engine YAMAHA WR 250F 2005 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: WR 250F, Model: YAMAHA WR 250F 2005Pages: 864, PDF Size: 18.1 MB

Page 76 of 864

1 - 51

GEN

INFO

EC1B0000

CLEANING AND

STORAGE

EC1B1000CLEANING

Frequent cleaning of your machine

will enhance its appearance, main-

tain good overall performance, and

extend the life of many components.

1. Before washing the machine,

block off the end of the exhaust

pipe to prevent water from enter-

ing. A plastic bag secured with a

rubber band may be used for this

purpose.

2. If the engine is excessively

greasy, apply some degreaser to

it with a paint brush. Do not

apply degreaser to the chain,

sprockets, or wheel axles.

3. Rinse the dirt and degreaser off

with a garden hose; use only

enough pressure to do the job.

CAUTION:

Excessive hose pressure may

cause water seepage and contami-

nation of wheel bearings, front

forks, brakes and transmission

seals. Many expensive repair bills

have resulted from improper high

pressure detergent applications

such as those available in coin-

operated car washers.

4. After the majority of the dirt has

been hosed off, wash all sur-

faces with warm water and a

mild detergent. Use an old tooth-

brush to clean hard-to-reach

places.

5. Rinse the machine off immedi-

ately with clean water, and dry

all surfaces with a soft towel or

cloth.

6. Immediately after washing,

remove excess water from the

chain with a paper towel and

lubricate the chain to prevent

rust.

7. Clean the seat with a vinyl uphol-

stery cleaner to keep the cover

pliable and glossy.

8. Automotive wax may be applied

to all painted or chromed sur-

faces. Avoid combination

cleaner-waxes, as they may con-

tain abrasives.

9. After completing the above, start

the engine and allow it to idle for

several minutes.

NETTOYAGE ET

REMISAGE

NETTOYAGE

Un nettoyage fréquent de la moto préser-

vera son apparence, maintiendra ses bon-

nes performances et augmentera la durée

de vie de nombre de ses composants.

1. Avant de nettoyer la moto, couvrir

la sortie du tuyau d’échappement

pour éviter toute pénétration d’eau.

Un sachet en plastique retenu par un

élastique fera l’affaire.

2. Si le moteur est fortement encrassé,

appliquer un peu de dégraissant à

l’aide d’un pinceau. Eviter tout con-

tact avec la chaîne, les pignons ou

les axes de roue.

3. Rincer la saleté et le dégraissant au

tuyau d’arrosage, en utilisant juste

la pression nécessaire.

ATTENTION:

Une pression excessive risque de cau-

ser des infiltrations d’eau dans les

roulements des roues, la fourche

avant, les freins et les joints de la

transmission. L’emploi abusif de

détergents sous forte pression, tels que

ceux utilisés dans les portiques de

lavage automatique, est nuisible à la

moto et peut entraîner des réparations

onéreuses.

4. Après avoir éliminé le plus gros de

la saleté au tuyau d’arrosage, laver

toutes les surfaces à l’eau chaude

savonneuse (employer un détergent

doux). Une vieille brosse à dents

convient parfaitement pour nettoyer

les parties difficiles d’accès.

5. Rincer immédiatement la moto à

l’eau claire et sécher toutes les sur-

faces à l’aide d’une peau de cha-

mois, d’une serviette ou d’un

chiffon doux absorbant.

6. Sécher immédiatement la chaîne à

l’aide d’une serviette en papier et la

graisser afin de la protéger contre la

rouille.

7. Nettoyer la selle à l’aide d’un pro-

duit de nettoyage pour similicuir

afin de conserver intacts la sou-

plesse et le lustre de la housse.

8. Une cire pour carrosserie peut être

utilisée pour toutes les surfaces

peintes et chromées. Ne pas

employer de cires détergentes car

elles contiennent souvent des abra-

sifs.

9. Lorsque le nettoyage est terminé,

mettre le moteur en marche et le

laisser tourner au ralenti pendant

plusieurs minutes.

CLEANING AND STORAGE

NETTOYAGE ET REMISAGE

Page 78 of 864

1 - 53

GEN

INFO

EC1B2001STORAGE

If your machine is to be stored for 60

days or more, some preventive mea-

sures must be taken to avoid deterio-

ration. After cleaning the machine

thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines,

and the carburetor float bowl.

2. Remove the spark plug, pour a

tablespoon of SAE 10W-30

motor oil in the spark plug hole,

and reinstall the plug. With the

engine stop switch pushed in,

kick the engine over several

times to coat the cylinder walls

with oil.

3. Remove the drive chain, clean it

thoroughly with solvent, and

lubricate it. Reinstall the chain or

store it in a plastic bag tied to the

frame.

4. Lubricate all control cables.

5. Block the frame up to raise the

wheels off the ground.

6. Tie a plastic bag over the

exhaust pipe outlet to prevent

moisture from entering.

7. If the machine is to be stored in a

humid or salt-air environment,

coat all exposed metal surfaces

with a film of light oil. Do not

apply oil to rubber parts or the

seat cover.

NOTE:Make any necessary repairs before

the machine is stored.REMISAGE

Si la moto doit être remisée pour 60

jours ou plus, il convient de prendre cer-

taines précautions pour éviter tout

endommagement. Après un nettoyage

complet de la moto, la préparer comme

suit pour le remisage:

1. Vidanger le réservoir de carburant,

le circuit de carburant et la cuve à

niveau constant du carburateur.

2. Déposer la bougie, verser une

cuillère à soupe d’huile moteur SAE

10W-30 dans le trou de bougie et

replacer la bougie. Enfoncer le

coupe-circuit du moteur et lancer

quelques fois le moteur à l’aide de

la pédale de kick afin de répartir

l’huile sur les parois du cylindre.

3. Déposer la chaîne de transmission,

la nettoyer soigneusement à l’aide

d’un solvant puis la graisser.

Remettre en place la chaîne ou la

conserver dans un sachet en plasti-

que (attaché au cadre pour éviter de

l’égarer).

4. Lubrifier tous les câbles de com-

mande.

5. Placer un support sous le cadre afin

de surélever les deux roues.

