Fork oil YAMAHA WR 250F 2005 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: WR 250F, Model: YAMAHA WR 250F 2005Pages: 864, PDF Size: 18.1 MB

Page 22 of 864

CHAPTER 4

ENGINE

SEAT, FUEL TANK AND SIDE

COVERS..................................... 4-1

EXHAUST PIPE AND

SILENCER.................................. 4-7

RADIATOR............................... 4-13

CARBURETOR........................ 4-21

CAMSHAFTS........................... 4-51

CYLINDER HEAD.................... 4-73

VALVES AND VALVE

SPRINGS.................................. 4-81

CYLINDER AND PISTON...... 4-101

CLUTCH................................. 4-117

OIL FILTER ELEMENT,

WATER PUMP AND RIGHT

CRANKCASE COVER........... 4-135

BALANCER............................ 4-151

OIL PUMP.............................. 4-159

KICK SHAFT AND

SHIFT SHAFT........................ 4-169

AC MAGNETO AND

STARTER CLUTCH............... 4-185

ENGINE REMOVAL............... 4-207

CRANKCASE AND

CRANKSHAFT....................... 4-221

TRANSMISSION, SHIFT CAM

AND SHIFT FORK................. 4-245

CHAPTER 5

CHASSIS

FRONT WHEEL AND REAR

WHEEL....................................... 5-1

FRONT BRAKE AND

REAR BRAKE.......................... 5-23

FRONT FORK.......................... 5-61

HANDLEBAR........................... 5-91

STEERING............................. 5-103

SWINGARM........................... 5-119

REAR SHOCK ABSORBER... 5-139

CHAPITRE 4

MOTEUR

SELLE, RESERVOIR DE

CARBURANT ET CACHES

LATERAUX..................................... 4-2

TUBE D’ECHAPPEMENT ET

SILENCIEUX................................... 4-8

RADIATEUR................................. 4-14

CARBURATEUR.......................... 4-22

ARBRES A CAMES...................... 4-52

CULASSE....................................... 4-74

SOUPAPES ET RESSORTS DE

SOUPAPES..................................... 4-82

CYLINDRE ET PISTON............ 4-102

EMBRAYAGE............................. 4-118

ELEMENT DE FILTRE A

HUILE, POMPE A EAU ET

DEMI-CARTER DROIT............ 4-136

BALANCIER............................... 4-152

POMPE A HUILE....................... 4-160

ARBRE DE KICK ET

AXE DE SELECTEUR............... 4-170

ALTERNATEUR AVEC ROTOR A

ALIMENTATION PERMANENTE

ET EMBRAYAGE DU

DEMARREUR............................. 4-186

DEPOSE DU MOTEUR.............. 4-208

CARTER MOTEUR ET

VILEBREQUIN........................... 4-222

