engine YAMAHA WR 250F 2004 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2004, Model line: WR 250F, Model: YAMAHA WR 250F 2004Pages: 864, PDF Size: 22.07 MB

Page 560 of 864

4 - 235

ENGCRANKCASE AND CRANKSHAFT

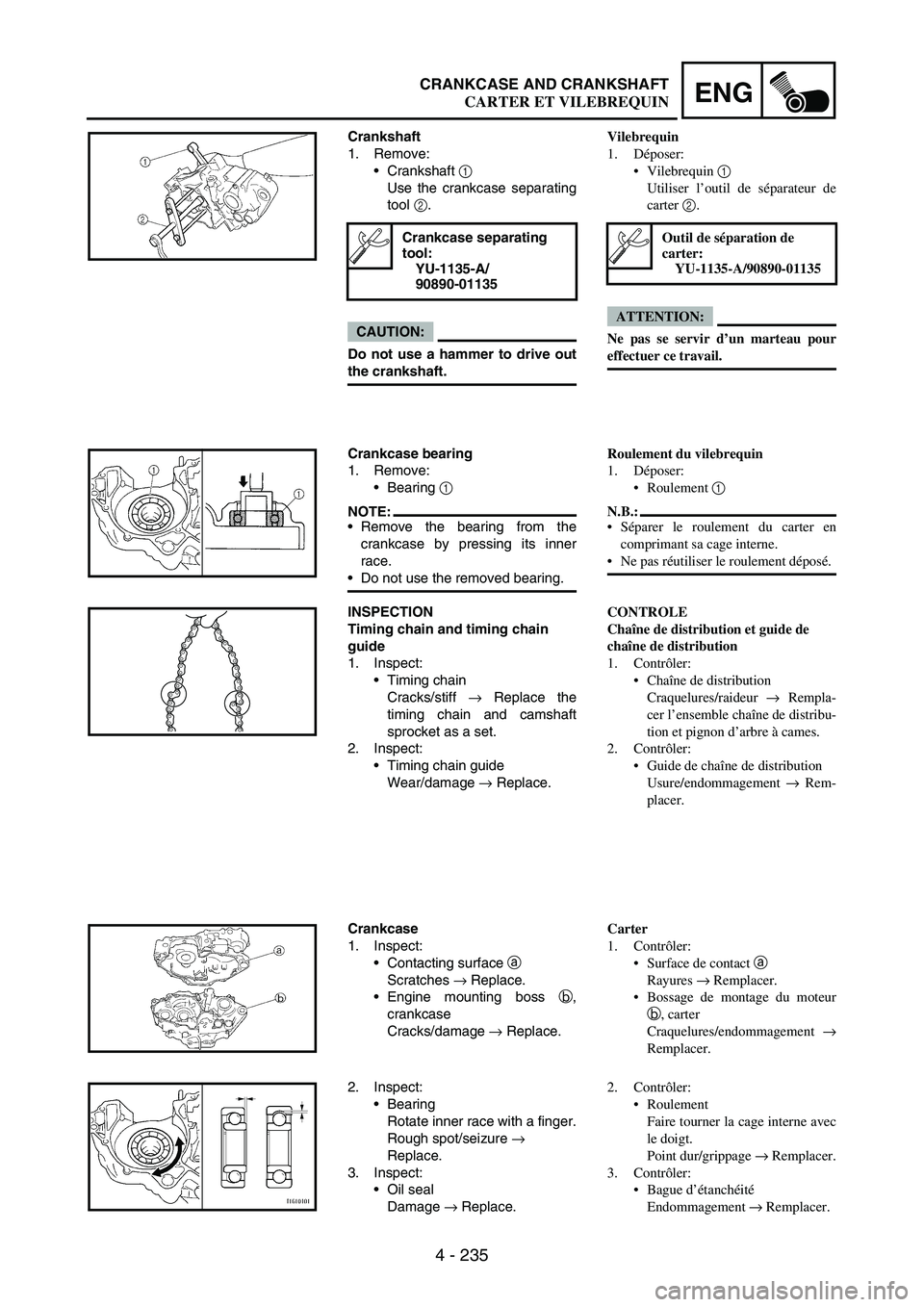

Crankshaft

1. Remove:

Crankshaft

1

Use the crankcase separating

tool

2.

CAUTION:

Do not use a hammer to drive out

the crankshaft.

Crankcase separating

tool:

YU-1135-A/

90890-01135

Crankcase bearing

1. Remove:

Bearing

1

NOTE:Remove the bearing from the

crankcase by pressing its inner

race.

Do not use the removed bearing.

INSPECTION

Timing chain and timing chain

guide

1. Inspect:

Timing chain

Cracks/stiff

→ Replace the

timing chain and camshaft

sprocket as a set.

2. Inspect:

Timing chain guide

Wear/damage

→ Replace.

Crankcase

1. Inspect:

Contacting surface

a

Scratches

→ Replace.

Engine mounting boss

b,

crankcase

Cracks/damage

→ Replace.

2. Inspect:

Bearing

Rotate inner race with a finger.

Rough spot/seizure

→

Replace.

3. Inspect:

Oil seal

Damage

→ Replace.

Vilebrequin

1. Déposer:

Vilebrequin 1

Utiliser l’outil de séparateur de

carter 2.

ATTENTION:

Ne pas se servir d’un marteau pour

effectuer ce travail.

Outil de séparation de

carter:

YU-1135-A/90890-01135

Roulement du vilebrequin

1. Déposer:

Roulement 1

N.B.:

Séparer le roulement du carter en

comprimant sa cage interne.

Ne pas réutiliser le roulement déposé.

CONTROLE

Chaîne de distribution et guide de

chaîne de distribution

1. Contrôler:

Chaîne de distribution

Craquelures/raideur → Rempla-

cer l’ensemble chaîne de distribu-

tion et pignon d’arbre à cames.

2. Contrôler:

Guide de chaîne de distribution

Usure/endommagement → Rem-

placer.

Carter

1. Contrôler:

Surface de contact a

Rayures → Remplacer.

Bossage de montage du moteur

b, carter

Craquelures/endommagement →

Remplacer.

2. Contrôler:

Roulement

Faire tourner la cage interne avec

le doigt.

Point dur/grippage → Remplacer.

3. Contrôler:

Bague d’étanchéité

Endommagement → Remplacer.

