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-45

Lead connectorsCheck that the AC magneto, CDI unit, and ignition coil are

connected tightly.P.1-9

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 42

Page 256 of 864

3 - 65

INSP

ADJ

EC360000

CHASSIS

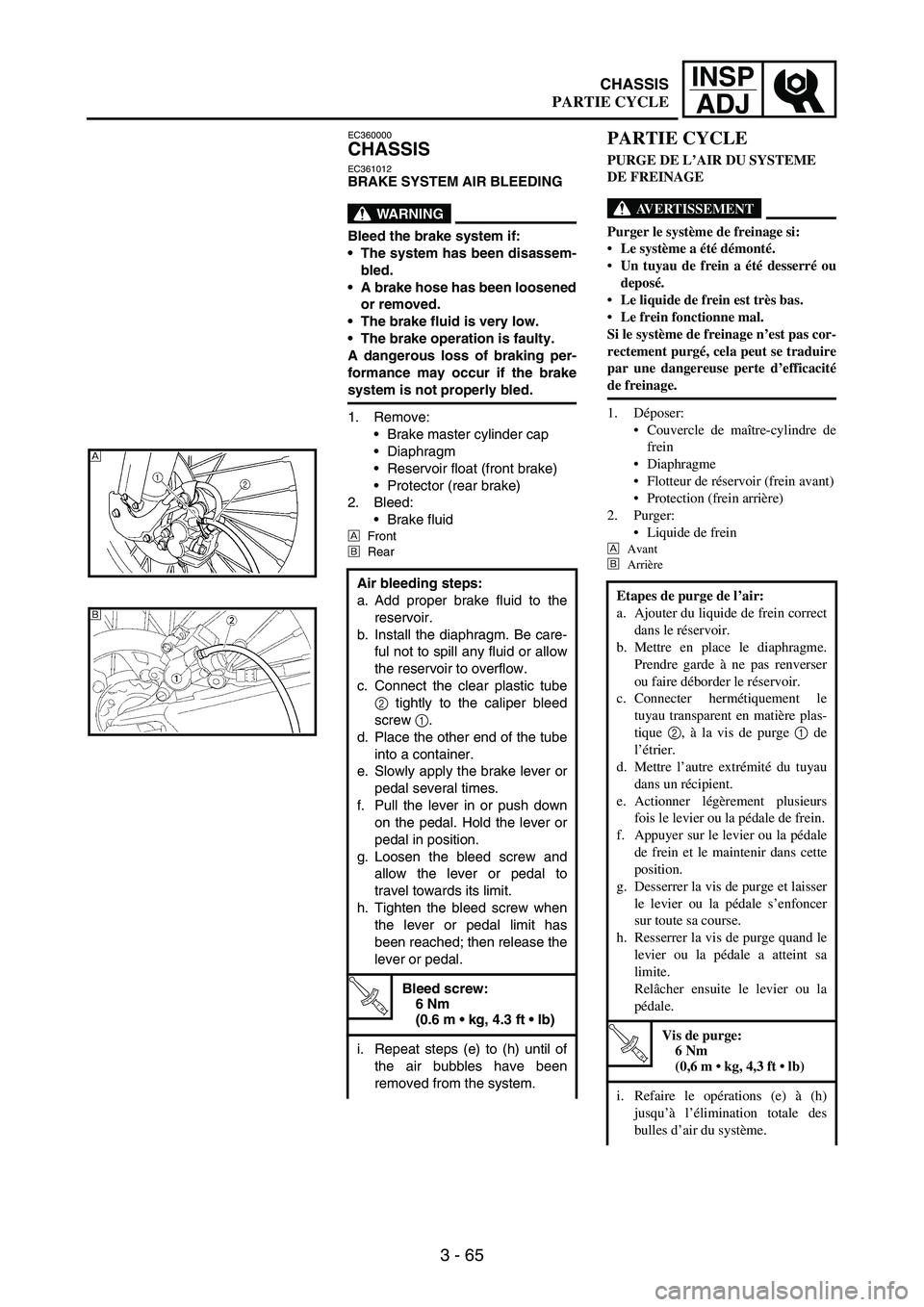

EC361012BRAKE SYSTEM AIR BLEEDING

WARNING

Bleed the brake system if:

The system has been disassem-

bled.

