fuel YAMAHA WR 250F 2004 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2004, Model line: WR 250F, Model: YAMAHA WR 250F 2004Pages: 864, PDF Size: 22.07 MB

Page 64 of 864

1 - 39

GEN

INFO

1. Inspect the coolant level.

2. Turn the fuel cock to “ON”.

3. Push on the main switch to “ON”.

4. Shift the transmission into neu-

tral.

5. Fully open the cold starter knob

1.

6. Start the engine by pushing the

start switch or by kicking the

kickstarter crank.

NOTE:If the engine fails to start by pushing

the start switch, release the switch,

wait a few seconds, and then try

again. Each starting attempt should

be as short as possible to preserve

the battery. Do not crank the engine

more than 10 seconds on any one

attempt. If the engine does not start

with the starter motor, try using the

kickstarter crank.

WARNING

If the starter motor will not turn

when pushing the start switch,

stop pushing it immediately and

kick start the engine in order to

avoid the load on the motor.

Do not open the throttle while

kicking the kickstarter crank.

Otherwise, the kickstarter crank

may kick back.

7. Return the cold starter knob to

its original position and run the

engine at 3,000 ~ 5,000 r/min for

1 or 2 minutes.

NOTE:Since this model is equipped with an

accelerator pump, if the engine is

raced (the throttle opened and

closed), the air/fuel mixture will be

too rich and the engine may stall.

Also unlike a two-stroke engine, this

model can idle.

CAUTION:

Do not warm up the engine for

extended periods of time.1. Contrôler le niveau du liquide de

refroidissement.

2. Tourner le robinet de carburant sur

“ON”.

3. Mettre le commutateur principal en

position de marche “ON”.

4. Passer la boîte au point mort.

5. Ouvrir le bouton de démarrage à

froid 1 à fond.

6. Démarrer le moteur en appuyant sur

le de démarrage ou en activant le

kick.

N.B.:

Si le moteur ne démarre pas avec le com-

mutateur de démarrage, relâcher le com-

mutateur, attendre quelques secondes et

ressayer. Chaque essai doit être bref,

sinon la batterie risque de s’user. Ne pas

essayer de mettre le moteur en marche

plus de 10 secondes chaque fois. Si le

moteur ne démarre pas, essayer avec le

kick.

AVERTISSEMENT

Si une pression du contacteur de

démarrage ne fait pas tourner le

démarreur, cesser immédiatement

d’appuyer dessus et démarrer le

moteur au kick pour éviter de sur-

charger le moteur.

Ne pas donner des gaz au moment

où l’on actionne le pedal de kick, car

celui-ci risque de se relever brutale-

ment.

7. Ramener le bouton de démarrage à

froid à sa position d’origine, puis

faire tourner le moteur à 3.000 à

5.000 tr/mn pendant 1 à 2 minutes.

N.B.:

Puisque ce modèle est équipé d’une

pompe d’accélération, le mélange air/

carburant devient trop riche et le moteur

risque de caler lorsque l’on emballe le

moteur (actionnement successif rapide

de l’accélérateur). A l’inverse d’un

moteur deux temps, ce modèle, comme

tous les quatre temps, peut tourner au

ralenti sans problème.

ATTENTION:

Ne pas laisser le moteur se réchauffer

trop longtemps.

STARTING AND BREAK-IN

MISE EN MARCHE ET RODAGE

Page 68 of 864

1 - 43

GEN

INFO

BREAK-IN PROCEDURES

1. Before starting the engine, fill the

fuel tank with the fuel.

2. Perform the pre-operation

checks on the machine.

3. Start and warm up the engine.

Check the idle speed, and check

the operation of the controls and

the engine stop switch. Then,

restart the engine and check its

operation within no more than 5

minutes after it is restarted.

4. Operate the machine in the

lower gears at moderate throttle

openings for five to eight min-

utes.

5. Check how the engine runs

when the machine is ridden with

the throttle 1/4 to 1/2 open (low

to medium speed) for about one

hour.

6. Restart the engine and check

the operation of the machine

throughout its entire operating

range. Restart the machine and

operate it for about 10 to 15

more minutes. The machine will

now be ready to race.

CAUTION:

After the break-in or before each

race, you must check the entire

machine for loose fittings and

fasteners as per “TORQUE-

CHECK POINTS”.

Tighten all such fasteners as

required.

When any of the following parts

have been replaced, they must

be broken in.

CYLINDER AND CRANKSHAFT:

About one hour of break-in

operation is necessary.

PISTON, RING, VALVES, CAM-

SHAFTS AND GEARS:

These parts require about 30

minutes of break-in operation at

half-throttle or less. Observe the

condition of the engine carefully

during operation.PROCEDURE DE RODAGE

1. Avant de mettre le moteur en mar-

che, faire le plein d’essence.

2. Effectuer les contrôles avant utilisa-

tion de la machine.

3. Lancer le moteur et le laisser se

réchauffer. Vérifier le régime de

ralenti, le fonctionnement des com-

mandes et l’efficacité du coupe-cir-

cuit. Remettre ensuite le moteur en

marche et vérifier son fonctionne-

ment dans les 5 minutes maximum.

4. Piloter la machine sur les rapports

inférieurs et à régime modéré durant

les cinq à huit premières minutes.

5. Vérifier le fonctionnement du

moteur en roulant pendant environ 1

heure à une ouverture des gaz de 1/4

à 1/2 (petite à moyenne vitesse) .

6. Remettre le moteur en marche et

vérifier son fonctionnement à tous

les régimes. Relancer le moteur et

piloter la machine pendant 10 à 15

minutes supplémentaires. Elle sera

alors prête pour la course.

ATTENTION:

Après le rodage ou avant chaque

course, il faut vérifier toutes les fixa-

tions et serrages comme indiqué

dans “POINTS DE VERIFICA-

TION DE COUPLE DE SER-

RAGE”.

Serrer toutes ces fixations comme

requis.