6. Couvrir la sortie du tuyau d’échap-

pement d’un sachet en plastique

pour empêcher la pénétration

d’humidité.

7. Si la moto doit être remisée dans un

lieu très humide ou exposé à l’air

marin, enduire toutes les surfaces

métalliques extérieures d’une fine

couche d’huile. Ne pas enduire

d’huile les parties en caoutchouc et

la housse de selle.

N.B.:

Effectuer toutes les réparations nécessai-

res avant de remiser la moto.

CLEANING AND STORAGE

NETTOYAGE ET REMISAGE

Page 80 of 864

GENERAL SPECIFICATIONS

2 - 1

SPEC

EC200000

SPECIFICATIONS

EC211000

GENERAL SPECIFICATIONS

Model name: WR250FT (USA, CDN, AUS, NZ)

WR250F (EUROPE, ZA)

Model code number: 5UM8 (USA)

5UM9 (EUROPE)

5UMA (CDN, AUS, NZ, ZA)

Dimensions: USA, ZA, CDN EUROPE, AUS, NZ

Overall length 2,190 mm (86.22 in) 2,180 mm (85.83 in)

Overall width 830 mm (32.68 in)←

Overall height 1,290 mm (50.79 in) 1,295 mm (50.98 in)

Seat height 985 mm (38.78 in) 990 mm (38.98 in)

Wheelbase 1,470 mm (57.87 in)←

Minimum ground clearance 370 mm (14.57 in) 375 mm (14.76 in)

Dry weight:

Without oil and fuel 105.5 kg (232.6 lb)

Engine:

Engine type Liquid cooled 4-stroke, DOHC

Cylinder arrangement Single cylinder, forward inclined

Displacement 249 cm

3 (8.76 Imp oz, 8.42 US oz)

Bore × stroke 77.0 × 53.6 mm (3.03 × 2.11 in)

Compression ratio 12.5 : 1

Kick and electric starter

Starting system

Lubrication system: Dry sump

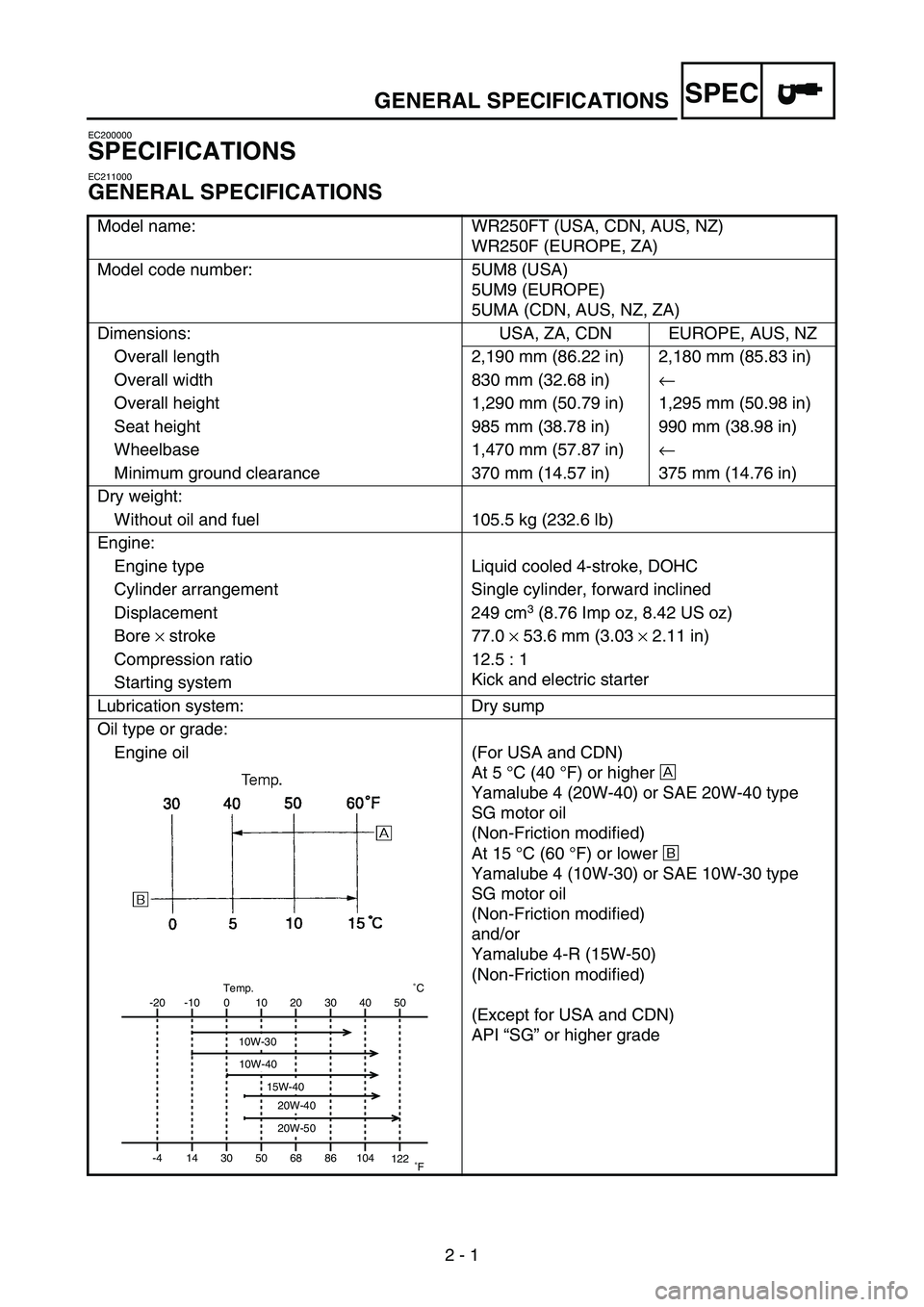

Oil type or grade:

Engine oil (For USA and CDN)

At 5 °C (40 °F) or higher È

Yamalube 4 (20W-40) or SAE 20W-40 type

SG motor oil

(Non-Friction modified)

At 15 °C (60 °F) or lower É

Yamalube 4 (10W-30) or SAE 10W-30 type

SG motor oil

(Non-Friction modified)

and/or

Yamalube 4-R (15W-50)

(Non-Friction modified)

(Except for USA and CDN)

API “SG” or higher grade

-20

-4-10

140

3010

5020

6830

8640 50

104

122˚CTemp.