A brake hose has been loosened

or removed.

The brake fluid is very low.

The brake operation is faulty.

A dangerous loss of braking per-

formance may occur if the brake

system is not properly bled.

1. Remove:

Brake master cylinder cap

Diaphragm

Reservoir float (front brake)

Protector (rear brake)

2. Bleed:

Brake fluid

ÈFront

ÉRear

Air bleeding steps:

a. Add proper brake fluid to the

reservoir.

b. Install the diaphragm. Be care-

ful not to spill any fluid or allow

the reservoir to overflow.

c. Connect the clear plastic tube

2 tightly to the caliper bleed

screw

1.

d. Place the other end of the tube

into a container.

e. Slowly apply the brake lever or

pedal several times.

f. Pull the lever in or push down

on the pedal. Hold the lever or

pedal in position.

g. Loosen the bleed screw and

allow the lever or pedal to

travel towards its limit.

h. Tighten the bleed screw when

the lever or pedal limit has

been reached; then release the

lever or pedal.

T R..

Bleed screw:

6 Nm

(0.6 m kg, 4.3 ft lb)

i. Repeat steps (e) to (h) until of

the air bubbles have been

removed from the system.

È

É

PARTIE CYCLE

PURGE DE L’AIR DU SYSTEME

DE FREINAGE

AVERTISSEMENT

Purger le système de freinage si:

Le système a été démonté.

Un tuyau de frein a été desserré ou

deposé.

Le liquide de frein est très bas.

Le frein fonctionne mal.

Si le système de freinage n’est pas cor-

rectement purgé, cela peut se traduire

par une dangereuse perte d’efficacité

de freinage.

1. Déposer:

Couvercle de maître-cylindre de

frein

Diaphragme

Flotteur de réservoir (frein avant)

Protection (frein arrière)

2. Purger:

Liquide de frein

È

Avant

É

Arrière

Etapes de purge de l’air:

a. Ajouter du liquide de frein correct

dans le réservoir.

b. Mettre en place le diaphragme.

Prendre garde à ne pas renverser

ou faire déborder le réservoir.

c. Connecter hermétiquement le

tuyau transparent en matière plas-

tique 2, à la vis de purge 1 de

l’étrier.

d. Mettre l’autre extrémité du tuyau

dans un récipient.

e. Actionner légèrement plusieurs

fois le levier ou la pédale de frein.

f. Appuyer sur le levier ou la pédale

de frein et le maintenir dans cette

position.

g. Desserrer la vis de purge et laisser

le levier ou la pédale s’enfoncer

sur toute sa course.

h. Resserrer la vis de purge quand le

levier ou la pédale a atteint sa

limite.

Relâcher ensuite le levier ou la

pédale.

T R..

Vis de purge:

6 Nm

(0,6 m kg, 4,3 ft lb)

i. Refaire le opérations (e) à (h)

jusqu’à l’élimination totale des

bulles d’air du système.

CHASSIS

PARTIE CYCLE

Page 258 of 864

3 - 67

INSP

ADJ

3. Install:

Protector (rear brake)

Reservoir float (front brake)