Après avoir remplacé les pièces sui-

vantes, un nouveau rodage est

nécessaire.

CYLINDRE ET VILEBREQUIN:

Une heure environ de rodage est

nécessaire.

PISTONS, SEGMENTS, SOUPAPES,

ARBRES A CAMES ET PIGNONS:

Ces pièces nécessitent un rodage de

30 minutes environ à une ouverture

des gaz de maximum 1/2. Surveiller

attentivement l’état du moteur pen-

dant la marche.

STARTING AND BREAK-IN

MISE EN MARCHE ET RODAGE

Page 70 of 864

1 - 45

GEN

INFO

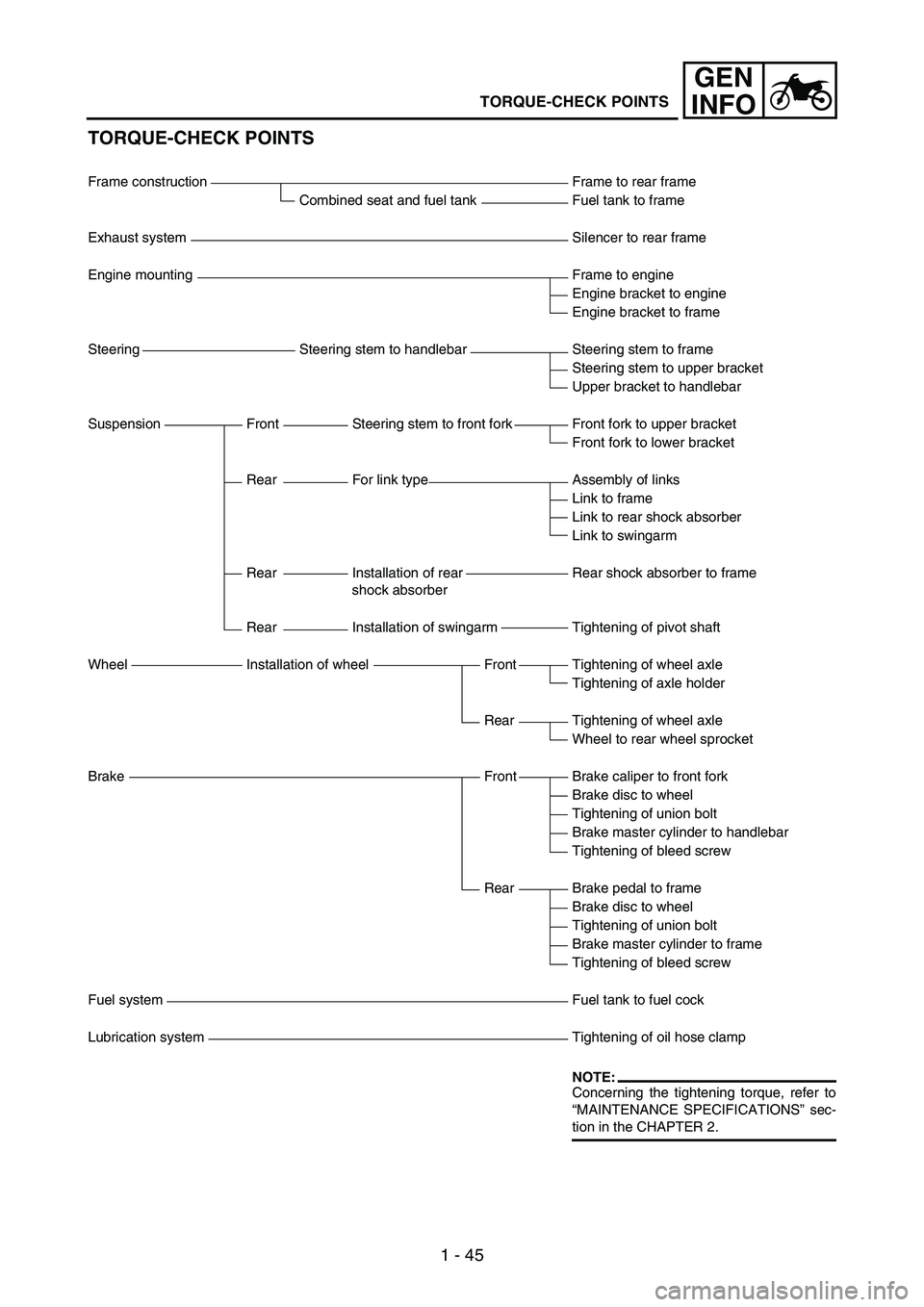

TORQUE-CHECK POINTS

Frame construction Frame to rear frame

Combined seat and fuel tank Fuel tank to frame

Exhaust system Silencer to rear frame

Engine mounting Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering Steering stem to handlebar Steering stem to frame

Steering stem to upper bracket

Upper bracket to handlebar

Suspension Front Steering stem to front fork Front fork to upper bracket

Front fork to lower bracket

Rear For link type Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Rear Installation of rear

shock absorberRear shock absorber to frame

Rear Installation of swingarm Tightening of pivot shaft

Wheel Installation of wheel Front Tightening of wheel axle

Tightening of axle holder

Rear Tightening of wheel axle

Wheel to rear wheel sprocket

Brake Front Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handlebar

Tightening of bleed screw

Rear Brake pedal to frame

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Fuel system Fuel tank to fuel cock

Lubrication system Tightening of oil hose clamp

NOTE:Concerning the tightening torque, refer to

“MAINTENANCE SPECIFICATIONS” sec-

tion in the CHAPTER 2.

TORQUE-CHECK POINTS

Page 78 of 864

1 - 53

GEN

INFO

EC1B2001STORAGE

If your machine is to be stored for 60

days or more, some preventive mea-

sures must be taken to avoid deterio-

ration. After cleaning the machine

thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines,

and the carburetor float bowl.

2. Remove the spark plug, pour a

tablespoon of SAE 10W-30

motor oil in the spark plug hole,

and reinstall the plug. With the

engine stop switch pushed in,

kick the engine over several

times to coat the cylinder walls

with oil.