˚F

10W-30

10W-40

20W-40

20W-50

15W-40

2

Page 81 of 864

GENERAL SPECIFICATIONS

2 - 2

SPEC

Oil capacity:

Engine oil

Periodic oil change 1.2 L (1.06 Imp qt, 1.27 US qt)

With oil filter replacement 1.3 L (1.14 Imp qt, 1.37 US qt)

Total amount 1.4 L (1.23 Imp qt, 1.48 US qt)

Coolant capacity (including all routes): 1.26 L (1.11 Imp qt, 1.33 US qt)

Air filter: Wet type element

Fuel:

Type Premium unleaded gasoline only with a

research octane number of 95 or higher.

Tank capacity 8.0 L (1.76 Imp gal, 2.11 US gal)

Reserve 1.1 L (0.24 Imp gal, 0.29 US gal)

Carburetor:

Type FCR-MX37

Manufacturer KEIHIN

Spark plug:

Type/manufacturer CR8E/NGK (resistance type)

Gap 0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

Clutch type: Wet, multiple-disc

Transmission:

Primary reduction system Gear

Primary reduction ratio 57/17 (3.353)

Secondary reduction system Chain drive

Secondary reduction ratio 52/13 (4.000)

Transmission type Constant mesh, 5-speed

Operation Left foot operation

Gear ratio: 1st 31/13 (2.385)

2nd 28/16 (1.750)

3rd 28/21 (1.333)

4th 25/24 (1.042)

5th 22/27 (0.815)

Chassis: USA, ZA, CDN EUROPE, AUS, NZ

Frame type Semi double cradle←

Caster angle 27.5°27.1°

Trail 121 mm (4.76 in) 117 mm (4.61 in)

Tire:

Type With tube

Size (front) 80/100-21 51M (For USA, CDN and ZA)

90/90-21 54R (For EUROPE, AUS and NZ)

Size (rear) 100/100-18 59M (For USA, CDN and ZA)

130/90-18 69R (For EUROPE, AUS and NZ)

Tire pressure (front and rear) 100 kPa (1.0 kgf/cm

2, 15 psi)

1

2

3

4

5

6

7

Page 83 of 864

MAINTENANCE SPECIFICATIONS

2 - 4

SPEC

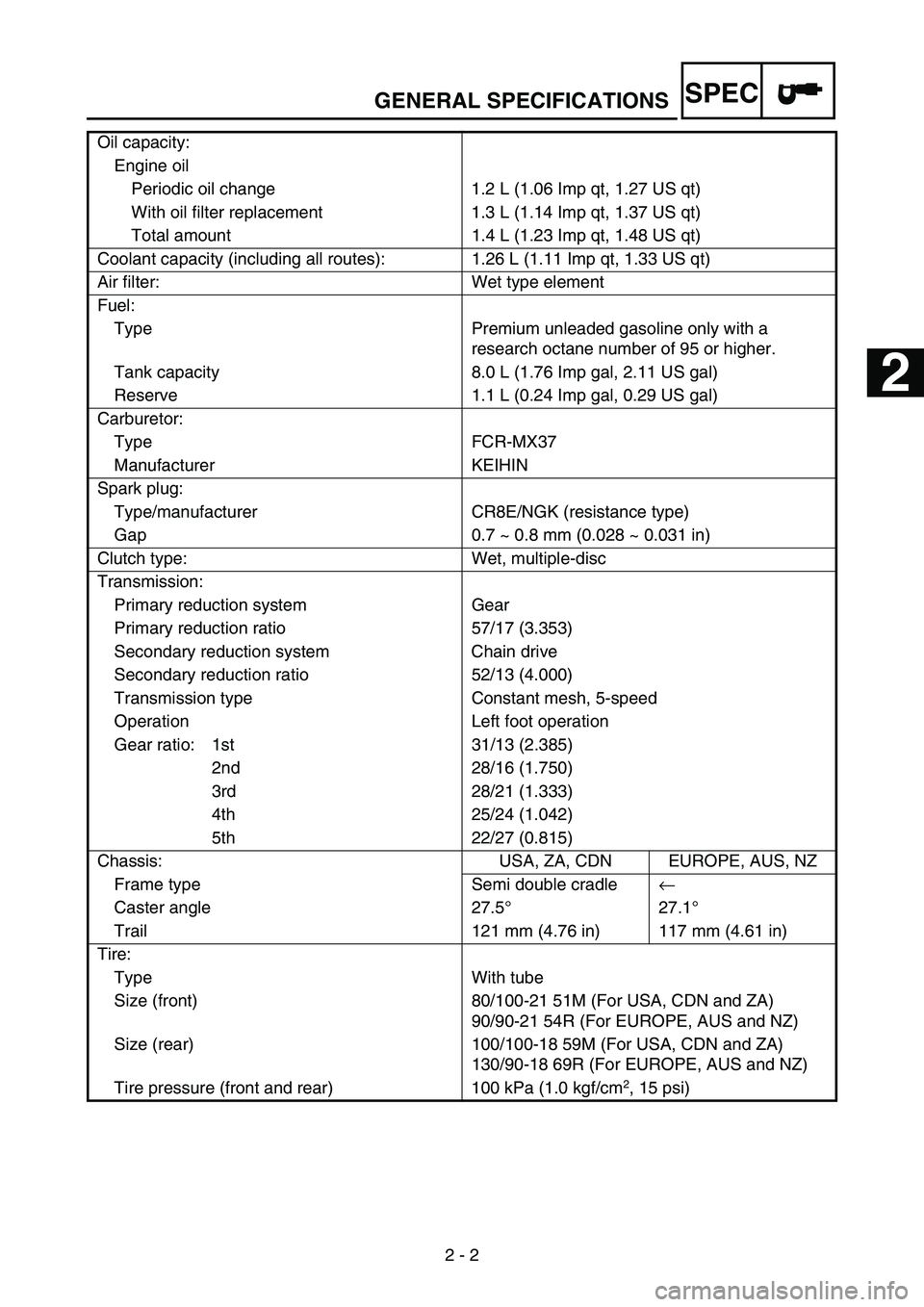

MAINTENANCE SPECIFICATIONS

ENGINE

Item Standard Limit

Cylinder head:

Warp limit ---- 0.05 mm

(0.002 in)

Cylinder:

Bore size 77.00 ~ 77.01 mm

(3.0315 ~ 3.0319 in)----

Out of round limit ---- 0.05 mm

(0.002 in)

Camshaft:

Drive method Chain drive (Left) ----

Camshaft cap inside diameter 22.000 ~ 22.021 mm

(0.8661 ~ 0.8670 in)----

Camshaft outside diameter 21.959 ~ 21.972 mm

(0.8645 ~ 0.8650 in)----

Shaft-to-cap clearance 0.028 ~ 0.062 mm

(0.0011 ~ 0.0024 in)0.08 mm

(0.003 in)

Cam dimensions

Intake“A”30.296 ~ 30.346 mm

(1.1923 ~ 1.1947 in)30.196 mm

(1.1888 in)

“B”22.45 ~ 22.55 mm

(0.8839 ~ 0.8878 in)22.35 mm

(0.8799 in)

Exhaust“A”30.399 ~ 30.499 mm

(1.1968 ~ 1.2007 in)30.299 mm

(1.1929 in)

“B”22.45 ~ 22.55 mm

(0.8839 ~ 0.8878 in)22.35 mm

(0.8799 in)

Camshaft runout limit ---- 0.03 mm

(0.0012 in)

A

B

Page 87 of 864

MAINTENANCE SPECIFICATIONS

2 - 8

SPEC

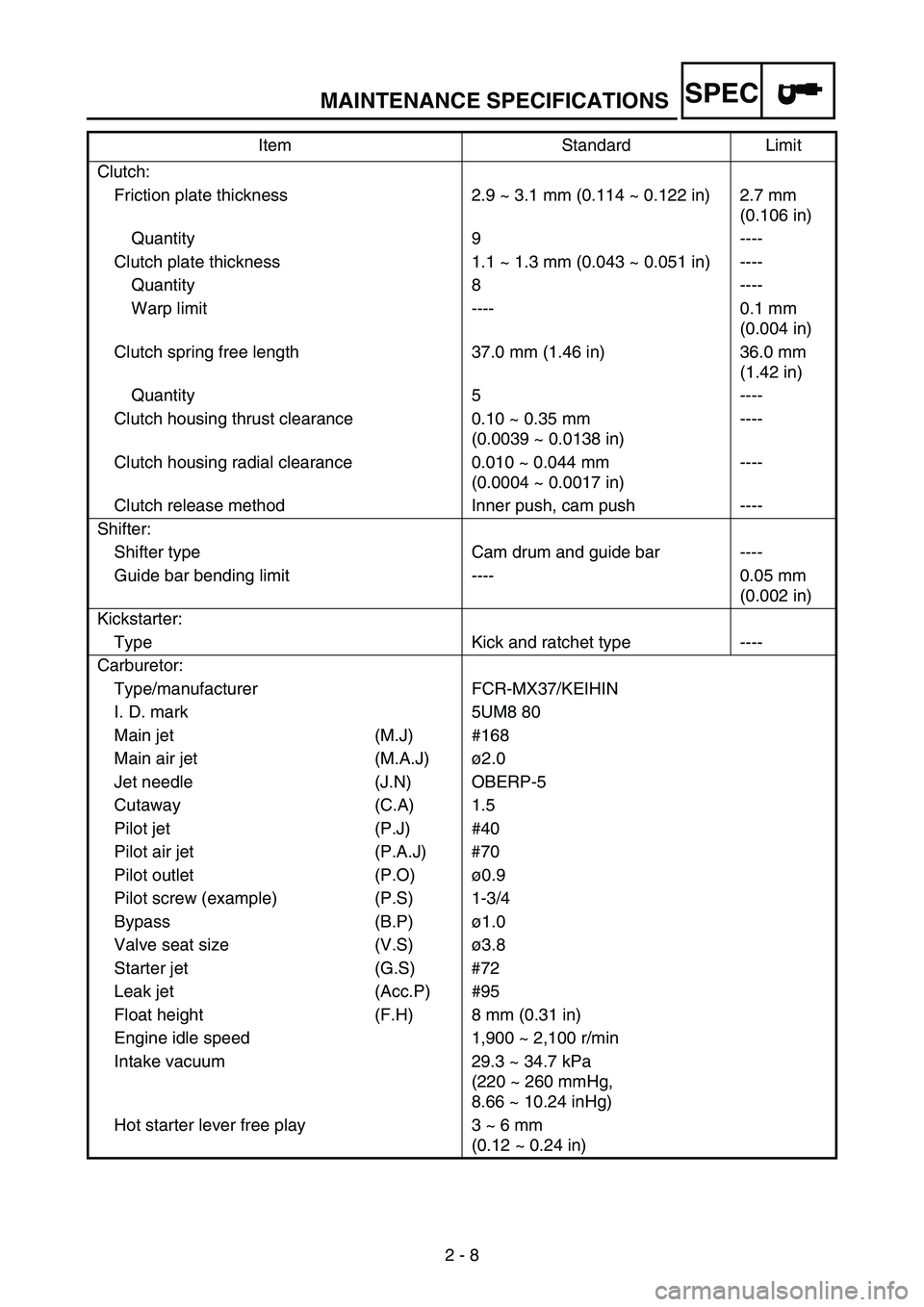

Clutch:

Friction plate thickness 2.9 ~ 3.1 mm (0.114 ~ 0.122 in) 2.7 mm

(0.106 in)

Quantity 9 ----

Clutch plate thickness 1.1 ~ 1.3 mm (0.043 ~ 0.051 in) ----

Quantity 8 ----

Warp limit ---- 0.1 mm

(0.004 in)