Diaphragm

Brake master cylinder cap

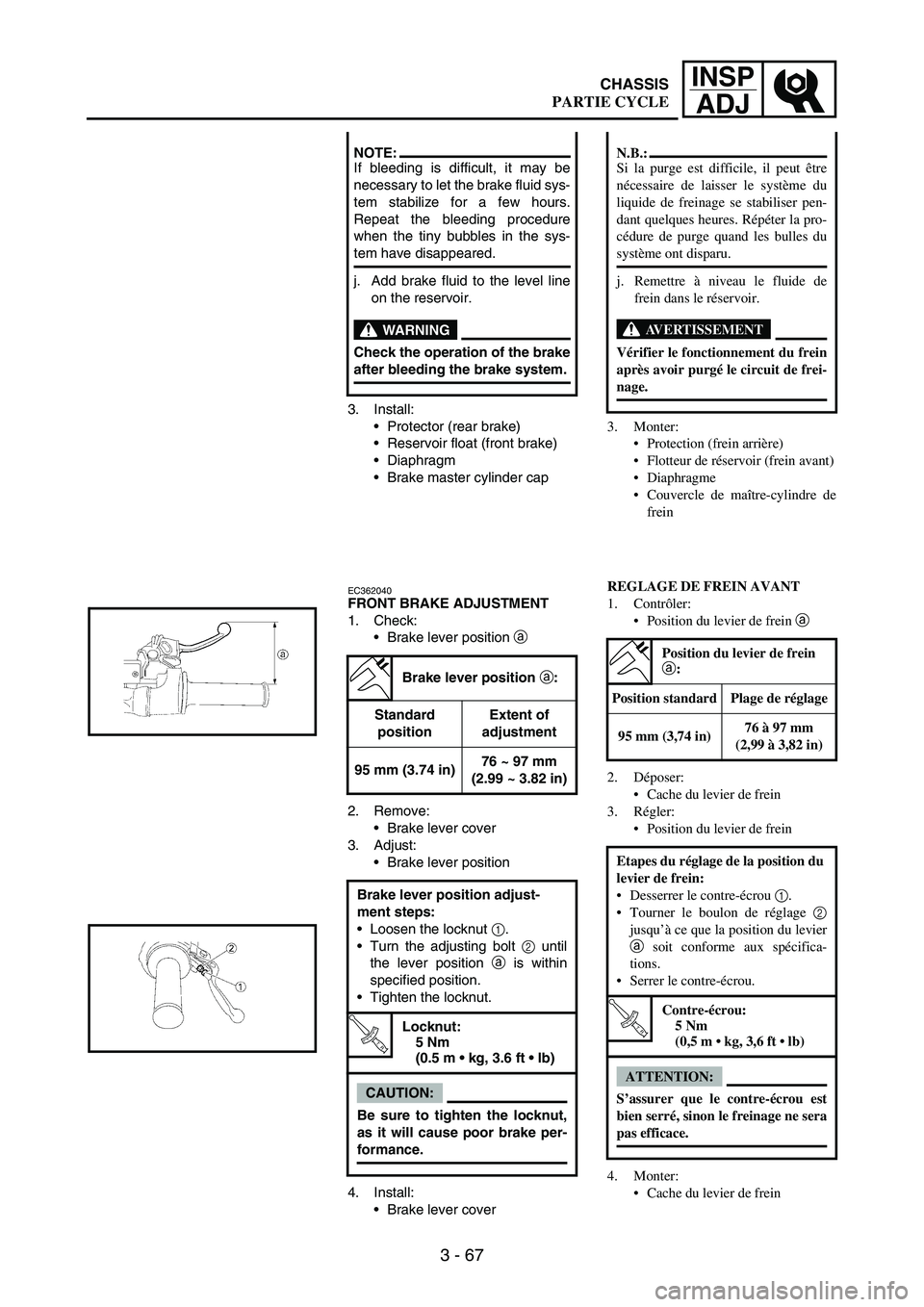

EC362040FRONT BRAKE ADJUSTMENT

1. Check:

Brake lever position

a

2. Remove:

Brake lever cover

3. Adjust:

Brake lever position

4. Install:

Brake lever cover

NOTE:If bleeding is difficult, it may be

necessary to let the brake fluid sys-

tem stabilize for a few hours.

Repeat the bleeding procedure

when the tiny bubbles in the sys-

tem have disappeared.

j. Add brake fluid to the level line

on the reservoir.

WARNING

Check the operation of the brake

after bleeding the brake system.

Brake lever position a:

Standard

positionExtent of

adjustment

95 mm (3.74 in)76 ~ 97 mm

(2.99 ~ 3.82 in)

Brake lever position adjust-

ment steps:

Loosen the locknut

1.

Turn the adjusting bolt

2 until

the lever position

a is within

specified position.

Tighten the locknut.

T R..

Locknut:

5 Nm

(0.5 m kg, 3.6 ft lb)

CAUTION:

Be sure to tighten the locknut,

as it will cause poor brake per-

formance.