3. Remove the drive chain, clean it

thoroughly with solvent, and

lubricate it. Reinstall the chain or

store it in a plastic bag tied to the

frame.

4. Lubricate all control cables.

5. Block the frame up to raise the

wheels off the ground.

6. Tie a plastic bag over the

exhaust pipe outlet to prevent

moisture from entering.

7. If the machine is to be stored in a

humid or salt-air environment,

coat all exposed metal surfaces

with a film of light oil. Do not

apply oil to rubber parts or the

seat cover.

NOTE:Make any necessary repairs before

the machine is stored.RANGEMENT

Si l’on remise la machine pour 60 jours

ou plus, il faut prendre des mesures de

conservation pour éviter sa détérioration.

Après un nettoyage soigné, préparer la

machine de la manière suivante:

1. Vider le réservoir, les conduites

d’essence et la cuve du carburateur.

2. Déposer la bougie, verser une

cuillère à soupe d’huile moteur SAE

10W-30 dans le trou de bougie, et la

remettre en place. Coupe-circuit à la

position arrêt, donner plusieurs

coups de kick pour enduire le cylin-

dre d’huile.

3. Déposer la chaîne, la nettoyer soi-

gneusement au dissolvant et lubri-

fier. Remonter la chaîne ou la

ranger dans un sachet plastique

fermé fixé au cadre.

4. Lubrifier tous les câbles de com-

mande.

5. Mettre le cadre sur plots pour soule-

ver les roues du sol.

6. Fixer un sachet plastique sur la sor-

tie du pot d’échappement pour évi-

ter l’introduction d’humidité.

7. Si la machine est placée dans une

atmosphère humide ou marine,

enduire toutes les surfaces métalli-

ques nues d’une fine couche

d’huile. Ne pas appliquer d’huile

sur les parties en caoutchouc ou sur

la selle.

N.B.:

Avant de ranger la machine, effectuer

toutes les réparations nécessaires.

CLEANING AND STORAGE

NETTOYAGE ET RANGEMENT

Page 80 of 864

GENERAL SPECIFICATIONS

2 - 1

SPEC

EC200000

SPECIFICATIONS

EC211000

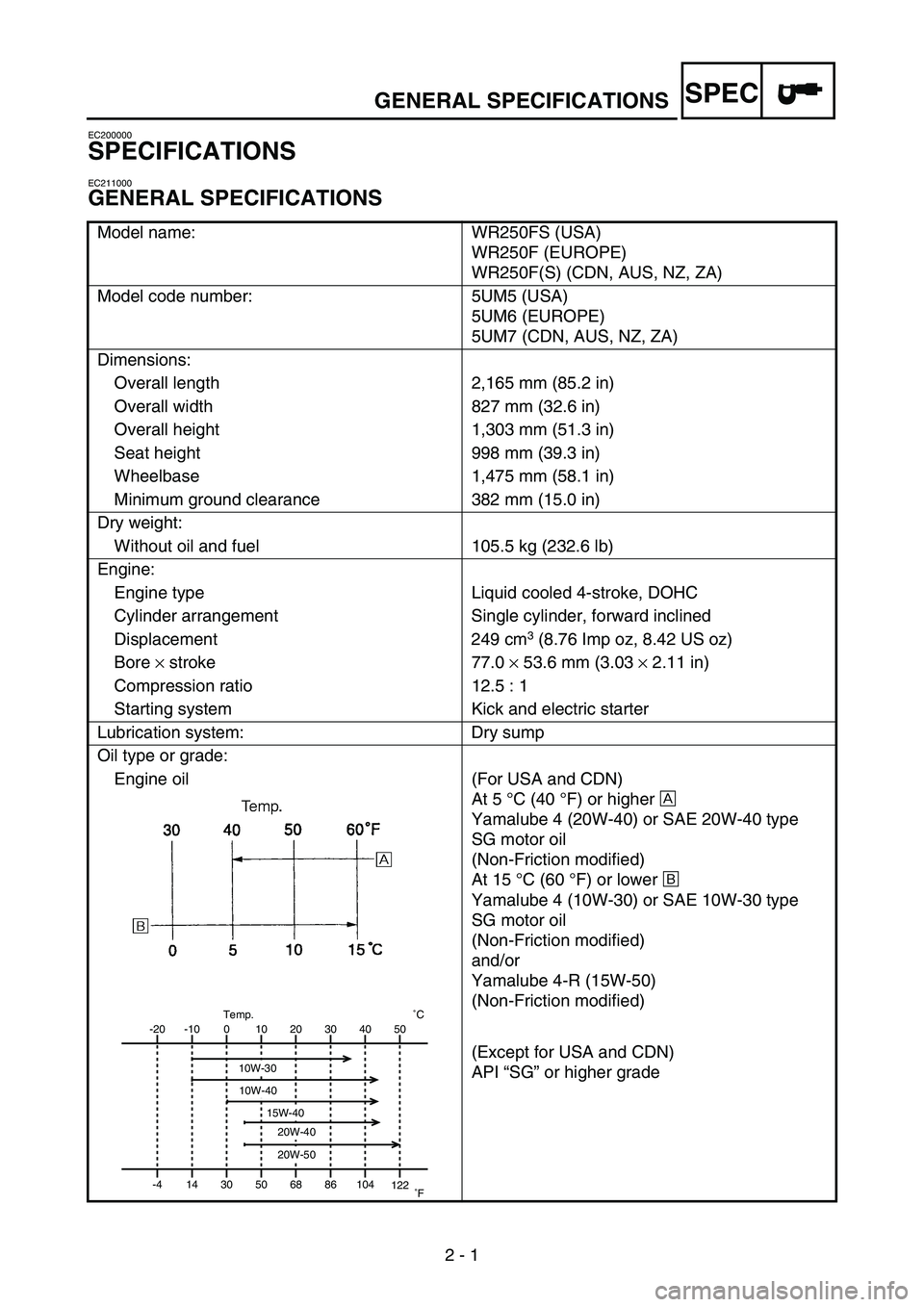

GENERAL SPECIFICATIONS

Model name: WR250FS (USA)