BOITE DE VITESSES, TAMBOUR

ET FOURCHETTES DE

SELECTION................................ 4-246

CHAPITRE 5

CHASSIS

ROUE AVANT ET ROUE

ARRIERE......................................... 5-2

FREIN AVANT ET FREIN

ARRIERE....................................... 5-24

FOURCHE..................................... 5-62

GUIDON......................................... 5-92

DIRECTION................................ 5-104

BRAS OSCILLANT.................... 5-120

AMORTISSEUR ARRIERE...... 5-140

Page 26 of 864

1 - 1

GEN

INFODESCRIPTION

EC100000

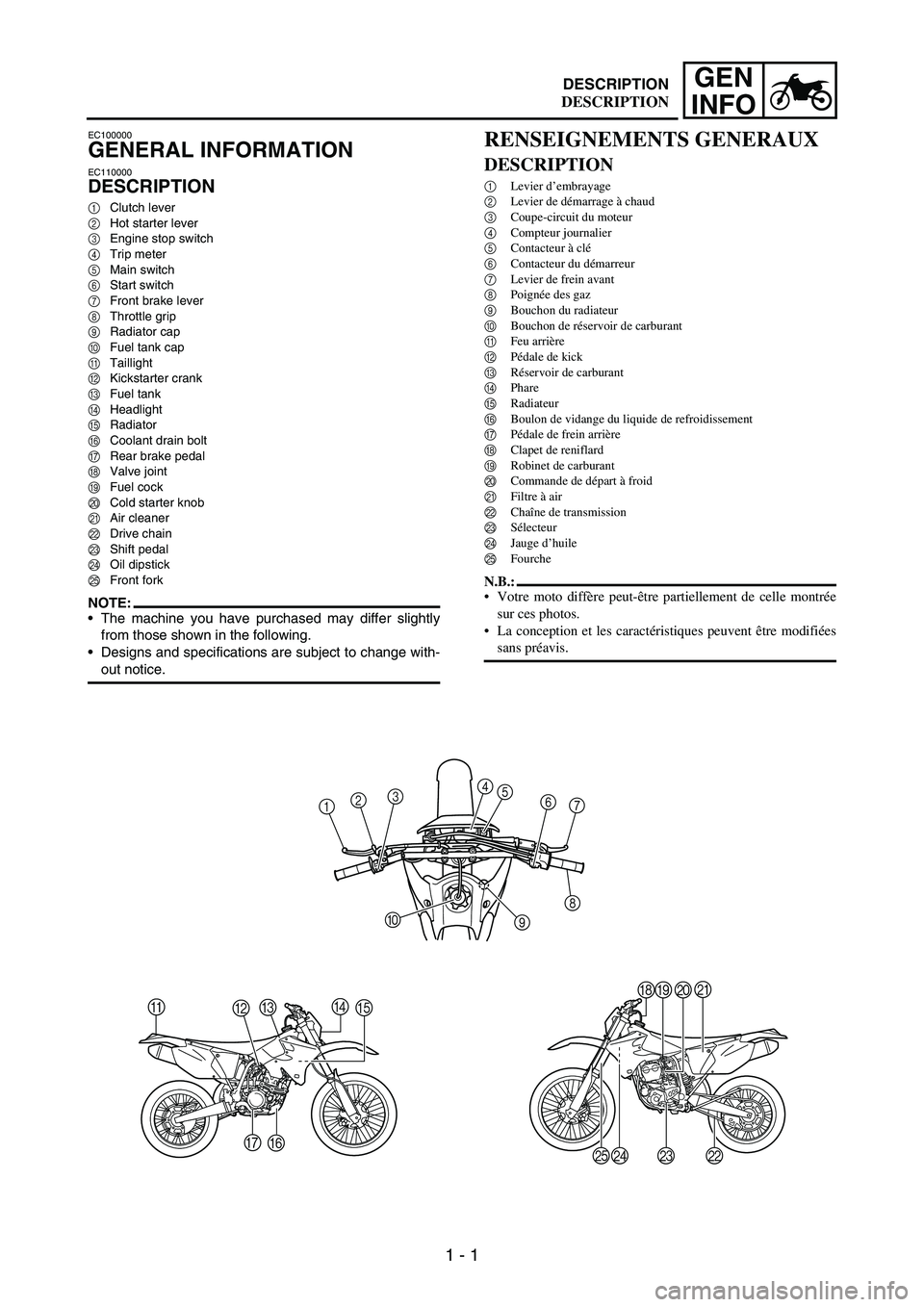

GENERAL INFORMATION

EC110000

DESCRIPTION

1Clutch lever

2Hot starter lever

3Engine stop switch

4Trip meter

5Main switch

6Start switch

7Front brake lever

8Throttle grip

9Radiator cap

0Fuel tank cap

ATaillight

BKickstarter crank

CFuel tank

DHeadlight

ERadiator

FCoolant drain bolt

GRear brake pedal

HValve joint

IFuel cock

JCold starter knob

KAir cleaner

LDrive chain

MShift pedal

NOil dipstick

OFront fork

NOTE:The machine you have purchased may differ slightly

from those shown in the following.

Designs and specifications are subject to change with-

out notice.

1234

5

6

7

8

9 0

A

BCDE

F G

HIJK

L M

N O

RENSEIGNEMENTS GENERAUX

DESCRIPTION

1Levier d’embrayage

2Levier de démarrage à chaud

3Coupe-circuit du moteur

4Compteur journalier

5Contacteur à clé

6Contacteur du démarreur

7Levier de frein avant

8Poignée des gaz

9Bouchon du radiateur

0Bouchon de réservoir de carburant

AFeu arrière

BPédale de kick

CRéservoir de carburant

DPhare

ERadiateur

FBoulon de vidange du liquide de refroidissement

GPédale de frein arrière

HClapet de reniflard

IRobinet de carburant

JCommande de départ à froid

KFiltre à air

LChaîne de transmission

MSélecteur

NJauge d’huile

OFourche

N.B.:

Votre moto diffère peut-être partiellement de celle montrée

sur ces photos.

La conception et les caractéristiques peuvent être modifiées

sans préavis.

DESCRIPTION

Page 36 of 864

1 - 11

GEN

INFO

SPECIAL TOOLS

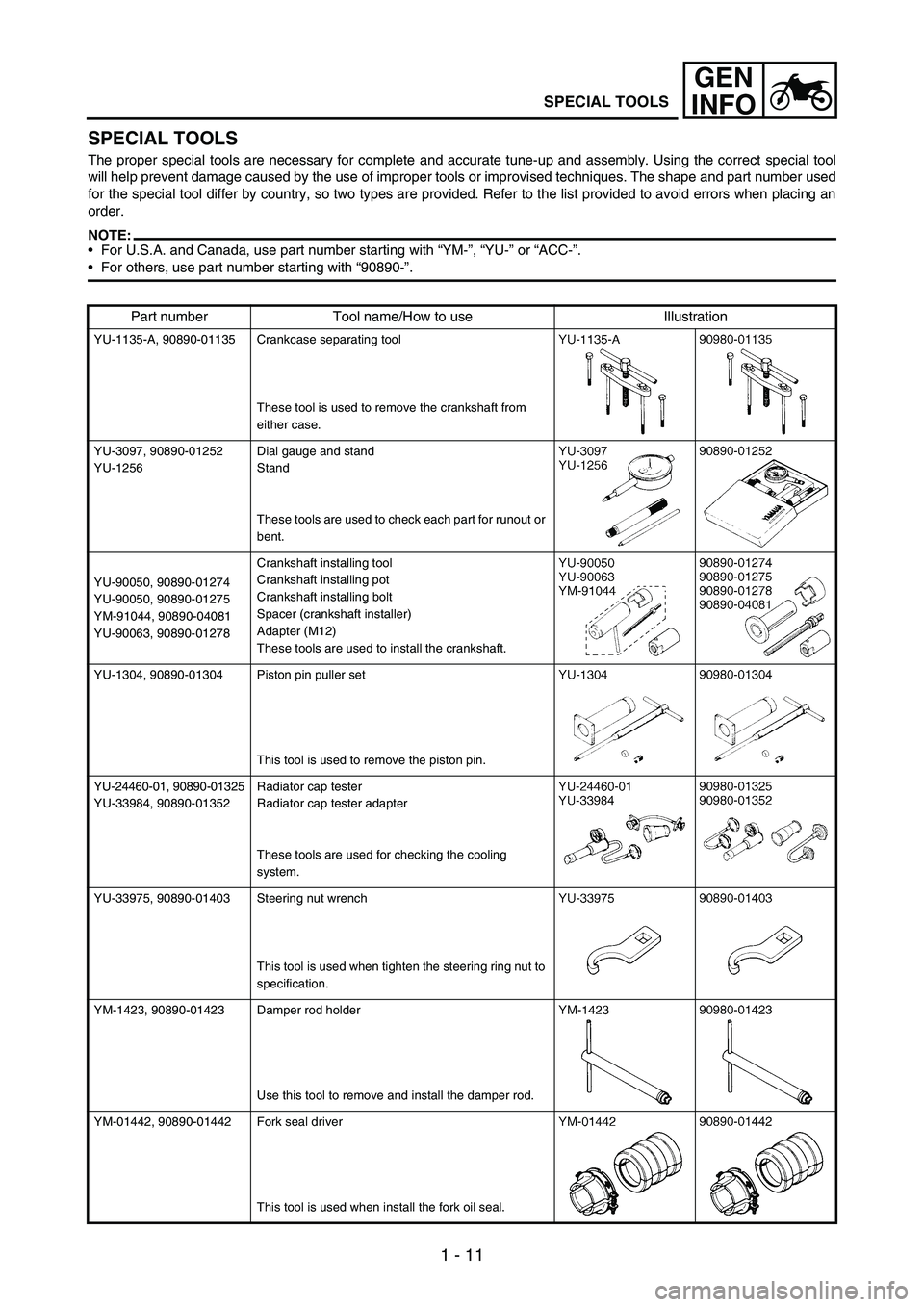

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the correct special tool

will help prevent damage caused by the use of improper tools or improvised techniques. The shape and part number used

for the special tool differ by country, so two types are provided. Refer to the list provided to avoid errors when placing an

order.