3. Monter:

Protection (frein arrière)

Flotteur de réservoir (frein avant)

Diaphragme

Couvercle de maître-cylindre de

frein

REGLAGE DE FREIN AVANT

1. Contrôler:

Position du levier de frein a

2. Déposer:

Cache du levier de frein

3. Régler:

Position du levier de frein

4. Monter:

Cache du levier de frein

N.B.:

Si la purge est difficile, il peut être

nécessaire de laisser le système du

liquide de freinage se stabiliser pen-

dant quelques heures. Répéter la pro-

cédure de purge quand les bulles du

système ont disparu.

j. Remettre à niveau le fluide de

frein dans le réservoir.

AVERTISSEMENT

Vérifier le fonctionnement du frein

après avoir purgé le circuit de frei-

nage.

Position du levier de frein

a:

Position standard Plage de réglage

95 mm (3,74 in)76 à 97 mm

(2,99 à 3,82 in)

Etapes du réglage de la position du

levier de frein:

Desserrer le contre-écrou 1.

Tourner le boulon de réglage 2

jusqu’à ce que la position du levier

a soit conforme aux spécifica-

tions.

Serrer le contre-écrou.

T R..

Contre-écrou:

5 Nm

(0,5 m kg, 3,6 ft lb)

ATTENTION:

S’assurer que le contre-écrou est

bien serré, sinon le freinage ne sera

pas efficace.