WR250F (EUROPE)

WR250F(S) (CDN, AUS, NZ, ZA)

Model code number: 5UM5 (USA)

5UM6 (EUROPE)

5UM7 (CDN, AUS, NZ, ZA)

Dimensions:

Overall length 2,165 mm (85.2 in)

Overall width 827 mm (32.6 in)

Overall height 1,303 mm (51.3 in)

Seat height 998 mm (39.3 in)

Wheelbase 1,475 mm (58.1 in)

Minimum ground clearance 382 mm (15.0 in)

Dry weight:

Without oil and fuel 105.5 kg (232.6 lb)

Engine:

Engine type Liquid cooled 4-stroke, DOHC

Cylinder arrangement Single cylinder, forward inclined

Displacement 249 cm

3 (8.76 Imp oz, 8.42 US oz)

Bore × stroke 77.0 × 53.6 mm (3.03 × 2.11 in)

Compression ratio 12.5 : 1

Starting system Kick and electric starter

Lubrication system: Dry sump

Oil type or grade:

Engine oil (For USA and CDN)

At 5 °C (40 °F) or higher È

Yamalube 4 (20W-40) or SAE 20W-40 type

SG motor oil

(Non-Friction modified)

At 15 °C (60 °F) or lower É

Yamalube 4 (10W-30) or SAE 10W-30 type

SG motor oil

(Non-Friction modified)

and/or

Yamalube 4-R (15W-50)

(Non-Friction modified)

(Except for USA and CDN)

API “SG” or higher grade

-20

-4-10

140

3010

5020

6830

8640 50

104

122˚CTemp.

˚F

10W-30

10W-40

20W-40

20W-50

15W-40

2

Page 81 of 864

GENERAL SPECIFICATIONS

2 - 2

SPEC

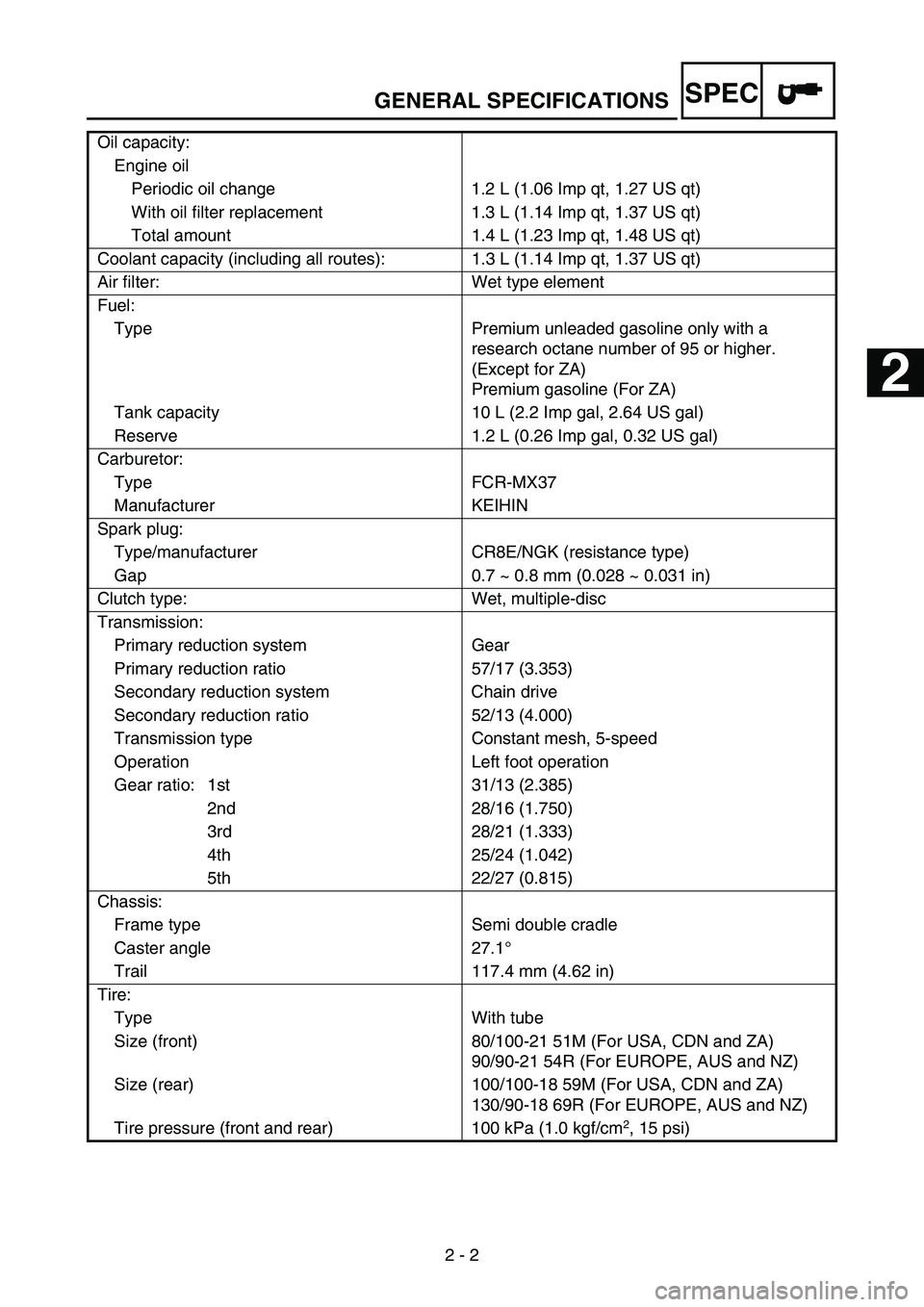

Oil capacity:

Engine oil

Periodic oil change 1.2 L (1.06 Imp qt, 1.27 US qt)

With oil filter replacement 1.3 L (1.14 Imp qt, 1.37 US qt)

Total amount 1.4 L (1.23 Imp qt, 1.48 US qt)

Coolant capacity (including all routes): 1.3 L (1.14 Imp qt, 1.37 US qt)

Air filter: Wet type element

Fuel:

Type Premium unleaded gasoline only with a

research octane number of 95 or higher.