NOTE:For U.S.A. and Canada, use part number starting with “YM-”, “YU-” or “ACC-”.

For others, use part number starting with “90890-”.

Part number Tool name/How to use Illustration

YU-1135-A, 90890-01135 Crankcase separating tool

These tool is used to remove the crankshaft from

either case.

YU-3097, 90890-01252

YU-1256Dial gauge and stand

Stand

These tools are used to check each part for runout or

bent.

YU-90050, 90890-01274

YU-90050, 90890-01275

YM-91044, 90890-04081

YU-90063, 90890-01278Crankshaft installing tool

Crankshaft installing pot

Crankshaft installing bolt

Spacer (crankshaft installer)

Adapter (M12)

These tools are used to install the crankshaft.

YU-1304, 90890-01304 Piston pin puller set

This tool is used to remove the piston pin.

YU-24460-01, 90890-01325

YU-33984, 90890-01352Radiator cap tester

Radiator cap tester adapter

These tools are used for checking the cooling

system.

YU-33975, 90890-01403 Steering nut wrench

This tool is used when tighten the steering ring nut to

specification.

YM-1423, 90890-01423 Damper rod holder

Use this tool to remove and install the damper rod.

YM-01442, 90890-01442 Fork seal driver

This tool is used when install the fork oil seal.

Page 70 of 864

1 - 45

GEN

INFO

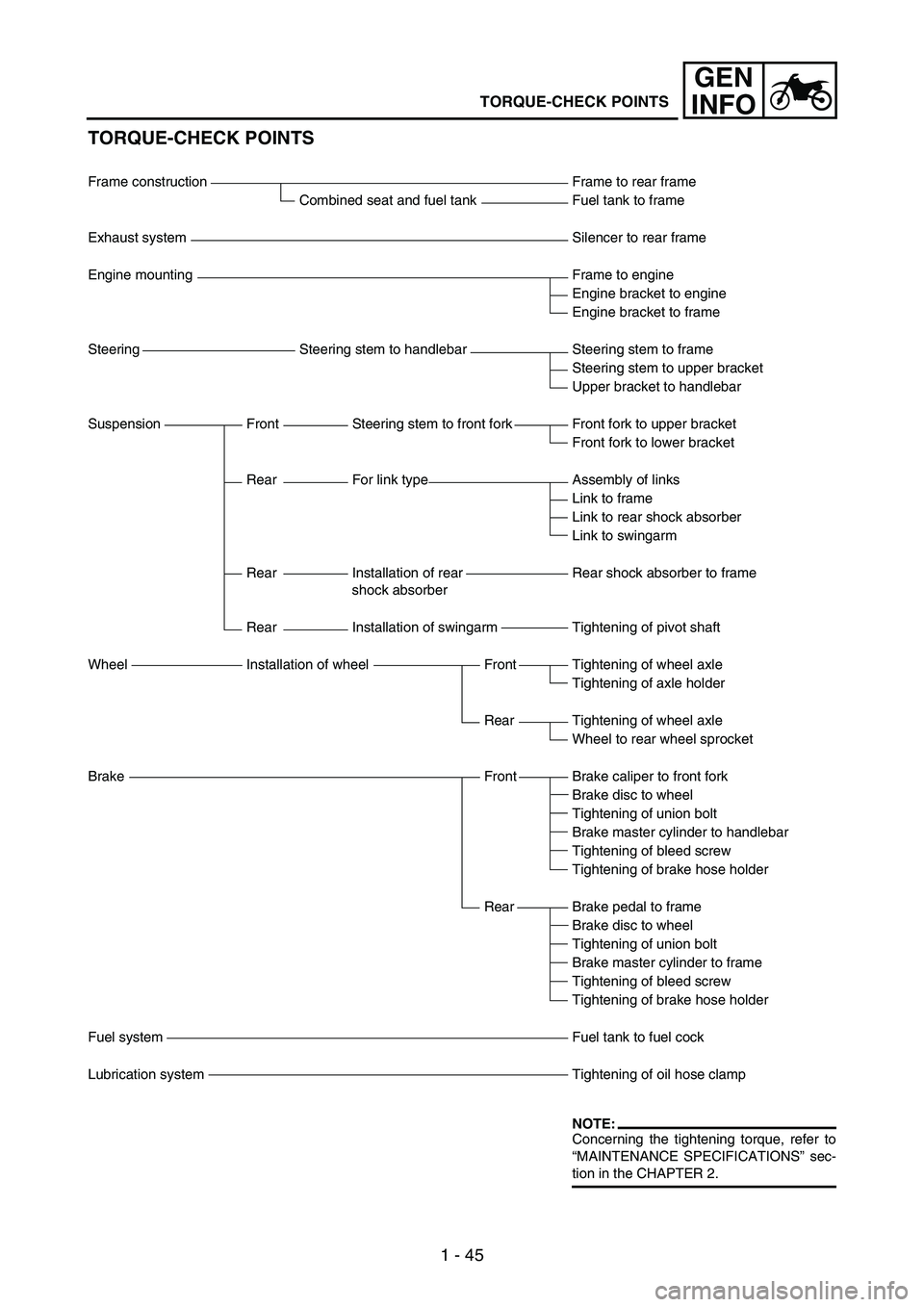

TORQUE-CHECK POINTS

Frame construction Frame to rear frame

Combined seat and fuel tank Fuel tank to frame

Exhaust system Silencer to rear frame

Engine mounting Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering Steering stem to handlebar Steering stem to frame

Steering stem to upper bracket

Upper bracket to handlebar

Suspension Front Steering stem to front fork Front fork to upper bracket

Front fork to lower bracket

Rear For link type Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Rear Installation of rear

shock absorberRear shock absorber to frame

Rear Installation of swingarm Tightening of pivot shaft

Wheel Installation of wheel Front Tightening of wheel axle

Tightening of axle holder

Rear Tightening of wheel axle

Wheel to rear wheel sprocket

Brake Front Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handlebar

Tightening of bleed screw

Tightening of brake hose holder

Rear Brake pedal to frame

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Tightening of brake hose holder

Fuel system Fuel tank to fuel cock

Lubrication system Tightening of oil hose clamp

NOTE:Concerning the tightening torque, refer to

“MAINTENANCE SPECIFICATIONS” sec-

tion in the CHAPTER 2.