CARTER ET VILEBREQUIN

Page 568 of 864

4 - 243

ENGCRANKCASE AND CRANKSHAFT

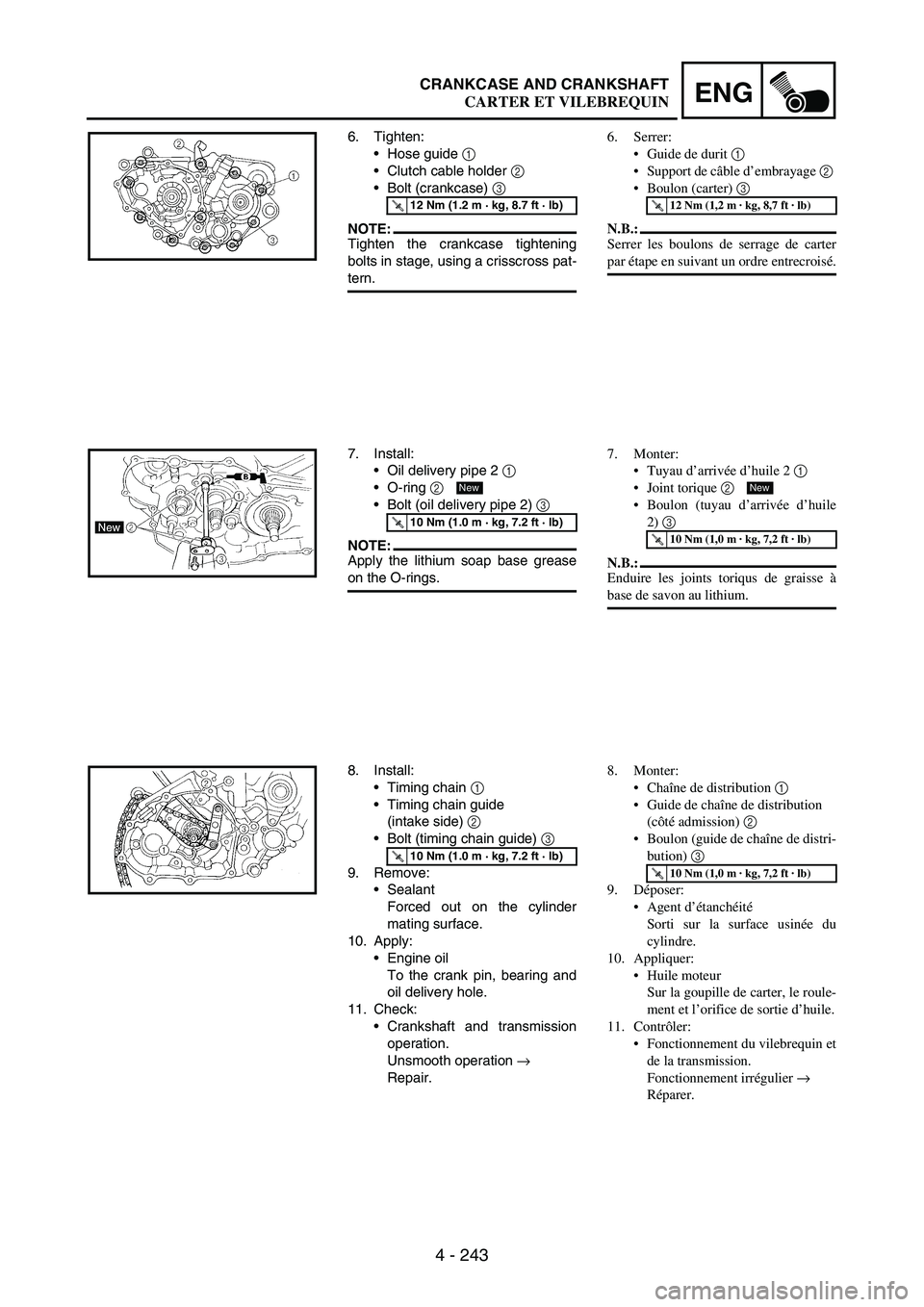

6. Tighten:

Hose guide

1

Clutch cable holder

2

Bolt (crankcase)

3

NOTE:Tighten the crankcase tightening

bolts in stage, using a crisscross pat-

tern.

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)

7. Install:

Oil delivery pipe 2

1

O-ring

2

Bolt (oil delivery pipe 2)

3

NOTE:Apply the lithium soap base grease

on the O-rings.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

New

8. Install:

Timing chain

1

Timing chain guide

(intake side)

2

Bolt (timing chain guide)

3

9. Remove:

Sealant

Forced out on the cylinder

mating surface.

10. Apply:

Engine oil

To the crank pin, bearing and

oil delivery hole.

11. Check:

Crankshaft and transmission

operation.

Unsmooth operation

→

Repair.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

6. Serrer:

Guide de durit 1

Support de câble d’embrayage 2

Boulon (carter) 3

N.B.:

Serrer les boulons de serrage de carter

par étape en suivant un ordre entrecroisé.

T R..12 Nm (1,2 m · kg, 8,7 ft · lb)

7. Monter:

Tuyau d’arrivée d’huile 2 1

Joint torique 2

Boulon (tuyau d’arrivée d’huile

2) 3

N.B.:

Enduire les joints toriqus de graisse à

base de savon au lithium.

T R..10 Nm (1,0 m · kg, 7,2 ft · lb)

New

8. Monter:

Chaîne de distribution 1

Guide de chaîne de distribution

(côté admission) 2

Boulon (guide de chaîne de distri-

bution) 3

9. Déposer:

Agent d’étanchéité

Sorti sur la surface usinée du

cylindre.

10. Appliquer:

Huile moteur

Sur la goupille de carter, le roule-

ment et l’orifice de sortie d’huile.

11. Contrôler:

Fonctionnement du vilebrequin et

de la transmission.

Fonctionnement irrégulier →

Réparer.