(Except for ZA)

Premium gasoline (For ZA)

Tank capacity 10 L (2.2 Imp gal, 2.64 US gal)

Reserve 1.2 L (0.26 Imp gal, 0.32 US gal)

Carburetor:

Type FCR-MX37

Manufacturer KEIHIN

Spark plug:

Type/manufacturer CR8E/NGK (resistance type)

Gap 0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

Clutch type: Wet, multiple-disc

Transmission:

Primary reduction system Gear

Primary reduction ratio 57/17 (3.353)

Secondary reduction system Chain drive

Secondary reduction ratio 52/13 (4.000)

Transmission type Constant mesh, 5-speed

Operation Left foot operation

Gear ratio: 1st 31/13 (2.385)

2nd 28/16 (1.750)

3rd 28/21 (1.333)

4th 25/24 (1.042)

5th 22/27 (0.815)

Chassis:

Frame type Semi double cradle

Caster angle 27.1°

Trail 117.4 mm (4.62 in)

Tire:

Type With tube

Size (front) 80/100-21 51M (For USA, CDN and ZA)

90/90-21 54R (For EUROPE, AUS and NZ)

Size (rear) 100/100-18 59M (For USA, CDN and ZA)

130/90-18 69R (For EUROPE, AUS and NZ)

Tire pressure (front and rear) 100 kPa (1.0 kgf/cm

2, 15 psi)

1

2

3

4

5

6

7

Page 94 of 864

MAINTENANCE SPECIFICATIONS

2 - 15

SPEC

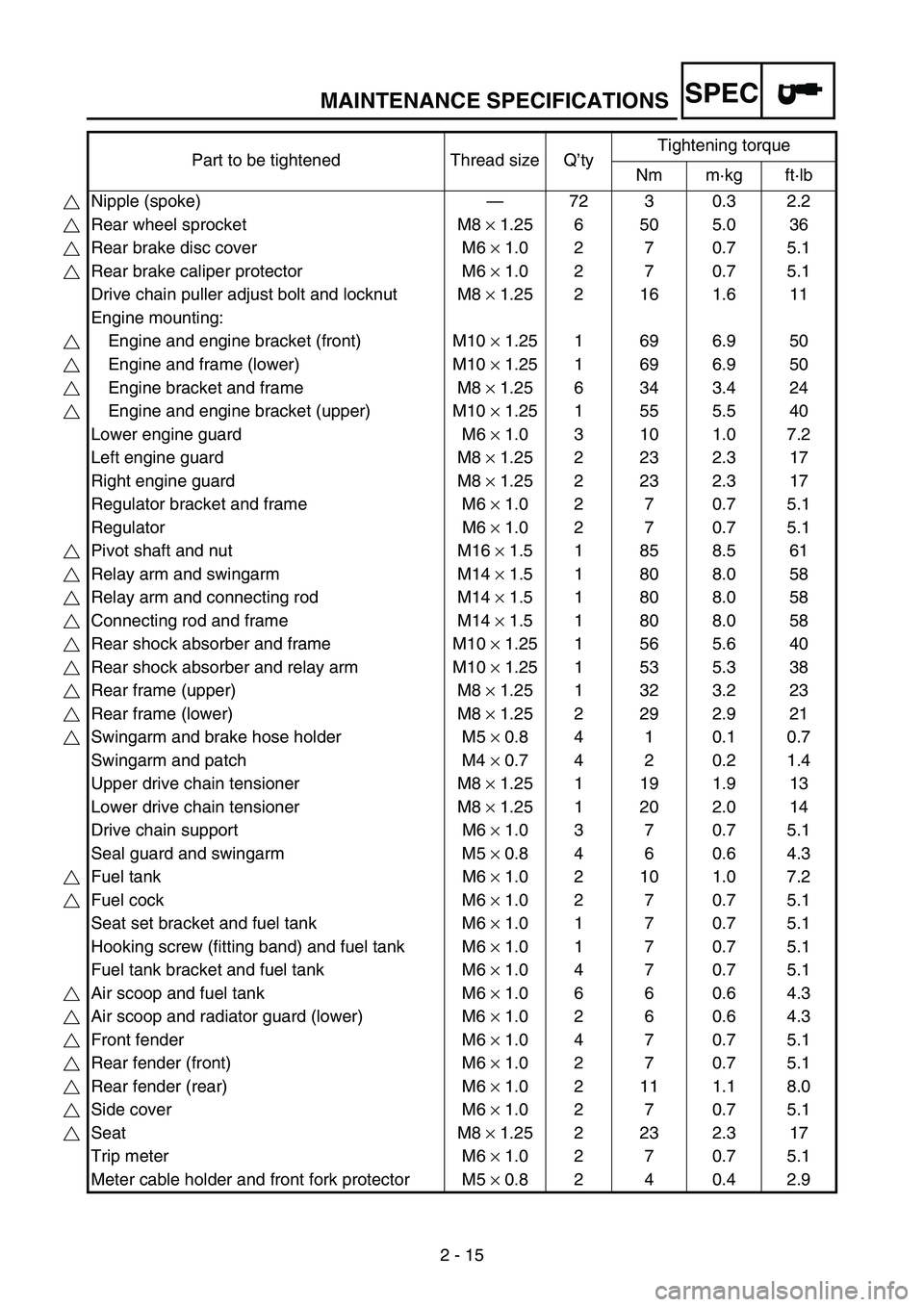

Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Nipple (spoke)—72 3 0.3 2.2

Rear wheel sprocket M8 × 1.25 6 50 5.0 36

Rear brake disc cover M6 × 1.0 2 7 0.7 5.1

Rear brake caliper protector M6 × 1.0 2 7 0.7 5.1

Drive chain puller adjust bolt and locknut M8 × 1.25 2 16 1.6 11

Engine mounting:

Engine and engine bracket (front) M10 × 1.25 1 69 6.9 50

Engine and frame (lower) M10 × 1.25 1 69 6.9 50

Engine bracket and frame M8 × 1.25 6 34 3.4 24

Engine and engine bracket (upper) M10 × 1.25 1 55 5.5 40

Lower engine guard M6 × 1.0 3 10 1.0 7.2

Left engine guard M8 × 1.25 2 23 2.3 17

Right engine guard M8 × 1.25 2 23 2.3 17

Regulator bracket and frame M6 × 1.0 2 7 0.7 5.1

Regulator M6 × 1.0 2 7 0.7 5.1

Pivot shaft and nut M16 × 1.5 1 85 8.5 61

Relay arm and swingarm M14 × 1.5 1 80 8.0 58

Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

Connecting rod and frame M14 × 1.5 1 80 8.0 58

Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

Rear frame (upper) M8 × 1.25 1 32 3.2 23

Rear frame (lower) M8 × 1.25 2 29 2.9 21

Swingarm and brake hose holder M5 × 0.8 4 1 0.1 0.7

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Upper drive chain tensioner M8 × 1.25 1 19 1.9 13

Lower drive chain tensioner M8 × 1.25 1 20 2.0 14

Drive chain support M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

Fuel tank M6 × 1.0 2 10 1.0 7.2

Fuel cock M6 × 1.0 2 7 0.7 5.1

Seat set bracket and fuel tank M6 × 1.0 1 7 0.7 5.1

Hooking screw (fitting band) and fuel tank M6 × 1.0 1 7 0.7 5.1

Fuel tank bracket and fuel tank M6 × 1.0 4 7 0.7 5.1

Air scoop and fuel tank M6 × 1.0 6 6 0.6 4.3

Air scoop and radiator guard (lower) M6 × 1.0 2 6 0.6 4.3

Front fender M6 × 1.0 4 7 0.7 5.1

Rear fender (front) M6 × 1.0 2 7 0.7 5.1