TORQUE-CHECK POINTS

Page 82 of 864

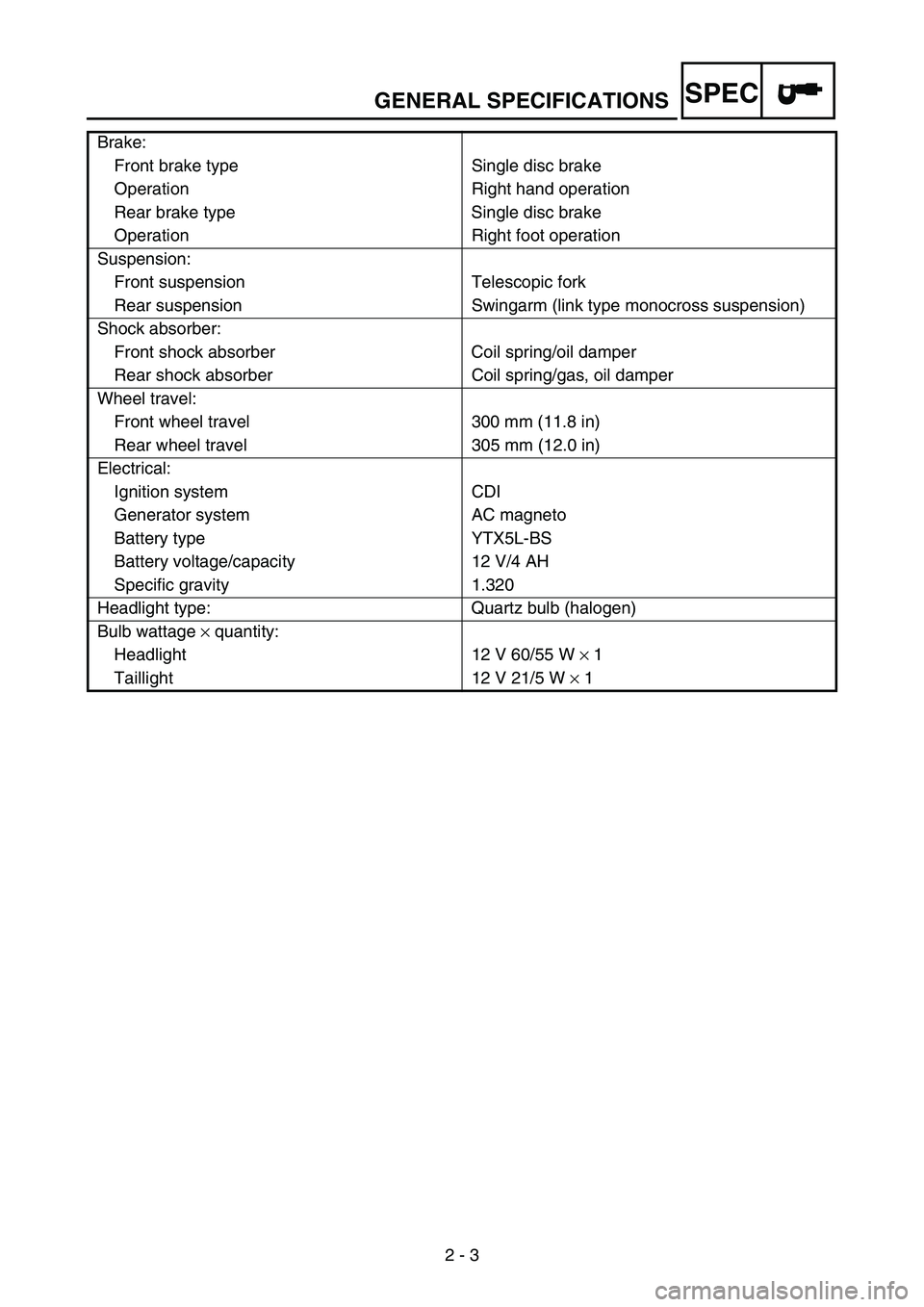

GENERAL SPECIFICATIONS

2 - 3

SPEC

Brake:

Front brake type Single disc brake

Operation Right hand operation

Rear brake type Single disc brake

Operation Right foot operation

Suspension:

Front suspension Telescopic fork

Rear suspension Swingarm (link type monocross suspension)

Shock absorber:

Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/gas, oil damper

Wheel travel:

Front wheel travel 300 mm (11.8 in)

Rear wheel travel 305 mm (12.0 in)

Electrical:

Ignition system CDI

Generator system AC magneto

Battery type YTX5L-BS

Battery voltage/capacity 12 V/4 AH

Specific gravity 1.320

Headlight type: Quartz bulb (halogen)

Bulb wattage × quantity:

Headlight 12 V 60/55 W × 1

Taillight 12 V 21/5 W × 1

Page 91 of 864

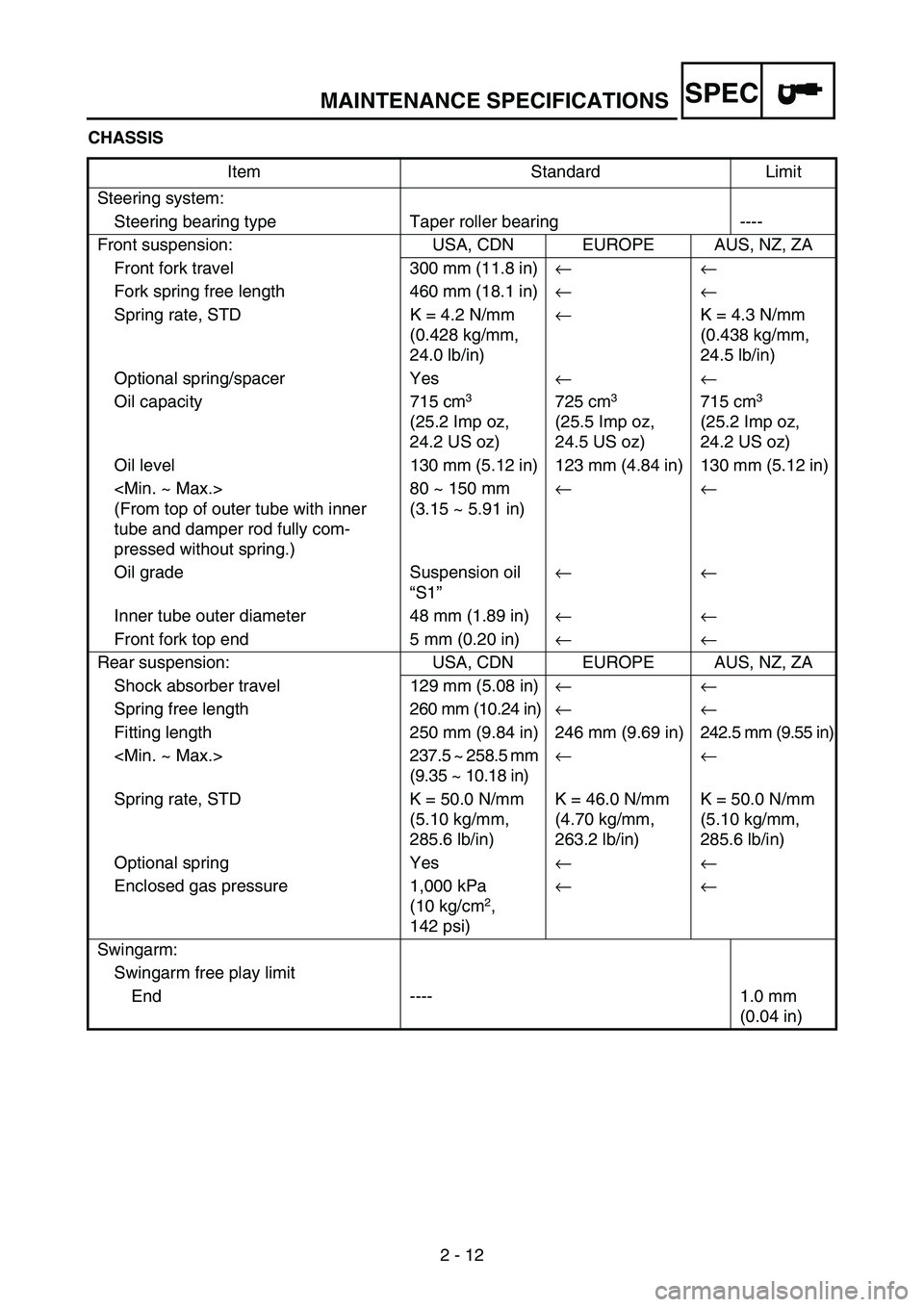

MAINTENANCE SPECIFICATIONS

2 - 12

SPEC

CHASSIS

Item Standard Limit

Steering system:

Steering bearing type Taper roller bearing ----

Front suspension: USA, CDN EUROPE AUS, NZ, ZA

Front fork travel 300 mm (11.8 in)←←

Fork spring free length 460 mm (18.1 in)←←

Spring rate, STD K = 4.2 N/mm

(0.428 kg/mm,

24.0 lb/in)←K = 4.3 N/mm

(0.438 kg/mm,

24.5 lb/in)

Optional spring/spacer Yes←←

Oil capacity 715 cm

3

(25.2 Imp oz,

24.2 US oz) 725 cm3

(25.5 Imp oz,

24.5 US oz) 715 cm3

(25.2 Imp oz,

24.2 US oz)

Oil level 130 mm (5.12 in) 123 mm (4.84 in) 130 mm (5.12 in)

(From top of outer tube with inner

tube and damper rod fully com-

pressed without spring.)80 ~ 150 mm

(3.15 ~ 5.91 in)←←

Oil grade Suspension oil

“S1”←←

Inner tube outer diameter 48 mm (1.89 in)←←

Front fork top end 5 mm (0.20 in)←←

Rear suspension: USA, CDN EUROPE AUS, NZ, ZA

Shock absorber travel 129 mm (5.08 in)← ←

Spring free length260 mm (10.24 in)← ←

Fitting length 250 mm (9.84 in) 246 mm (9.69 in) 242.5 mm (9.55 in)

(9.35 ~ 10.18 in)← ←

Spring rate, STD K = 50.0 N/mm

(5.10 kg/mm,

285.6 lb/in)K = 46.0 N/mm

(4.70 kg/mm,

263.2 lb/in)K = 50.0 N/mm

(5.10 kg/mm,

285.6 lb/in)

Optional spring Yes← ←

Enclosed gas pressure 1,000 kPa

(10 kg/cm

2,

142 psi)← ←

Swingarm:

Swingarm free play limit

End ---- 1.0 mm

(0.04 in)