T R..10 Nm (1,0 m · kg, 7,2 ft · lb)

CARTER ET VILEBREQUIN

Page 570 of 864

4 - 245

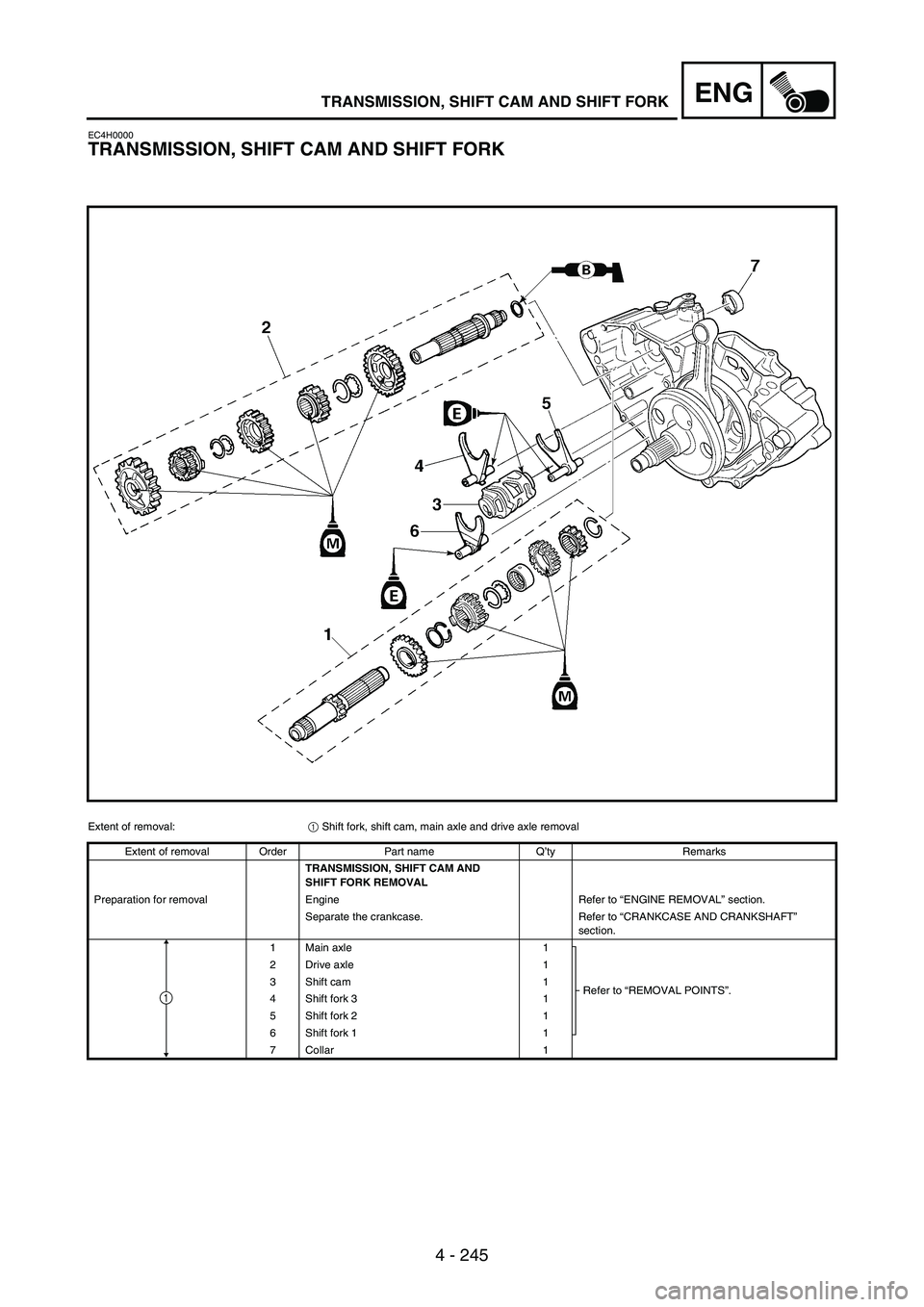

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

EC4H0000

TRANSMISSION, SHIFT CAM AND SHIFT FORK

Extent of removal:

1 Shift fork, shift cam, main axle and drive axle removal

Extent of removal Order Part name Q’ty Remarks

TRANSMISSION, SHIFT CAM AND

SHIFT FORK REMOVAL

Preparation for removal Engine Refer to “ENGINE REMOVAL” section.

Separate the crankcase. Refer to “CRANKCASE AND CRANKSHAFT”

section.