Rear fender (rear) M6 × 1.0 2 11 1.1 8.0

Side cover M6 × 1.0 2 7 0.7 5.1

Seat M8 × 1.25 2 23 2.3 17

Trip meter M6 × 1.0 2 7 0.7 5.1

Meter cable holder and front fork protector M5 × 0.8 2 4 0.4 2.9

Page 176 of 864

SPEC

2 - 97

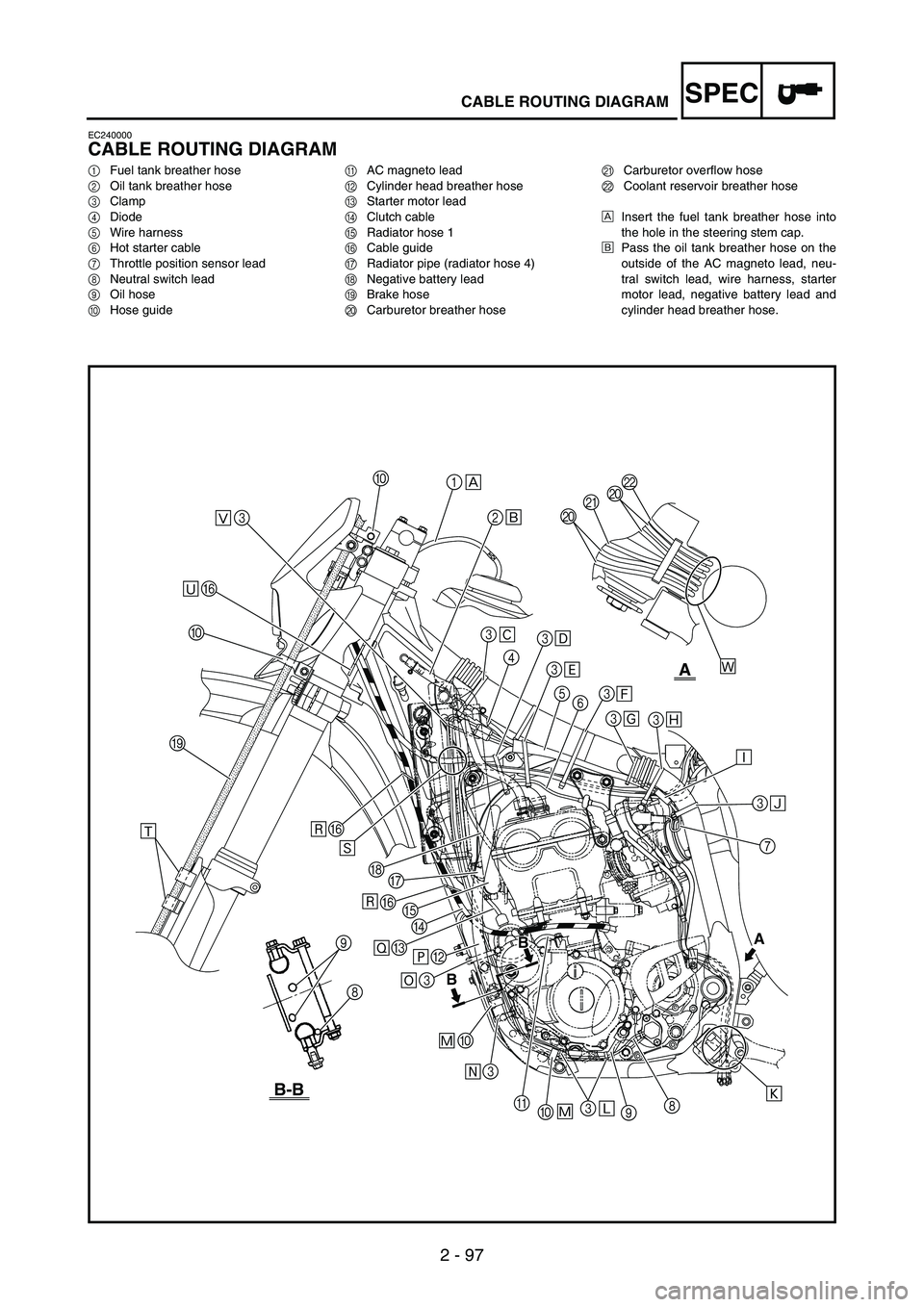

CABLE ROUTING DIAGRAM

EC240000

CABLE ROUTING DIAGRAM

1Fuel tank breather hose

2Oil tank breather hose

3Clamp

4Diode

5Wire harness

6Hot starter cable

7Throttle position sensor lead

8Neutral switch lead

9Oil hose

0Hose guideAAC magneto lead

BCylinder head breather hose

CStarter motor lead

DClutch cable

ERadiator hose 1

FCable guide

GRadiator pipe (radiator hose 4)

HNegative battery lead

IBrake hose

JCarburetor breather hoseKCarburetor overflow hose

LCoolant reservoir breather hose

ÈInsert the fuel tank breather hose into

the hole in the steering stem cap.

ÉPass the oil tank breather hose on the

outside of the AC magneto lead, neu-

tral switch lead, wire harness, starter

motor lead, negative battery lead and

cylinder head breather hose.

A

A

B-B

B

B

Þ 3

4

3

5

63

3

3

3

7 J

JKL

8

9 3

0 A 3 0 3B CD E FG H F

9

8 I0F30

1

2 È

É

Ê

Ì

Î Í

3

Ë

Ï

Ð

Ñ

Ò

Ó

Ô Õ Ö× Ø Ù

Ú Û

Ô Ù ÜÝ

Page 193 of 864

3 - 2

INSP

ADJ

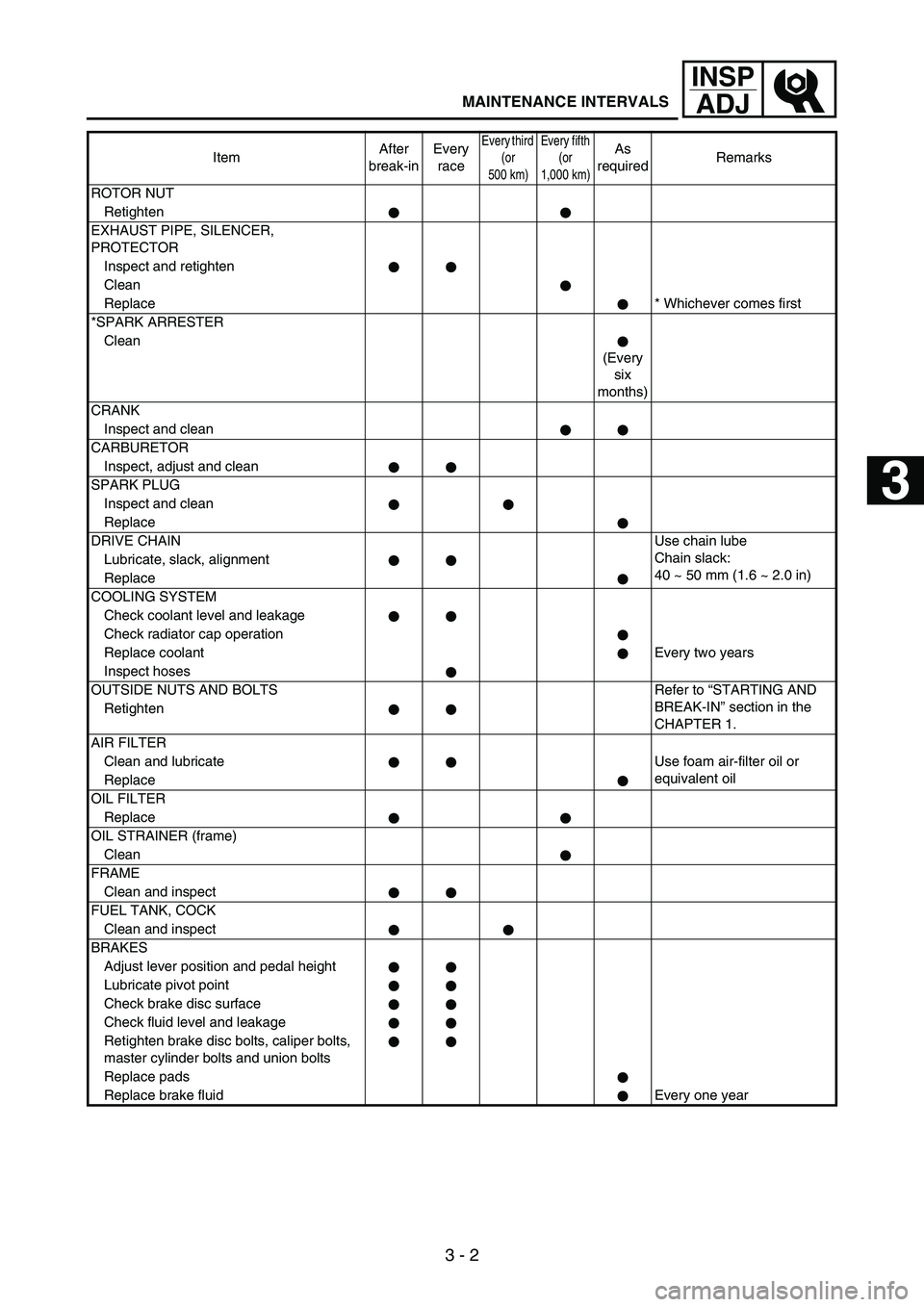

MAINTENANCE INTERVALS

ROTOR NUT

Retighten

EXHAUST PIPE, SILENCER,

PROTECTOR

Inspect and retighten

Clean

Replace* Whichever comes first

*SPARK ARRESTER

Clean

(Every

six

months)