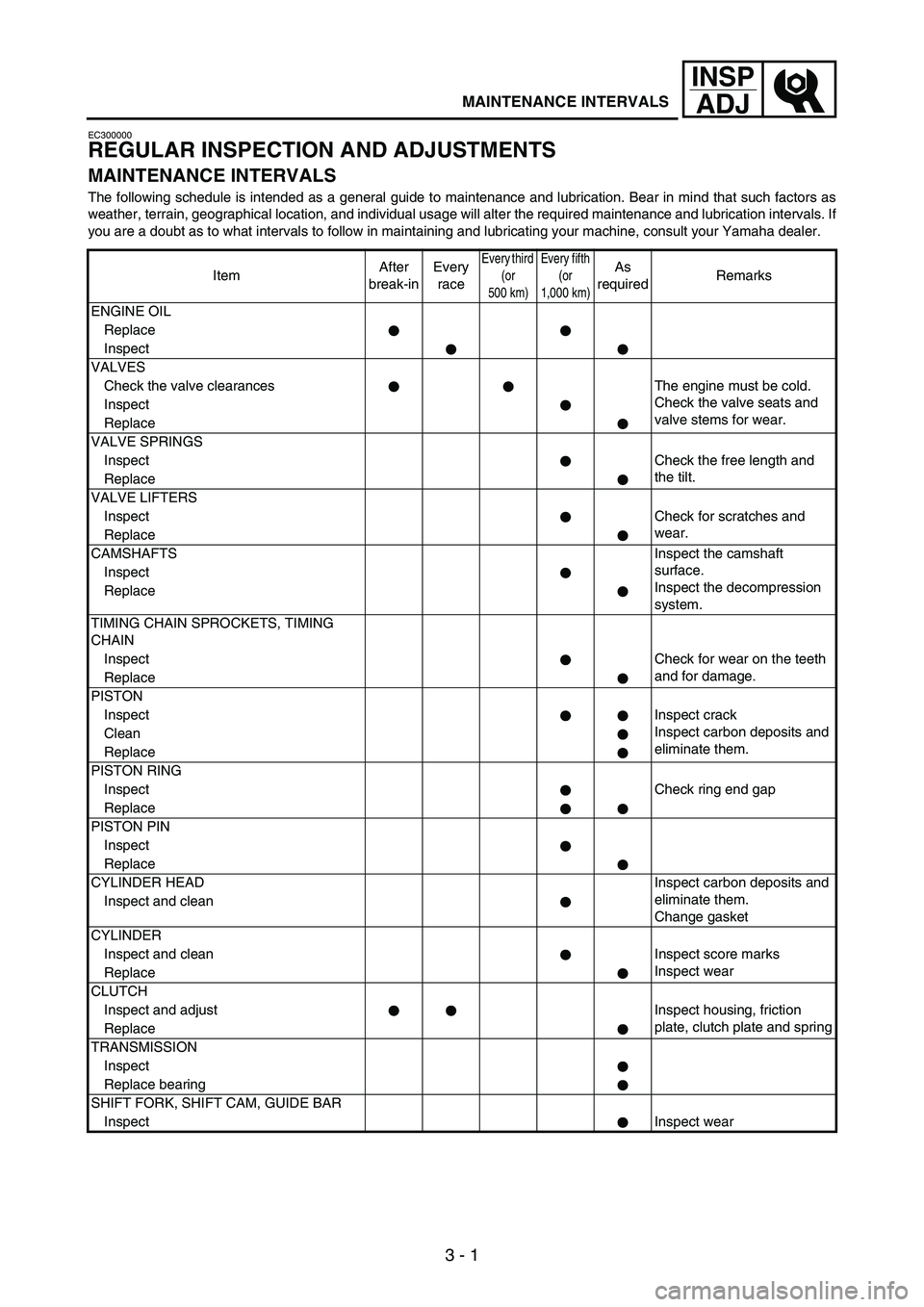

Page 192 of 864

3 - 1

INSP

ADJ

MAINTENANCE INTERVALS

EC300000

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as

weather, terrain, geographical location, and individual usage will alter the required maintenance and lubrication intervals. If

you are a doubt as to what intervals to follow in maintaining and lubricating your machine, consult your Yamaha dealer.

ItemAfter

break-inEvery

race

Every third

(or

500 km)Every fifth

(or

1,000 km)As

requiredRemarks

ENGINE OIL

Replace

Inspect

VALVES

Check the valve clearances The engine must be cold.

Check the valve seats and

valve stems for wear. Inspect

Replace

VALVE SPRINGS

InspectCheck the free length and

the tilt.

Replace

VALVE LIFTERS

InspectCheck for scratches and

wear.

Replace

CAMSHAFTSInspect the camshaft

surface.

Inspect the decompression

system. Inspect

Replace

TIMING CHAIN SPROCKETS, TIMING

CHAIN

InspectCheck for wear on the teeth

and for damage.

Replace

PISTON

InspectInspect crack

Inspect carbon deposits and

eliminate them. Clean

Replace

PISTON RING

InspectCheck ring end gap

Replace

PISTON PIN

Inspect

Replace

CYLINDER HEADInspect carbon deposits and

eliminate them.

Change gasket Inspect and clean

CYLINDER

Inspect and clean Inspect score marks

Inspect wear

Replace

CLUTCH

Inspect and adjust Inspect housing, friction

plate, clutch plate and spring

Replace

TRANSMISSION

Inspect

Replace bearing

SHIFT FORK, SHIFT CAM, GUIDE BAR

InspectInspect wear

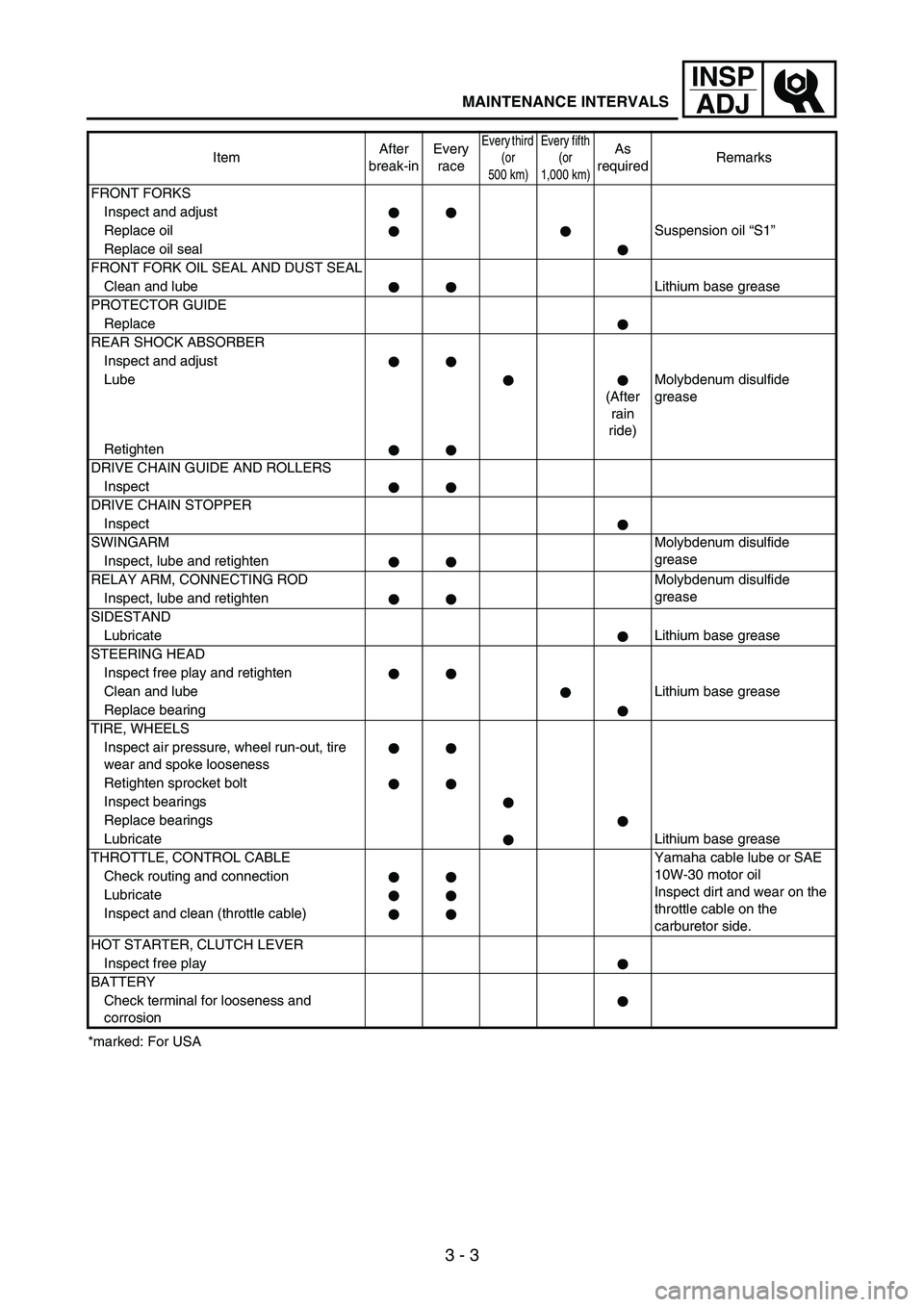

Page 194 of 864

3 - 3

INSP

ADJ

MAINTENANCE INTERVALS

*marked: For USAFRONT FORKS

Inspect and adjust

Replace oilSuspension oil “S1”