1 Main axle 1

Refer to “REMOVAL POINTS”. 2 Drive axle 1

3 Shift cam 1

4 Shift fork 3 1

5 Shift fork 2 1

6 Shift fork 1 1

7 Collar 1

1

Page 580 of 864

4 - 255

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

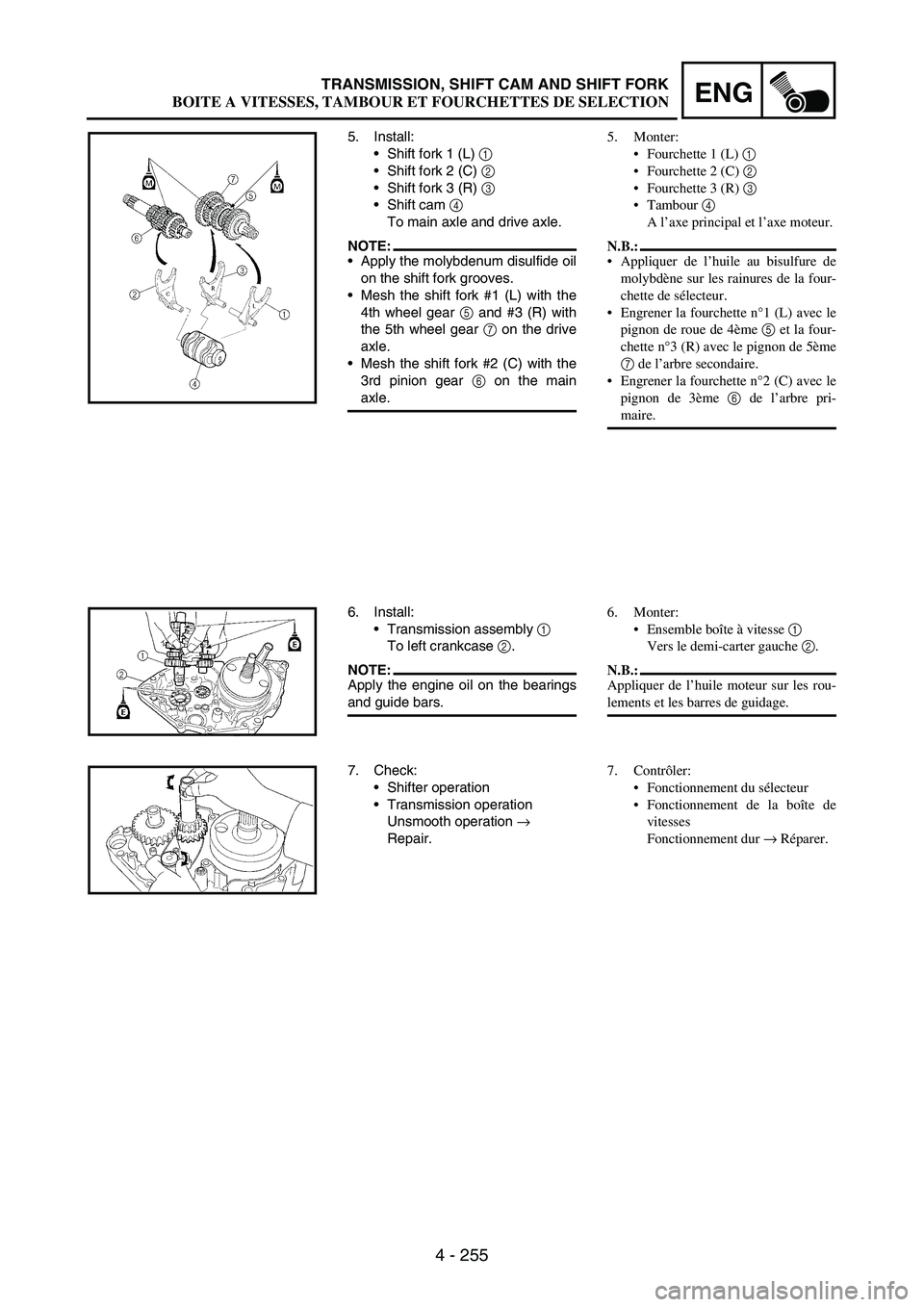

5. Install:

Shift fork 1 (L)

1

Shift fork 2 (C)

2

Shift fork 3 (R)

3

Shift cam

4

To main axle and drive axle.

NOTE:Apply the molybdenum disulfide oil

on the shift fork grooves.

Mesh the shift fork #1 (L) with the

4th wheel gear

5 and #3 (R) with

the 5th wheel gear

7 on the drive

axle.

Mesh the shift fork #2 (C) with the

3rd pinion gear

6 on the main

axle.

6. Install:

Transmission assembly

1

To left crankcase

2.

NOTE:Apply the engine oil on the bearings

and guide bars.

7. Check:

Shifter operation

Transmission operation

Unsmooth operation

→

Repair.

5. Monter:

Fourchette 1 (L) 1

Fourchette 2 (C) 2

Fourchette 3 (R) 3

Tambour 4

A l’axe principal et l’axe moteur.

N.B.:

Appliquer de l’huile au bisulfure de

molybdène sur les rainures de la four-

chette de sélecteur.

Engrener la fourchette n°1 (L) avec le

pignon de roue de 4ème 5 et la four-

chette n°3 (R) avec le pignon de 5ème

7 de l’arbre secondaire.

Engrener la fourchette n°2 (C) avec le

pignon de 3ème 6 de l’arbre pri-

maire.

6. Monter:

Ensemble boîte à vitesse 1

Vers le demi-carter gauche 2.

N.B.:

Appliquer de l’huile moteur sur les rou-

lements et les barres de guidage.

7. Contrôler:

Fonctionnement du sélecteur

Fonctionnement de la boîte de

vitesses

Fonctionnement dur → Réparer.

BOITE A VITESSES, TAMBOUR ET FOURCHETTES DE SELECTION

Page 582 of 864

5 - 1

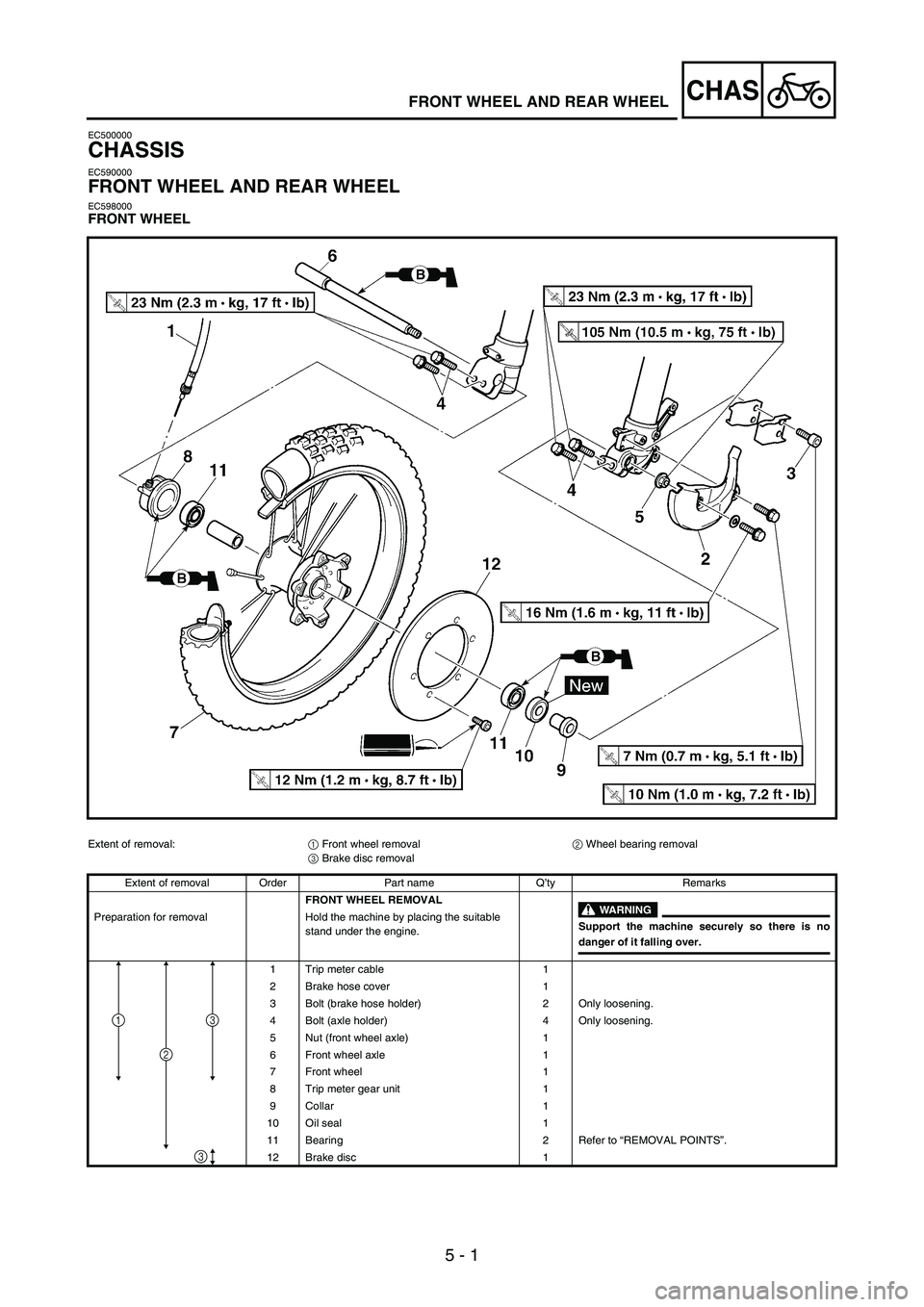

CHASFRONT WHEEL AND REAR WHEEL

EC500000

CHASSIS

EC590000

FRONT WHEEL AND REAR WHEEL

EC598000FRONT WHEEL

Extent of removal:

1 Front wheel removal

2 Wheel bearing removal

3 Brake disc removal

Extent of removal Order Part name Q’ty Remarks

FRONT WHEEL REMOVAL

WARNING

Support the machine securely so there is nodanger of it falling over. Preparation for removal Hold the machine by placing the suitable

stand under the engine.

1 Trip meter cable 1

2 Brake hose cover 1

3 Bolt (brake hose holder) 2 Only loosening.

4 Bolt (axle holder) 4 Only loosening.

5 Nut (front wheel axle) 1

6 Front wheel axle 1

7 Front wheel 1

8 Trip meter gear unit 1

9 Collar 1

10 Oil seal 1

11 Bearing 2 Refer to “REMOVAL POINTS”.

12 Brake disc 1

1

2

3

3

Page 586 of 864

5 - 5

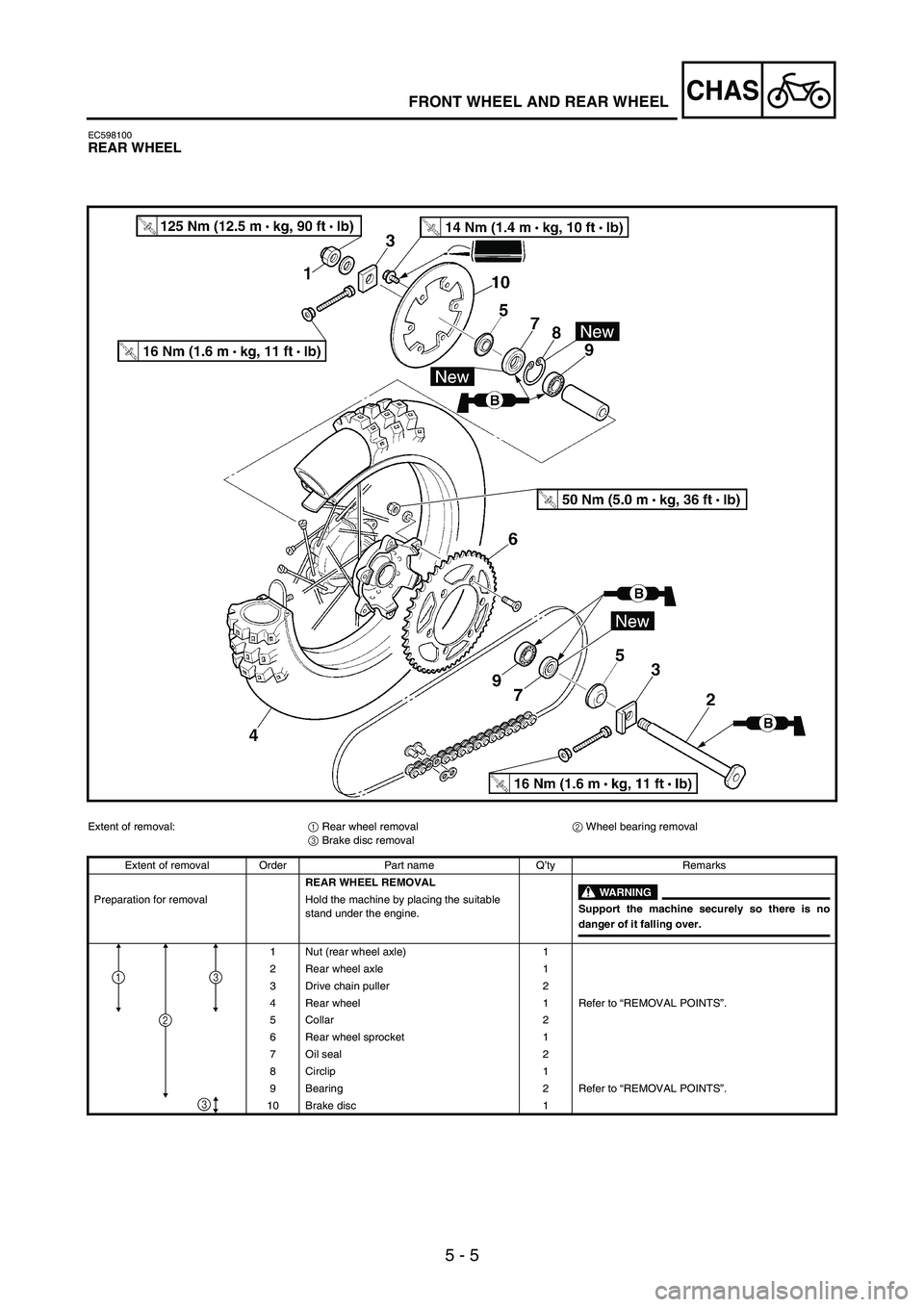

CHASFRONT WHEEL AND REAR WHEEL

EC598100REAR WHEEL

Extent of removal:

1 Rear wheel removal

2 Wheel bearing removal

3 Brake disc removal

Extent of removal Order Part name Q’ty Remarks

REAR WHEEL REMOVAL

WARNING

Support the machine securely so there is nodanger of it falling over. Preparation for removal Hold the machine by placing the suitable

stand under the engine.