CRANK

Inspect and clean

CARBURETOR

Inspect, adjust and clean

SPARK PLUG

Inspect and clean

Replace

DRIVE CHAINUse chain lube

Chain slack:

40 ~ 50 mm (1.6 ~ 2.0 in) Lubricate, slack, alignment

Replace

COOLING SYSTEM

Check coolant level and leakage

Check radiator cap operation

Replace coolantEvery two years

Inspect hoses

OUTSIDE NUTS AND BOLTS Refer to “STARTING AND

BREAK-IN” section in the

CHAPTER 1. Retighten

AIR FILTER

Clean and lubricate Use foam air-filter oil or

equivalent oil

Replace

OIL FILTER

Replace

OIL STRAINER (frame)

Clean

FRAME

Clean and inspect

FUEL TANK, COCK

Clean and inspect

BRAKES

Adjust lever position and pedal height

Lubricate pivot point

Check brake disc surface

Check fluid level and leakage

Retighten brake disc bolts, caliper bolts,

master cylinder bolts and union bolts

Replace pads

Replace brake fluid Every one yearItemAfter

break-inEvery

race

Every third

(or

500 km)Every fifth

(or

1,000 km)As

requiredRemarks

1

2

3

4

5

6

7

Page 207 of 864

3 - 16

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

EC320000

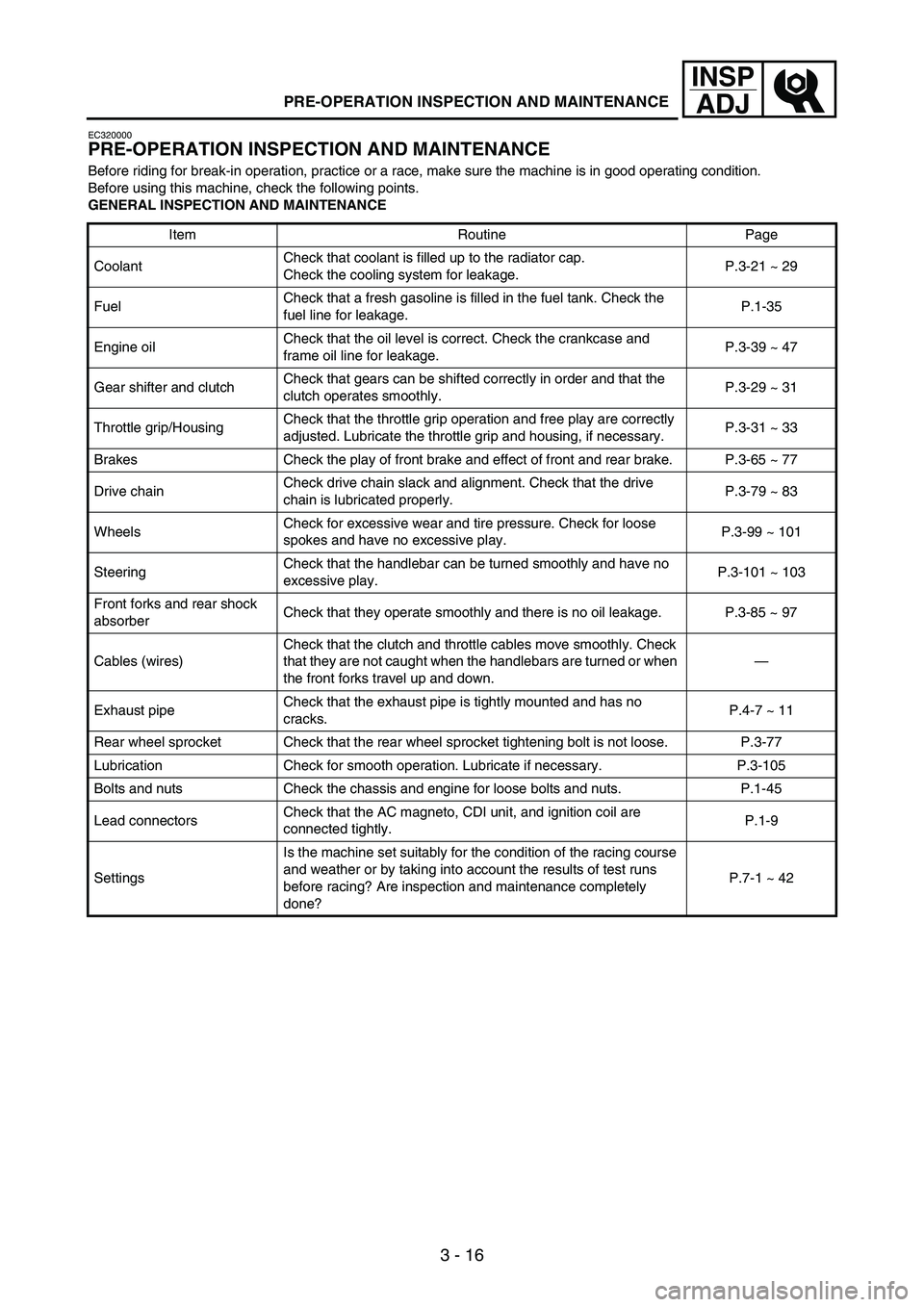

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.P.3-21 ~ 29

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-35

Engine oilCheck that the oil level is correct. Check the crankcase and

frame oil line for leakage.P.3-39 ~ 47

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-29 ~ 31

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-31 ~ 33

Brakes Check the play of front brake and effect of front and rear brake. P.3-65 ~ 77

Drive chainCheck drive chain slack and alignment. Check that the drive

chain is lubricated properly.P.3-79 ~ 83

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-99 ~ 101

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-101 ~ 103

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-85 ~ 97

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and has no

cracks.P.4-7 ~ 11

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-77

Lubrication Check for smooth operation. Lubricate if necessary. P.3-105

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-45

Lead connectorsCheck that the AC magneto, CDI unit, and ignition coil are

connected tightly.P.1-9

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 42