CHASSIS

PARTIE CYCLE

Page 260 of 864

3 - 69

INSP

ADJ

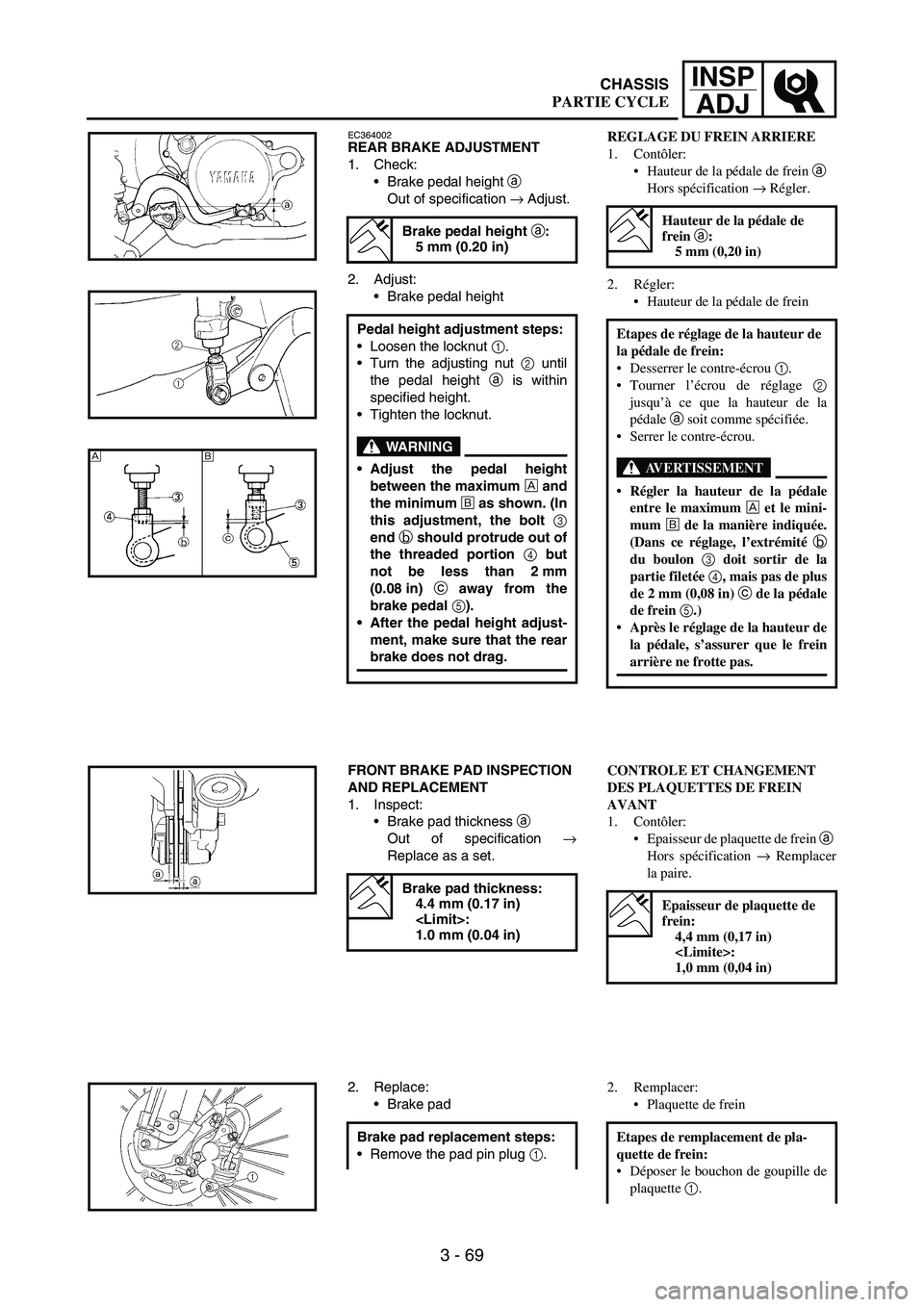

EC364002REAR BRAKE ADJUSTMENT

1. Check:

Brake pedal height

a

Out of specification

→ Adjust.

2. Adjust:

Brake pedal height

Brake pedal height a:

5 mm (0.20 in)

Pedal height adjustment steps:

Loosen the locknut

1.

Turn the adjusting nut

2 until

the pedal height

a is within

specified height.

Tighten the locknut.

WARNING

Adjust the pedal height

between the maximum È and

the minimum É as shown. (In

this adjustment, the bolt 3

end b should protrude out of

the threaded portion 4 but

not be less than 2 mm

(0.08 in) c away from the

brake pedal 5).

After the pedal height adjust-

ment, make sure that the rear

brake does not drag.

ÈÉ

FRONT BRAKE PAD INSPECTION

AND REPLACEMENT

1. Inspect:

Brake pad thickness

a

Out of specification

→

Replace as a set.

Brake pad thickness:

4.4 mm (0.17 in)

1.0 mm (0.04 in)

2. Replace:

Brake pad

Brake pad replacement steps:

Remove the pad pin plug

1.

REGLAGE DU FREIN ARRIERE

1. Contôler:

Hauteur de la pédale de frein a

Hors spécification → Régler.

2. Régler:

Hauteur de la pédale de frein

Hauteur de la pédale de

frein a:

5 mm (0,20 in)

Etapes de réglage de la hauteur de

la pédale de frein:

Desserrer le contre-écrou 1.

Tourner l’écrou de réglage 2

jusqu’à ce que la hauteur de la

pédale a soit comme spécifiée.

Serrer le contre-écrou.

AVERTISSEMENT

Régler la hauteur de la pédale

entre le maximum È et le mini-

mum É de la manière indiquée.

(Dans ce réglage, l’extrémité b

du boulon 3 doit sortir de la

partie filetée 4, mais pas de plus

de 2 mm (0,08 in) c de la pédale

de frein 5.)

Après le réglage de la hauteur de

la pédale, s’assurer que le frein

arrière ne frotte pas.

CONTROLE ET CHANGEMENT

DES PLAQUETTES DE FREIN

AVANT

1. Contôler:

Epaisseur de plaquette de frein a

Hors spécification → Remplacer

la paire.

Epaisseur de plaquette de

frein:

4,4 mm (0,17 in)

1,0 mm (0,04 in)

2. Remplacer:

Plaquette de frein

Etapes de remplacement de pla-

quette de frein:

Déposer le bouchon de goupille de

plaquette 1.