1 Nut (rear wheel axle) 1

2 Rear wheel axle 1

3 Drive chain puller 2

4 Rear wheel 1 Refer to “REMOVAL POINTS”.

5 Collar 2

6 Rear wheel sprocket 1

7 Oil seal 2

8 Circlip 1

9 Bearing 2 Refer to “REMOVAL POINTS”.

10 Brake disc 1

1

2

3

3

Page 604 of 864

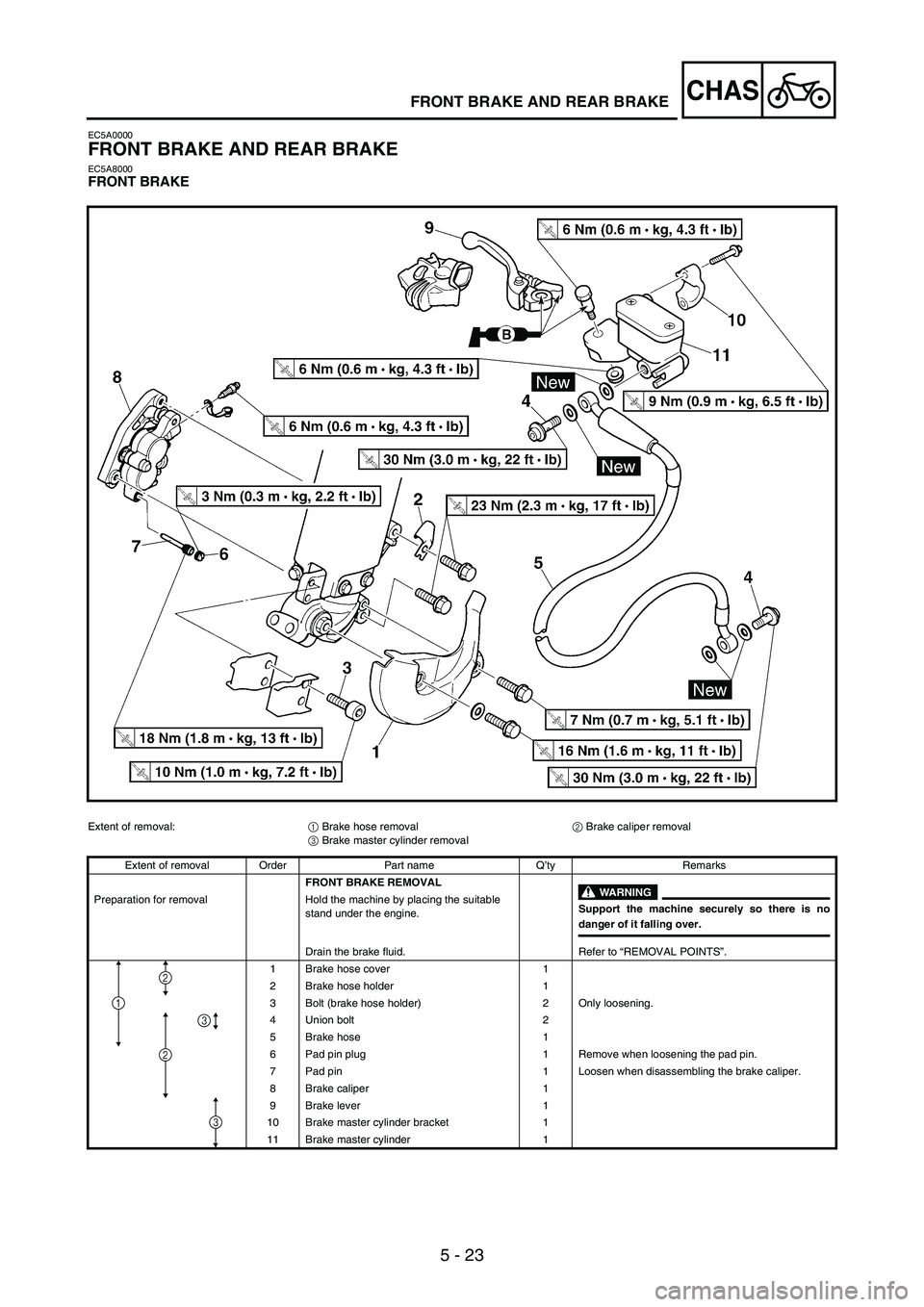

5 - 23

CHASFRONT BRAKE AND REAR BRAKE

EC5A0000

FRONT BRAKE AND REAR BRAKE

EC5A8000FRONT BRAKE

Extent of removal:

1 Brake hose removal

2 Brake caliper removal

3 Brake master cylinder removal

Extent of removal Order Part name Q’ty Remarks

FRONT BRAKE REMOVAL

WARNING

Support the machine securely so there is nodanger of it falling over. Preparation for removal Hold the machine by placing the suitable

stand under the engine.

Drain the brake fluid. Refer to “REMOVAL POINTS”.