Replace oil seal

FRONT FORK OIL SEAL AND DUST SEAL

Clean and lubeLithium base grease

PROTECTOR GUIDE

Replace

REAR SHOCK ABSORBER

Inspect and adjust

Lube

(After

rain

ride)Molybdenum disulfide

grease

Retighten

DRIVE CHAIN GUIDE AND ROLLERS

Inspect

DRIVE CHAIN STOPPER

Inspect

SWINGARMMolybdenum disulfide

grease

Inspect, lube and retighten

RELAY ARM, CONNECTING ROD Molybdenum disulfide

grease

Inspect, lube and retighten

SIDESTAND

LubricateLithium base grease

STEERING HEAD

Inspect free play and retighten

Clean and lubeLithium base grease

Replace bearing

TIRE, WHEELS

Inspect air pressure, wheel run-out, tire

wear and spoke looseness

Retighten sprocket bolt

Inspect bearings

Replace bearings

LubricateLithium base grease

THROTTLE, CONTROL CABLE Yamaha cable lube or SAE

10W-30 motor oil

Inspect dirt and wear on the

throttle cable on the

carburetor side. Check routing and connection

Lubricate

Inspect and clean (throttle cable)

HOT STARTER, CLUTCH LEVER

Inspect free play

BATTERY

Check terminal for looseness and

corrosionItemAfter

break-inEvery

race

Every third

(or

500 km)Every fifth

(or

1,000 km)As

requiredRemarks

Page 207 of 864

3 - 16

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

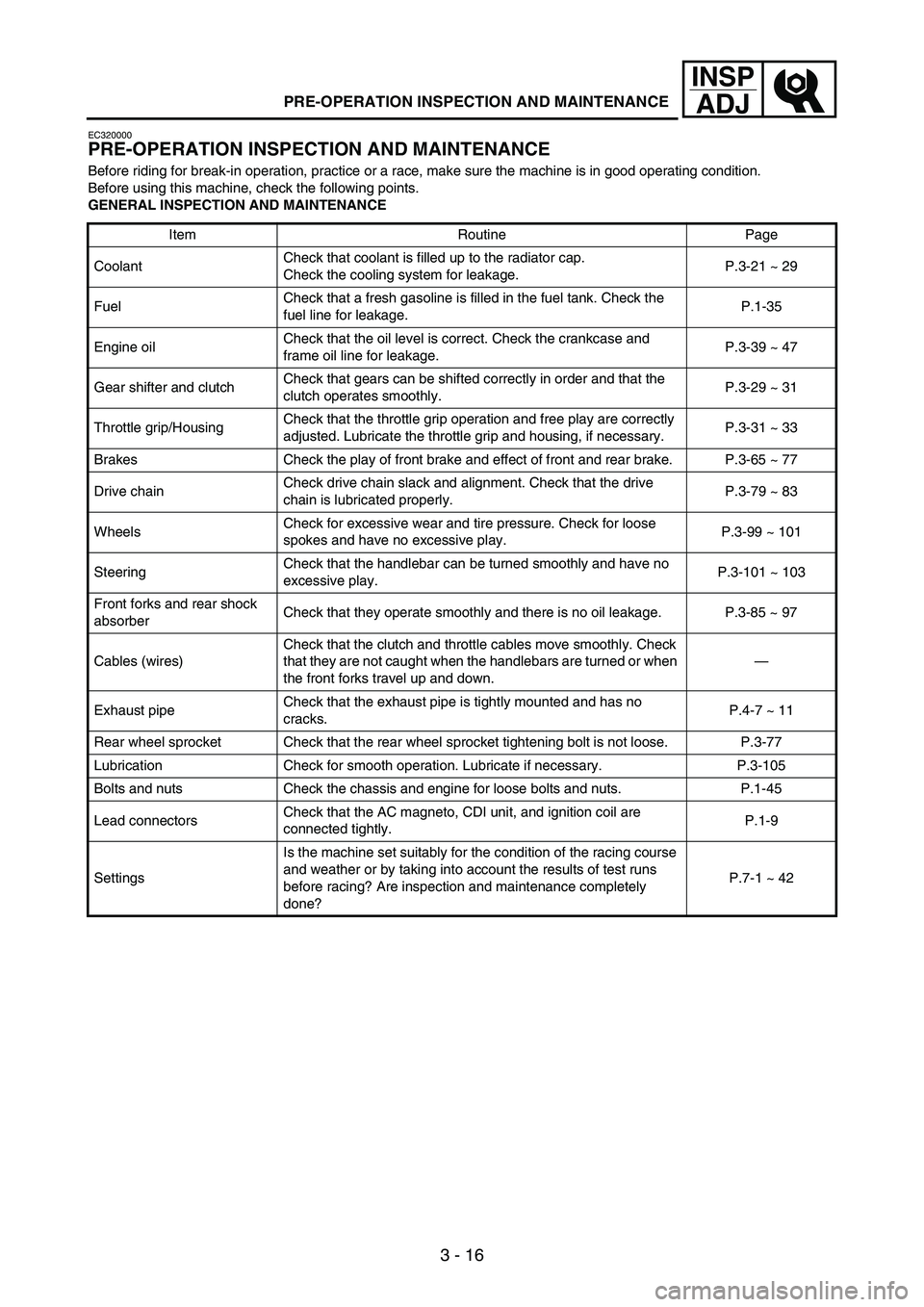

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.P.3-21 ~ 29

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-35

Engine oilCheck that the oil level is correct. Check the crankcase and

frame oil line for leakage.P.3-39 ~ 47

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-29 ~ 31

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-31 ~ 33

Brakes Check the play of front brake and effect of front and rear brake. P.3-65 ~ 77