Clutch spring free length 37.0 mm (1.46 in) 36.0 mm

(1.42 in)

Quantity 5 ----

Clutch housing thrust clearance 0.10 ~ 0.35 mm

(0.0039 ~ 0.0138 in)----

Clutch housing radial clearance 0.010 ~ 0.044 mm

(0.0004 ~ 0.0017 in)----

Clutch release method Inner push, cam push ----

Shifter:

Shifter type Cam drum and guide bar ----

Guide bar bending limit ---- 0.05 mm

(0.002 in)

Kickstarter:

Type Kick and ratchet type ----

Carburetor:

Type/manufacturer FCR-MX37/KEIHIN

I. D. mark 5UM8 80

Main jet (M.J) #168

Main air jet (M.A.J)ø2.0

Jet needle (J.N) OBERP-5

Cutaway (C.A) 1.5

Pilot jet (P.J) #40

Pilot air jet (P.A.J) #70

Pilot outlet (P.O)ø0.9

Pilot screw (example) (P.S) 1-3/4

Bypass (B.P)ø1.0

Valve seat size (V.S)ø3.8

Starter jet (G.S) #72

Leak jet (Acc.P) #95

Float height (F.H) 8 mm (0.31 in)

Engine idle speed 1,900 ~ 2,100 r/min

Intake vacuum 29.3 ~ 34.7 kPa

(220 ~ 260 mmHg,

8.66 ~ 10.24 inHg)

Hot starter lever free play 3 ~ 6 mm

(0.12 ~ 0.24 in) Item Standard Limit

Page 94 of 864

MAINTENANCE SPECIFICATIONS

2 - 15

SPEC

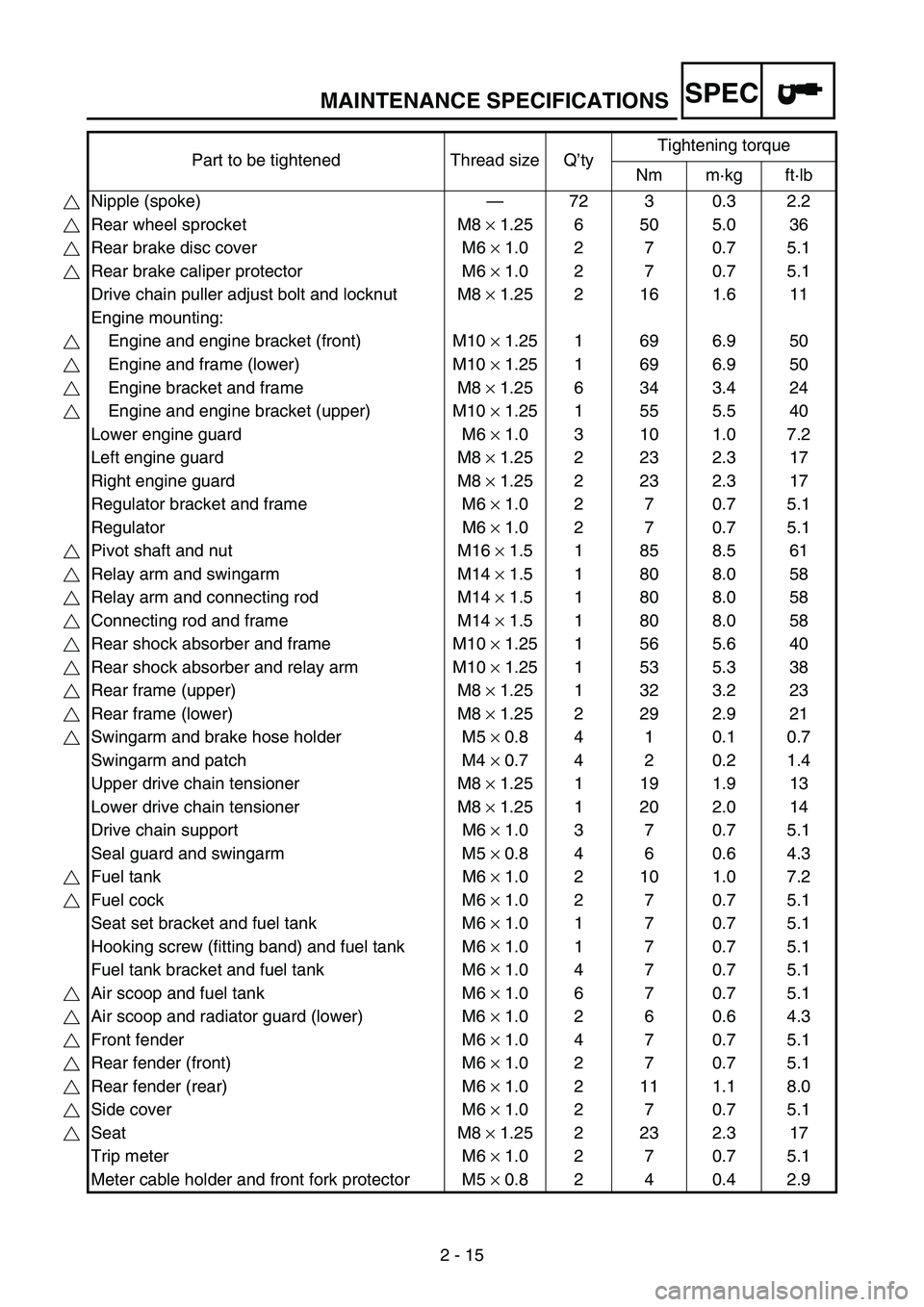

Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Nipple (spoke)—72 3 0.3 2.2

Rear wheel sprocket M8 × 1.25 6 50 5.0 36

Rear brake disc cover M6 × 1.0 2 7 0.7 5.1

Rear brake caliper protector M6 × 1.0 2 7 0.7 5.1

Drive chain puller adjust bolt and locknut M8 × 1.25 2 16 1.6 11

Engine mounting:

Engine and engine bracket (front) M10 × 1.25 1 69 6.9 50

Engine and frame (lower) M10 × 1.25 1 69 6.9 50

Engine bracket and frame M8 × 1.25 6 34 3.4 24

Engine and engine bracket (upper) M10 × 1.25 1 55 5.5 40

Lower engine guard M6 × 1.0 3 10 1.0 7.2

Left engine guard M8 × 1.25 2 23 2.3 17

Right engine guard M8 × 1.25 2 23 2.3 17

Regulator bracket and frame M6 × 1.0 2 7 0.7 5.1

Regulator M6 × 1.0 2 7 0.7 5.1

Pivot shaft and nut M16 × 1.5 1 85 8.5 61

Relay arm and swingarm M14 × 1.5 1 80 8.0 58

Relay arm and connecting rod M14 × 1.5 1 80 8.0 58

Connecting rod and frame M14 × 1.5 1 80 8.0 58

Rear shock absorber and frame M10 × 1.25 1 56 5.6 40

Rear shock absorber and relay arm M10 × 1.25 1 53 5.3 38

Rear frame (upper) M8 × 1.25 1 32 3.2 23

Rear frame (lower) M8 × 1.25 2 29 2.9 21

Swingarm and brake hose holder M5 × 0.8 4 1 0.1 0.7

Swingarm and patch M4 × 0.7 4 2 0.2 1.4

Upper drive chain tensioner M8 × 1.25 1 19 1.9 13

Lower drive chain tensioner M8 × 1.25 1 20 2.0 14

Drive chain support M6 × 1.0 3 7 0.7 5.1

Seal guard and swingarm M5 × 0.8 4 6 0.6 4.3

Fuel tank M6 × 1.0 2 10 1.0 7.2

Fuel cock M6 × 1.0 2 7 0.7 5.1

Seat set bracket and fuel tank M6 × 1.0 1 7 0.7 5.1

Hooking screw (fitting band) and fuel tank M6 × 1.0 1 7 0.7 5.1

Fuel tank bracket and fuel tank M6 × 1.0 4 7 0.7 5.1

Air scoop and fuel tank M6 × 1.0 6 7 0.7 5.1

Air scoop and radiator guard (lower) M6 × 1.0 2 6 0.6 4.3

Front fender M6 × 1.0 4 7 0.7 5.1

Rear fender (front) M6 × 1.0 2 7 0.7 5.1

Rear fender (rear) M6 × 1.0 2 11 1.1 8.0

Side cover M6 × 1.0 2 7 0.7 5.1

Seat M8 × 1.25 2 23 2.3 17

Trip meter M6 × 1.0 2 7 0.7 5.1

Meter cable holder and front fork protector M5 × 0.8 2 4 0.4 2.9

Page 98 of 864

2 - 19

GENERAL TORQUE SPECIFICATIONS/

DEFINITION OF UNITS

SPEC

EC220001

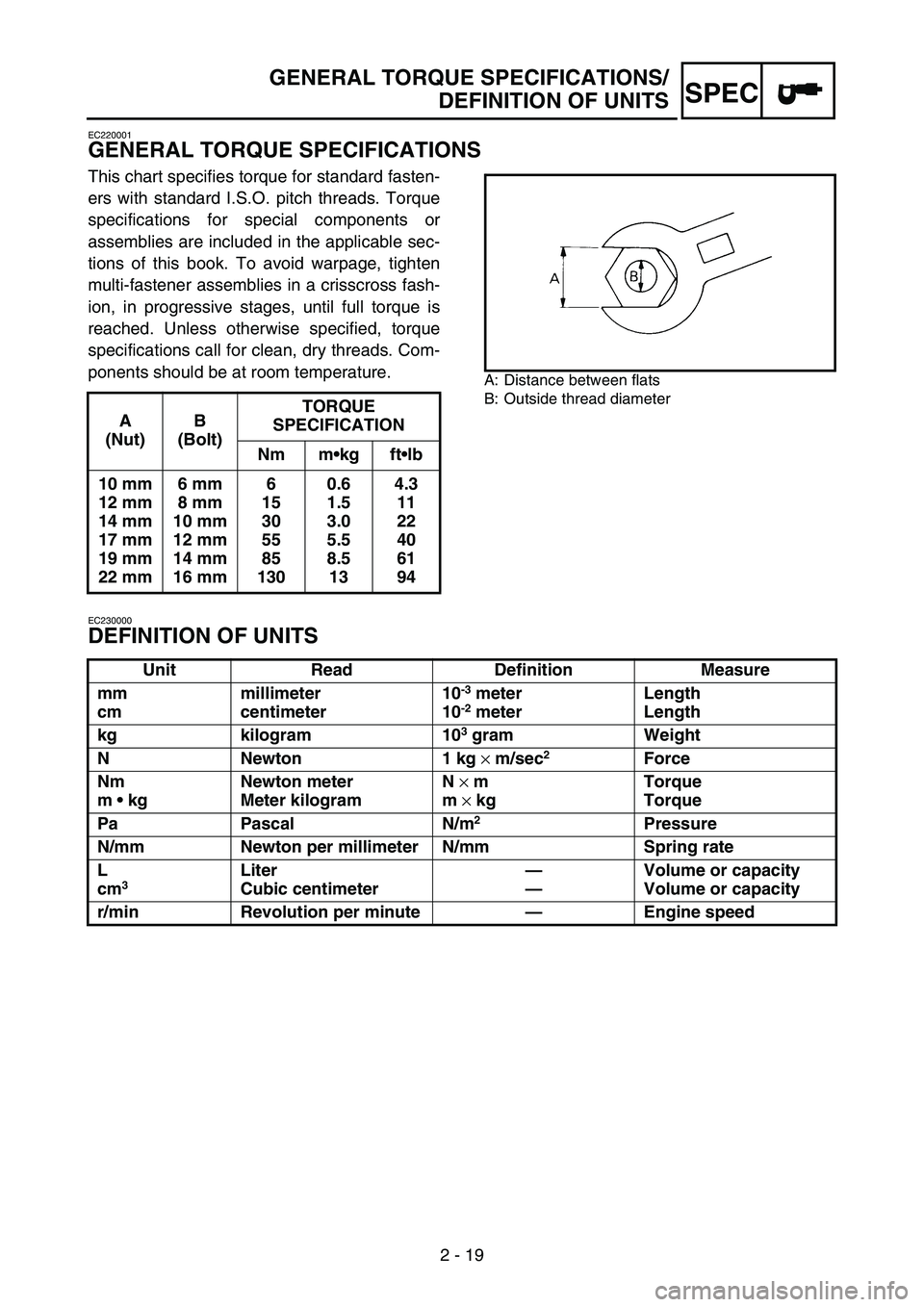

GENERAL TORQUE SPECIFICATIONS

This chart specifies torque for standard fasten-

ers with standard I.S.O. pitch threads. Torque

specifications for special components or

assemblies are included in the applicable sec-

tions of this book. To avoid warpage, tighten

multi-fastener assemblies in a crisscross fash-

ion, in progressive stages, until full torque is

reached. Unless otherwise specified, torque

specifications call for clean, dry threads. Com-

ponents should be at room temperature.