1 Brake hose cover 1

2 Brake hose holder 1

3 Bolt (brake hose holder) 2 Only loosening.

4 Union bolt 2

5 Brake hose 1

6 Pad pin plug 1 Remove when loosening the pad pin.

7 Pad pin 1 Loosen when disassembling the brake caliper.

8 Brake caliper 1

9 Brake lever 1

10 Brake master cylinder bracket 1

11 Brake master cylinder 1

1

2

2

3

3

Page 608 of 864

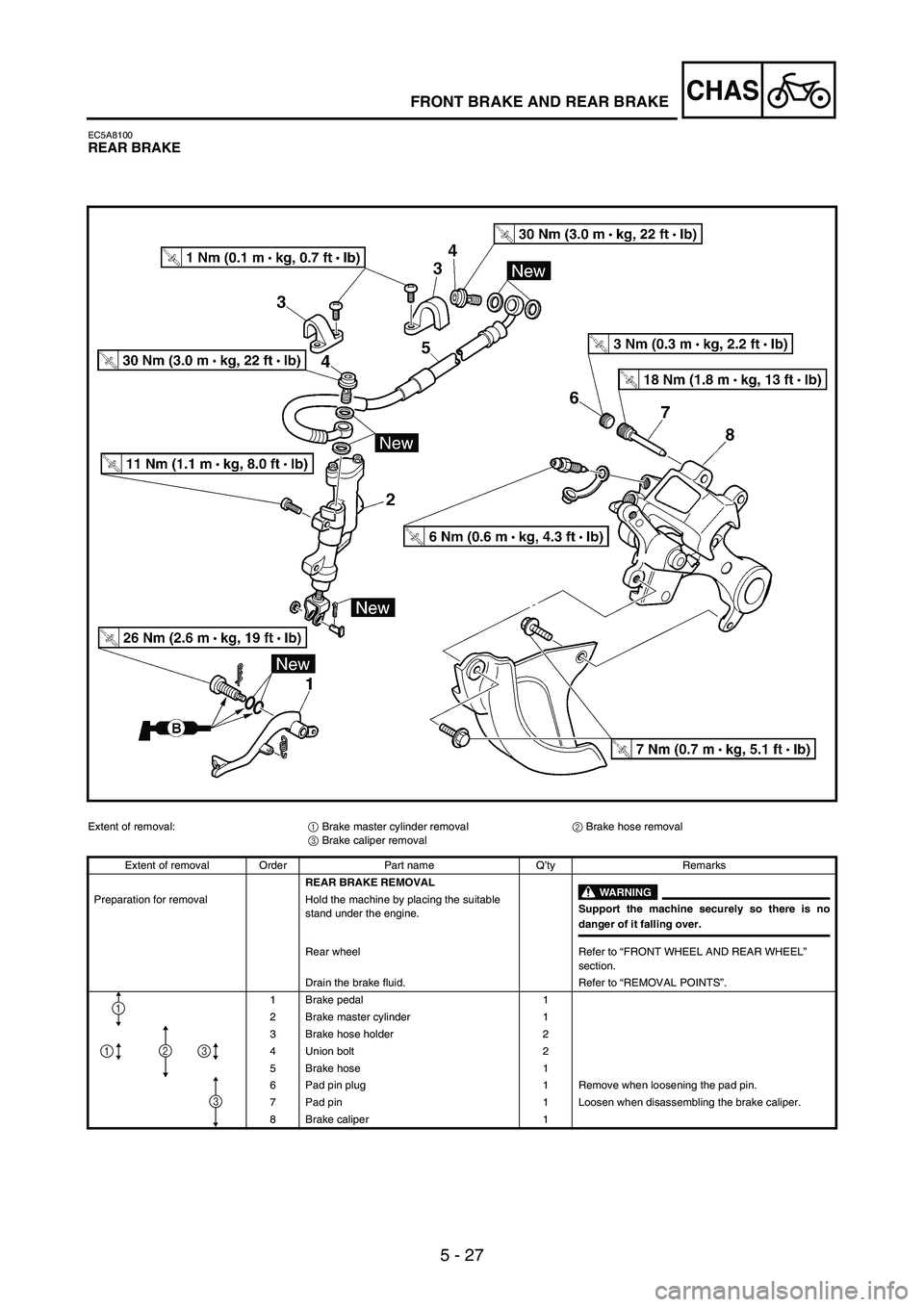

5 - 27

CHASFRONT BRAKE AND REAR BRAKE

EC5A8100REAR BRAKE

Extent of removal:

1 Brake master cylinder removal

2 Brake hose removal

3 Brake caliper removal

Extent of removal Order Part name Q’ty Remarks

REAR BRAKE REMOVAL

WARNING

Support the machine securely so there is nodanger of it falling over. Preparation for removal Hold the machine by placing the suitable

stand under the engine.

Rear wheel Refer to “FRONT WHEEL AND REAR WHEEL”

section.

Drain the brake fluid. Refer to “REMOVAL POINTS”.

1 Brake pedal 1

2 Brake master cylinder 1

3 Brake hose holder 2

4 Union bolt 2

5 Brake hose 1

6 Pad pin plug 1 Remove when loosening the pad pin.

7 Pad pin 1 Loosen when disassembling the brake caliper.

8 Brake caliper 1

1

13

3

2

Page 642 of 864

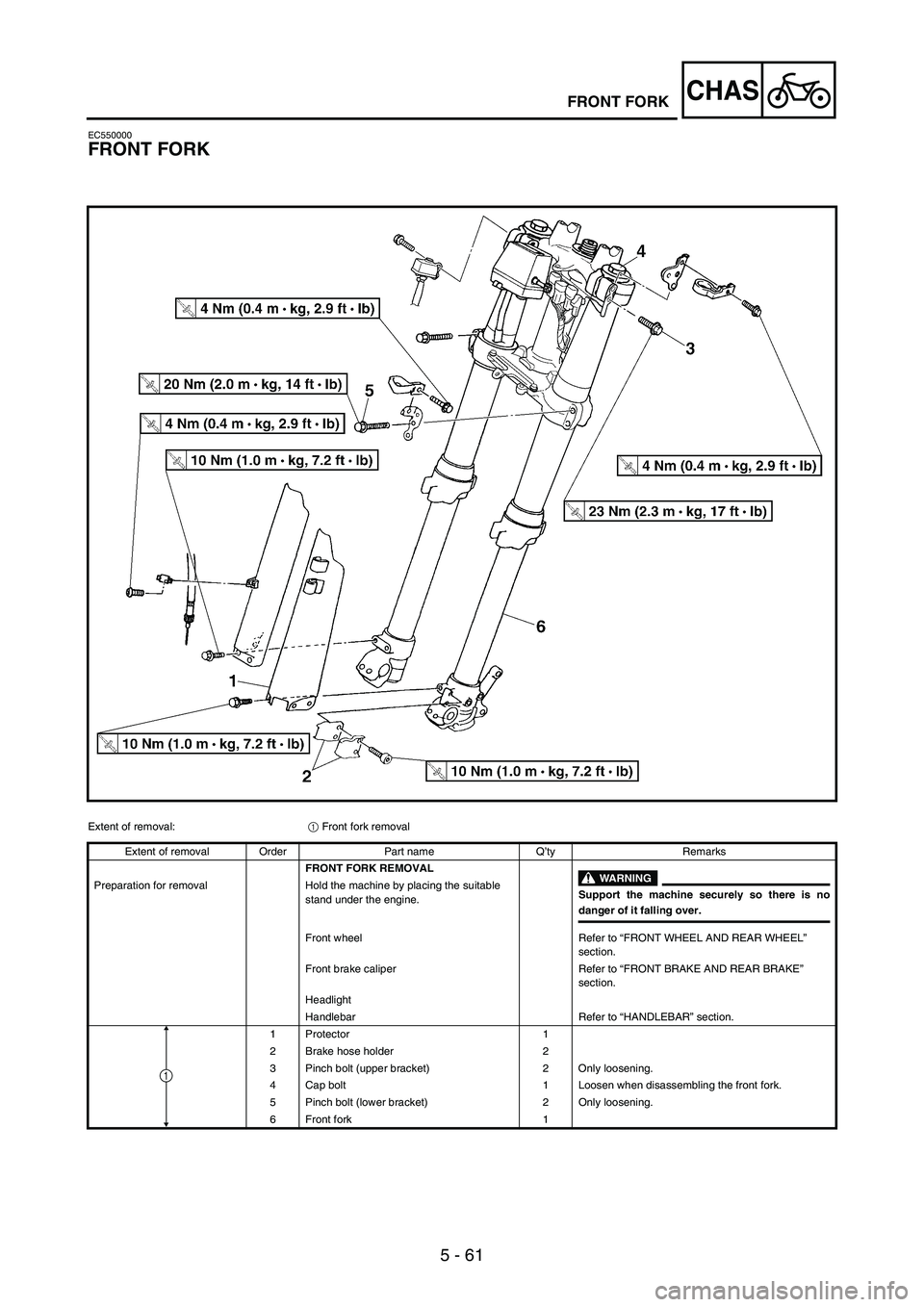

5 - 61

CHASFRONT FORK

EC550000

FRONT FORK

Extent of removal:

1 Front fork removal

Extent of removal Order Part name Q’ty Remarks

FRONT FORK REMOVAL

WARNING

Support the machine securely so there is nodanger of it falling over. Preparation for removal Hold the machine by placing the suitable

stand under the engine.