Drive chainCheck drive chain slack and alignment. Check that the drive

chain is lubricated properly.P.3-79 ~ 83

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-99 ~ 101

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-101 ~ 103

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-85 ~ 97

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and has no

cracks.P.4-7 ~ 11

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-77

Lubrication Check for smooth operation. Lubricate if necessary. P.3-105

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-45

Lead connectorsCheck that the AC magneto, CDI unit, and ignition coil are

connected tightly.P.1-9

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 42

Page 276 of 864

3 - 85

INSP

ADJ

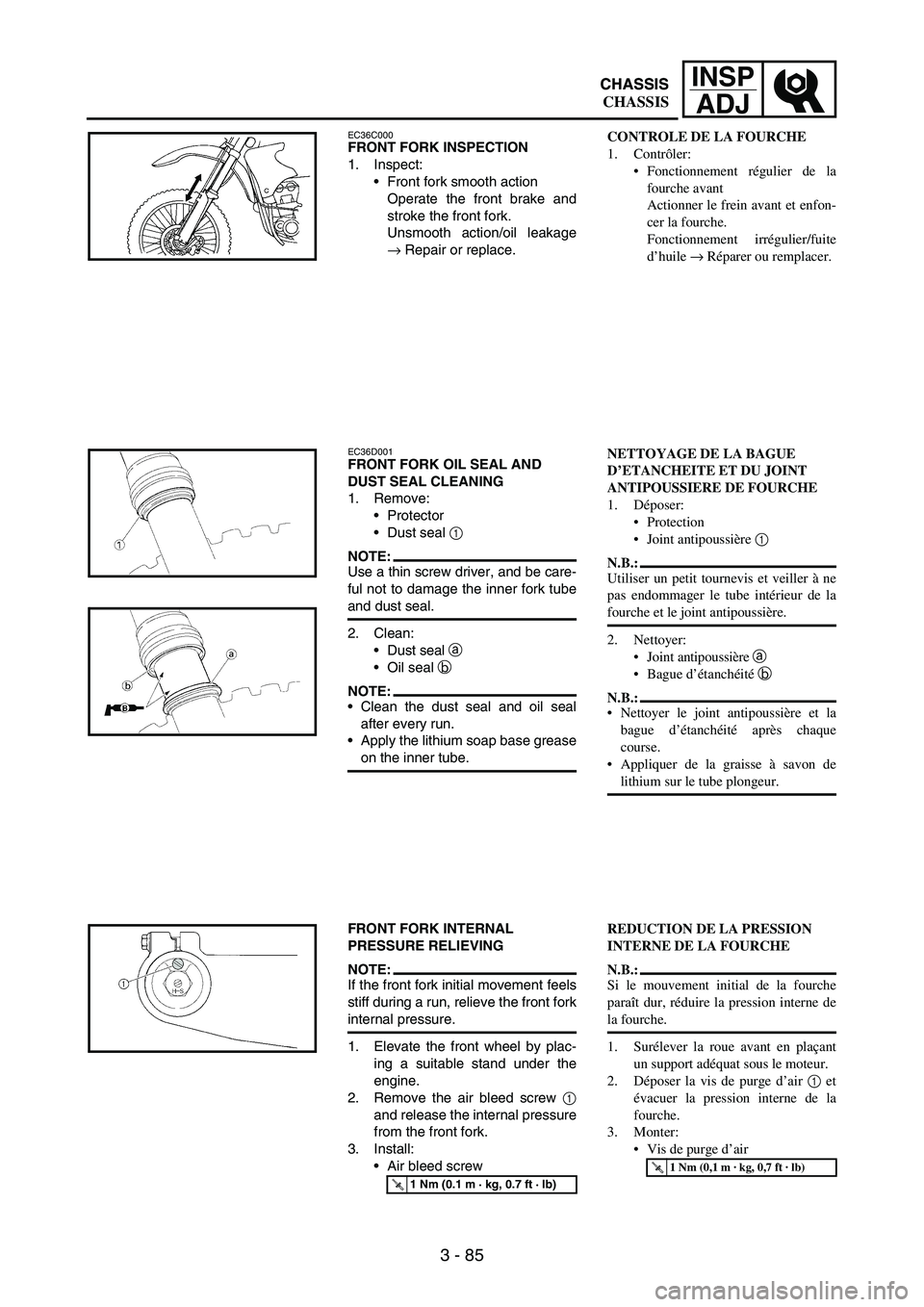

EC36C000FRONT FORK INSPECTION

1. Inspect:

Front fork smooth action

Operate the front brake and

stroke the front fork.

Unsmooth action/oil leakage

→ Repair or replace.

EC36D001FRONT FORK OIL SEAL AND

DUST SEAL CLEANING

1. Remove:

Protector

Dust seal

1

NOTE:Use a thin screw driver, and be care-

ful not to damage the inner fork tube

and dust seal.

2. Clean:

Dust seal

a

Oil seal

b

NOTE:Clean the dust seal and oil seal

after every run.

Apply the lithium soap base grease

on the inner tube.

FRONT FORK INTERNAL

PRESSURE RELIEVING

NOTE:If the front fork initial movement feels

stiff during a run, relieve the front fork

internal pressure.

1. Elevate the front wheel by plac-

ing a suitable stand under the

engine.

2. Remove the air bleed screw

1

and release the internal pressure

from the front fork.

3. Install:

Air bleed screw

T R..1 Nm (0.1 m · kg, 0.7 ft · lb)

CONTROLE DE LA FOURCHE

1. Contrôler:

Fonctionnement régulier de la

fourche avant

Actionner le frein avant et enfon-

cer la fourche.

Fonctionnement irrégulier/fuite

d’huile → Réparer ou remplacer.

NETTOYAGE DE LA BAGUE

D’ETANCHEITE ET DU JOINT

ANTIPOUSSIERE DE FOURCHE

1. Déposer:

Protection

Joint antipoussière 1

N.B.:

Utiliser un petit tournevis et veiller à ne

pas endommager le tube intérieur de la

fourche et le joint antipoussière.

2. Nettoyer:

Joint antipoussière a

Bague d’étanchéité b

N.B.:

Nettoyer le joint antipoussière et la

bague d’étanchéité après chaque

course.

Appliquer de la graisse à savon de

lithium sur le tube plongeur.

REDUCTION DE LA PRESSION

INTERNE DE LA FOURCHE

N.B.:

Si le mouvement initial de la fourche

paraît dur, réduire la pression interne de

la fourche.

1. Surélever la roue avant en plaçant

un support adéquat sous le moteur.

2. Déposer la vis de purge d’air 1 et

évacuer la pression interne de la

fourche.

3. Monter:

Vis de purge d’air

T R..1 Nm (0,1 m · kg, 0,7 ft · lb)

CHASSIS

CHASSIS CHASSIS