A: Distance between flats

B: Outside thread diameter

EC230000

DEFINITION OF UNITS

A

(Nut)B

(Bolt)TORQUE

SPECIFICATION

Nm mkg ftlb

10 mm

12 mm

14 mm

17 mm

19 mm

22 mm6 mm

8 mm

10 mm

12 mm

14 mm

16 mm6

15

30

55

85

1300.6

1.5

3.0

5.5

8.5

134.3

11

22

40

61

94

Unit Read Definition Measure

mm

cmmillimeter

centimeter10

-3 meter

10-2 meterLength

Length

kg kilogram 10

3 gram Weight

N Newton 1 kg

× m/sec

2 Force

Nm

m kgNewton meter

Meter kilogramN

× m

m

× kgTorque

Torque

Pa Pascal N/m

2Pressure

N/mm Newton per millimeter N/mm Spring rate

L

cm

3 Liter

Cubic centimeter—

—Volume or capacity

Volume or capacity

r/min Revolution per minute—Engine speed

Page 190 of 864

SPEC

2 - 111

CABLE ROUTING DIAGRAM

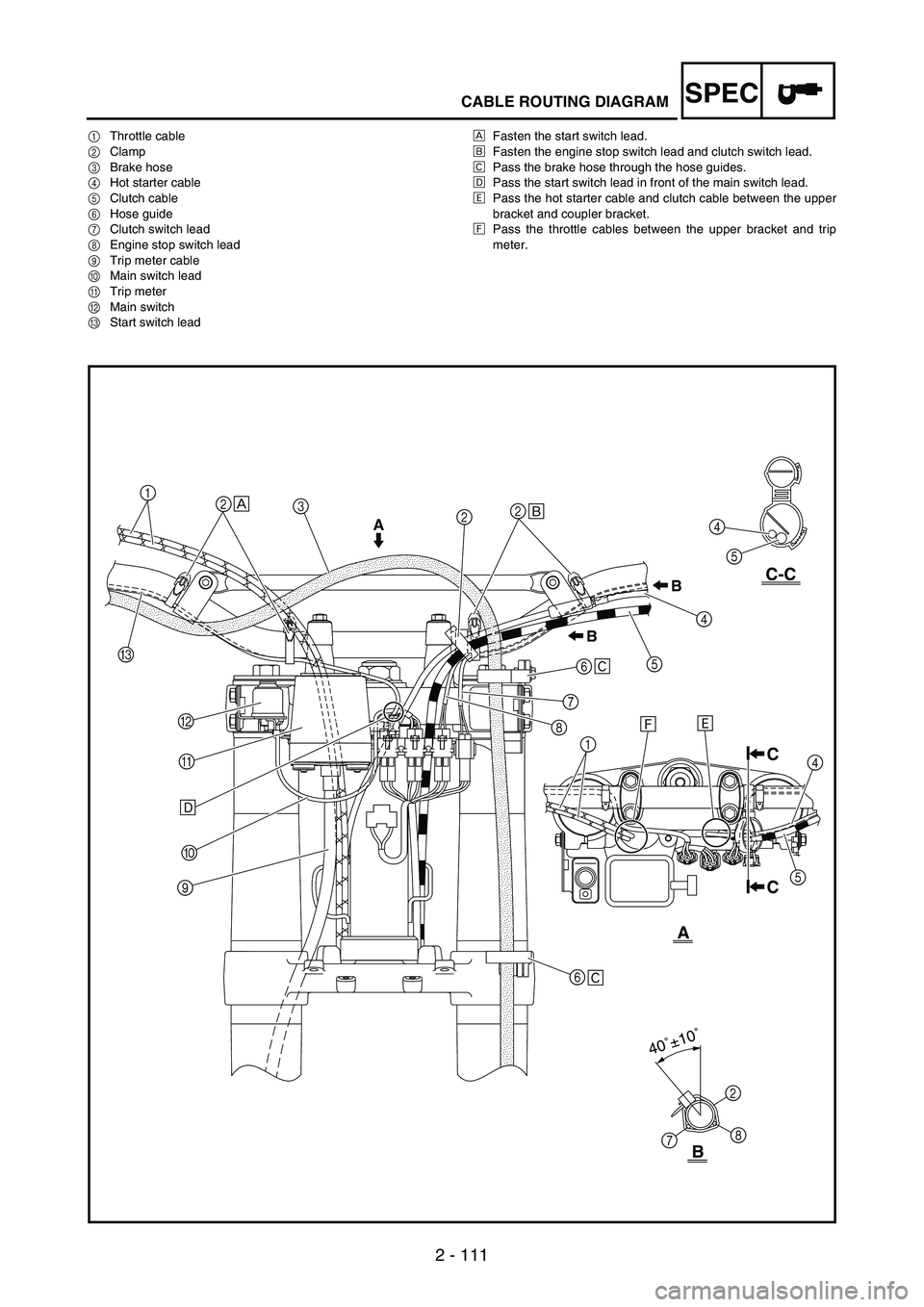

1Throttle cable

2Clamp

3Brake hose

4Hot starter cable

5Clutch cable

6Hose guide

7Clutch switch lead

8Engine stop switch lead

9Trip meter cable

0Main switch lead

ATrip meter

BMain switch

CStart switch leadÈFasten the start switch lead.