CHASSIS

PARTIE CYCLE

Page 262 of 864

3 - 71

INSP

ADJ

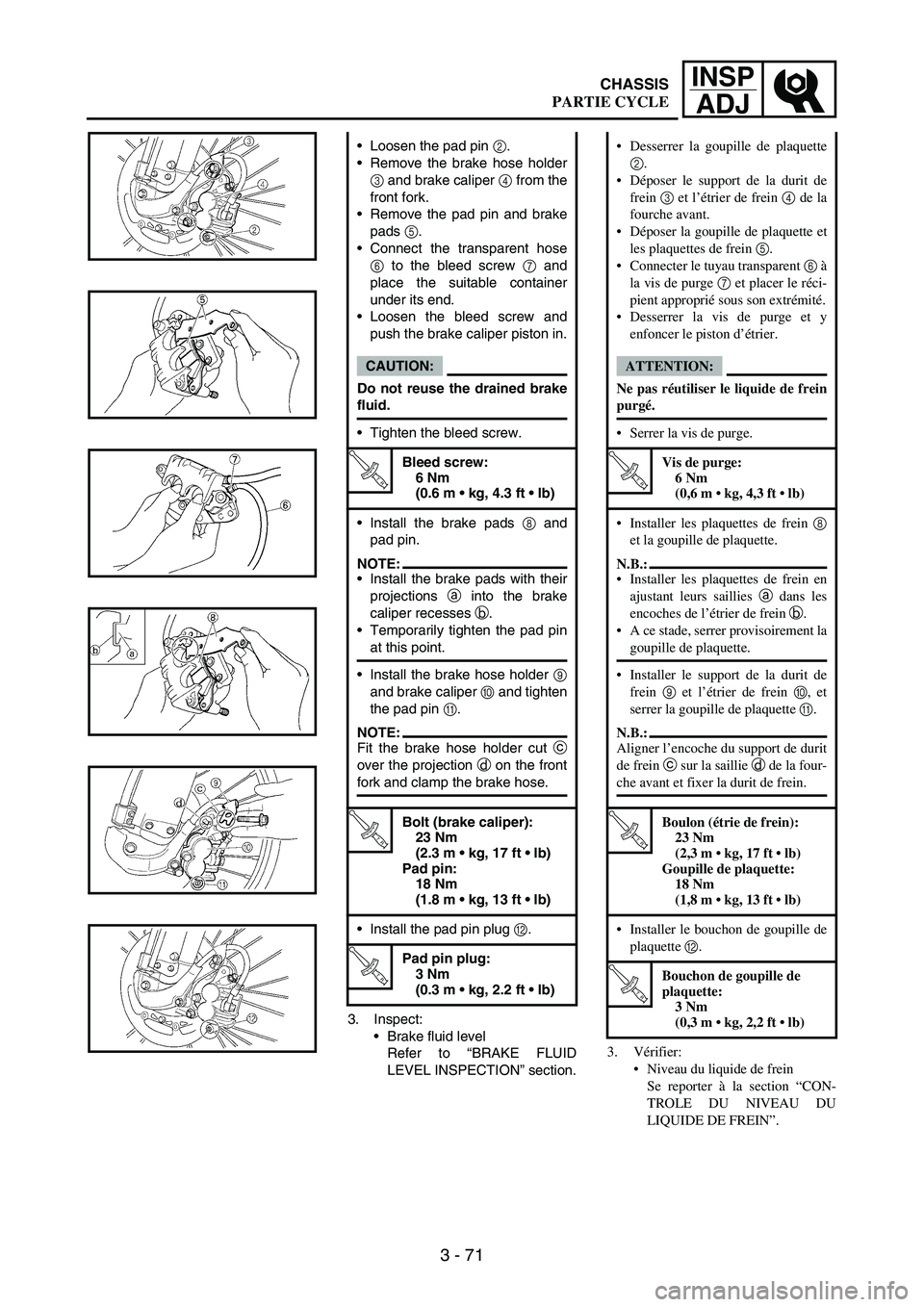

3. Inspect:

Brake fluid level

Refer to “BRAKE FLUID

LEVEL INSPECTION” section. Loosen the pad pin

2.

Remove the brake hose holder

3 and brake caliper

4 from the

front fork.

Remove the pad pin and brake

pads

5.

Connect the transparent hose

6 to the bleed screw

7 and

place the suitable container

under its end.

Loosen the bleed screw and

push the brake caliper piston in.

CAUTION:

Do not reuse the drained brake

fluid.

Tighten the bleed screw.

T R..

Bleed screw:

6 Nm

(0.6 m kg, 4.3 ft lb)

Install the brake pads

8 and

pad pin.

NOTE:Install the brake pads with their

projections

a into the brake

caliper recesses

b.

Temporarily tighten the pad pin

at this point.

Install the brake hose holder

9

and brake caliper

0 and tighten

the pad pin

A.

NOTE:Fit the brake hose holder cut

c

over the projection

d on the front

fork and clamp the brake hose.

T R..