Front wheel Refer to “FRONT WHEEL AND REAR WHEEL”

section.

Front brake caliper Refer to “FRONT BRAKE AND REAR BRAKE”

section.

Headlight

Handlebar Refer to “HANDLEBAR” section.

1 Protector 1

2 Brake hose holder 2

3 Pinch bolt (upper bracket) 2 Only loosening.

4 Cap bolt 1 Loosen when disassembling the front fork.

5 Pinch bolt (lower bracket) 2 Only loosening.

6 Front fork 1

1

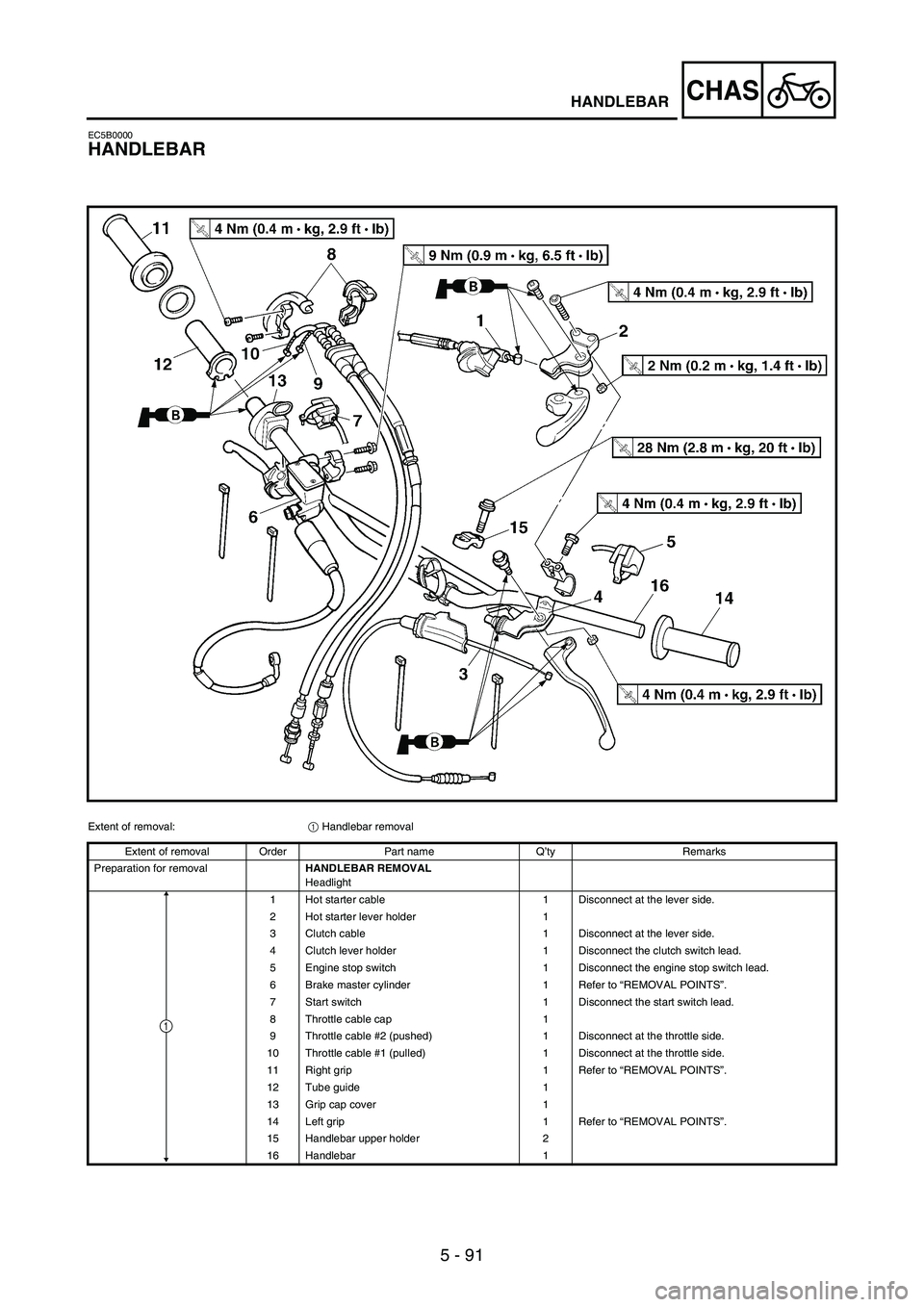

Page 672 of 864

5 - 91

CHASHANDLEBAR

EC5B0000

HANDLEBAR

Extent of removal:

1 Handlebar removal

Extent of removal Order Part name Q’ty Remarks

Preparation for removal

HANDLEBAR REMOVAL

Headlight

1 Hot starter cable 1 Disconnect at the lever side.

2 Hot starter lever holder 1

3 Clutch cable 1 Disconnect at the lever side.

4 Clutch lever holder 1 Disconnect the clutch switch lead.

5 Engine stop switch 1 Disconnect the engine stop switch lead.

6 Brake master cylinder 1 Refer to “REMOVAL POINTS”.

7 Start switch 1 Disconnect the start switch lead.

8 Throttle cable cap 1

9 Throttle cable #2 (pushed) 1 Disconnect at the throttle side.

10 Throttle cable #1 (pulled) 1 Disconnect at the throttle side.

11 Right grip 1 Refer to “REMOVAL POINTS”.

12 Tube guide 1

13 Grip cap cover 1

14 Left grip 1 Refer to “REMOVAL POINTS”.

15 Handlebar upper holder 2

16 Handlebar 1

1