ÉFasten the engine stop switch lead and clutch switch lead.

ÊPass the brake hose through the hose guides.

ËPass the start switch lead in front of the main switch lead.

ÌPass the hot starter cable and clutch cable between the upper

bracket and coupler bracket.

ÍPass the throttle cables between the upper bracket and trip

meter.

C

A

B

C-C

4

5

2

8

7

1

4

5

Ì

Í

B

B

A

1

C2

3

22

4

5

6

7

8

6 90 A BÈ

É

Ê

Ê Ë

C

40˚±10˚

Page 192 of 864

3 - 1

INSP

ADJ

MAINTENANCE INTERVALS

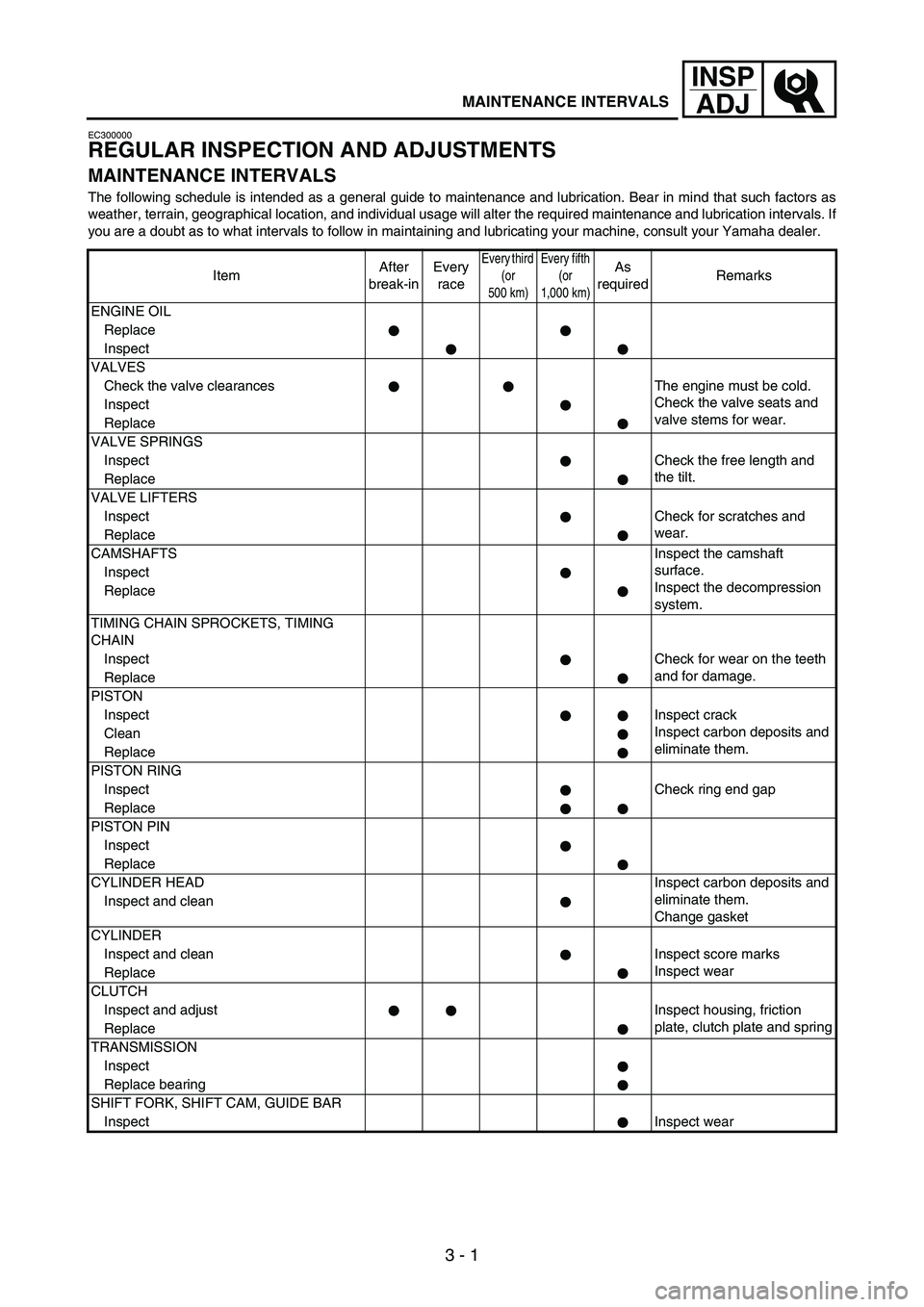

EC300000

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as

weather, terrain, geographical location, and individual usage will alter the required maintenance and lubrication intervals. If

you are a doubt as to what intervals to follow in maintaining and lubricating your machine, consult your Yamaha dealer.

ItemAfter

break-inEvery

race

Every third

(or

500 km)Every fifth

(or

1,000 km)As

requiredRemarks

ENGINE OIL

Replace

Inspect

VALVES

Check the valve clearances The engine must be cold.

Check the valve seats and

valve stems for wear. Inspect

Replace

VALVE SPRINGS

InspectCheck the free length and

the tilt.

Replace

VALVE LIFTERS

InspectCheck for scratches and

wear.

Replace

CAMSHAFTSInspect the camshaft

surface.

Inspect the decompression

system. Inspect

Replace

TIMING CHAIN SPROCKETS, TIMING

CHAIN

InspectCheck for wear on the teeth

and for damage.

Replace

PISTON

InspectInspect crack

Inspect carbon deposits and

eliminate them. Clean

Replace

PISTON RING

InspectCheck ring end gap

Replace

PISTON PIN

Inspect

Replace

CYLINDER HEADInspect carbon deposits and

eliminate them.

Change gasket Inspect and clean

CYLINDER

Inspect and clean Inspect score marks

Inspect wear

Replace

CLUTCH

Inspect and adjust Inspect housing, friction

plate, clutch plate and spring

Replace

TRANSMISSION

Inspect

Replace bearing

SHIFT FORK, SHIFT CAM, GUIDE BAR

InspectInspect wear