Bolt (brake caliper):

23 Nm

(2.3 m kg, 17 ft lb)

Pad pin:

18 Nm

(1.8 m kg, 13 ft lb)

Install the pad pin plug

B.

T R..

Pad pin plug:

3 Nm

(0.3 m kg, 2.2 ft lb)

3. Vérifier:

Niveau du liquide de frein

Se reporter à la section “CON-

TROLE DU NIVEAU DU

LIQUIDE DE FREIN”. Desserrer la goupille de plaquette

2.

Déposer le support de la durit de

frein 3 et l’étrier de frein 4 de la

fourche avant.

Déposer la goupille de plaquette et

les plaquettes de frein 5.

Connecter le tuyau transparent 6 à

la vis de purge 7 et placer le réci-

pient approprié sous son extrémité.

Desserrer la vis de purge et y

enfoncer le piston d’étrier.

ATTENTION:

Ne pas réutiliser le liquide de frein

purgé.

Serrer la vis de purge.

T R..

Vis de purge:

6 Nm

(0,6 m kg, 4,3 ft lb)

Installer les plaquettes de frein 8

et la goupille de plaquette.

N.B.:

Installer les plaquettes de frein en

ajustant leurs saillies a dans les

encoches de l’étrier de frein b.

A ce stade, serrer provisoirement la

goupille de plaquette.

Installer le support de la durit de

frein 9 et l’étrier de frein 0, et

serrer la goupille de plaquette A.

N.B.:

Aligner l’encoche du support de durit

de frein c sur la saillie d de la four-

che avant et fixer la durit de frein.

T R..

Boulon (étrie de frein):

23 Nm

(2,3 m kg, 17 ft lb)

Goupille de plaquette:

18 Nm

(1,8 m kg, 13 ft lb)

Installer le bouchon de goupille de

plaquette B.

T R..

Bouchon de goupille de

plaquette:

3 Nm

(0,3 m kg, 2,2 ft lb)

CHASSIS

PARTIE CYCLE

Page 264 of 864

3 - 73

INSP

ADJ

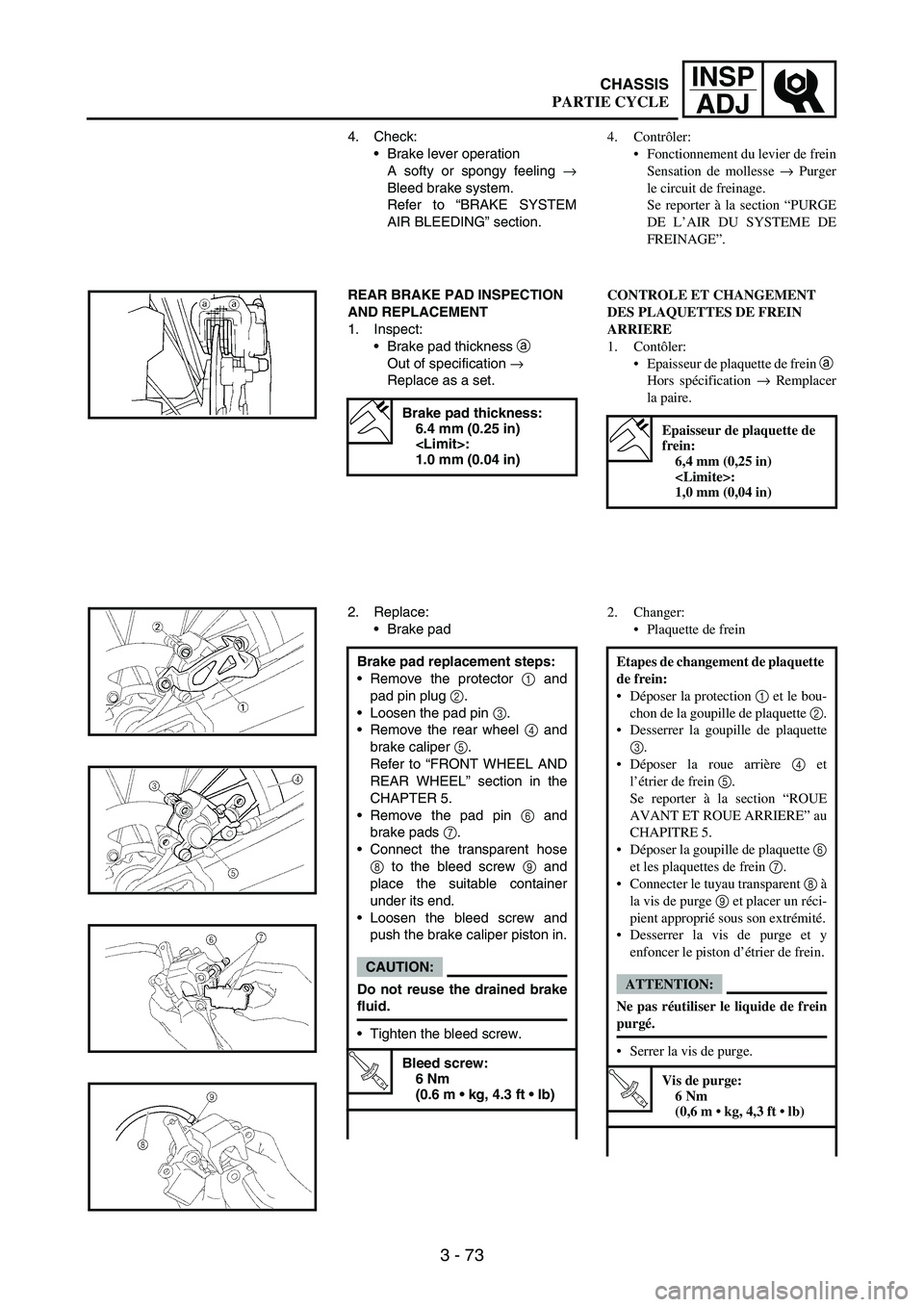

4. Check:

Brake lever operation

A softy or spongy feeling

→

Bleed brake system.

Refer to “BRAKE SYSTEM

AIR BLEEDING” section.

REAR BRAKE PAD INSPECTION

AND REPLACEMENT

1. Inspect:

Brake pad thickness

a

Out of specification

→

Replace as a set.

Brake pad thickness:

6.4 mm (0.25 in)

1.0 mm (0.04 in)

2. Replace:

Brake pad

Brake pad replacement steps:

Remove the protector

1 and

pad pin plug

2.

Loosen the pad pin

3.

Remove the rear wheel

4 and

brake caliper

5.

Refer to “FRONT WHEEL AND

REAR WHEEL” section in the

CHAPTER 5.

Remove the pad pin

6 and

brake pads

7.

Connect the transparent hose

8 to the bleed screw

9 and

place the suitable container

under its end.

Loosen the bleed screw and

push the brake caliper piston in.

CAUTION:

Do not reuse the drained brake

fluid.

Tighten the bleed screw.

T R..

Bleed screw:

6 Nm

(0.6 m kg, 4.3 ft lb)

4. Contrôler:

Fonctionnement du levier de frein

Sensation de mollesse → Purger

le circuit de freinage.

Se reporter à la section “PURGE

DE L’AIR DU SYSTEME DE

FREINAGE”.

CONTROLE ET CHANGEMENT

DES PLAQUETTES DE FREIN

ARRIERE

1. Contôler:

Epaisseur de plaquette de frein a

Hors spécification → Remplacer

la paire.

Epaisseur de plaquette de

frein:

6,4 mm (0,25 in)

1,0 mm (0,04 in)

2. Changer:

Plaquette de frein

Etapes de changement de plaquette

de frein:

Déposer la protection 1 et le bou-

chon de la goupille de plaquette 2.

Desserrer la goupille de plaquette

3.

Déposer la roue arrière 4 et

l’étrier de frein 5.

Se reporter à la section “ROUE

AVANT ET ROUE ARRIERE” au

CHAPITRE 5.

Déposer la goupille de plaquette 6

et les plaquettes de frein 7.

Connecter le tuyau transparent 8 à

la vis de purge 9 et placer un réci-

pient approprié sous son extrémité.

Desserrer la vis de purge et y

enfoncer le piston d’étrier de frein.

ATTENTION:

Ne pas réutiliser le liquide de frein

purgé.

Serrer la vis de purge.

T R..

Vis de purge:

6 Nm

(0,6 m kg, 4,3 ft lb)

CHASSIS

PARTIE CYCLE